Zinc-Nickel Plating Market Size and Forecast 2025 to 2034

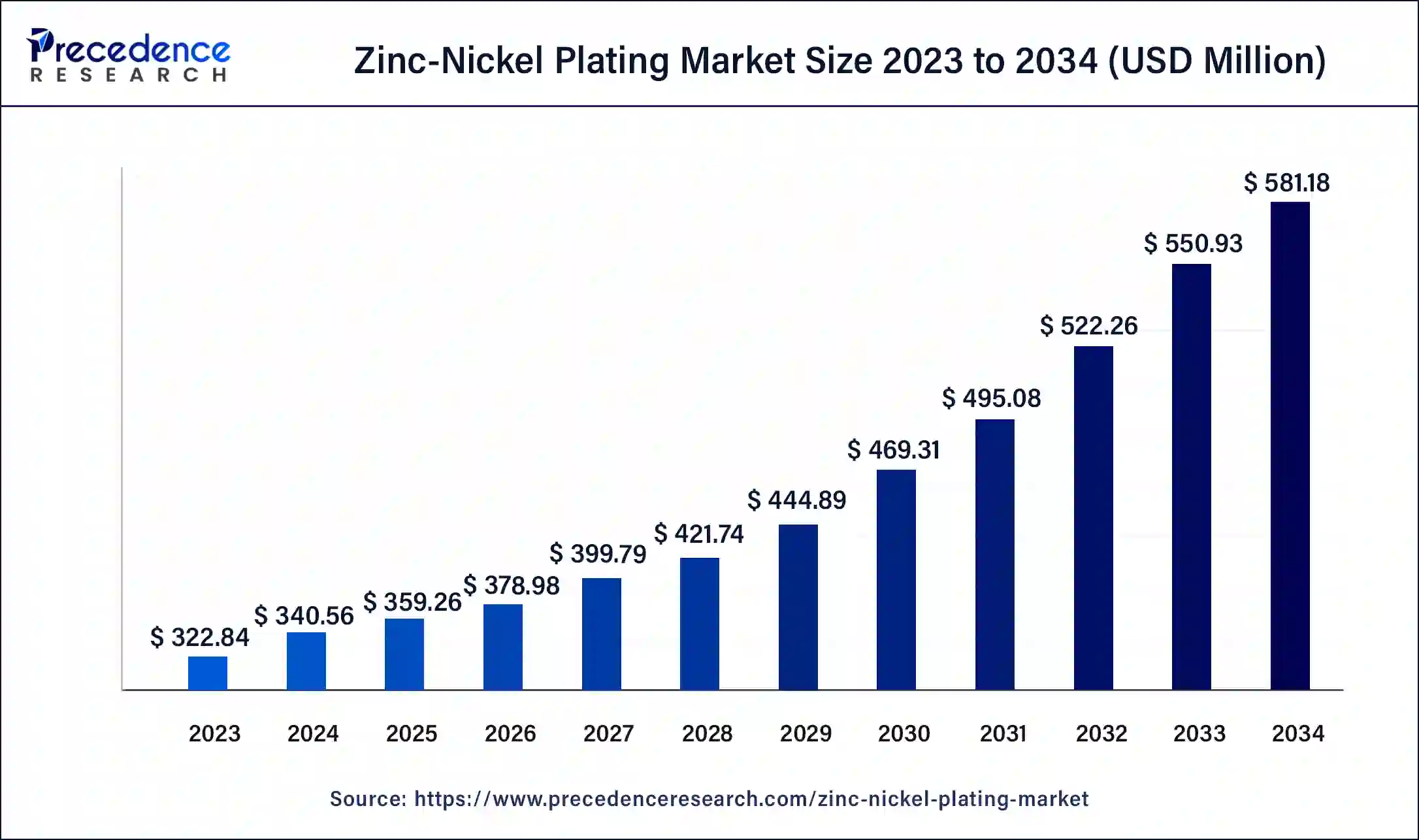

The global zinc-nickel plating market size was exhibited at USD 340.56 million in 2024 and is anticipated to reach around USD 581.18 million by 2034, expanding at a solid CAGR of 5.49% over the forecast period 2025 to 2034. Increasing adoption of environmentally friendly and anti-corrosive plating across various sectors like automotive, electronics, and aerospace, along with the global push towards the adoption of EVs, are major driving factors for the zinc-nickel plating market.

Zinc-Nickel Plating Market Key Takeaways

- The global zinc-nickel plating market was valued at USD 340.56 million in 2024.

- It is projected to reach USD 581.18 million by 2034.

- The zinc-nickel plating market is expected to grow at a CAGR of 5.49% from 2025 to 2034.

- Asia Pacific accounted for the largest share of the zinc-nickel plating market in 2024.

- North America is expected to host the fastest-growing market in the coming years.

- By type, the 5 12% segment accounted for the largest share of the market in 2024 and is expected to sustain its position throughout the forecast period.

- By type, the 12 20% segment is predicted to experience noticeable growth in the market in the foreseeable period.

- By application, in 2024, the automotive segment dominated the global market.

- By application, electronics is projected to expand rapidly in the market in the coming years.

AI Impact on the Market

AI can have a significant impact on the zinc-nickel plating market by improving quality control and cost minimization while optimizing the production process. Furthermore, with the help of predictive analytics, AI can determine equipment maintenance and ways to minimize downtime, which will extend the machinery's life. AI-based systems can also aid in the precise chemical composition to ensure quality and consistency of plating and thickness.

For quality checks, image recognition by AI can help recognize surface defects in real-time, which will lead to instant actions to fix them. It reduces downtime and extra working hours for fault detection and increases better product outcomes, resulting in greater turnover of the enterprises. Additionally, AI can be used to predict and control waste generation and diffusion by the proper way of neutralizing it for better environmental sustainability and compliance with regulatory bodies for safety and the environment.

Market Overview

The zinc-nickel plating market is set to experience a significant growth rate in the upcoming period owing to the increasing demand for corrosion-free products in various industries like aerospace, electrical, automotive, and industrial end-use. Basically, zinc-nickel plating is a method used for corrosion-free applications, where a thinner layer of zinc-nickel alloy is deposited on a metal substrate. Such a deposition of the alloy's layer helps prevent the corrosion of a metal due to the extreme weather conditions that lead to the inevitable process called corrosion on metals.

As per the data, the automotive industry is the major contributor to the expansion of the zin-nickel plating market on a wider scale globally. The rise in demand for technically advanced automobiles worldwide is fuelling the automotive industry and, thus, the zinc-nickel plating market also. Governments in most developed countries have banned a hexavalent chromium coating used in industrial applications as a coating for metals, which is observed to be a harmful element to the environment.

Zinc-Nickel Plating Market Growth Factors

- Increasing demand for durable and corrosive-resistant material across various sectors.

- Proliferation of the automotive industry across the globe.

- Manufacturers are inclined to adopt climate-friendly material for coatings.

- Technological innovations in coating methods are increasing to meet the various requirements of different industries.

- Increasing adoption of electric vehicles globally.

- Stringent government regulations for environment-friendly coating usage.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 581.18 Million |

| Market Size in 2025 | USD 359.26 Million |

| Market Size in 2024 | USD 340.56 Million |

| Market Growth Rate from 2025 to 2034 | CAGR of 5.49% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and the Middle East & Africa |

Market Dynamics

Driver

High corrosion protection and excellent heat tolerance

A major driving factor that propels the zinc-nickel plating market is the excellent protection offered by this plating against heat and environmental abrasion, along with providing a barrier against corrosion due to the free radicals- reactive elements present in the climate. Another important aspect of this process is plating, which is done by a chemistry supplier who thoroughly understands the chemical reactions and their possible effect on climate. Zinc nickel plate provides a higher rate of activation than alkaline. Therefore, it is mostly used in high-carbon and heat-treated steel components such as calipers.

Moreover, acid zinc-nickel plating provides a faster speed owing to its higher efficiency, even distribution, and high ductile nature. It offers even distribution across the current density ranges, which is the ideal solution for plating complex geometrics in various types of machinery. This is a major growth factor of the zinc-nickel plating market. Super ductility results in reduced cracking along with protection from corrosion, which is the major factor why automotive manufacturers are adopting zinc-nickel plating, in particular for brake line systems in vehicles.

Restraint

High wastage concern

A major restraining factor for the zinc-nickel plating market is the management of the huge amounts of waste produced during the process of plating, which can lead to serious environmental impacts that need to be addressed and resolved. Furthermore, including waste management, workers' safety protocols, and compliance with stringent regulations about human safety and environmental factors could be challenging for the growth of the market if not followed properly.

Waste management plays a crucial role as it directly affects the environment. Waste produced by zinc-nickel plating can contain a poisonous element that needs to be disposed of carefully. To remove these contaminants, filtration methods are generally used along with chemical treatments that help neutralize the harmful impact before disposing of it outside. Additionally, personal protective equipment means a PPE kit is also mandatory as per rules in terms of workers' safety, again increasing the overall spending on the process, which might be a barrier for some manufacturing plants where the budget is constrained.

Opportunity

Eco-friendly and advanced plating technologies

A significant opportunity that the zinc-nickel plating market holds is innovations and technological advancement in plating techniques that are supportive of the environment. Such an eco-friendly approach and sustainable practices are the major factors that are shaping the market prominently. Technological advancements like automated plating systems are creating waves in the market since it is helpful in reducing labor costs and increasing accuracy, making it a more effective and highly efficient technique for plating. Automation can aid in producing a large batch of plating products, increasing overall turnover and sales in the market.

Moreover, techniques like pulse plating and high-speed plating are also gaining traction with manufacturers as they help control the process better, while the deposition process for smoother and uniform coatings can further minimize corrosion possibilities and defects. High speed, as the name suggests, can significantly minimize production time and improve the quality of the products, offering rapid turnaround time to industries. Innovations like the adoption of nanotechnology into the plating further create lucrative options in the global zinc-nickel plating market. Depositing nanoparticles in the plating solution can maximize its properties, like stiffness, hardness, and resistance to moisture deposition, leading to corrosion present in the air.

Type Insights

The 5 12% segment accounted for the largest share of the zinc-nickel plating market in 2024 and is expected to sustain its position throughout the forecast period. This range of nickel concentration offers optimal strength and flexibility specifically for highly demanding sectors like aerospace and automotive. The equipment coated with this concentration of nickel withstands adverse environmental conditions, leading to greater efficiency and fuelling this segment's growth.

The 12 20% segment is predicted to experience noticeable growth in the zinc-nickel plating market in the foreseeable period. The growth of this segment is due to its ability to handle the equipment in extreme, vulnerable conditions like aggressive and highly reactive chemicals, extreme heat, and marine environments that causes permanent damage to the equipment.

Application Insights

The automotive segment dominated the global zinc-nickel plating market in 2024. The growth of this segment is due to the rapid expansion of the automotive sector across the world. Zinc-nickel plating is widely adopted as an anti-corrosion plating. Since automobile parts have to go through lots of abrasion and friction regularly, they are more exposed to high temperatures and moisture as well, which results in a faster rate of corrosion while damaging the internal automobile parts. To avoid this damage, zinc-nickel coatings are extremely helpful, increasing the overall efficiency of the automobile.

The electronics is projected to expand rapidly in the zinc-nickel plating market in the coming years. The growth of this segment is related to the greater benefits provided by zinc-nickel plating in the electronics industry, such as higher corrosion protection, more wear resistance in moving parts of the machine, and the reduction of the thermal stress subjected to the higher temperature settings in the machinery.

Regional Insights

Asia Pacific accounted for the largest share of the zinc-nickel plating market in 2024. The dominance of this region is due to the proliferation of automotive, aerospace, and electronics sectors in technologically emerging countries like China, India, and Japan. These sectors are in high need of corrosive metals and products to manufacture parts of vehicles, aerial vehicles, and other electronic goods, driving the demand for the zinc-nickel plating market. Moreover, increasing urbanization, availability of low-cost labor, and rapid industrialization aid in infrastructural development.

Top nickel-producing Asian countries in 2023.

| Indonesia | World's largest nickel producer, with reserves of 21 Global nickel production was expected to increase to 3,372.3 kt in 2023, 20.6% of the global total. |

| Philippines | Produced an estimated 360,000 tons of contained nickel in 2022. 11% of global production of nickel. |

| China | The seventh largest nickel producer produced an estimated 110.4 kt in 2023. 26.9% of the global total |

North America is expected to host the fastest-growing zinc-nickel plating market in the coming years. The growth of this region is due to the proliferation of advanced automotive, defense, and aerospace industries, which require highly corrosion-resistant coatings due to their sensitive performance. North America has a focus on sustainable products and environmentally friendly practices, which leads to a higher demand for zinc-nickel plating across various sectors. Zinc-nickel plating is proven as a non-toxic element that does not harm the climate even after disposing of it. This factor is gaining the traction of many manufacturers who are adopting zinc-nickel plating in their production area.

Technological advancements like automated plating processes help improve overall product efficiency and cost-effectiveness, leading to further market growth. Major projects for nickel production in Canada are significant contributors to the region's growth in the zinc-nickel plating market.

- According to the sources, Canada produced 132.4 kt of nickel in 2023. Glencore is the sole proprietor of the Onaping Depth project in Canada, which is currently in construction. The project is set to commence operations in 2025 and has an annual production capacity of 20 kt of saleable nickel.

Zinc-Nickel Plating Market Companies

- KC Jones Plating

- MacDermid

- Zinc Nickel Plating

- Chem Processing

- Paramount Metal Finishing

- Micro Metal Finishing

- Plating Technology

- DeKalb Metal Finishing

- Pioneer Metal Finishing PMF

Recent Development

- In July 2024, Vedanta Nico was announced as the supplier of nickel to a U.S.-based innovator in advanced battery technologies; nickel-zinc batteries promise substantial advantages over current battery technologies, including higher energy density, power, enhanced cost efficiency, rapid charging, and superior performance.

- In March 2023, Canada's Tartisan Nickel company owns the Kenbridge project, a developing mine in Canada currently under construction. The company hired Nordmin Engineering to oversee Kenbridge's exploration and development activities.

Segments Covered in the Report

By Type

- Nickel: 12 20%

- Nickel: 10 15%

- Nickel: 6 20%

- Nickel: 5 12%

- Other

By Application

- Automotive

- Electronics

- Aerospace and Defense

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting