3D Food Printing Market Size and Forecast 2025 to 2034

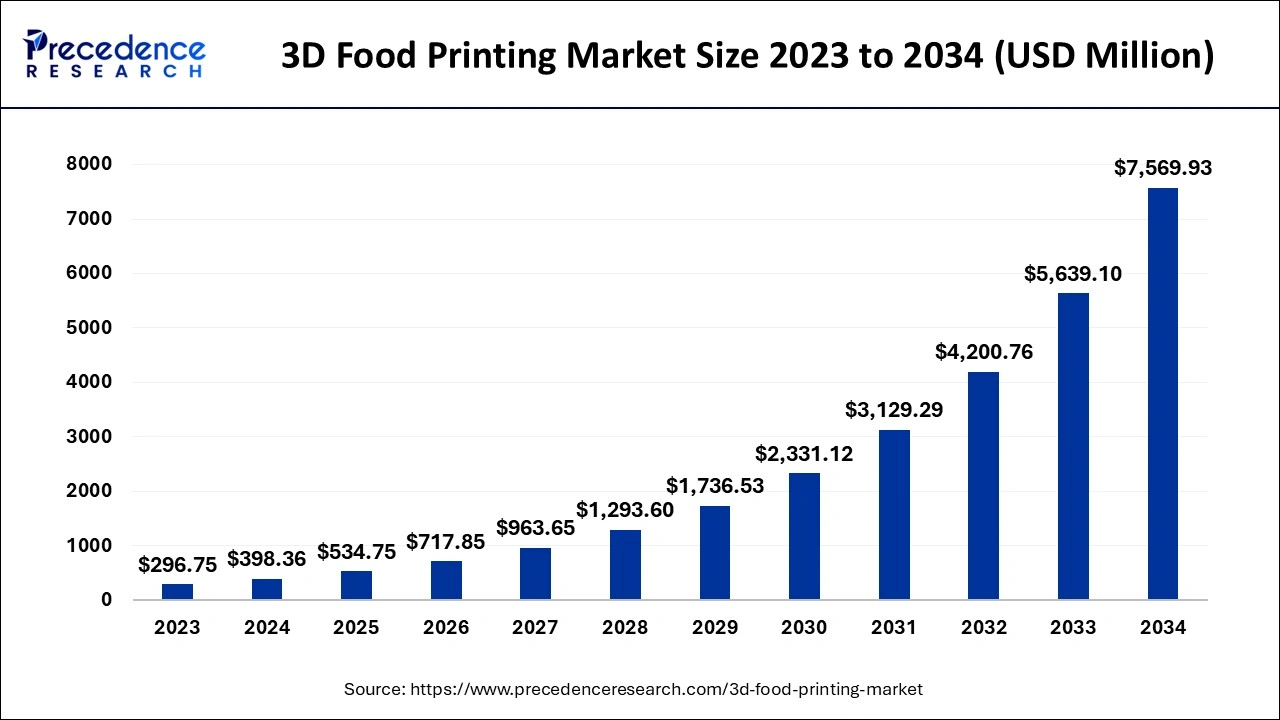

The global 3D food printing market size was USD 398.36 million in 2024, calculated at USD 534.75 million in 2025 and is expected to reach around USD 7,569.93 million by 2034, expanding at a CAGR of 34.24% from 2025 to 2034.

3D Food Printing Market Key Takeaways

- In terms of revenue, the market is valued at $534.75 billion in 2025.

- It is projected to reach $7,569.93 billion by 2034.

- The market is expected to grow at a CAGR of 34.24% from 2025 to 2034.

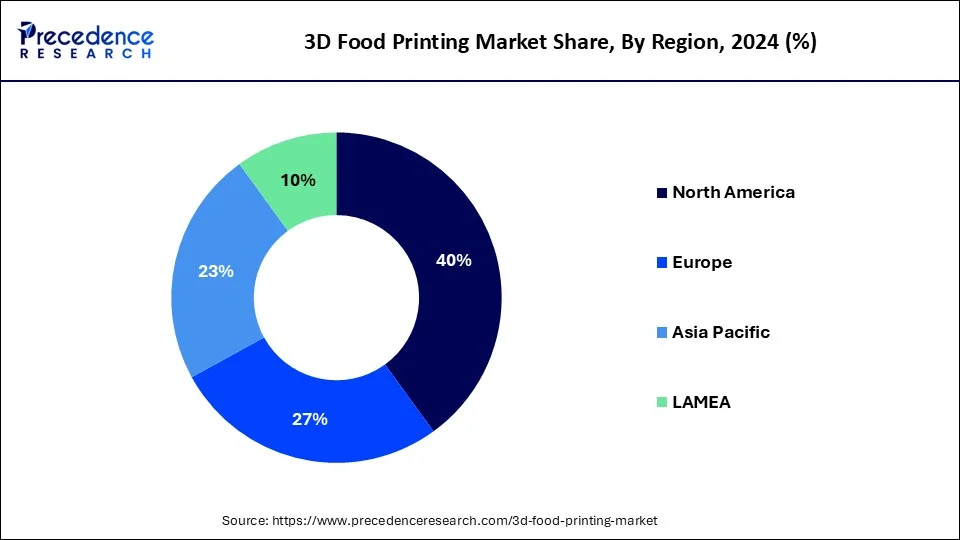

- North America contributed more than 40% of revenue share in 2024. On the other hand, Europe is estimated to expand the fastest CAGR between 2025 and 2034.

- By ingredient, the carbohydrates segment has held the largest market share of 38% in 2024. On the other hand, the proteins segment is anticipated to grow at a remarkable CAGR of 12.7% between 2025 and 2034.

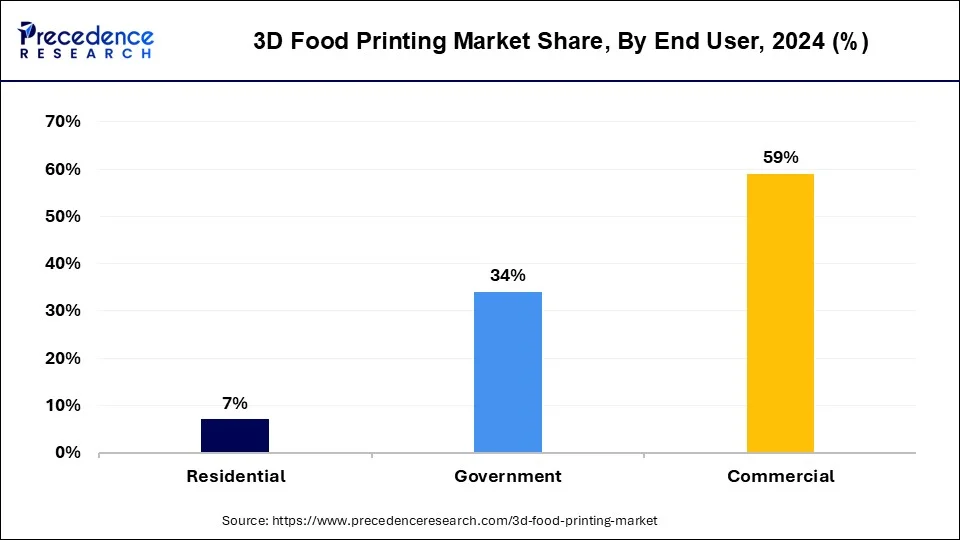

- By end user, the commercial segment generated over 59% of revenue share in 2024. Whereas the residential segment is expected to expand at the fastest CAGR over the projected period.

- By technology, the extrusion-based printing segment had the largest market share of 51.2% in 2025. Whereas the inkjet printing segment is expected to expand at the fastest CAGR over the projected period.

Market Overview

The 3D food printing market encompasses the use of advanced additive manufacturing techniques to create three-dimensional edible structures and designs with various ingredients. This innovative technology is revolutionizing the food industry by enabling the customization of food products for nutrition, flavor, and dietary needs.

By using food-grade materials, 3D food printers can produce intricate and personalized dishes, snacks, and confections. The market's growth is driven by the rising demand for personalized nutrition, the exploration of sustainable food production methods, and the increasing adoption of technology in the culinary world, opening new possibilities for creating unique and visually appealing food items.

U.S. 3D Food Printing Market Size and Growth 2025 To 2034

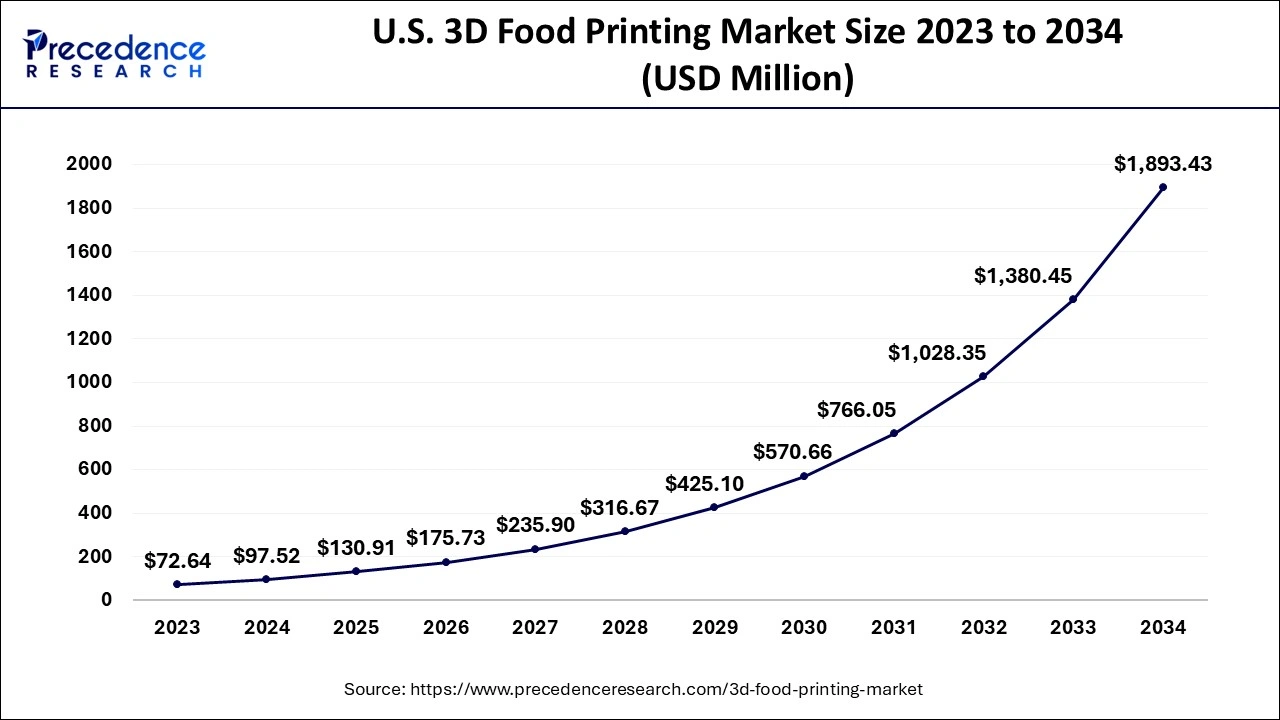

The U.S. 3D food printing market size was valued at USD 97.52 million in 2024 and is expected to grow to USD 1,893.43million by 2034, growing at a CAGR of 34.53% from 2025 to 2034.

North America has held the largest revenue share 40% in 2024. North America has been a prominent region for the 3D food printing market, with robust growth driven by technological innovation and a rising focus on personalized nutrition. The United States, in particular, has witnessed a surge in startups and research initiatives exploring 3D food printing applications, especially in healthcare settings. The market has also been supported by the increasing popularity of gourmet and artisanal food products that benefit from the unique designs and shapes enabled by3D printing technology.

Europe is estimated to witness the fastest expansion. In Europe, 3D food printing has seen adoption in both consumer and commercial settings. European countries have been at the forefront of experimenting with printed confections and intricate dessert designs. Furthermore, sustainability and reducing food waste are key trends, with the technology being employed to create appealing food presentations while minimizing leftovers. As environmental concerns continue to grow, Europe's 3D food printing market is poised for further expansion in the coming years.

China distinguishes itself in the Asia Pacific 3D food printing sector due to its robust manufacturing capabilities, favorable government policies, and increasing consumer enthusiasm for innovative food alternatives. The nation's emphasis on food safety, sustainability, and technological progress has spurred greater investment in research and development of 3D food printing. Chinese enterprises are investigating applications that range from personalized nutrition to solving food security issues, positioning China at the forefront of this burgeoning market.

3D Food Printing Market Growth Factors

- 3D printing enables the creation of intricate food structures and designs that were previously challenging to achieve with traditional methods, expanding culinary creativity. The demand for complex food structures is observed to propel the growth of the industry.

- Restaurants and food service providers can use 3D printing to offer unique dining experiences by crafting customized dishes that cater to customers' tastes and dietary restrictions.

- Collaborations between technology companies, food manufacturers, and culinary experts are on the rise, driving innovation and the development of new applications.

- 3D food printing is ushering in a new era of culinary creativity, with chefs and food designers experimenting with artistic and visually appealing food presentations.

- The market is expanding beyond high-end restaurants to include food retailers, home consumers, and institutional settings, presenting a range of opportunities for growth.

- Sustainability and environmentally friendly practices are integral to the growth of the 3D food printing market, aligning with consumer demand for eco-conscious food options.

- Research is ongoing into using alternative and novel ingredients, such as plant-based materials, to create healthier and more sustainable 3D-printed food products.

- While currently more prominent in certain regions, the market is seeing global adoption, offering significant potential in various culinary traditions and dietary requirements.

- Raising awareness and educating consumers about the benefits and possibilities of 3D-printed food will be essential to drive acceptance and growth in the market.

- The technology presents an opportunity to reduce food waste and promote sustainability by utilizing ingredients efficiently and minimizing the environmental impact of food production.

Major Key Trends in 3D Food Printing Market

- Customization of Nutrition and Diet: 3D food printing allows for the creation of meals specifically designed to meet individual nutritional requirements, accommodating unique dietary needs, health conditions, and personal tastes, thereby enhancing wellness and satisfaction.

- Use of Sustainable and Alternative Protein Sources: This technology promotes the incorporation of sustainable ingredients such as plant-based proteins and cultured meats, addressing environmental issues and decreasing dependence on conventional animal farming methods.

- Synergy with Smart Technologies: Integrating 3D food printing with artificial intelligence AI and IoT enables real-time oversight, recipe enhancement, and streamlined production processes, resulting in improved consistency and innovation in food preparation.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 7569.93 Million |

| Market Size in 2025 | USD 534.75 Million |

| Market Size in 2024 | USD 398.36 Million |

| Growth Rate from 2025 to 2034 | CAGR of 34.24% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Ingredient, End User, Technology, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Personalized nutrition and customization in food service

Personalized nutrition has become a focal point in the health and wellness sector. Consumers are increasingly seeking diets tailored to their unique health needs and dietary preferences. 3D food printing plays a pivotal role in this trend by allowing the creation of highly customized food products. 3D food printing facilitates precise personalization in various aspects of nutrition. Such fine-grained personalization not only caters to unique dietary requirements but also contributes to the overall health and well-being of consumers.

Moreover, customization in food service has revolutionized the restaurant and catering industries. 3D food printing empowers chefs and food service providers to offer exclusive and bespoke dining experiences to their patrons. From crafting intricate edible decorations to producing dishes tailored to customers' tastes, dietary restrictions, and cultural preferences, 3D food printing adds a unique dimension to culinary innovation. This enhanced level of customization boosts customer satisfaction and loyalty, driving the demand for 3D food printing solutions in the food service sector.

Restraint

Limited ingredient compatibility and design complexity

The 3D food printing market faces certain constraints, including limited ingredient compatibility and design complexity. Firstly, the technology's compatibility with ingredients can be restrictive, as not all food materials are suitable for 3D printing. Some ingredients may not have the necessary texture, consistency, or binding properties required for the printing process. This limits the range of foods that can be effectively printed, excluding certain traditional or culturally significant dishes from 3D printing. Additionally, ingredients often need to be modified or processed to meet the requirements of 3D printing, which can lead to added costs and alterations to the original recipes.

Moreover, the complexity of designing printable food products is another challenge. Creating 3D food designs necessitates expertise in both culinary arts and digital modeling. Chefs and food technologists must collaborate with engineers and designers to ensure that the final products not only look appealing but also taste good. The intricate nature of design, especially for complex shapes and structures, demands specialized skills and can be time-consuming. This challenge may hinder the widespread adoption of 3D food printing, particularly in small-scale culinary operations.

Opportunity

Food production in event catering and hospitality

The 3D food printing market is experiencing increased demand due to its adoption in diverse sectors, including food production in space, event catering, and hospitality. In space exploration, 3D food printing addresses the challenges of providing astronauts with nutritious and safe meals. The technology allows for the creation of custom meals that cater to individual dietary needs, ensuring that astronauts receive proper nutrition while reducing food waste. This innovation is vital for long-duration space missions and lunar or Mars colonization plans.

In the hospitality and event catering industry, 3D food printing is gaining popularity as a tool to create unique and visually appealing dishes. Caterers and chefs can use this technology to craft intricate food designs, enhancing the overall dining experience. Whether it's personalized wedding cakes or branded corporate event catering, 3D food printing adds a touch of sophistication and originality. As these industries increasingly embrace cutting-edge culinary technologies, the 3D food printing market is set to thrive further, driven by the desire for culinary innovation and customer satisfaction.

Ingredient Insights

The carbohydrates segment held 38% revenue share in 2024. Carbohydrates, often sourced from various flours, are utilized to create the base or dough for printed food items. The trend in carbohydrate-based 3D food printing revolves around optimizing these materials for texture, taste, and nutritional content. Innovations include gluten-free flours, alternative starch sources, and personalized flour blends to cater to various dietary requirements and preferences.

The proteins segment is anticipated to expand at a significant CAGR of 12.7% during the projected period. Proteins are another crucial ingredient in 3D food printing, providing structure and nutrition to printed food. Emerging trends involve incorporating plant-based proteins and experimenting with alternative protein sources like algae and fungi. The drive for sustainable and personalized protein options has prompted the exploration of these novel ingredients in 3D food printing applications, offering consumers a broader range of choices for healthier and eco-friendly food products.

End User Insights

The commercial is anticipated to hold the largest market share of 59% in 2024. The commercial segment of the 3D food printing market is primarily focused on the food service industry, including restaurants, hotels, and catering services. These businesses employ 3D food printers to create visually appealing and customized dishes. Trend-wise, there's growing interest in using 3D food printing for event catering and fine dining, where intricate and artistic food presentations can captivate customers. Additionally, the pandemic accelerated the adoption of touchless food preparation, making 3D food printing an appealing technology for the hospitality sector.

The residential segment is projected to grow at the fastest rate over the projected period. In the residential sector, 3D food printing is still in the early stages, with limited adoption. However, it's steadily gaining interest among tech-savvy consumers who want to explore culinary creativity at home. The trend here is toward more accessible and user-friendly 3D food printers designed for home kitchens. Companies are developing smaller, more affordable, and easy-to-operate devices, which are expected to drive increased adoption for personalized and artistic food creations at home.

Technology Insights

The extrusion-based printing segment had the highest market share of 51.2% in 2024 based on the technology. Extrusion-based 3D food printing is a technique where food materials are pushed through a nozzle, similar to how a pastry bag dispenses frosting. It's a widely used technology known for its ability to create intricate shapes and structures. In this method, food is extruded layer by layer to form the desired 3D shape.

The inkjet printing segment is anticipated to expand at the fastest rate over the projected period. In contrast, inkjet 3D food printing is akin to traditional inkjet printing but uses edible inks to create intricate food designs. It's gaining traction due to its precision and ability to add fine details to dishes. The trend in 3D food printing leans towards a combination of these technologies to offer a wider range of food creations, from complex structures to intricately decorated desserts.

3D Food Printing Market Companies

- Dovetailed, Aniwaa Pte. Ltd

- 3D Systems, Inc.

- TNO, byFlow B.V.

- Print4taste GmbH

- Natural Machines

- Shiyin Technology Co., Ltd.

- Systems and Materials Research Corporation

- Barilla G. e R. Fratelli S.p.A

- Redefine Meat Ltd.

- 3Desserts Graphiques

- BeeHex, NOVAMEAT

- Modern Meadow

- Natural Machines

- ByFlow B.V.

- BeeHex, Inc.

Recent Developments

- In October 2024, Revo Foods launched the world's largest 3D food printing facility in Vienna, capable of producing up to 60 tons of 3D-printed food each month. This facility aims to enhance the production of plant-based seafood alternatives, beginning with their leading product, THE FILET, to cater to the rising demand for sustainable food choices.

- In September 2024, 3D Systems entered into a collaboration with NASA to create 3D-printed food products that are suitable for prolonged space missions. This partnership focuses on developing nutrient-rich, sustainable food options that can be efficiently generated and consumed by astronauts during extended travel, addressing both nutritional requirements and logistical challenges.

- In July 2024, Global pasta manufacturer Barilla collaborated with 3D printing company WASP to create customizable 3D-printed pasta shapes. This innovation enables consumers to personalize pasta designs, enhancing their culinary experience while minimizing food waste through the use of sustainable ingredients and precise portion control.

- In 2022, SavorEat, an Israeli startup, introduced its 3D-printed plant-based burgers in the United States. These products are kosher, vegan, and gluten-free, offering a unique and inclusive alternative in the plant-based food market.

- In 2021, NASA collaborated with Systems and Materials Research Corporation (SMRC) to create 3D printers and nutritious food to sustain astronauts physically and mentally in space. SMRC has devised a pizza printing system using nutrient-rich powdered foods, enabling automated meal production in space.

- In 2020, Meat-Tech 3D Ltd. unveiled its acquisition of Peace of Meat PV, a pioneering Belgian cultured avian product producer, for EUR 15 million. The deal is structured with a combination of cash and Meat-Tech ordinary shares and is headquartered in Ness Ziona, Israel.

Segments Covered in the Report

By Ingredient

- Dough

- Fruits and Vegetables

- Proteins

- Sauces

- Dairy Products

- Carbohydrates

- Others

By End User

- Government

- Commercial

- Residential

By Technology

- Extrusion-based Printing

- Binder Jetting

- Selective Laser Sintering

- Inkjet Printing

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting