Extruded Plastics Market Size and Forecast 2025 to 2034

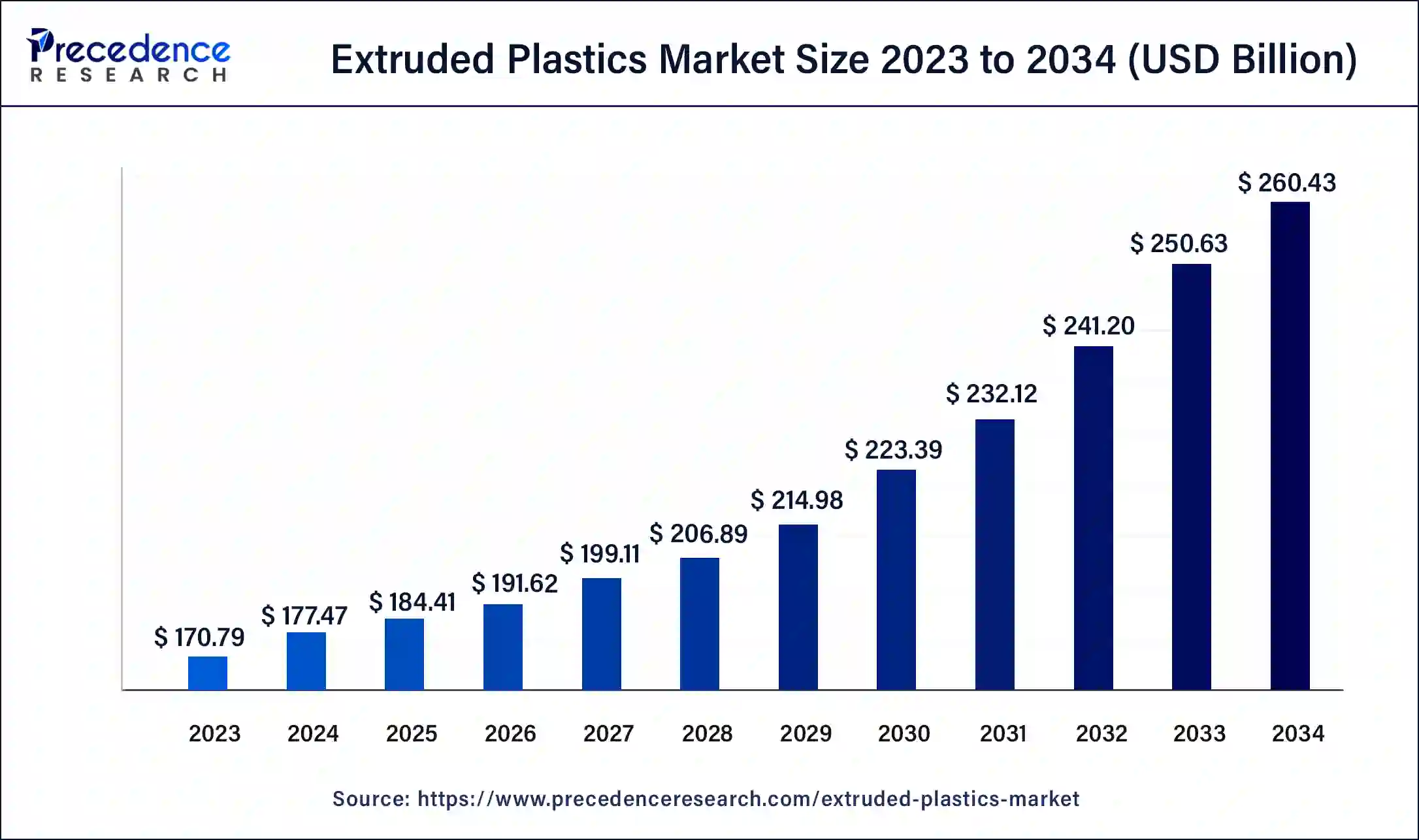

The global extruded plastics market size was valued at USD 177.47 billion in 2024 and is anticipated to reach around USD 260.43 billion by 2034, growing at CAGR of 3.91% over the forecast period 2025 to 2034. The rising demand for the polymer component from the various industries for the development of equipments, devices, and packaging material drives the growth of the market.

Extruded Plastics Market Key Takeaways

- In terms of revenue, the extruded plastics market is valued at $184.41 billion in 2025.

- It is projected to reach $260.43 billion by 2034.

- The extruded plastics market is expected to grow at a CAGR of 3.91% from 2025 to 2034.

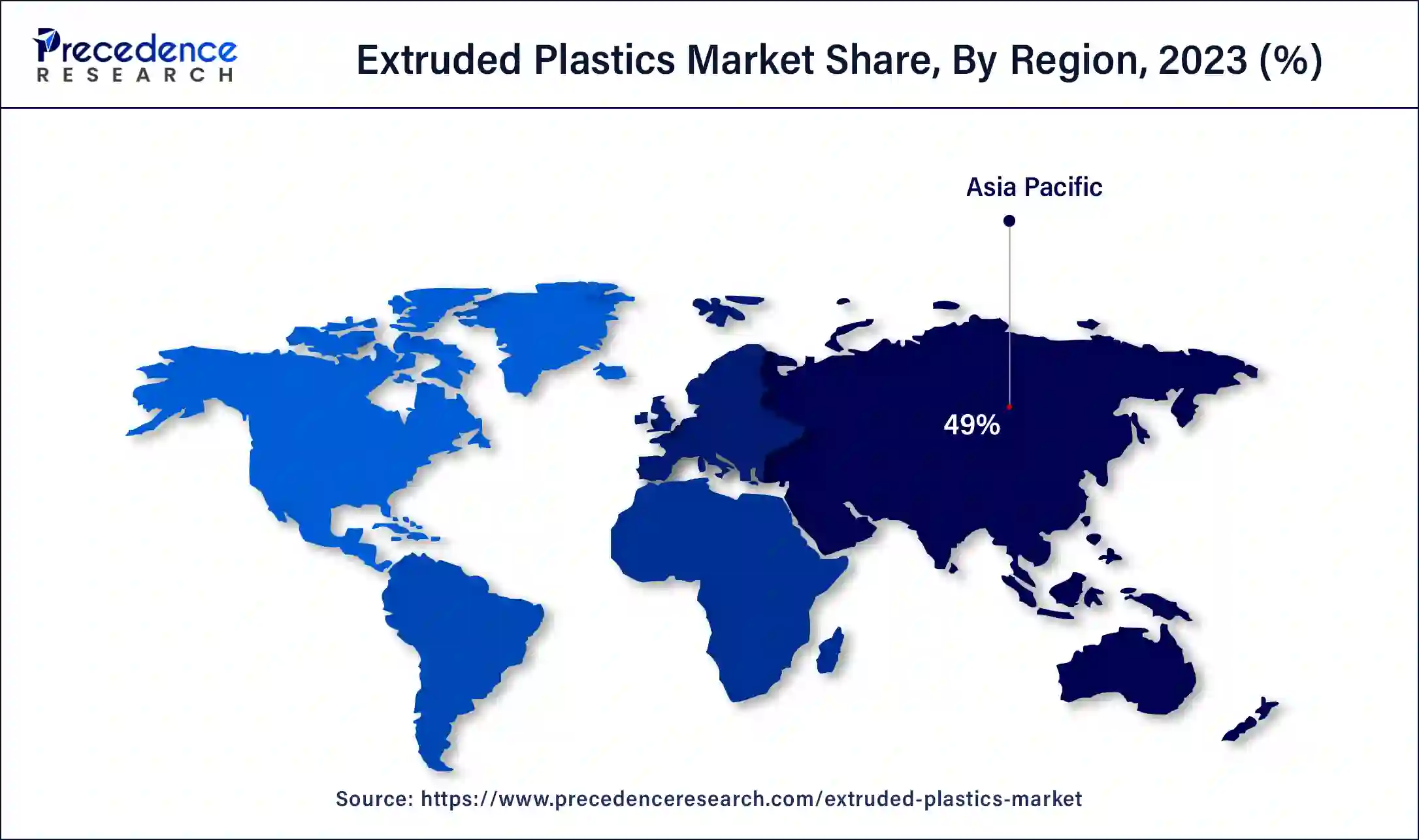

- Asia Pacific held the dominant share of the extruded plastics market with the largest market share of 49% in 2024.

- North America is anticipated to grow at the fastest rate in the market during the forecast period.

- By material, the polyethylene segment captured the biggest market share of 43% in 2024.

- By material, the polycarbonate segment is predicted to witness significant growth in the market over the forecast period.

- By application, the profiles segment contributed the highest market share of 43% in 2024.

- By end-user, the packaging segment has held the largest market share of 34% in 2024.

- By end-user, the construction segment is expected to gain a significant share of the extruded plastics market over the studied period of 2025 to 2034.

How Can AI Impact the Extruded Plastics Market?

The integration of AI into the plastic industry is revolutionizing the process and operations of the industry with predictive maintenance that predicts the failure of equipment failure. It emerges as a transformative tool that helps evolve technologies in the plastic industry. With the integration of AI in the plastic industry, manufacturers reduce maintenance costs, enhance quality, and optimize production processes. It provides valuable insights about the equipment data, enhances production efficiency, reduces downtime, improves safety, and increases product quality. A number of market players like SABIC and INEOS are using AI for productive maintenance in their operations.

- In October 2022, LS Mtron Injection Molding Machines launched Artificial Intelligence (AI)-in two different systems, Smart Weight Control and AI Molding Assistant. With the integration of AI, molding assistance reduces the time needed to stabilize the starting molding process by learning and mimicking the behavior of highly skilled molding specialists.

Asia Pacific Extruded Plastics Market Size and Growth 2025 to 2034

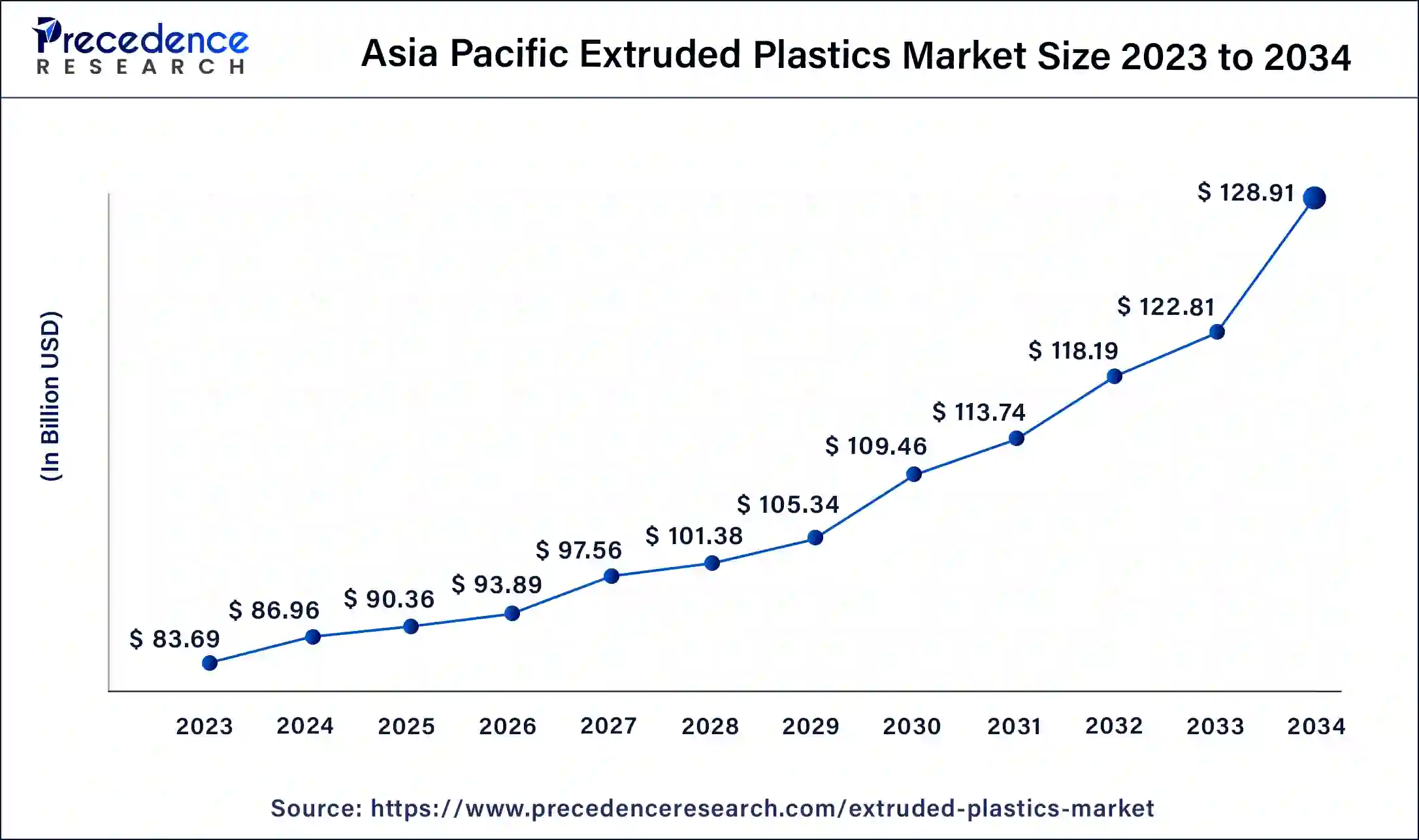

The Asia Pacific extruded plastics market size was exhibited at USD 86.96 billion in 2024 and is projected to be worth around USD 128.91 billion by 2034, poised to grow at a CAGR of 4.02% from 2025 to 2034.

Asia Pacific held the dominant share of the extruded plastics market in 2024. The growth of the market is attributed to the rising population and the demand for industrialization. The rising industries and manufacturing units across the region, such as automobile, electronics, building and construction, packaging, industrial machinery, and others, are driving the demand for extruded plastics. The rising demand for polymer materials in the regional developed and developing economies like China, India, and Japan due to the rising consumer segment and demand for packaging material drives the growth of the extruded plastics market in the region.

- The plastic industry is one of the leading sectors contributing to India's economy. The industry is becoming more available across the country, with more than 2500 exporters. The government of India is planning to expand the current level of economic activity in the plastic industry from Rs.3 lakh crore (US$37.8 billion) to Rs. 10 lakh crore (US$126 billion) in the next 4-5 years.

- The Plastic Export Promotion Council (PLEXCONCIL) has targeted to expand the plastic exports of the country to US$ 25 billion by 2027. The Government of India will release the funds up to 50% of the project costs or a ceiling cost of Rs. 40 crore (US$ 5 million) per project.

Currently, Asia Pacific is dominating the extruded plastics market. The large industrial sector and accelerating urbanization directly open the door for the requirement of packaging. The high production and consumption rate of packaging by the automotive and electronics industries is a boon to the market in the region.

North America is anticipated to grow at the fastest rate in the market during the forecast period. The growth of the market is attributed to the rising technological adoption in the industries by regional countries like the U.S. and Canada and the rise in the consumer base that drives the demand for consumer electronics, food and beverages products, and other applications that drive the demand for the plastic material for the packaging and other purpose that boosts the growth of the extruded plastics market in the region.

As per the U.S. Bureau of Labor Statistics, an estimated 608,000 employees were working on plastic product manufacturing in November 2023, which is likely to reduce in number in December 2023.

Market Overview

The extruded plastic or plastic extrusion is generally the process of manufacturing in which thermoplastic material, which is in the form of granulates, pallets, and powders, is melted and forced into the shaping die with pressing weight to gain the desired size and shape of the plastic product. The extrusion process goes through four different zones, including the feed zone, transition zone or compressor zone, mixing zone, metering zone, heat transfer, friction, and extruder barrel. There are different types of extruders used by the manufacturing industries, such as single screw extruders, twin screw extruders, multi-crew extruders with more than two screwsdisk extruders, stepped disk extruders, drum extruders, disk pack extruders, elastic melt extruders, single ram extruders, multi ram extruder.

Extruded Plastics Market Growth Factors

- The growth of the market is attributed to rising industrialization in areas such as automotive, electric and electronics, building and construction, healthcare, pharmaceutical, and other industries, which are driving the demand for extruded plastics in the manufacturing process.

- The rising disposable income in the population that drives the demand for the consumer segment such as the food and beverages industry and consumer electronics, which drives the demand for the polymer component polyethylene, polycarbonate, and others for packaging and electronics covering for safety purposes that boosts the demand for the extruded plastics market.

- The rising use of plastics as a disposable material in the food and beverage industry and the demand for sustainable packaging solutions in different industries are driving the growth of extruded plastic to cater to the demands of the industries.

- The rise in technological advancements in manufacturing and other industrial developments in a wide range of applications and machines boosts the demand for the extruded plastics market.

- The increasing regional government regularities in the disposable and sustainability of plastic materials and the investment in the development of sustainability in plastic production and usage are contributing to the expansion of the market.

Extruded Plastics Market Trends

- In February 2024, Haitian UK launched the 5th Generation of Injection Moulding Machinery. The 5th generation injection molding consists of a wide range of versatile integration functions as standards, such as the ability to self-recognize, self-reconstruct, self-decide, and self-adapt.

Technological Advancement

Technological advancements in the extruded plastics market feature automation, multi-layer extrusion, and nanotechnology. The automation and smart extrusion, like machine learning and AI, automate tasks and speed up the process. The multi-layer extrusion is a technique that creates a product, differentiating properties with a single extrusion process. The nanotechnology enhances and improves materials properties to meet the application requirements of the extruded plastics. The sustainable process is an advancement in the market.

The Dow Chemical Company approached a recycling solution for extruded plastic products. This is a measure step towards sustainability. Other advancements, such as 3D extrusion technology and modular extruder design, are fueling the growth of the extruded plastics market. The innovation and eco-friendly motive highlight the market globally.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 260.43 Billion |

| Market Size in 2025 | USD 184.41 Billion |

| Market Size in 2024 | USD 177.47 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 3.91% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material, Application, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Driver

The rising use of medical plastics by the healthcare industry

The rise in the healthcare industry and the demand for plastic material equipment in the medical used for the manufacturing of devices and used as disposable materials are driving the growth of the extruded plastics market in the healthcare industry. Medical plastics are widely used in the healthcare industry due to their highly cost-effective nature, flexibility, biocompatibility, and various chemical resistance. In the healthcare industry, tubing extrusion is highly used to manufacture medical plastic parts. With the use of tubing extrusion, the rigid, flexible, and number of medical equipment are made with plastics as per requirements.

Restraint

Quality issues

The unavailability or raw material, environmental concern regarding the increased use of plastic materials, and maintaining quality and quantity standards are some of the limitations in the extruded plastics market.

Opportunity

Advancements in the extruded plastics market

The rising investment in the future and innovations in the extrusion process drive the opportunity for the expansion of the extruded plastics market. There are some significant advancements in extruded plastics, including co-extrusion, which allows increased capabilities such as adhesion characteristics, barrier properties, or aesthetic features. 3D printing integration, formed extrusion, microcellular extrusion, and Profile Extrusion with In-Line Processing are some of the advanced features of plastic extrusion.

Material Insights

The polyethylene segment dominated the extruded plastics market in 2024. The extensive use of polyethylene material in a wide range of applications and in different product manufacturing drives the demands for the polyethylene material segment. Polyethylene is the most commonly found plastic material in a different range of forms, such as low-density (extruded LDPE), medium (extruded MDPE), and high (extruded HDPE) grades. Polyethylene has several beneficial properties that are flexible, lower in cost, and versatile, making it the perfect material for various end-use products and packaging materials. Polyethylene is regularly extruded in a variety of molds such as bottles, packaging, and food containers. The extruded polyethylene can be used in a wide variety of industries such as healthcare, manufacturing, packaging, and others, which increases the demand for the polyethylene material segment.

The polycarbonate segment is predicted to witness significant growth in the extruded plastics market over the forecast period. The growth of the segment is owing to its higher strength, impact to resistance, high-temperature resistance, strong polymer, great optical properties, and high transparency. Polycarbonate is majorly used in electronic applications to protect walls, refrigerators, electrical cabinets, and display cabinets. Extruded polycarbonates with a high gloss appearance are attractive.

Applications Insights

The profiles segment led the extruded plastics market in 2024. Profile extrusion is one of the types of extrusion processes that do not include film products and forming sheets. In the process of profile extrusion, the plastic products are made of solids like vinyl siding or hollow. The profile extrusion can be used in the manufacturing of various products such as plastic pipe and tubing, vinyl siding, window frames, plastic fencing, automotive body side moldings, electrical conduit and cable protectors, refrigerator seals, medical blood and IV tubing, and drinking straws.

End-Use Insights

The packaging segment held the largest share of the extruded plastics market in 2024. The increasing industrialization and the demand for consumer products like food and beverages, electronics, and other products drive the demand for effective packaging solutions, which boosts the demand for strong, versatile, and flexible material solutions that drive the demand for plastics and plastic extrusion. The increasing population and disposable income drive the demands for a number of end-use industries such as healthcare, households, food, and beverages, which accelerated the demand for the extruded plastics process for the different shapes and sizes of packaging.

The construction segment will gain a significant share of the extruded plastics market over the studied period of 2025 to 2034. The rising adoption of plastics and different types of polymer components in the building and construction segment is driving the growth of the extruded plastics process. The industry has wide applications in which plastic is used, such as roofing, piping, insulation, flooring, and others. Plastic is corrosion-proof and efficient in fluid and transport of other materials, and the rising investment in the development of plastics in the building and construction industry is accelerating the growth of the market.

Extruded Plastics Market Companies

- LyondellBasell

- Repsol

- Berry Global Inc.

- JM Eagle, Inc.

- Engineered Profiles LLC

- Bemis Company Inc.

- Amcor Limited

- Sealed Air Corporation

- Formosa Plastics Corporation

- Saudi Basic Industries Corp. (SABIC)

- Compagnie de Saint-Gobain S.A.

- Sigma Plastics Group

Recent Developments

- In October 2024, Austrian plastics machinery manufacturer MAS Maschinen-und Anlagenbau Schulz GmbH launched its new 110 compact extruder. The new extruder combines human expertise and artificial intelligence. (Source - https://www.recyclingtoday.com)

- In April 2025, Plastifab Industries Inc., a portfolio company of Regimen Equity Partners, announced the acquisition of key assets and intellectual property from R&M Plastics, related to the manufacturing of its well-regarded pole line products. Manufactured in Barrie, Ontario, these extruded plastic guards protect the cable lines securing utility poles across North America. (Source - https://www.globenewswire.com)

- In September 2024, Mark Fenwick, technical sales manager at Condale Plastics Ltd, explored the integral role of plastic extrusion in data centre infrastructure and the meteoric expansion of AI. (Source - https://interplasinsights.com)

- In May 2024, Clariant introduced AddWorks PKG 158, a highly efficient antioxidant solution with enhanced color protection, and AddWorks PPA, a perfluoroalkyl substances (PFAS)-free polymer processing that helps in the product line. These are the latest solutions that were developed to support the plastic industry in enhancing efficiency and safety, reducing waste, and increasing circularity at NPE2024, which is happening now in Orlando, Florida.

- In July 2022, Trinseo launched the Altuglas R-Life Acrylics, the latest range of sustainable materials for the European marketplace. The launch is the umbrella brand that includes mechanically and chemically recycled, bio-based polymethyl methacrylate (PMMA) and reused for cast and extruded sheets, compounds, and resins.

Segments Covered in the Report

By Material

- Polyethylene

- Polyvinyl Chloride

- Polystyrene

- Polycarbonate

- Others

By Application

- Profiles

- Pipes & Tubes

- Sheets & Films

- Cables & Wires

- Filaments

- Others

By End-use

- Packaging

- Construction

- Automotive

- Electronics

- Consumer Goods

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting