What is the Industrial Foam Market Size?

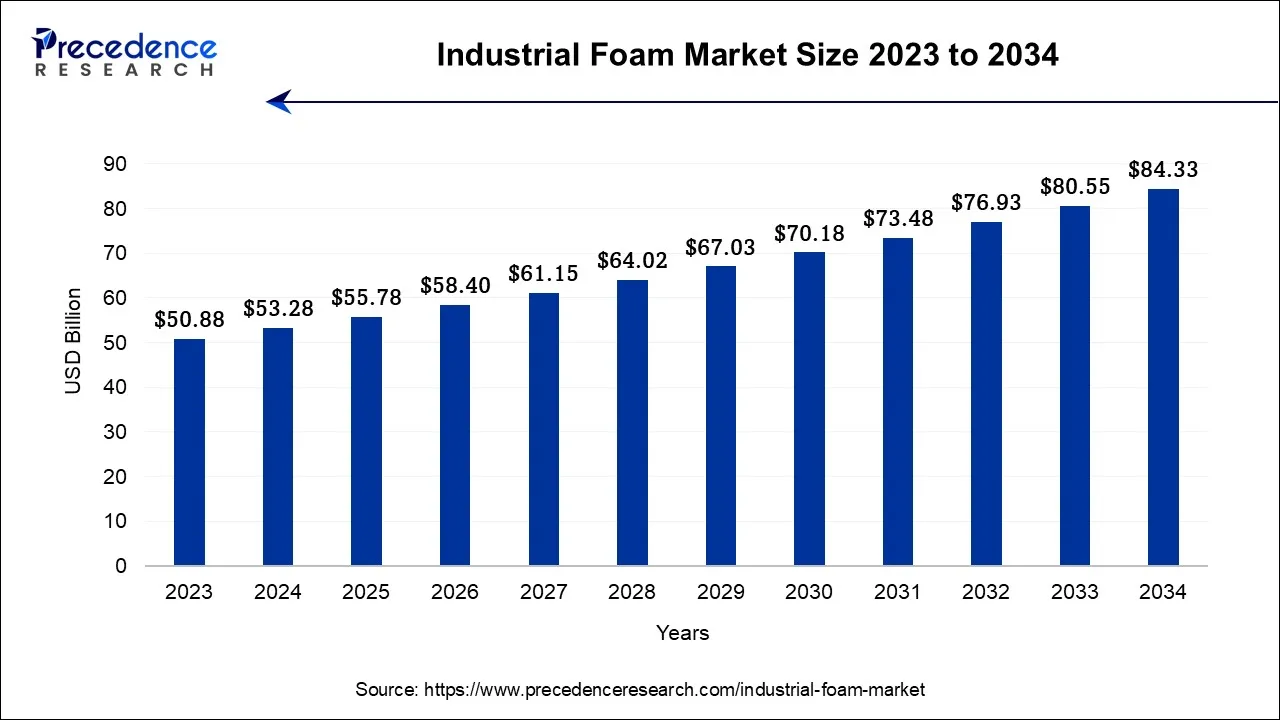

The global industrial foam market size accounted for USD 55.78 billion in 2025 and is predicted to increase from USD 58.40 billion in 2026 to approximately USD 88 billion by 2035, growing at a CAGR of 4.66% from 2026 to 2035.

Industrial Foam Market Key Takeaways

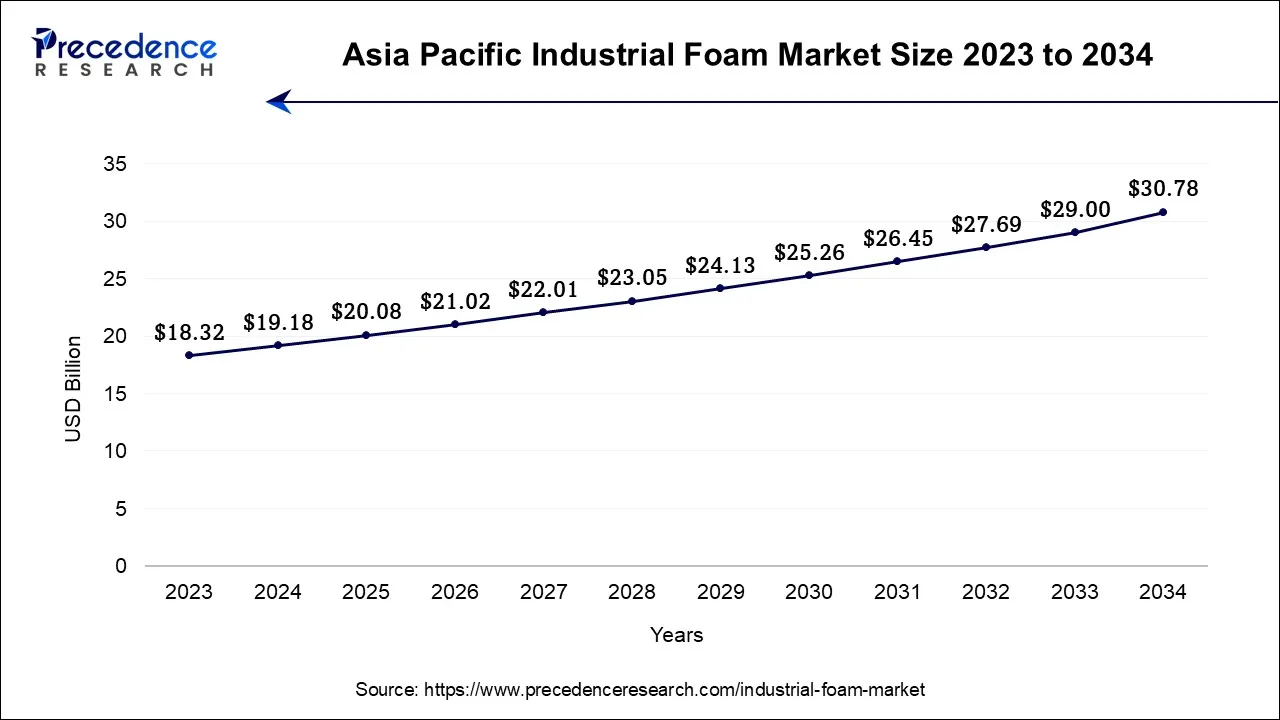

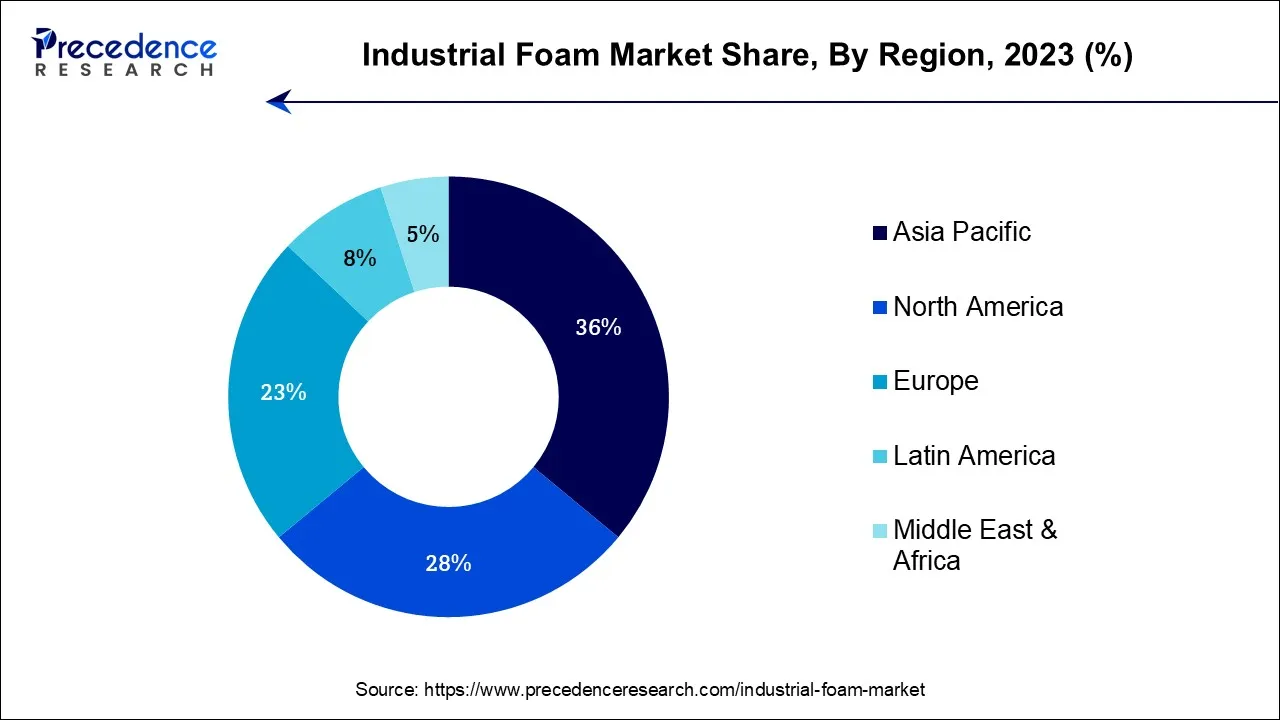

- Asia-Pacific contributed more than 36% of revenue share in 2025.

- Europe region is expected to expand at the fastest CAGR from 2026 to 2035.

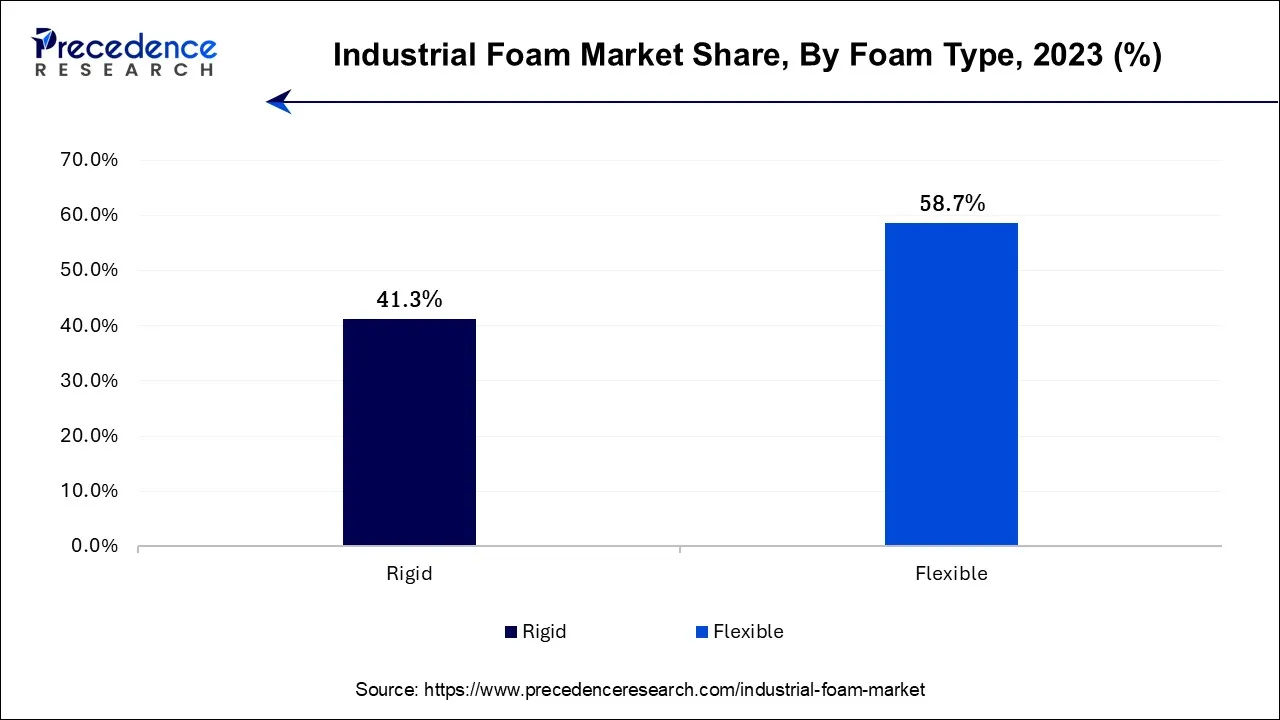

- By Foam Type, the flexible segment captured the maximum market share of around 58.7% in 2025.

- By Foam Type, the rigid segment is expected to expand at the fastest CAGR of 7.8% between 2026 and 2035.

- By End use, the building & construction segment accounted more than 29% of revenue share in 2025.

- By End use, the HVAC segment is expected to grow at the fastest CAGR over the projected period.

- By Resin Type, the Polyurethane foam segment generated more than 38.4% of revenue share in 2025.

- By Resin Type, the polyolefin foam segment is expected to expand at the fastest CAGR over the projected period.

What is Going on in the Industrial Foam Industry?

The industrial foam market encompasses the production and distribution of versatile foam materials tailored for various industrial applications. The industrial foam market pertains to a diverse range of foam materials, such as polyurethane, polyethylene, and polystyrene, which play a crucial role across sectors including construction, automotive, aerospace, and packaging. These industrial foams are highly valued for their lightweight composition and exceptional attributes, which encompass insulation, cushioning, and sound absorption capabilities. Their nature is characterized by adaptability to diverse requirements, enabling the creation of energy-efficient structures, safer transportation, and efficient packaging solutions. As industries continue to innovate and prioritize sustainability, the industrial foam market is evolving to offer eco-friendly options, reflecting the growing demand for greener alternatives.

How is AI contributing to the Industrial Foam Industry?

The use of Artificial Intelligence in the foam manufacturing industry has resulted in a significant improvement of the quality control process, which is now done in real-time alongside the optimization of the chemical processes and the support of material generative design, among others like predicting the failure of the equipment, improving the forecasting of the supply chain, and encouraging the use of the eco-friendly production process.

Industrial Foam Market Growth Factors

- The industrial foam market is a dynamic sector driven by various industry trends and growth factors. Industrial foams, encompassing materials like polyurethane, polyethylene, and polystyrene, play a crucial role in various industries such as construction, automotive, aerospace, and packaging. Their significance lies in their lightweight composition and remarkable attributes, which encompass insulation, cushioning, and sound absorption capabilities.

- In the industrial foam market, there is an increasing demand for lightweight and eco-friendly foam solutions. As industries strive for greater energy efficiency and sustainability, there's a growing need for innovative foam materials that reduce carbon footprints. Additionally, the automotive industry's shift towards electric vehicles has spurred the demand for lightweight foam materials, contributing to market growth. Moreover, the construction sector's emphasis on energy-efficient building materials further propels the adoption of industrial foam products.

- Moreover, the industrial foam market is also boosted by the rapid expansion of the construction industry, particularly in emerging economies. As urbanization and infrastructure development continue to surge, there's a rising demand for insulation and soundproofing materials, thus driving the growth of industrial foams. Additionally, advancements in manufacturing processes and the development of new foam formulations are enhancing product performance and expanding applications, positively impacting market growth.

Market Outlook

- Industry Growth Overview: The market growth draws strength from the increase in demand for construction, automotive, and packaging materials, and the materials have to be more powerful.

- Sustainability Trends: The production of foam materials that are bio-based, recyclable, and energy-efficient is the new trend in the industry.

- Global Expansion: The Asia Pacific region is the foremost in the expansion, which is a result of the developing infrastructure and the increasing manufacturing capacity.

- Major Investors: Investors such as BASF SE, Covestro AG, Dow Inc., Huntsman, and Saint-Gobain S.A. are among those who have invested the most.

Market Scope

| Report Coverage | Details |

| Market Size by 2035 | USD 88 Billion |

| Market Size in 2026 | USD 58.40 Billion |

| Market Size in 2025 | USD 55.78 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 4.66% |

| Largest Market | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Foam Type, End Use Industry Resin Type, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Automotive industry advancements and E-commerce packaging needs

Automotive industry advancements, driven by the pursuit of lighter and more fuel-efficient vehicles, surge demand in the industrial foam market. Industrial foams, prized for their lightweight properties, are extensively used in automotive interiors, insulation, and lightweight solutions. As automakers increasingly prioritize these materials to meet emission standards and enhance performance, the industrial foam market experiences a significant upswing in demand, bolstering its growth and relevance within the automotive sector.

Moreover, the surge in E-commerce has significantly increased demand for the market. Industrial foams are essential for packaging fragile items purchased online, providing cushioning and protection during shipping. With the ever-growing volume of online orders, businesses require effective packaging solutions, thereby driving up the demand for industrial foam materials. This trend is expected to continue as E-commerce continues to expand, making industrial foams a vital component of the packaging supply chain.

Restraints

Substitute materials, recycling, and waste management

The industrial foam market faces constraints due to substitute materials offering comparable properties. Alternatives like natural fibers, recycled materials, and composites can provide insulation and cushioning, reducing the demand for traditional foam products. Additionally, as sustainability becomes a priority, industries are exploring environmentally friendly alternatives, impacting market demand for foam materials. To remain competitive, the industrial foam sector must adapt by developing eco-friendly solutions and showcasing the unique advantages of foam materials over substitutes.

Moreover, recycling and waste management efforts present challenges for the industrial foam market by promoting eco-conscious practices and reducing waste generation. While this is beneficial for the environment, it can restrain market demand as companies seek sustainable alternatives and recycling options for foam materials. Stricter regulations on foam disposal and increased recycling initiatives may limit the market's growth potential, pushing manufacturers to innovate and develop more environmentally friendly foam products.

Opportunities

Sustainable foam development and diversification

The surge in sustainable foam development has significantly boosted market demand in the industrial foam market. As industries prioritize eco-friendly solutions, the availability of biodegradable and recyclable foam materials has driven adoption. Consumers, regulators, and businesses alike are seeking foam products that align with sustainability goals, leading to increased market demand for these environmentally responsible alternatives, which cater to the growing need for greener, more sustainable industrial practices.

Moreover, diversification in the industrial foam market, offering a broader range of foam materials and applications, surges market demand. By catering to various industries such as construction, automotive, aerospace, and packaging with specialized foam solutions, it amplifies opportunities for growth. This diversification not only expands the customer base but also ensures resilience in the face of changing economic conditions and industry-specific trends, driving overall market demand and sustainability.

Segment Insights

Foam Type Insights

The flexible segment held a 58.7% revenue share in 2023. Flexible foams in the industrial foam market are characterized by their ability to deform under pressure and return to their original shape, offering resilience and cushioning. A notable trend in this segment is the growing demand for eco-friendly and recyclable flexible foams, driven by sustainability concerns. Additionally, advancements in material technology are enabling the development of flexible foams with improved performance attributes, enhancing their suitability for diverse applications across industries like automotive, furniture, and bedding.

The rigid segment is anticipated to expand at a significant CAGR of 7.8% during the projected period. Rigid foam, a prevalent type in the industrial foam market, is characterized by its structural stability and minimal flexibility. This foam type is widely used in insulation applications across the construction and refrigeration industries. Recent trends in the industrial foam market show a growing preference for eco-friendly rigid foams with improved insulation properties. Increasing demand for energy-efficient solutions and stricter regulations on building codes are driving the adoption of advanced rigid foam materials, creating opportunities for sustainable innovation.

End-use Industry Insights

The building & construction is anticipated to hold the largest market share of 29% in 2023. In the industrial foam market, the building & construction sector refers to the utilization of foam materials in construction projects. A prominent trend in this segment is the increasing demand for energy-efficient insulation foams to meet stringent environmental regulations. Additionally, lightweight and durable foam solutions are sought after for their ease of installation and ability to reduce construction costs. These trends reflect the industry's commitment to sustainable building practices and cost-effective construction techniques.

On the other hand, the HVAC segment is projected to grow at the fastest rate over the projected period. HVAC, or Heating, Ventilation, and Air Conditioning, is a critical end-use industry for the Industrial Foam Market. It relies on foam materials for insulation, sound absorption, and temperature control within heating and cooling systems. A significant trend in this sector is the growing demand for energy-efficient HVAC solutions, driving the need for advanced foam materials that enhance insulation and reduce energy consumption. As regulations tighten to promote sustainability, industrial foam innovations that meet these requirements will play a pivotal role in the HVAC industry.

Resin Type Insights

The Polyurethane foam segment had the highest market share of 38.4% in 2023. Polyurethane foam, a versatile resin type in the Industrial Foam Market, is known for its exceptional insulation, cushioning, and sound absorption properties. In recent trends, polyurethane foam has gained prominence due to its eco-friendly formulations, contributing to sustainability goals. It finds increased application in automotive lightweight, energy-efficient construction, and furniture manufacturing. The demand for polyurethane foam is rising as industries prioritize eco-conscious materials and energy efficiency in their products and processes.

The polyolefin foam is anticipated to expand at the fastest rate over the projected period. Polyolefin foam, a prominent variety within the industrial foam category, is distinguished by its composition of polyethylene and polypropylene resins. This foam type is renowned for its exceptional attributes, including lightweight composition, effective thermal insulation, and remarkable resistance to moisture. A significant trend in the industrial foam market is the increasing demand for polyolefin foam due to its versatility and eco-friendly nature. Industries such as construction, packaging, and automotive are increasingly turning to polyolefin foam for insulation and cushioning applications, driven by sustainability and energy-efficiency considerations.

Regional Insights

What is the U.S. Industrial Foam Market Size?

The Asia Pacific industrial foam market size was exhibited at USD 20.08 billion in 2025 and is projected to surpass around USD 32.25 billion by 2035, expanding at a CAGR of 4.85% between 2026 and 2035.

Asia-Pacific held the largest revenue share of 36% in 2023. In the Asia-Pacific region, the industrial foam market is witnessing robust growth due to rapid urbanization, infrastructure development, and increased manufacturing activities. Key trends include a rising demand for eco-friendly foam solutions in response to stringent environmental regulations. Additionally, the automotive and construction sectors are driving substantial foam consumption, while the region's expanding consumer electronics market is also contributing to market growth. Asia-Pacific's dynamic economic landscape and emphasis on sustainability are shaping the industrial foam market's trajectory in the region.

In Europe, the industrial foam market is witnessing several notable trends. There is a growing emphasis on sustainable foam materials to align with stringent environmental regulations. The automotive industry is increasingly adopting lightweight foams for electric vehicles, driven by green initiatives. Additionally, the construction sector is favoring foam insulation for energy-efficient buildings. Furthermore, the region is witnessing an expansion in aerospace applications, contributing to the market's steady growth in Europe.

Additionally, in North America, the industrial foam market is witnessing notable trends. There's a growing emphasis on sustainable and eco-friendly foam solutions, driven by environmental regulations and consumer preferences. Additionally, the automotive industry's shift towards electric vehicles is increasing the demand for lightweight foams. The construction sector is booming, particularly in urban centers, creating a robust need for foam insulation and soundproofing materials. These trends indicate a promising future for the industrial foam market in North America, with a focus on innovation and sustainability.

Industrial Foam Market-Value Chain Analysis

- Feedstock Procurement: Sourcing of quality polymers, catalysts, and additives that ensure the best price, availability, and quality.

Key Players: Dow, BASF, Huntsman, Covestro - Chemical Synthesis and Processing: Reactants are converted into the base foam by performing controlled reactions and are synthesized as feedstock.

Key players: BASF, Dow, Huntsman, Covestro - Compound Formulation and Blending: The application-specific properties of the foam materials are created through the addition of additives.

Key Players: Huntsman, Trelleborg, BASF, Dow, Covestro - Quality Testing and Certification: The assessment of physical, chemical, and performance properties is done to ensure compliance with the industry standards.

Key Players: SGS, Intertek, Bureau Veritas, TÜV SÜD - Packaging and Labelling of Industrial Foam: Packaging and labeling of the finished foam products for safe distribution are done by cutting the packaging and labeling.

Key players: Sealed Air Corporation, Storopack, Nefab, Pregis, Amcor

Industrial Foam Market Companies

- BASF SE:Flame-retardant polyurethane systems with low odor for insulation and industrial applications are among the specialty chemicals that the company produces for foam manufacturing.

- Dow Inc.: Providing performance and environmental efficiency, the company supports the use of advanced blowing agents in foam applications with the offering of chemicals and plastics.

- Huntsman Corporation: The company provides a range of polyurethane systems and spray foam insulation that help to achieve quick and effective construction with the performance and durability of the products.

Other Major Key Players

- Recticel NV/SA

- Rogers Corporation

- Armacell International S.A.

- Sealed Air Corporation

- Saint-Gobain Performance Plastics

- Foamcraft, Inc.

- UFP Technologies, Inc.

- Zotefoams PLC

- Vita Group

- Foam Supplies, Inc.

- INOAC Corporation

- Future Foam, Inc.

Recent Developments

- In December 2025, BASF is expanding its spray polyurethane foam portfolio with WALLTITE RSB, a sustainable closed-cell foam that offers high performance. The foam incorporates recycled and renewable content for reduced carbon emissions. (Source:https://www.sprayfoammagazine.com/)

- In July 2025, Covestro launched next-gen flame-retardant polyurethane foam technology to enhance battery safety in electric vehicles. This reinforces its role as a key materials partner in the EV industry. (Source:https://www.indianchemicalnews.com/ )

- In 2023, BASF,Huntsman, Shanghai Hua Yi, Shanghai Chlor-Alkali Chemical Co. Ltd., and Sinopec Shanghai Gaoqiao Petrochemical Co. Ltd. have announced plans to separate joint MDI (Methylene Diphenyl Diisocyanate) production operations in Caojing, China, as part of their strategic restructuring initiatives in the polyurethane market.

- In 2020, BASFpartnered with Zhengming, focusing on joint efforts to develop high-quality products and solutions. This collaboration aims to leverage both companies' expertise for innovation and excellence in various industrial sectors.

- In 2020, Huntsman Corporation revealed its acquisition of Icynene-Lapolla, a significant move to expand its portfolio in the insulation and polyurethanes market. This strategic acquisition aims to strengthen Huntsman's position in providing insulation and construction solutions.

- In 2020,Univar Solutions expanded its distribution agreement with Dow, enhancing its distribution reach across multiple regions. This agreement enables Univar Solutions to offer an extended range of Dow's industrial and specialty chemicals to meet customer demands effectively.

Segments Covered in the Report

By Foam Type

- Flexible

- Rigid

By End Use Industry

- Building & Construction

- HVAC

- Industrial Pipe Insulation

- Marin

- Aerospace

- Others

By Resin Type

- Polyurethane

- Polystyrene

- Polyolefin

- Phenolic

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting