What is the Lyophilization Equipment Market Size?

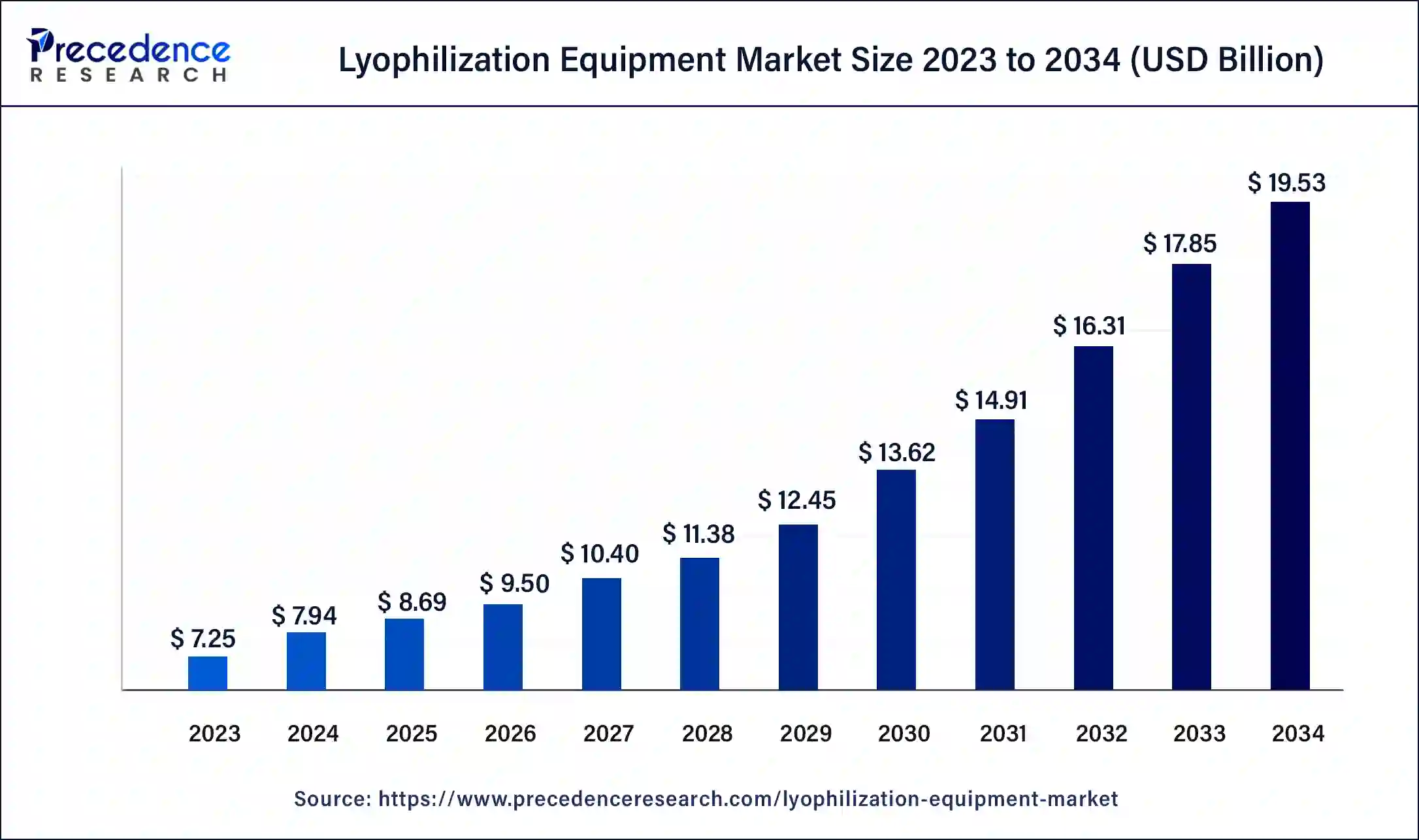

The global lyophilization equipment market size is calculated at USD 7.94 billion in 2025 and is predicted to increase from USD 9.50 billion in 2026 to approximately USD 19.53 billion by 2034 at a CAGR of 9.44% from 2025 to 2034. The lyophilization equipment market helps in various industries like biomedical, biotechnology, pharmaceutical, and food processing for various applications. It helps to reduce sample contamination risks, increases reliability and robustness, and simplifies assay setup.

Lyophilization Equipment Market Key Takeaways

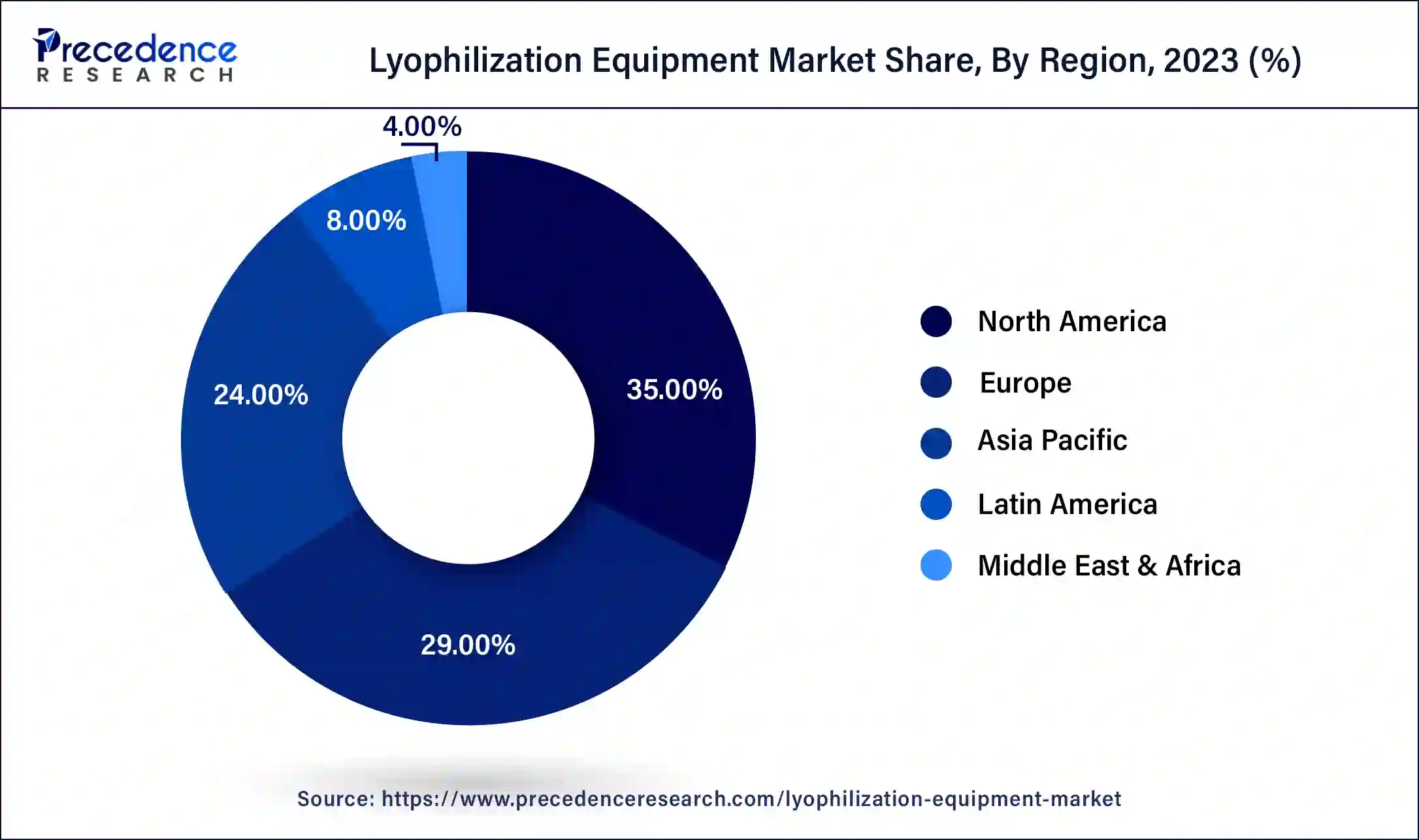

- North America dominated the global lyophilization equipment market with the largest market share of 35% in 2024.

- Asia Pacific is estimated to host the fastest-growing market during the forecast period of 2025-2034.

- By product, the manifold freeze dryers segment dominated the market in 2024.

- By product, the tray-style freeze dryers segment is projected to grow significantly in the market during the forecast period.

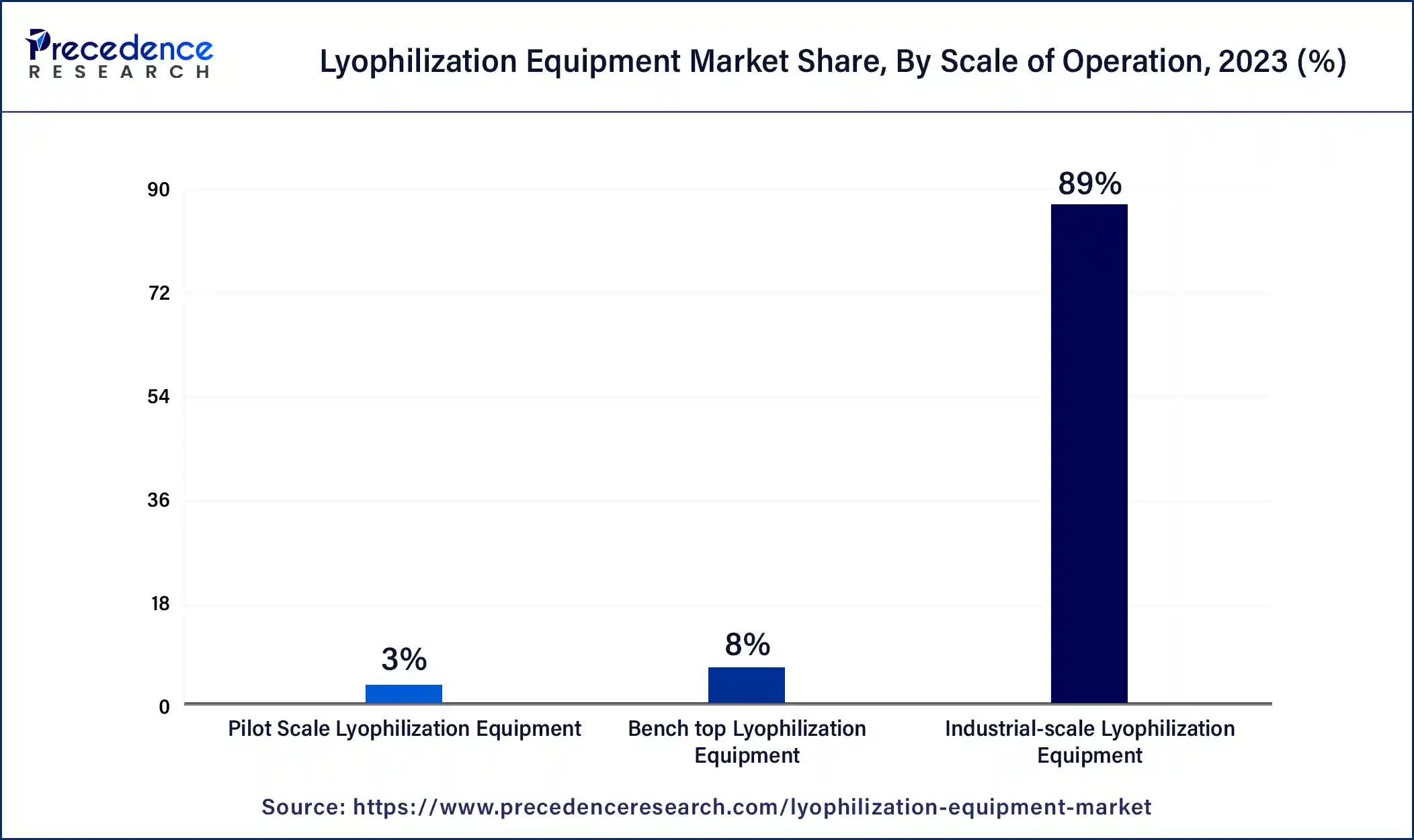

- By the scale of operation, the industrial-scale lyophilization equipment segment contributed more than 89% of market share in 2024.

- By the scale of operation, the bench-top lyophilization equipment segment is expected to grow at the fastest rate in the market during the forecast period.

- By application, the food processing segment generated the biggest market share of 30% in 2024.

- By application, the pharmaceutical segment will witness rapid expansion in the market during the forecast period.

Market Overview

Lyophilization equipment, also known as lyophilizer or freeze dryer, is used to conduct the lyophilization process, which is also referred to as freeze-drying, in which water is removed completely from a product after it is frozen and kept under a vacuum, which helps to the product stabilization. The lyophilization equipment market deals with industries such as food processing, biomedical, biotechnology, and pharmaceuticals for their applications.

The lyophilization equipment market helps with sample stabilization, which permits the production of single-dose, pre-dispensed reagents that help to reduce the sample contamination risks, increase assay reliability and robustness, and simplify assay setup. Lyophilization equipment helps to boost product quality and improve reliability and data quality. It helps save costs, simplify end-user workflows, and reduce training requirements and environmental impact. It helps to ship less hazardously than wet reagents, and it does not require any special license.

Key factors influencing future market trends

- Increasing Need of Freeze Drying in the Pharmaceutical Sector: The sensitivity of drugs, vaccines, and biologics, pharmaceutical manufacturers are increasingly accepting freeze-drying technology in order to maintain the strength and shelf life of these products. With the increase in the demand for temperature-stable pharmaceuticals, freeze drying becomes more stable, and it helps minimize degradation.

- Increase in Food Processing Usages: Food such as fruits, vegetables, meat, and coffee products is aided by packs that are light and easy to transport. The demand for food processing equipment related to freeze drying is driven by the growing consumer demand for convenient, high-quality quality and long-lasting food products.

Market Outlook

- Industry Growth Overview: The lyophilization equipment market is growing steadily due to increasing demand for freeze-dried pharmaceuticals, biologics, vaccines, and preserved food products. Advancements in automation, sterile processing, and energy-efficient systems are also driving market growth. Moreover, the rising adoption across the pharmaceutical, biotech, and food processing sectors boosts the market growth.

- Global Expansion:The market is expanding globally due to the rapid expansion of the pharmaceutical, biotechnology, and food processing industries, which rely heavily on freeze-drying to enhance product stability. Emerging regions such as Asia‑Pacific, Latin America, and the Middle East & Africa offer immense opportunities due to the rising healthcare and biotech investment, increasing export‑oriented food processing, and expanding cold‑chain infrastructure.

- Major Investors: Major investors in the market include leading manufacturers and industrial/biopharmaceutical companies such as SP Industries, GEA Group, Azbil Corporation, Labconco, and IMA Life, which invest heavily in research, development, and global production capacity. These investors invest heavily in developing advanced, automated, and energy-efficient freeze-drying systems, enabling pharmaceutical, biotech, vaccine, and food companies to scale production and meet rising global demand for stable, shelf‑life-extended products.

- Startup Ecosystem: The startup ecosystem in the market is expanding as emerging companies focus on compact, energy-efficient, and automated freeze-drying systems tailored for small pharma, biotech labs, and nutraceutical brands. Startups emphasize modular designs, real-time monitoring, and cost-effective pilot-scale solutions to support rapid biologics and vaccine development.

Lyophilization Equipment Market Growth Factors

- Lyophilization equipment helps to boost the quality of the product, batch-to-batch consistency for all samples, and provides room temperature stability for up to 2 years. It improves reliability and data quality.

- This lyophilization equipment helps to reduce contamination risks and environmental impact. It also reduces the volume and weight of the samples during shipping, and the cost of transportation which helps to the growth of the market.

- It helps to increase shelf life with less waste, saves costs, and simplifies workflows. No need for wet or dry ice for transportation.

- It provides less hazardous shipping than wet reagents and it does not require any special licenses which helps to the growth of the lyophilization equipment market.

- It helps to increase reliability and robustness and to simplify assay setup. It also has various benefits in many industries, such as improving stability and biological activity and preserving sensitive materials like vaccines, enzymes, and proteins. These factors help to the growth of the market.

- Product degradation can be prevented by the removal of water which prevents chemical reactions which result in ambient temperature stability of the product.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 19.53 Billion |

| Market Size in 2026 | USD 9.50 Billion |

| Market Size in 2025 | USD 8.69 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 9.44% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product Type, Scale of Operation, Application Type, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Drivers

Improved stability and biological activity

The lyophilization equipment market services helps to improve product quality, data quality, and reliability. It also reduces the risk of contamination through single-dose and pre-dispensed assays. It provides room-temperature stability for up to 2 years without any activity loss. Lyophilization equipment is beneficial for biological activity preservation of sensitive materials like vaccines, enzymes, and proteins. The drying and gentle freezing process in the lyophilization process reduces the damage to the sensitive compounds and loss of activity risks. In various industries like food processing, biomedical, biotechnological, and pharmaceutical products, lyophilization equipment is used to stabilize and promote biological activity.

Restraint

Disadvantages and risks of the lyophilization equipment

There are also disadvantages and risks of the lyophilization equipment market. It includes contamination risks and high costs. It has the necessity of sterile diluent. Extensive clean-up is also necessary between the batches. Contracting these services and purchasing lyophilization equipment are expensive. It increases processing and handling time. It has the potential to loss the biological activity of molecules, including enzymes and proteins. Factors like protein aggregation and freezing-induced denaturation during the lyophilization process may compromise the stability of the product. In addition, it also affects the physical changes, including cake cracking and shrinkage, which can occur and affect the reconstitution and appearance properties of the final product.

Opportunity

Research and development activities

The main point of the lyophilization equipment market product is the high cost. To reduce these costs, the development of lyophilization types of equipment is necessary. There is a need for development at the point of increasing production throughput and reducing operating costs. Development of lyophilized, stable protein drug products, tablet vaccines, and coarse powders that need lyophilization equipment in the pharmaceutical, biomedical, and biotechnology sectors.

Segment Insights

Product Insights

The manifold freeze dryers segment dominated the lyophilization equipment market in 2024. For pre-freezing, the sample manifold freeze dryers are highly used. Manifold dryers use ambient heating. There are 2 types of manifold freeze dryers these are drum and tree. In high throughput applications, tree manifold freeze dryers are used, and drum manifold freeze dryers have large internal cavities and save more space. Manifold freeze dryers are the popular choice, and they make use of valves, flasks, and stainless-steel manifolds to sublimate samples.

In the pharmaceutical sector, lyophilization and freeze dryers are highly used. This manifold freeze dryer has a smaller budget. The small individual samples in larger numbers can be dried in the manifold freeze dryers. It has an automatic on or off-function facility to ensure the start and shut down of this lyophilization equipment type. Most of the manifold freeze dryers are used as modular. These factors help the growth of the manifold freeze dryers segment and contribute to the growth of the lyophilization equipment market.

The tray-style freeze dryers segment is projected to grow significantly in the lyophilization equipment market during the forecast period. Tray-style freeze dryers are used for storing dry materials, and they include a large reservoir. A rectangular-shaped reservoir with trays and shelves is generally used to store tissue extracts and pharmaceutical solutions that are collected in the reservoir. These tray-style freeze dryers are easy to operate and simple freeze dryers lyophilization equipment. Tray-style freeze dryers provide tools for the optimization of the primary drying circles and freezing for critical process parameters, as well as the shortest freeze-drying time for cycle transfer.

This type of dryer helps to avoid the loss of materials at the time of loading or unloading. Tray-style freeze dryers are simple in construction; for valuable materials, they are more efficient; they do not require skilled labor; for batch-wise operation, they may be used to help with the easy handling of materials. These factors help the growth of the tray-style freeze dryers segment and contribute to the lyophilization equipment market.

Scale of Operation Insights

The industrial-scale lyophilization equipment segment dominated the lyophilization equipment market in 2024. The lyophilization equipment is used in various industries, including food processing, biomedical, biotechnology, and pharmaceutical sectors, for different applications. The benefits of the lyophilization equipment include process optimization, computational modeling, pharmaceutical manufacturing, scale-up and tech transfer, freeze drying, or lyophilization.

In the pharmaceutical industry, lyophilization equipment is used to improve the shelf-life of vaccines, antibiotics, and protein-based drugs. In the pharmaceutical industry, lyophilization equipment is used to keep drugs and APIs sterile and to enhance manufacturing practices. These factors help the growth of the industrial-scale segment and contribute to the growth of the market.

The bench-top lyophilization equipment segment is expected to grow at the fastest rate in the lyophilization equipment market during the forecast period. Bench-top lyophilization equipment has the benefit of storing material in a dry state that makes sure it is stable all the time. Without using high temperatures, the pressed materials are dried. Preserved materials that are in the dry states are less costly than those that are in liquid form. Bench-top lyophilization equipment is a table-top-sized and compact freeze dryer that is generally used in smaller-scale businesses, research laboratories, and pharmaceutical development. These factors help to the growth of the bench-top lyophilization equipment segment and contribute to the growth of the lyophilization equipment market.

Application Type Insights

The food processing segment led the global lyophilization equipment market in 2024. In the food processing segment, there is a high use of lyophilization equipment. There are many benefits of lyophilization equipment, including reduction of product volume and weight, improved shelf life, and preservation of product properties and structures. These benefits are helpful for the storage and easy transportation of sensitive materials. In food processing applications, mainly for food developed for astronauts and military rations, the early use of lyophilization equipment is high because it improves the shelf-life of the food products. These factors help to the growth of the food processing segment and contribute to the growth of the market.

The pharmaceutical segment will witness rapid expansion in the lyophilization equipment market during the forecast period. In the pharmaceutical and biomedical industries for the different research projects, lyophilization equipment is used. Minimization of liquid product formulations with their solid constituents in the non-destructive way the lyophilization equipment is used in the pharmaceutical industry. For drying, improving storage and stability of pharmaceutical labile products like proteins and antibiotics are helpful for the growth of the segment. Removing solvent or water may increase the shelf-life of the vaccines and injectables. Pharmaceutical industries may easily ship or store the materials in their original form for the injections. These factors help the growth of the pharmaceutical application segment and contribute to the growth of the lyophilization equipment market.

Regional Insights

U.S. Lyophilization Equipment Market Size and Growth 2025 to 2034

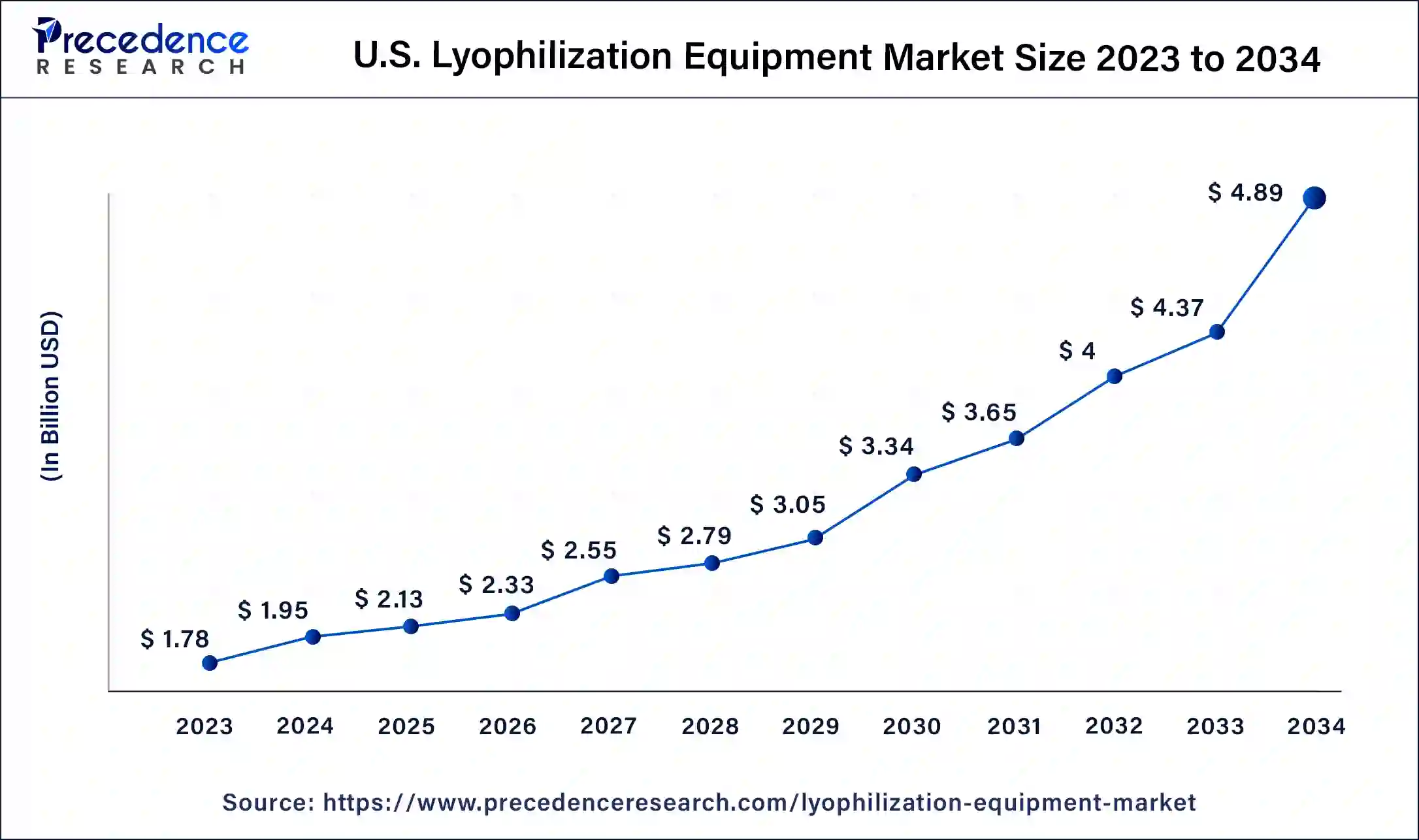

The U.S. lyophilization equipment market size is exhibited at USD 2.13 billion in 2025 and is projected to be worth around USD 4.89 billion by 2034, poised to grow at a CAGR of 9.62% from 2025 to 2034.

What Made North America the Dominant Region in the Market?

North America dominated the global lyophilization equipment market in 2024. Increased innovation in pharmaceutical manufacturing, research and development, and increasing expenditure helps the growth of the market in North American. The United States and Canada are the leading countries of the region for the growth of the market.

- In April 2022, a total of USD 1.2 million in funding for the four organizations to develop technology for strengthening the United States' innovation and manufacturing across industries was awarded by the United States Department of Commerce's National Institute of Standards and Technology (NIST) to strengthen advanced manufacturing for Biomanufacturing, Microelectronics, and Digital.

- In June 2022, a global manufacturer, Dara Group, Coolvacuum freeze drying or lyophilization equipment to North America was launched by the NJM. NJM has initiated the product to Canada and the United States. This equipment is helpful for biotech and pharmaceutical manufacturers to achieve the highest product quality standards.

- In May 2024, IMA Life North America set to build a new pharma freeze-drying or lyophilization equipment production site in Tonawanda, New York, U.S. to increase production capabilities.

What Makes Asia Pacific the Fastest-Growing Region in the Market?

Asia Pacific is estimated to host the fastest-growing lyophilization equipment market during the forecast period of 2025 to 2034. Increased demand for freeze-dried food products like nutraceuticals and functional foods for health benefits leads to the growth of the lyophilization equipment market in the region. It reduces the volume and wetness by using the lyophilization process.

- In July 2023, a fully automated, high-potency sterile injectable manufacturing line was launched by WuXi STA at its drug product site in Wuxi, China. This line supplies two 20 m² lyophilization equipment.

What Is Driving the Growth of the Lyophilization Equipment Market in the Middle East & Africa?

The Middle East & Africa region shows promising growth potential in the lyophilization equipment and services market. This regional expansion is led by the GCC countries, especially Saudi Arabia and the United Arab Emirates, owing to their well-developed healthcare infrastructure is well developed, rising pharmaceutical production, and investments in research labs. Such countries are adapting modern technologies of lyophilization to enhance drug stability, increase the shelf life of products, and guarantee temperature consistency in the hot zones. This trend is fuelled by the increase in demand for lyophilized products in both drug and food companies, and by government attempts to modernize manufacturing and medical facilities.

How Big is the Success of Europe in the Market?

Europe is a notably growing region in the lyophilization equipment market due to its strong pharmaceutical and biotechnology manufacturing base, high investment in biologics and injectable drug development, and expansion of GMP-compliant production facilities. Increasing clinical trials, rising adoption of personalized medicine, and supportive regulatory frameworks encouraging sterile and freeze-dried formulations further stimulate demand. Additionally, advancements in automation and energy-efficient freeze-drying technologies speed up equipment upgrades across European pharma and research laboratories.

How Crucial is the Role of Latin America in the Lyophilization Equipment Market?

Latin America plays a vital role in the market due to rising investment in pharmaceutical and biotechnology manufacturing, increasing production of generic injectables, and expanding vaccine development programs across Brazil, Mexico, and Argentina. Government incentives for strengthening local drug supply chains and heightened demand for temperature-stable formulations support equipment adoption. Growing interest in nutraceuticals and freeze-dried food products further accelerates the use of lyophilization systems in the region.

Value Chain Analysis

R&D

This stage involves designing innovative, automated, and energy-efficient lyophilization equipment to meet pharmaceutical, biotech, and food industry requirements.

- Key Players: SP Industries, Azbil Corporation, GEA Group, IMA Life, Telstar.

Component Manufacturing

This stage includes production of critical components such as vacuum pumps, refrigeration units, and control systems that ensure the reliability and efficiency of freeze-drying equipment.

Key Players: Buchi Labortechnik AG, Labconco Corporation, Telstar, GEA Group.

Equipment Assembly & Integration

Assembling and integrating all components into fully functional lyophilization systems, including benchtop and industrial-scale units.

- Key Players:SP Industries, IMA Life, Azbil Corporation, Labconco Corporation.

Distribution & Sales

Marketing and delivering lyophilization equipment globally to pharmaceutical manufacturers, biotech firms, food processors, and research institutions.

- Key Players: SP Industries, GEA Group, IMA Life, Azbil Corporation, Labconco Corporation.

Top Companies in the Lyophilization Equipment Market & Their Offerings

- GEA Group: Offers industrial-scale lyophilization systems, automated freeze-dryers, high-capacity loading/unloading systems, and advanced process control software for pharmaceutical and biotech manufacturing.

- SP Industries (SP Scientific):Provides laboratory, pilot-scale, and production freeze-dryers, including LyoStar and LyoConstellation series, with advanced temperature-controlled shelves and automated monitoring technologies.

- Telstar (Azbil Telstar Technologies):Supplies GMP-compliant freeze-drying equipment, aseptic loading systems, and integrated isolation technology for sterile drug production and biologics.

- Martin Christ Gefriertrocknungsanlagen:Specializes in laboratory, pilot-scale, and production lyophilizers, focusing on energy efficiency, high-precision temperature control, and modular expansion options.

- Labconco:Offers laboratory freeze-drying systems designed for research, pharmaceuticals, nutraceuticals, and biotechnology applications with compact, benchtop, and mobile configurations.

- Millrock Technology:Provides pilot and production freeze-dryers, LyoPAT and LyoSIM smart control systems, and scalable technology suitable for formulation development and commercial manufacturing.

- HOF Sonderanlagenbau:Manufactures custom large-capacity pharmaceutical freeze-dryers, including steam sterilization, automated loading platforms, and hydrogen peroxide decontamination systems for aseptic environments.

Other Companies

- AZBIL CORPORATION

- Buchi

- Biopharma Process Systems Ltd.

- Scala Scientific and Zirbus Technology GmbH

- Thermo Fischer Scientific Inc.

Recent Developments

- In May 2024, Millrock Technology announced a strategic partnership with LyoWave to add LyoWave's system to existing and new freeze dryers, starting with the REVO Research and Development Freeze Dryer. This collaboration increased Millrock's product portfolio by integrating advanced freeze-drying technologies that will continue to reinforce Millrock's mission to provide emerging technologies to the pharmaceutical and biotech industries.

(Source: https://www.millrocktech.com) - In February 2024, TaqMan qPCR master mixes with an excipient, ready-to-use, optimized formulation for the lyophilization process introduced by Thermo Fischer Scientific. The lyophilization process is the difficult part of any workflow.

- In December 2023, Penguin Classic Laboratory Lyophilizer or Freeze Dryer was launched by VFL Sciences.

- In June 2023, a new GMP lyophilization equipment or freeze-drying production facility was launched by Biopharma Group.

Segments Covered in the Report

By Product Type

- Tray-Style Freeze Dryers

- Manifold Freeze Dryers

- Rotary Freeze Dryers

By Scale of Operation

- Bench Top Lyophilization Equipment

- Pilot Scale Lyophilization Equipment

- Industrial-Scale Lyophilization Equipment

By Application Type

- Pharmaceutical

- Biotechnology

- Biomedical

- Food Processing

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting