Packed Bed Reactor Market Size and Forecast 2025 to 2034

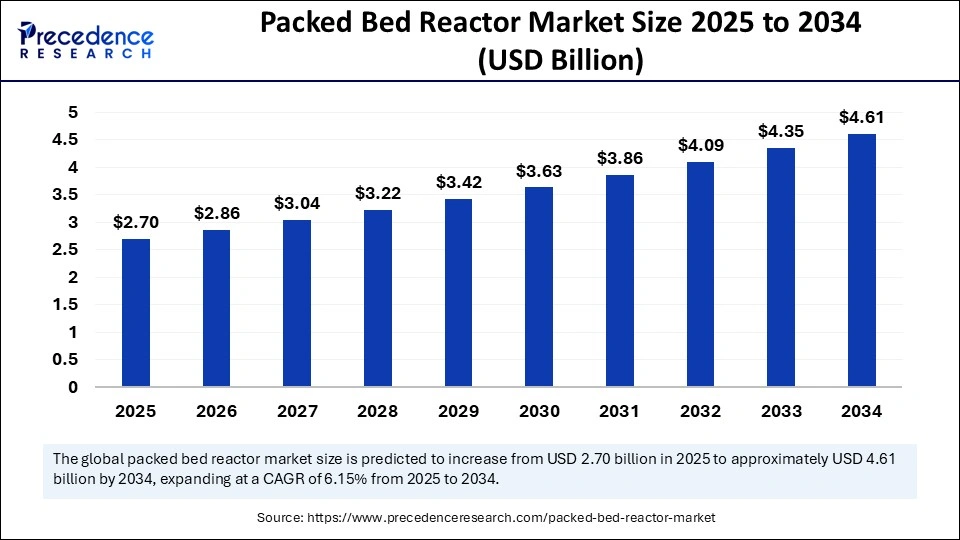

The global packed bed reactor market size accounted for USD 2.54 billion in 2024 and is predicted to increase from USD 2.70 billion in 2025 to approximately USD 4.61 billion by 2034, expanding at a CAGR of 6.15% from 2025 to 2034. The market growth is driven by increasing application of packed bed reactors in sustainable and continuous chemical processing. These reactors are preferred for their high efficiency and scalability.

Packed Bed Reactor Market Key Takeaways

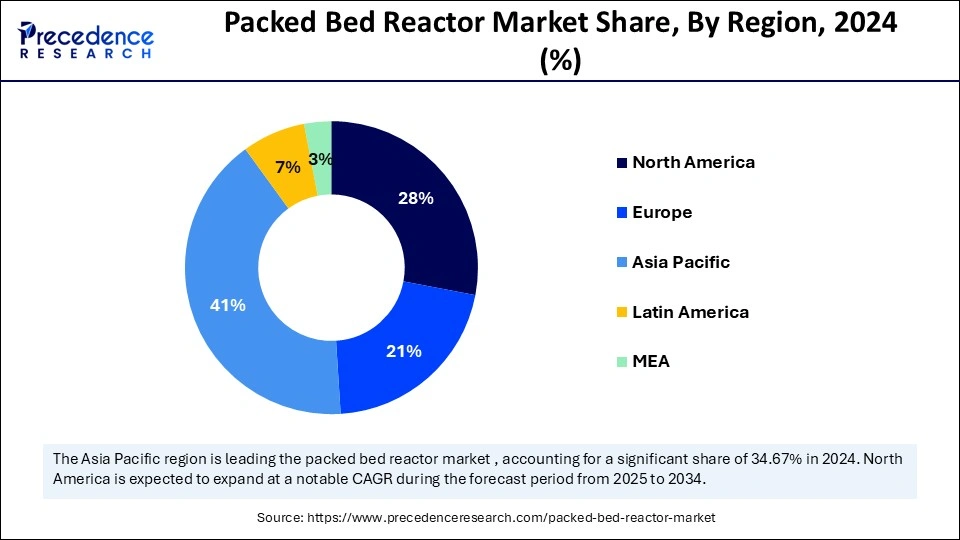

- Asia Pacific dominated the market with the largest share of 41% in 2024.

- The Middle East & Africa is expected to expand at the fastest CAGR during the forecast period.

- By type of reactor, the fixed bed reactor segment contributed the biggest market share in 2024.

- By type of reactor, the fluidized bed reactor segment is expected to witness significant growth during the predicted timeframe.

- By feedstock type, the petroleum-based feedstock segment captured the highest market share in 2024.

- By feedstock type, the bio-based feedstock segment is projected to grow rapidly in the coming years.

- By application, the petrochemicals segment generated the major market share in 2024.

- By application, the wastewater treatment segment is expected to grow at the fastest CAGR during the forecast period.

- By end-use industry, the chemical industry segment held the largest market share in 2024.

- By end-use industry, the water treatment segment is expected to grow at the fastest CAGR in the upcoming period.

- By operating conditions, the medium segment led the market in 2024.

How can AI improve efficiency and uptime in packed bed reactors?

Packed bed reactors are widely used in chemicals, petrochemicals, and pharmaceutical industries for processes like catalytic reactions and adsorption. By incorporating intelligent systems into these reactors, important parameters like temperature pressure and flow rate can be continuously monitored. Early indications of catalyst deactivation, clogging, or inefficiencies can be found by examining this data in real-time. By predicting equipment wear or failure, predictive models help minimize unscheduled shutdowns and enable timely maintenance. Artificial Intelligence can analyze vast datasets and optimize reactor design parameters, leading to improved performance. Additionally, these systems support adaptive control strategies, guaranteeing better resource utilization and ideal reaction times. Operations become more dependable, economical, and energy-efficient as a result.

Digital twins of reactors that mimic real-time performance and forecast behavior under various conditions have been made feasible by recent developments in sensor technology and machine-based analytics. These resources support operator training, troubleshooting, and decision-making. Additionally, machine-driven diagnostics aids in improving product yield, cutting down on material waste and tailoring reaction pathways. Moreover, intelligent tools facilitate smooth integration into a more extensive industry 4.0 framework. This shift changes the game for chemical engineering in the modern era by encouraging safer operations, increased productivity, and less environmental impact.

Asia Pacific Packed Bed Reactor Market Size and Growth 2025 to 2034

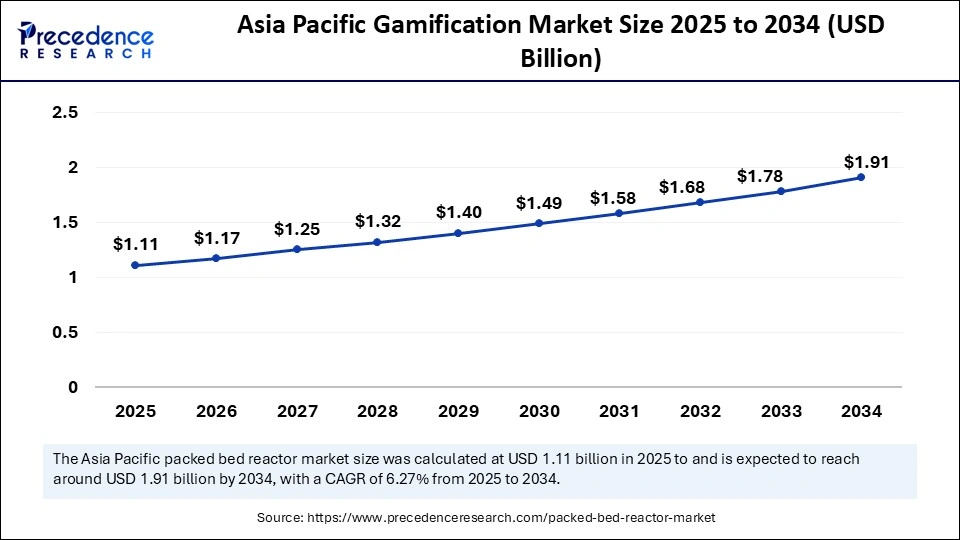

Asia Pacific packed bed reactor market size was exhibited at USD 1.04 billion in 2024 and is projected to be worth around USD 1.91 billion by 2034, growing at a CAGR of 6.27% from 2025 to 2034.

Asia Pacific dominated the packed bed reactor market in 2024 supported by a robust industrial base fast urbanization and rising investments in industries like wastewater treatment chemicals and pharmaceuticals. Cost-effective production, highly qualified labor, and advantageous government regulations that promote manufacturing and environmental adherence all benefit the areas. Demand is still being driven by industrial expansion and the growing need for effective processing technologies. Asia Pacific is anticipated to continue to hold its dominant position in the global market as both established industries and new developments pick up speed.

Middle East & Africa are seen growing at the fastest rate in the upcoming years led by a growing emphasis on sustainable infrastructure industrial diversification and water conservation. Governments and businesses are investing in modern technologies which is increasing demand for effective treatment and processing systems. Applications for packed bed reactors are expanding ranging from wastewater treatment to petrochemicals. Rapid infrastructure development and technological adoption are occurring in the region along with a greater focus on resource optimization and environmental management.

North America is observed to grow at a considerable growth rate in the upcoming period renewed for its robust industrial infrastructure regulatory standards and technological innovation. The area is concentrated on lowering environmental impact improving process efficiency and updating current systems. By implementing sustainable practices digital monitoring tools and smart reactor technologies North America maintains its relevance in both established and developing industries. The company's continuous dedication to green chemistry and advanced manufacturing strengthens its hold on international market trends.

Market Overview

The packed bed reactor market is experiencing steady growth, driven by its extensive use in industries such as chemicals, petrochemicals, pharmaceuticals, and environmental engineering. These reactors can be used for continuous and large-scale operations because of their energy efficiency, high surface area for catalytic reactions, and straightforward designs. Packed bed reactors are being incorporated into contemporary processing systems to increase productivity and lower operating costs as industries embrace automation and process intensification.The need for packed bed reactors in processes like gas treatment, wastewater purification, and biofuel production is increasing due to environmental regulations and the global trend toward cleaner production methods. Growing R&D investments continue to spur innovation and market expansion, while the use of sophisticated catalyst materials and better reactor designs is broadening the range of applications.

Packed Bed Reactor Market Growth Factors

- Rising Demand in Chemical and Petrochemical Industries: Packed bed reactors are widely used for catalytic reactions in chemical and petrochemical processes, offering high efficiency and scalability for continuous production.

- Adoption of Green and Sustainable Technologies: Industries are shifting toward eco-friendly processing methods, and packed bed reactors support clean production through catalytic and biocatalytic reactors with minimal waste.

- Process Efficiency and Cost Effectiveness: Their simple design, ease of maintenance, and high conversion rates make them a cost-efficient choice for industrial applications, especially where space and energy saving are important.

- Expanding Pharmaceutical and Biotech Sectors: Increased pharmaceutical production, especially post-pandemic, has driven demand for reactors that offer controlled, efficient, and sterile processing environments.

- Advancements in Catalyst Technology: The development of more effective catalysts and improved packing materials is enhancing reactor performance and broadening application potential.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 4.61 Billion |

| Market Size in 2025 | USD 2.7 Billion |

| Market Size in 2024 | USD 2.54 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 6.15% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | Middle East & Africa |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type of Reactor, Feedstock Type, Application, End-Use Industry, Operating Condition and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Industrial Shift Toward Continuous Processing

Industries are seeking solutions to maintain consistency in processing, which is driving the growth of the packed bed reactor market. Continuous processes are becoming more and more preferred over traditional batch operations in the global manufacturing landscape. Reactors with packed beds enable continuous production, minimizing downtime and enhancing output reliability. These reactors are ideal for high throughput sectors like petrochemicals and fine chemicals. Continuous systems also make automation simpler and less prone to human error. The need for such reactors keeps increasing as industries strive for leaner operations. Continuous processing also reduces waste production and facilitates real-time monitoring and optimization, allowing businesses to react swiftly to deviations in their operations. This increases cost-effectiveness and resource utilization in addition to safety.

Technological Advancements in Reactor Design

Ongoing technological advancements in reactor design drive the growth of the packed bed reactor market. Structured packing, improved heat transfer systems, and better catalyst distribution are some of the innovations being used to optimize modern packed bed reactors. These advancements result from better conversion rates, reduced pressure drops, and increased safety. Some designs now use hybrid systems that combine fluidized zones with packed beds to optimize performance. These developments are particularly important for sectors that demand high product purity and selectivity. Reactor design will only become more efficient as materials science research advances. Digital twins and real-time data analytics integration are also transforming process control by enabling predictive maintenance and increased process transparency. For manufacturers, this digital transformation is a significant value addition.

Restraints

Inflexibility in Handling Solid Byproducts or Fouling

Packed bed reactors experience fouling and catalyst deactivation in some processes, resulting in solid byproducts. Solid deposition can eventually obstruct flow channels or decrease effective surface areas, which lowers performance and increases maintenance requirements. Operations may be disrupted by frequent shutdowns for cleaning or catalyst replacement, which reduces its suitability for continuous processing under such conditions. This restricts its application to specific reaction types. Additionally, the fixed nature of the catalyst bed makes in-situ cleaning or regeneration difficult, often requiring complete systems disassembly. This leads to higher downtime, increased operational costs, and reduced overall process flexibility.

Scale-Up Challenges and Design Constraints

Packed bed reactors can be difficult to scale up from laboratory or pilot scale to industrial scale, limiting the growth of the packed bed reactor market. Larger scales result in more complicated heat management and uniform flow distribution. Custom reactor designs may also be necessary for applications that raise design costs and, therefore, are less desirable for projects with tight deadlines or budgets. Many organizations struggle with transferring lab-scale results to commercial operations due to scale-dependent parameters. Inconsistent scale-up can lead to reduced yields or failed batch runs, resulting in financial and resource losses.

Opportunities

Integration with Green and Sustainable Technologies

Packed bed reactors have the potential to be a key component of green chemistry and cleaner production techniques as global industries strive for sustainability. Eco-friendly industrial goals are perfectly aligned with their capacity to support catalytic and bio-catalytic processes with minimal waste. To reduce emissions and improve resource efficiency industries like waste-to-energy carbon capture and biofuels are looking more and more into packed bed systems.

Their sustainability quotient can be further raised by using biodegradable feedstocks and renewable catalysts in packed bed reactors. The market is expanding significantly as a result of incentives provided by governments and environmental organizations for industries to implement such solutions. Businesses can capitalize on the quickly expanding green technology market by concentrating on the sustainable design and operation of packed bed reactors.

Rising Demand in Niche Sectors

Beyond more conventional industries like pharmaceuticals and petrochemicals, packed bed reactors are becoming more popular in other sectors, like specialty chemicals, food processing, and cosmetics, which creates immense opportunities in the packed bed reactor market. Packed bed systems provide consistent performance and customization options for these industries which frequently need precise small batch processing. A distinct growth area is also presented by the biotech industry's increasing interest in enzymatic processes and bioreactor applications for product development. The ability to easily adapt packed bed systems to these specialized applications through the modifications and catalyst types opens high-margin innovation-driven markets.

Type of Reactor Insights

The fixed bed reactors segment dominated the packed bed reactor market with the largest share in 2024. This is mainly due to the heightened use of these reactors in the petrochemical, chemical, and pharmaceutical sectors. These reactors are the go-to option for large-scale continuous processes because of their reputation for stability and dependability. They work better in adsorption and catalytic reactions where exact control over temperature, pressure, and flow is essential. High operational efficiency and superior control over reaction conditions are two benefits of fixed-bed reactors that result in reliable product quality. These reactors have become more effective, thanks to monitoring and control systems improvements, which allow for real-time data collection to spot possible problems like clogging or catalyst deactivation.

The fluidized bed reactor segment is expected to witness significant growth during the predicted timeframe. This is mainly due to their effectiveness and adaptability to high-volume reactions. These reactors are perfect for processes requiring high reaction rates and consistent temperature control because they provide excellent heat and mass transfer. Fluidized bed reactors are suitable for applications requiring scalability and flexibility, like manufacturing biofuel, pharmaceuticals, and fine chemicals. Fluidized bed reactors are becoming more and more significant due to the rising need for renewable feedstocks and green technologies. Advancements in reactor design and catalyst development can expand their area of applications.

Feedstock Type Insights

The petroleum-based feedstock segment dominated the packed bed reactor market with the largest share in 2024. Petroleum-based feedstock is widely used to produce chemicals, in which packed bed reactors play a crucial role. These feedstocks are derived from fossil fuels such as natural gas and crude oil and provide established processing technologies of high reliability and scalability. Since they offer a reliable and reasonably priced source of raw materials, they have become essential to contemporary industrial production. Even though resource depletion and environmental sustainability are still major concerns, petrochemical feedstocks are still essential to sectors of the economy that depend on the large-scale production of chemicals. Ongoing advancements are improving the efficiency of feedstock development in petrochemical extraction and refining techniques, solidifying the segment's position on the market.

The bio-based feedstock segment is projected to grow rapidly in the coming years. A more sustainable alternative to petrochemical-based resources, bio-based feedstocks are derived from renewable sources like algae, plant oils, and agricultural residues. The use of bio-based feedstocks in manufacturing biofuel, bioplastics, and specialty chemicals is growing. As industries work to lower their carbon footprint and implement greener practices, the use of packed bed reactors is increasing in biomass conversion methods, supporting segmental growth.

Application Insights

The petrochemicals segment led the packed bed reactor market in 2024. This is mainly due to the widespread application of packed bed reactors in large-scale petrochemical production and refining processes. Hydrocracking, hydrogeneration, and catalytic reforming are three essential petrochemical plant processes that are depend on these reactors. They are perfect for producing fuels, polymers, and industrial chemicals because of their capacity to run continuously at high temperatures and pressures. The growth of the segment is further bolstered by increased investments in process optimization and emission control within petrochemical operations.

The wastewater treatment segment is expected to grow at the fastest rate during the forecast period. This is mainly due to the increasing need for sustainable water management solutions and stricter environmental regulations. Wastewater treatment plants increasingly use sophisticated technologies to rid organic and inorganic pollutants. Reactors with packed beds, particularly those that are combined with catalytic or biofilm-based systems, are very effective at lowering and breaking down pollutants. The global push for water reuse and the increasing demand for clean water further bolster the growth of the segment.

End-Use Industry Insights

The chemical industry segment dominated the packed bed reactor market with the largest share in 2024 because of the increased application of packed bed reactors in the production of bulk chemicals. These reactors are used extensively in oxidation, polymerization, and acid-based reaction processes, making them essential to the production of fertilizers, dyes, and intermediates. They are perfect for continuous processing. Thus, they are widely used in large-scale chemical plants because of their high efficiency, scalability, and capacity.

The water treatment segment is expected to grow at the fastest rate in the upcoming period, driven by growing environmental awareness, stringent discharge guidelines, and growing water scarcity awareness. These reactors are being used more and more to treat municipal and industrial wastewater by eliminating suspended solids, heavy metals, and organic pollutants. Packed bed reactors with biofilms ion exchange materials or catalytic media integrated offer space-saving designs and high treatment efficiency. They are appropriate for sophisticated purification systems due to their capacity to manage a range of loads and function in challenging environments. The rising need for effective and portable treatment solutions and rising water reuse initiatives further support segmental growth.

Operating Condition Insights

The medium segment dominated the packed bed reactor market with the largest share in 2024. because of its broad application in many different industries and its adaptability. In mid-scale chemical plants pilot facilities and specialty manufacturing units, these reactors provide a well-balanced solution because they are both big enough to manage sizable processing volumes and small enough to operate with flexibility. When space efficiency and accuracy are crucial in the manufacturing of fine chemicals pharmaceuticals and agrochemicals, they are particularly preferred. For operations needing both performance and flexibility medium-sized packed bed reactors are the best option because they are simpler to integrate with current infrastructure and enable optimal health and mass transfer. Their dominance in the global market is further reinforced by their increasing adoption in process optimization projects and emerging economies.

Packed Bed Reactor Market Companies

- Parker Autoclave Engineers

- Vapourtec

- HiTec Zang GmbH

- AP-Miniplant GmbH

- Th. WINKELS GmbH

- Quality Engineers

- Amar Equipments

- Lelesil Innovative Systems

- Equipline Technologies

- Trident Labortek

Latest Announcements

- On 3 March 2025, Hero Future Energies & Rockman Industries Inaugurated a Rs 1000 crore green hydrogen plant in Tirupati Andra Pradesh Chief Minister N. Chandrababu Naidu virtually inaugurated the plant, highlighting its role in industrial decarbonization. He stated, “This pioneering project blends Green Hydrogen with LPG/PNG for industrial applications, marking a significant breakthrough in industrial decarbonization.”

- On 31 December 2024, BHEL Bhopal delivered a compact & energy efficient 110 MVAR 765 kV reactor to POWERGRID for installation at Khavda Substation, Gujrat this reactor is designed to harness energy from solar and wind power plants, contributing to India's target of achieving 500 GW of non-fossil power capacity by 2030.

Recent Developments - On 11 March 2025, Vapourtec Ltd launched a high-temperature packed bed reactor. They introduced a modular reactor enhancing its E-Series and R-Series flow chemistry systems. This reactor operates up to 250 degrees and 50 bar pressure, enabling advanced reactions like high-temperature click chemistry and continuous flow hydrogenations.

Segments Covered in the Report

By Type of Reactor

- Fixed Bed Reactors

- Moving Bed Reactors

- Trickle Bed Reactors

- Fluidized Bed Reactors

By Feedstock Type

- Petroleum-based Feedstock

- Bio-based Feedstock

- Synthetic Feedstock

- Coal and Natural Gas Derived Feedstock

By Application

- Petrochemicals

- Polymer Production

- Chemical Synthesis

- Environmental Applications (e.g., Wastewater Treatment)

By End-Use Industry

- Chemical

- Petroleum Refining

- Food and Beverages

- Pharmaceuticals

- Water Treatment

By Operating Condition

- Temperature (Low, Medium, High)

- Pressure (Atmospheric, Elevated Pressure)

- Catalyst Type (Heterogeneous, Homogeneous)

By Region

- North America

- Europe

- Asia Pacific

- Middle East & Africa

- Latin America

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting