What is the Plastic Injection Molding Machine Market Size?

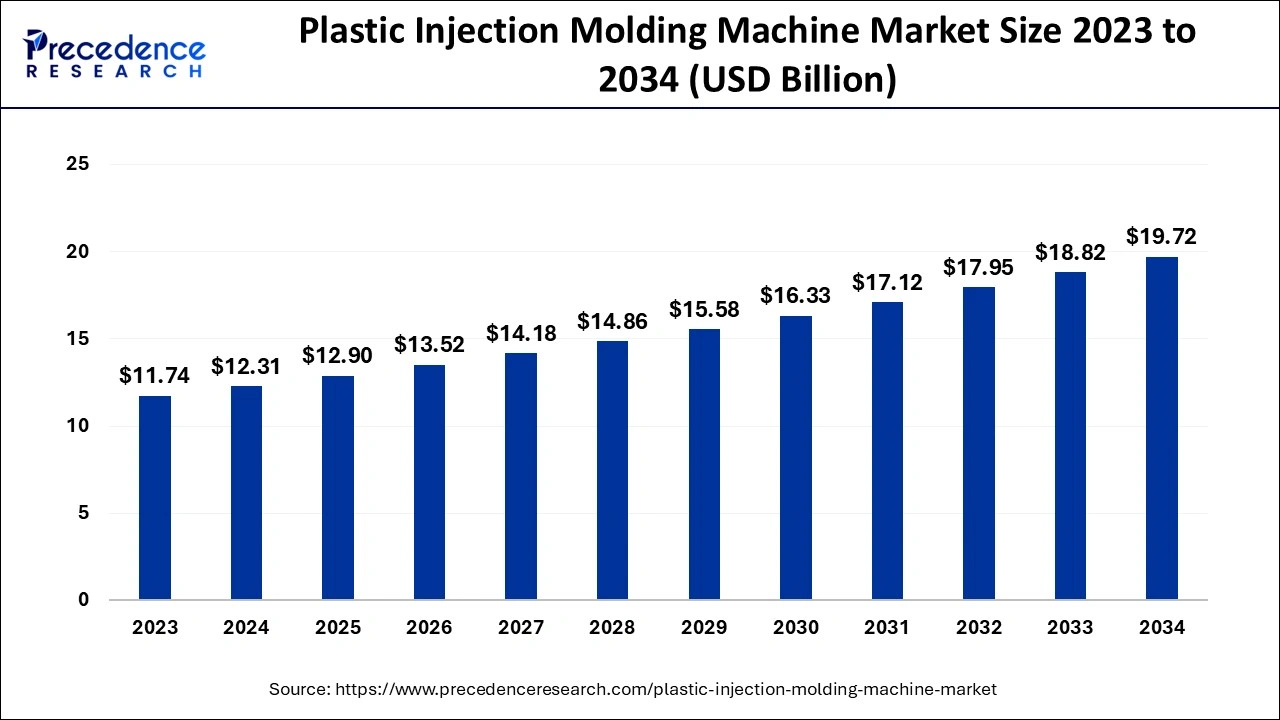

The global plastic injection molding machine market size is valued at USD 12.90 billion in 2025 and is predicted to increase from USD 13.52 billion in 2026 to approximately USD 19.72 billion by 2034, growing at a CAGR of 4.83% from 2025 to 2034. The plastic injection molding machine market is growing because of the adoption of complex technologies, rising demand across industries, opportunities to lower costs, and concerns for sustainability.

Plastic Injection Molding Machine Market Key Takeaways

- The global plastic injection molding machine market was valued at USD 12.31 billion in 2024.

- It is projected to reach USD 19.72 billion by 2034.

- The plastic injection molding machine market is expected to grow at a CAGR of 4.83% from 2025 to 2034.

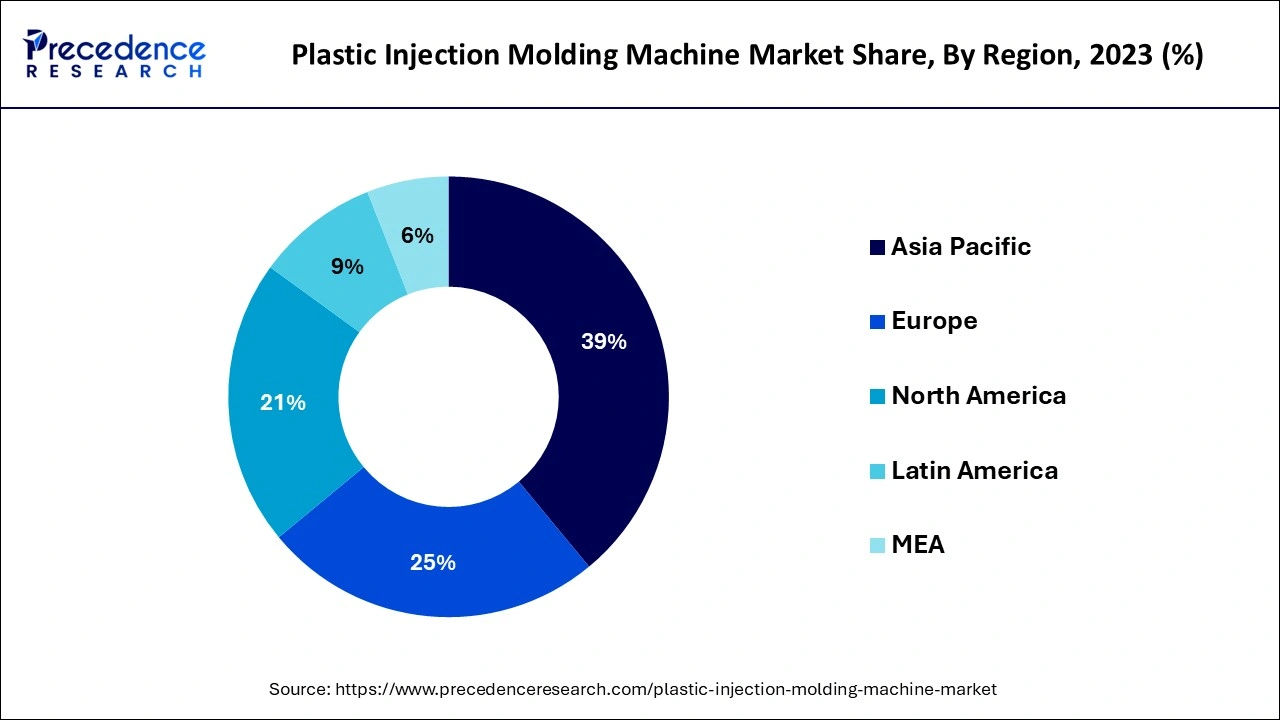

- Asia Pacific dominated the global market with the largest market share of 39% in 2024.

- North America is anticipated to witness the fastest growth during the forecasted years.

- By technology, the hydraulic technology segment noted the largest market share of 53% in 2024.

- By technology, the electric technology segment is anticipated to expand at a CAGR of 5.54% from 2025 to 2034.

- By end-use, the automotive end-use segment has contributed the largest market share of 30% in 2024.

- By end-use, the medical segment is projected to grow at a significant CAGR of 5.94% during the forecast period.

What is the Impact of Artificial Intelligence (AI) on the Plastic Injection Molding Machine Market?

Using AI in the plastic injection molding machine market makes the processes much more efficient, accurate, and affordable. It can automatically determine from sensor data when a mold could likely fail, thus preventing the issue by performing preventive maintenance. These sensors correspond with information on molding-related factors like temperature, pressure, and flow rate. The application of AI in injection molding is changing the industry and bringing new prospects largely in terms of speed, effectiveness, and cost. The major aid of AI in injection molding is the capability to improve the production process.

What is a Plastic Injection Molding Machine?

A plastic injection molding machine is the equipment used to form products with heat and pressure manufactured from plastics. It is also called an injection press. Plastic injection molding machines are used to create a wide range of plastic parts and products with precise forms and sizes. They employ a pressure system to force the molten plastic into the mold to create accurate and complicated parts for industries such as automotive, electronics, and packaging while promising efficiency, accuracy, and cost-effectiveness in mass production.

The global plastic injection molding machine market is growing because of increasing usage and demand for injection molded plastics across segments like automotive, packaging, and electronic industries. The advancements in injection molding machines, which include automation and accuracy in operations, have led to enhanced output and reduced expenses for manufacturers' operations across the globe.

What are the Growth Factors in the Plastic Injection Molding Machine Market?

- Increasing automotive industry: Plastics utilized in injection molding processes are widely used for interiors, exteriors, and bodily panels. As these industries develop, the requirement for high accuracy and low cost of plastic parts increases.

- Cost efficiency and scalability: They aid companies in manufacturing a variety of complex, high-accuracy plastic parts in large volumes with low manpower and material wastage.

- Trends affecting the packaging industry: The packaging industry across the world, especially in the food and beverages, consumer goods, and e-commerce segment, is expanding at a very high rate. Injection molding machines are very important in the manufacture of packaging products like bottles, caps, and containers.

- Sustainability: The growth of more sustainable and recyclable plastics also creates the demand for plastic products. Manufacturers are using bioplastics, recycled plastics, and energy-efficiency technologies to address environmental standards that require the manufacturing of green products.

Plastic Injection Molding Machine Market Outlook

- Industry Growth Overview: The sector is projected to experience stable growth from 2025 to 2030, driven by an increase in demand for high-precision molding within the automotive, packaging, and electronics industries. Additionally, this growth is catalyzed by advances in automation and the rapidly growing manufacturing hubs in the Asia-Pacific and North America.

- Sustainability Trends: The industry is trending towards energy-efficient, all-electric machines and more compatible materials for recyclability. In response to international regulations to decrease emissions and support sustainable production processes, manufacturers are investing more in R&D for low-waste molding production methods.

- Global Expansion: Manufacturers are involved in international expansion into locations such as Southeast Asia, Eastern Europe, and LATAM to take advantage of lower manufacturing costs and increasing demand from suppliers in the consumer goods and automotive industries. Manufacturers are establishing localized plants to reduce lead times and enhance customer support.

- Major Investor: Everyone is showing better interest in private equity and strategic investors because of stable margins, the increase of automation adoption in manufacturing, and having long-term industrial growth built into business plans. Investors such as KKR and Carlyle are increasingly interested in investments in machinery manufacturers offering high-efficiency systems.

- Startup Ecosystem: New entrants have begun emerging in the categories of smart molding, AI-based process optimization, and compact electric machines. Some of these startups are gaining investment traction in Japan, China, and India based on their innovation to reduce energy use, reduce defects, and reduce cycle times.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 19.72 Billion |

| Market Size in 2026 | USD 13.52 Billion |

| Market Size in 2025 | USD 12.90 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 4.83% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Technology, End-Use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East, and Africa |

Market Dynamics

Driver

Growing construction sector

The growth in the residential construction industry raises the need for the plastic injection molding machine market. The building construction industry utilizes plastic injection molding for cheap, flexible, durable, and high-performance construction products. In plastic injection molding, it is possible to make large quantities of acceptable plastic components by using different thermoplastic polymers. These parts are used in the construction area in both construction goods and products, as well as in the construction of commodities for use in flooring, roofing, and construction tools and equipment. Amongst durable plastics, each of such materials presents certain characteristics that make it suitable for construction exercises.

- The Indian government, in its Union Budget 2022-23, has allocated INR 48 000 crore (USD 6.44 billion) for its scheme ‘PM Aawas Yojana' and remain ‘Housing for all' exercise to construct 80 00,000 housing units for urban and rural poor in the fiscal year 2022-23.

Restraint

High initial investment costs

The key challenge for the plastic injection molding machine market is the capital costs, which are generally high and might not be easily achievable by small and medium-sized businesses (SMEs) and start-ups. Such devices require huge capital to purchase, install, and other recurrent expenditures that are likely to discourage potential customers. In addition, training operators and enhancing technology need more money, which is also a burden on the budget. However, the initial cost involved in penetrating the injection molding market and the increasing popularity of other potential and substitutive technologies, such as 3D printing, are projected to limit the market growth.

Opportunity

Increasing usage in the packaging and automotive industry

The plastic injection molding machine market services use high pressure to produce plastic parts for a variety of industries, including automotive and packaging. The use of this type of molding machine has particularly risen in the automobile industry in recent years due to the incorporation of more plastic products in automotive production. The need to use injection molding in the market is due to its expansion in the automobile sector, and it's the demand to meet packaging needs.

Technology Insights

The hydraulic segment noted the largest share of the plastic injection molding machine market in 2024. Hydraulic technology is widely used in plastic injection molding machines; the primary applications of hydraulic systems are the clamping of molds and the injection of plastic material. The market will expand due to the high-rate production of complex parts for the automotive industry, more affordable than electrical equipment, high-precision molds, high wear resistance hydraulic parts, and the most extensive use in the automotive industry, ships, aerospace, and other spheres. The distinctive feature of the plastic injection molding machine is that the hydraulic system must produce reliable performance.

The electric segment is projected to witness the fastest growth in the plastic injection molding machine market during the forecast period. The electric segment is adopting accurate control and monitoring mechanisms, and the molding condition might be easily maintained. It is an electric injection molding machine with digital control, high speed, and high efficiency throughout the whole production process due to separate motors controlling injection, extruder, clamping, and ejection. Electric injection molding utilizes high-speed servo motors instead of hydraulics to power the machine. This makes a more accurate, quicker, and less power-intensive functionality.

End-Use Insights

The automotive segment contributed the largest share of the plastic injection molding machine market in 2024. Injection molding machines are widely used in the automobile industry, where body parts like door panels, car door trim, automobile bumpers, trunk trims, rear & front covering, floor rails, sensor holders, automobile grilles, wheel arches, and fenders/mudguards are used. Some of the products made with plastic injection molding technology include auto parts such as the body panels, the inside part, and the engine. It is widely used mainly by industries participating in high-volume production of plastic parts due to its speed, cost efficiency, and low material requirements. Automotive companies use flexible, lightweight polymeric materials, which are adaptable when manufacturing plastic products.

The medical segment is projected to witness the fastest growth in the plastic injection molding machine market during the forecast period. The growing requirement for medical disposables, improvements in technology and usage in healthcare, and growing demand for plastics in medical applications and consumptions are contributing to the growth in the plastic injection molding machine industry. The process of medical injection molding is the process of melting the right type of medical-grade plastics and forming them into the right shape of medical tools. Plastic injection molding is a cheap and very effective method of manufacturing medical and pharmaceutical parts with a high degree of precision, accuracy, and quality. It is employed in manufacturing a substrate out of various medical appliances and equipment, lab equipment, and testing devices.

Regional Insights

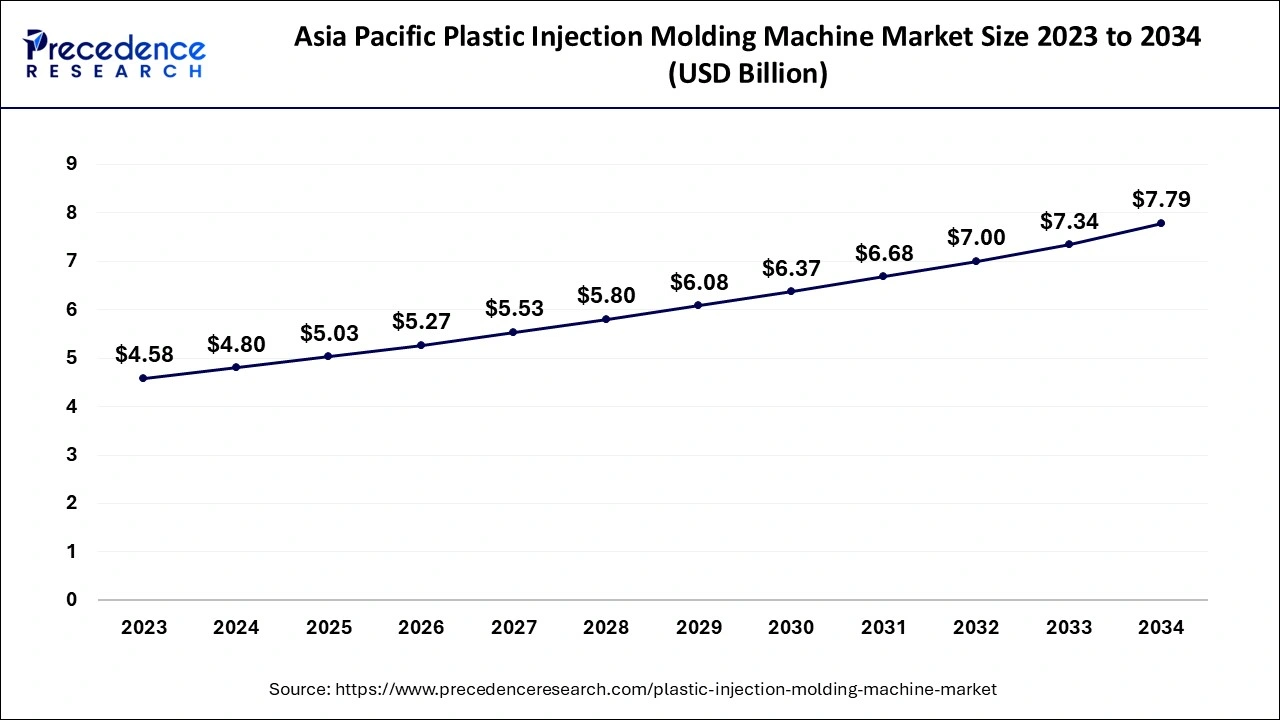

Asia Pacific Plastic Injection Molding Machine Market Size and Growth 2025 to 2034

The Asia Pacific plastic injection molding machine market size is exhibited at USD 5.03 billion in 2025 and is projected to be worth around USD 7.79 billion by 2034, growing at a CAGR of 4.96% from 2025 to 2034.

Asia Pacific accounted for the largest share of the plastic injection molding machine market in 2024. Increased spending on manufacturing infrastructure is anticipated to bolster the growth of the plastic injection molding machine market in the Asia Pacific. The demand for plastic injection molding machines is growing due to the increasing awareness of energy savings and the rise in manufacturing activities. China, India, and Japan are rapidly industrializing. The demand from industries such as health care, packaging, and automobile industries, among others, is boosting the uptake of injection molded plastics.

- As per China's Association of Automobile Manufacturers, China produced and sold automobiles of 27.021 million units and 26.864 million units, respectively, up by 3.4% and 2.1% compared to last year.

North America is anticipated to witness the fastest growth in the plastic injection molding machine market during the forecasted years. Strong industrial growth and technical advances have had an impact on the North American plastic injection molding machine industry market. The region's strong manufacturing proficiencies and commitment to innovation drive demand for high-precision, efficient manufacture of complex parts used in the automotive, aerospace, electronics, and healthcare industries. Plastic injection molding machines play a crucial role in the automotive industry, aiding the mass production of complex and modified plastic components used in automobiles.

- According to the Flexible Packaging Association of the United States, the Flexible Packaging segment stands as the second largest in the United States, accounting for about 21% of USD 180.3 billion in the packaging market.

North America: U.S. Plastic Injection Molding Machine Market Trends

The U.S. market is experiencing steady growth as demand rises from automotive, packaging, medical devices, and consumer goods manufacturing. Manufacturers are increasingly adopting energy-efficient, all-electric, and hybrid machines to reduce operating costs and improve production precision. Automation and Industry 4.0 integration are also shaping market trends, with smart sensors and real-time monitoring becoming standard features. Additionally, the shift toward sustainable materials and lightweight components is encouraging investments in advanced molding technologies.

Why did Europe Experience Steady Growth in the Plastic Injection Molding Machine Market?

Europe expanded steadily since it relied on high-end manufacturing, stringent environmental restrictions, and increased use of electric injection machines. The automotive, medical devices, and packaging industries have modernized energy-efficient systems to reduce carbon emissions. The region also developed a demand for advanced molding machines and precision molds, for example, in Germany, Italy, and France. Extensive research and development, a skilled workforce, and increasing demand for sustainable, eco-friendly, and recyclable plastic products supported market growth.

Germany Plastic Injection Molding Machine Market Trends

Germany was a leader in the European market owing to its precision engineering and high-quality molded parts. Automotive and medical device companies in Germany adopted modern, advanced electric machines to meet stringent standards. Automation capabilities and digital monitoring using smart sensors were widespread in German factories, allowing for increased speed, reduced defects, and variation with machinery.

Why did Latin America Experience Strong Growth in the Plastic Injection Molding Machine Market?

Latin America demonstrated strong growth driven by production increases in packaging, automotive, and consumer goods. Countries were willing to invest in new plants, and companies were happy to phase out the old machines and replace them with electric and hybrid versions. There were opportunities for growth in food packaging, building materials, and household goods products. Urbanization continued to rise along with consumer demand, and both contributed to growth in these markets. Brazil and Mexico became key markets for machine installations.

Brazil Plastic Injection Molding Machine Market Trends

Brazil was the leader in the Latin American market as it has the largest industrial base and the strongest demand for molded plastics in the packaging and automotive sectors. Companies with modernized machinery to improve quality and reduce waste. Various government programs encouraged local manufacturing, and these programs also supported the procurement of new equipment. Additionally, Brazil's consumer market grew, which increased demand for molded products.

Why did the Middle East and Africa experience steady growth in the plastic injection molding machine market?

The Middle East and Africa continued to experience steady growth through the broadening packaging, construction, and consumer goods sectors. Various countries continued pouring investment into industrial zones or legislative measures to encourage local manufacturing to reduce imports. Opportunities and growth accelerated within food packaging, household goods, and automotive parts. Several new manufacturing facilities based in the UAE, Saudi Arabia, and South Africa fostered even regional machine demand, especially energy-efficient systems.

The UAE Plastic Injection Molding Machine Market Trends

The UAE is leading the region due to its deeper investment in diversifying manufacturing and investing in advanced technologies. Companies involved in packaging, healthcare, and consumer goods have adopted modern injection molding machinery to produce products with better quality. The government initiatives to support visibility for industrial innovation allow more factories to upgrade to energy-efficient systems. The country also has a strong logistics system that supports the installation of new technology machine systems.

Plastic Injection Molding Machine Market Companies

- Arburg GmbH + Co KG

- HAITIAN INTERNATIONAL

- KraussMaffei

- Milacron

- NISSEI PLASTIC INDUSTRIAL CO., LTD.

- ENGEL AUSTRIA GmbH

- Chen Hsong Holdings Limited

- UBE Machinery Inc.

- Husky Technologies

- WITTMANN Technology GmbH

Announcements by Industry Leaders

- In February 2023, TOKYO Sumitomo Heavy Industries, Ltd announced the launch of the iM18E, a hybrid injection molding machine. Optimized for a range of applications related to electronics for connectors and precision gears, it is characterized by a high injection speed of 600 millimeters a second.

Recent Developments

- In February 2024, Haitian launched the new 5th generation of injection molding machinery. By applying AI algorithms with modern sensor technology, the company has succeeded in implementing intelligent process control and endowing machinery with intelligent characteristics of recognition, adaptation, decision-making, and reconstruction.

- In July 2023, Haitian International introduced a manufacturing facility in Jalisco, Mexico, marking its first site in North America. The USD 50 million plant aims to enhance production, expedite regional deliveries, and potentially serve the broader North American market.

Segments Covered in the Report

By Technology

- Hydraulic

- Electric

- Hybrid

By End-Use

- Automotive

- Consumer Goods

- Packaging

- Electronics

- Construction

- Medical

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting