What is the Plastic Injection Molding Market Size?

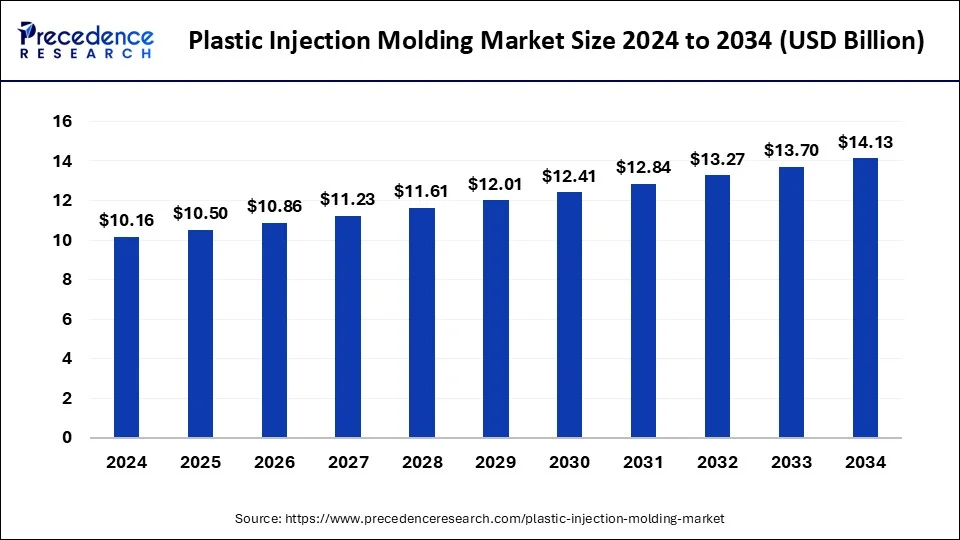

The global plastic injection molding market size is calculated at USD 10.50 billion in 2025 and is predicted to increase from USD 10.86 billion in 2026 to approximately USD 14.56 billion by 2035, expanding at a CAGR of 3.32% from 2026 to 2035.

Plastic Injection Molding Market Key Takeaways

- Asia Pacific led the global market with the highest market share in 2025.

- By raw material type, the polypropylene segment has held the largest market share in 2025.

- By application, the packaging segment is estimated to hold the highest market share in 2025.

Plastic Injection Molding Market Growth Factors

The injection molding is a plastic product manufacturing technique that involves injecting molten material into a mold, where it is cooled, melted, and solidified as the final part or product. Injection molded plastics, both thermosetting and thermoplastic, are used in a variety of sectors to create diverse parts and components. Polypropylene, high-density polyethylene, polycarbonate, polyvinyl chloride, low density polyethylene, and polysulfide are some of the most common thermoplastic polymers used in injection molding. Some of the thermosetting polymers used for injection molding include melamine formaldehyde and polyester.

Consumer preferences for high performance materials, as well as the adoption of new manufacturing technologies and government rules promoting energy efficient structures and smart building technologies, will all contribute to the construction industry's growth.

The increased construction expenditure, particularly in developing countries, should help the plastic injection molding market by boosting public infrastructure and housing construction. In addition, rising industrialization, as well as stringent government requirements on energy efficient buildings and smart building technology, will drive industrial growth in Asia-Pacific region.

The injected molded plastics are used to replace a range of alloys and metals in the construction sector to improve weight, ultraviolet protection, insulation, cost-effectiveness, and waterproofness. The flooring, plumbing, walls, roofs, and insulation are the most common applications for plastics in the construction and building industry. The injection molded plastics' broad use in diverse sectors is expected to stimulate demand.

The use of injection molded plastics in conjunction with an automated process lowers manufacturing costs. In the manufacturing or production process, it also decreases waste creation. The injection molded plastics market expansion will be aided by lower production waste and a speedier manufacturing process. Furthermore, the technique may create plastic components using multiple types of plastics at the same time. Moreover, the technical advancements in the plastic injection molding process, where robots are employed to execute various activities, such as assembling and finishing injection molded parts, as well as loading components into the injection molding would help the plastic injection molding market to develop. The plastic injection molding market's expansion, however, may be hampered by high initial tooling costs and variable oil and gas prices.

For precision and little waste, injection molded plastics are utilized in the manufacturing of complicated and intricately shaped parts. The injection molded plastics are employed in the production of vehicle components, interior covering, and other miscellaneous assembly parts because of these benefits. It's also utilized in packaging to make packaging objects and components that improve the packaging's appearance and consumer appeal. Due to the durability, strength, and look of the injection molded plastics are frequently used in building and construction. The plastic components and parts are commonly used in insulation, piping systems, and roofing systems in the construction and building industry.

During the projected period, the plastic injection molding sector's fastest growing application segment will be the healthcare industry. Due to the lightweight, ease of serializability, and cost effectiveness of injection molded plastic, blood sample analysis pipettes, needle housings, pregnancy test devices, and pieces of medical devices are only a few of the chosen segments.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 10.50 Billion |

| Market Size in 2026 | USD 10.86 Billion |

| Market Size by 2035 | USD 14.56 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 3.32% |

| Largest Market | Asia Pacific |

| Fastest Growing Market | Europe |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Raw Material, Application, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segment Insights

Raw Material Type Insights

Due to its expanding use in automotive components, packaging applications, and household products, the polypropylene segment dominated the plastic injection molding market, accounting for the highest market share during the forecast period. Over the projected period, increasing polypropylene finished product penetration in protective caps in electrical connections, food packaging, and battery housings is expected to boost the demand.

On the other hand, Acrylonitrile Butadiene Styrene is expected to be the opportunistic raw material for plastic injection molding in 2023. Over the projection period, the rising demand for Acrylonitrile Butadiene Styrene components in medical devices, automotive components, electronic housings, and consumer appliances manufacturing is likely to fuel demand.

Application Insights

Based on the application, the packaging segment dominated the global plastic injection molding market in 2024, in terms of revenue and is estimated to sustain its dominance during the forecast period. To comply with regulatory rules and end user needs, final packaging items go through several development stages. Increased life of food products and improved durability are just a few of the requirements that plastics must achieve for packaging applications.

On the other hand, the healthcare is estimated to be the most opportunistic segment during the forecast period. The injection molded plastics are projected to be in high demand in the healthcare business due to their optical clarity, cost-effective, and biocompatibility manufacturing methods.

Region Insights

How was the Asia Pacific Influencing the Plastic Injection Molding Market in 2025?

The Asia-Pacific segment dominated the global plastic injection molding market in 2025, in terms of revenue and is estimated to sustain its dominance during the forecast period. The rapid industrialization and the expansion of various plastics end user sectors are the primary drivers of market growth. Furthermore, the factors such as easy access to raw materials and inexpensive labor costs are enticing other plastic manufacturers to set up a base in this region. Moreover, improved living standards and disposable income are expected to promote the market expansion over the projection period.

India Plastic Injection Molding Market Analysis

The Indian industry is growing through the expansion of healthcare and pharmaceuticals, and the rising demand for consumer goods and electronics. India's manufacturing capacity and export performance are strengthening due to the production-linked incentive (PLI) scheme. The PLI scheme drives ₹2 Lakh Crore investment and boosts production and employment across 14 sectors.

How was Europe heading towards Momentous Growth in the Plastic Injection Molding Market?

On the other hand, the Europe is estimated to be the most opportunistic segment during the forecast period. The Europe region's main economic driver is increased demand for automobile and consumer goods industries. People in this region have a lot of discretionary wealth, thus there's a lot of demand for high-end luxury products made of plastics.

North America

What are the Opportunities in the Plastic Injection Molding Market in North America?

North America is expected to grow rapidly in the market during the forecast period, owing to smart manufacturing, advanced materials, and supply chain optimization. The other major regional growth drivers include mandatory reporting, innovation funding, and Extended Producer Responsibility (EPR) initiatives.

U.S. Plastic Injection Molding Market Trends

The U.S. industry is experiencing shifts in automotive design, technological innovation, and the rising demand for specialized medical components. Additionally, the reshoring of manufacturing and investments in domestic production capacity are supporting the long-term growth of the US plastic injection molding brand. In October 2024, PCS Company invested $3 million as it leads as the only U.S. mold base producer and component supplier.

Latin America

What is the Potential of the Plastic Injection Molding Market in Latin America?

Latin America is expected to experience significant growth during the forecast period, driven by local production incentives, sustainable manufacturing, shifting global supply chains, automation, and Industry 4.0. In November 2025, Falcon Plastics announced the acquisition of Avid International Molding Solutions' manufacturing facility in Mexico.

MEA

What is the Considerable Growth of the Middle East and Africa in the Plastic Injection Molding Market?

MEA is expected to grow at a lucrative rate in the market in the coming years, driven by sustainability and regulatory shifts, industrial diversification, and the expansion across major end-use sectors such as packaging, construction, and automotive. The industrial funding in South Africa, Saudi Arabian mega projects, and recycling infrastructure drive the regional expansion.

Plastic Injection Molding Market-Value Chain Analysis

- Raw Material Sourcing

Plastic injection molding relies on resins such as polypropylene, ABS, polycarbonate, and nylon. Additives like colorants, stabilizers, and fillers are used to enhance the performance. The demand for such materials is growing even more with the help of the automotive, packaging, medical, and consumer goods sectors.

Key Players: BASF, Dow, SABIC - Manufacturing and Processing

In this stage, manufacturers use injection molding machines in order to produce high-volume plastic components. The production process includes mold designing, material melting, injecting, cooling, and ejecting. Automation and robotics are widely used in this stage as they help to ensure consistency and also reduce cycle time.

Key Players: Arburg, ENGEL, Milacron - Distribution and End Users

In this stage, injection-molded parts are directly distributed to Tier 1 suppliers and OEMs. Key end users of this market include automotive, medical devices, electronics, and packaging. Long-term contracts can be quite beneficial here in order to ensure stable production planning.

Key Players: Toyota, Medtronic, Bosch

Plastic Injection Molding Market Companies

- Magna International Inc.

- Toshiba Corporation

- DOW Inc.

- LyondellBasell

- HTI Plastics

- DuPont

- Valder Kunststoffverarbeitungs GmbH

- Huntsman Corporation

- Coastal Plastic Molding Inc.

- BASF SE

Recent Developments in the Plastic Injection Molding Industry

- In December 2024, Toshiba Industrial Products Asia Co., Ltd. won the Japan Management Association 2025 GOOD FACTORY award for its constant efforts to promote excellence in manufacturing. This achievement marks the third year in a row win of the Toshiba Group company.

(Source: https://www.global.toshiba ) - In January 2025, ARBURG displayed its latest injection molding machines, including the electric Allrounder 720 E Golden Electric and the hybrid Allrounder 470 H. The 720 E Golden Electric, featuring a 2,800 kN clamping force and compact design, demonstrated efficient production for the mobility sector. This helps customers to meet current challenges such as increasing price pressure combined with rising costs for labor, energy, and materials, as well as shortening product life cycles and faster product changes.

(Source:injectionmouldingworld.com) - In August 2019, American Injection Molding Linc. & American Extruded Plastics Inc. was acquired by Pexco LLC, a North American plastic extruder. Pexco LLC made this acquisition in order to provide integrated molded plastics solutions to its customers.

- In June 2020, Pacific Plastics Injection Molding, a division of Diversified Plastics Inc., has expanded its California facility by 5,000 square feet of office and manufacturing space. This addition was made to increase productivity and ensure a safe working environment.

Segments Covered in the Report

By Raw Material

- Polypropylene

- AcrylonitrileButadieneStyrene

- Polystyrene

- High Density Polyethylene

- Others

By Application

- Automobile

- Consumer Goods

- Electronics

- Packaging

- Building & Construction

- Healthcare

By Geography

- North America

- U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Asia-Pacific

- China

- India

- Japan

- South Korea

- Rest of the World

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting