Electric Vehicle Adhesives Market is Representing 23.50% Growth by 2032

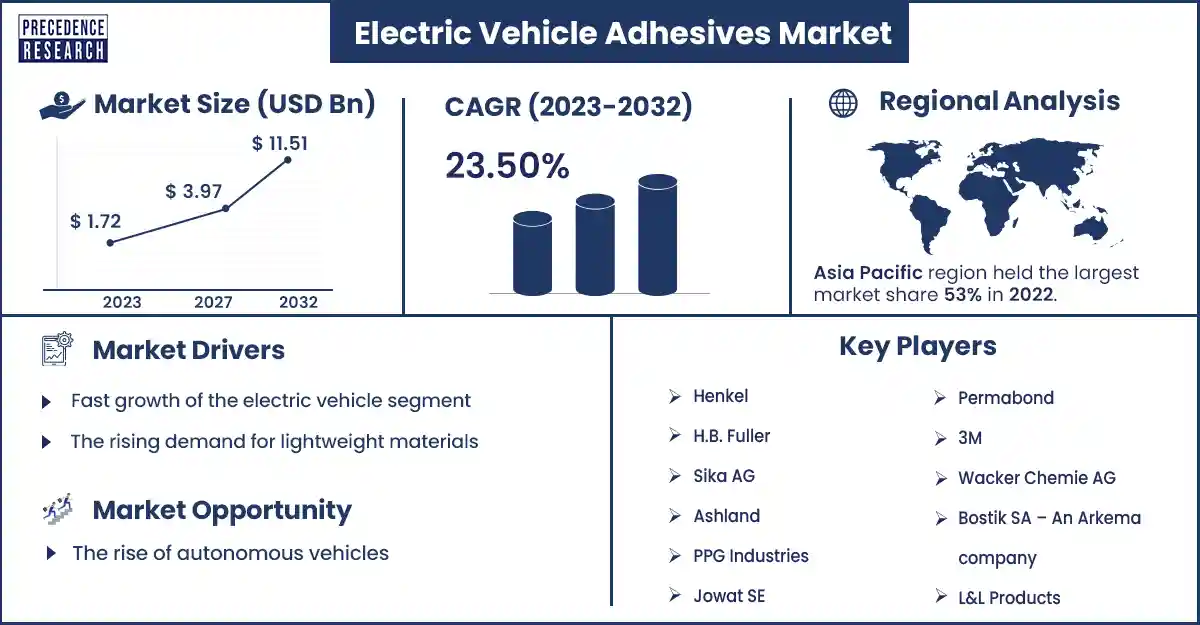

The global electric vehicle adhesives market size was exhibited at USD 1.72 billion in 2023 and is anticipated to touch around USD 11.51 billion by 2032, expanding at a CAGR of 23.50% from 2023 to 2032.

Market Overview

The electric vehicle adhesives market is attributed to the rising adoption of adhesives in EVs for battery assembly and increasing demand for electric vehicles. Electric vehicle adhesives are the adhering element that supplies bonding between two pieces without impacting their functionality. In addition to permitting the element’s systematic operation, it produces a solid optical link between the battery’s components. Electric vehicle adhesives can supply a flexible solution, which has a positive effect on the size of the EV adhesives market because of their flexibility and strength.

The industry outlook is accelerated because of the impact absorption and additional vibration reduction it supplies without passing the energy on to the elements. Rising demand for electric vehicles will increase the need for electric vehicle adhesives in the market. With issues related to the environment, such as global warming, various creativities were initiated by the governments. This enthusiasm focused on raising the manufacture and promotion of electric vehicles. The maximum use of electric vehicles will help decrease the carbon footprint in the market.

Regional Snapshot

Asia Pacific dominated the electric vehicle adhesives market in 2023. It is estimated to grow at the highest compound yearly growth rate during the forecast period. The EV adhesives market is expected to grow well during the forecast period due to the increase in investments made in electric vehicle production. Many manufacturing industries are setting up factories that increase the manufacturing of batteries needed for electric vehicles. Due to an increase in the number of electric vehicles, the EV adhesives market is expected to grow during the forecast period. China is the major producer of these electric vehicle cars. Increasing trade tensions and low worker costs in China have pushed several adhesive end-users to develop and transfer production bases in Asian regions. This transfer is expected to drive adhesive demand in Asian regions. India supplies low-cost workers, which can lead to sufficient investment potential for industries. Additional opportunities in the infrastructure and industrial construction region may be made available by government initiatives like “Make in India” and the recommended scheme on industrialism development. All these major factors are expected to boost the electric vehicle adhesives market in the Asia Pacific region.

North America is estimated to grow fastest in the fastest period. In the North American region, there has been a maximum sale of electric vehicles in recent years. The future is bright for the American electric vehicle adhesives market, and demand enhances the development. In the United States, auto manufacturers are competitive if they choose the right partners for modern technological growth, such as inverters and electronic control units, and build high-quality electric vehicle batteries. These are the factors that must boost the growth of the electric vehicle adhesive market in North America.

- In America, the BNEF announced that 500 million passenger electric vehicles will be on the road around the world by 2040.

Electric Vehicle Adhesives Market Report Scope

| Report Coverage | Details |

| Market Revenue in 2023 | USD 1.72 Billion |

| Projected Forecast Revenue by 2032 | USD 11.51 Billion |

| Growth Rate from 2023 to 2032 | CAGR of 23.50% |

| Largest Market | Asia Pacific |

| Base Year | 2022 |

| Forecast Period | 2023 to 2032 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Fast growth of the electric vehicle segment

The market for electric vehicles is expanding rapidly, as seen by the latest spike in sales. India has the world's largest market for two and three-wheeler vehicles. It is ranked between the global top five for commercial vehicles and private cars. The shift towards electric vehicles in India will have an important effect on the environment. Currently, the transportation region in India is a major contributor to pollution, and electric vehicles play an important role in controlling environmental pollution. Electric vehicles have a major impact on India’s environmental areas, reducing air pollution, reducing noise pollution and improving operational efficiency. This major driver can boost the electric vehicle adhesives market growth in the coming years.

Restraint

Toxic Chemicals

Different types of adhesives and sealants are used in electric vehicles, and many of them contain toxic chemicals. These chemicals are harmful to the environment and other living beings. Workers and communities who live near the manufacturing plants of these adhesives have a high risk of getting intoxicated. A lot of waste is also generated in the electric vehicle adhesives market that ends up in landfills and creates pollution. Valuable materials that can be recovered in the recycling process of EVs also become challenging due to adhesives, which can lead to more pollution. All these things restrain the market growth. Better and environment-friendly adhesives can be developed to overcome these challenges.

Opportunities

The rise of autonomous vehicles

As autonomous vehicles become more extensive, there will be a rising demand for adhesives that can help improve the reliability and safety of electric vehicles. These materials can help critical components, cameras, and other secure sensors. They will make sure that they function properly in all conditions. This opportunity will drive the demand for electric vehicle adhesives market in the coming years.

The rising demand for lightweight materials

As the demand for electric vehicles increases rapidly, there will also be an increasing need for lightweight materials that can help improve their range and efficiency. Adhesives play an important role in enabling the use of these lightweight materials, such as plastics and components, by supplying durable and strong bonds that can withstand the stresses of driving. This opportunity can also enhance the electric vehicle adhesives market demand and growth.

Recent Developments

- In October 2023, in Mumbai, India, Bostik, a main global adhesive specialist, exhibited its new Thermal Conductive Adhesives. It is the range at India Battery Show between 4 and 6 October 2023. The range of thermal-conductive adhesives was a result of a partnership between Polytec and Bostik to handle the provocation of thermal administration in the latest cell-to-pack battery structure for e-mobility solutions.

- In February 2023, Henkel, a global leader in functional coatings, sealants, and adhesives, introduced a revolutionary Battery Engineering Center within its special Inspiration Center in Dusseldorf. The opening stiffens the company’s role as an innovative partner and premier structure for automotive OEMs and battery producers worldwide.

- In September 2023, in Shanghai, China, DuPont held a ceremony to officially announced its new adhesives manufacturing facilities in Zhangjigang in East China. The advanced facility will produce adhesives to cater to consumers in the transportation industry, fast-growing vehicle electrification, and primarily lightweight applications.

- In September 2022, Henkel AG and Co. KGaA completed the accomplishment of Nanoramic Laboratoires's Thermal Management Materials business. Henkel applied this acquisition to build up its Adhesives Technologies business unit’s function in the growing markets for Thermal Interface Materials by enlarging its capacities in high-performance segments.

- In January 2022, in the UK, H.B. Fuller Company announced that it completed the accomplishment of Apollo, the largest independent producer of liquid adhesives, primers for the roofing and coatings, and construction and industrial markets in the UK.

Key Market Players

- Henkel (Germany), H.B. Fuller (US)

- Sika AG (Switzerland)

- Ashland (US)

- PPG Industries (US)

- Permabond (UK)

- 3M (US)

- Wacker Chemie AG (Germany)

- Bostik SA – An Arkema company (France)

- L&L Products (US)

- Jowat SE (Germany)

By Vehicle

- Battery electric vehicle

- Plug in hybrid electric vehicle

By Application

- Exterior

- Interior

- Powertrain

By Resin

- Epoxy

- Silicon

- Polyurethane

- Acrylics

- Others

By Substrate

- Plastic

- Composite

- Metals

- Others

By Form

- Liquid

- Film & Tape

- Others

By End User

- Pack & module bonding

- Thermal interface bonding

- Battery cell encapsulation

- Others

Buy this Research Report@ https://www.precedenceresearch.com/checkout/1894

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308