What is the Electric Vehicle Adhesives Market Size?

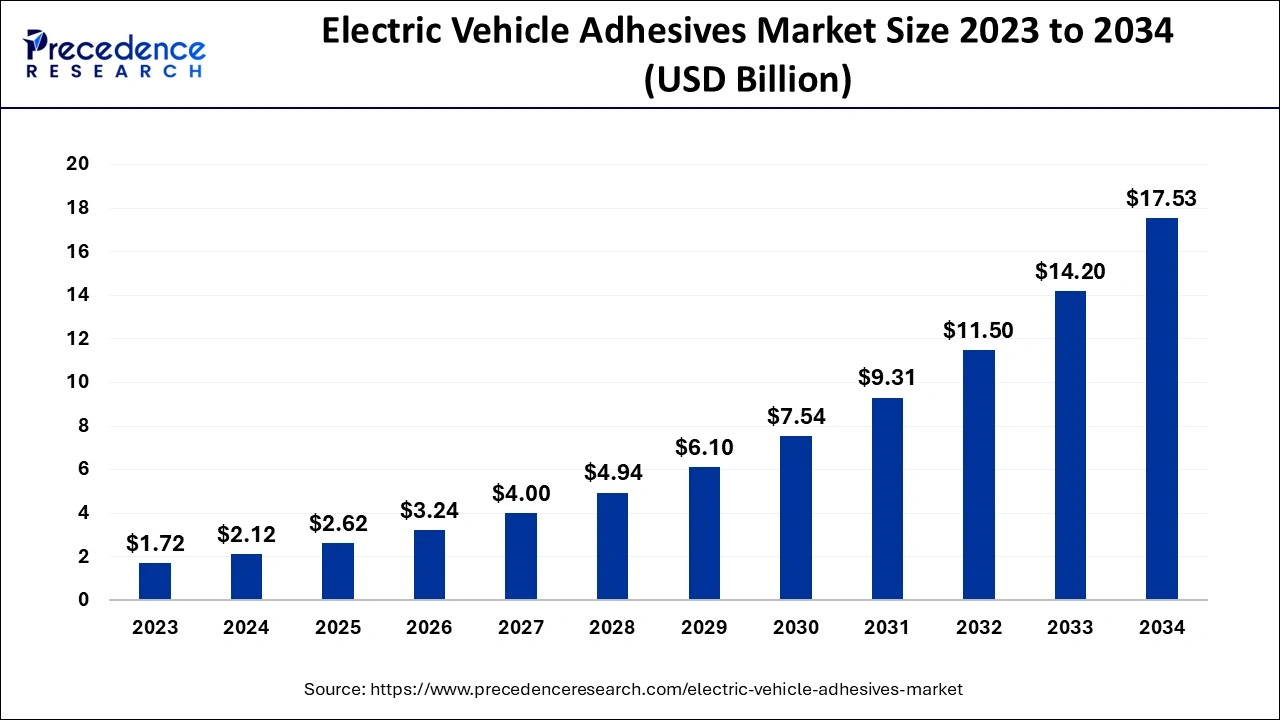

The global electric vehicle adhesives market size is valued at USD 2.62 billion in 2025 and is predicted to increase from USD 3.24 billion in 2026 to approximately USD 17.53 billion by 2034, expanding at a CAGR of 23.50% from 2025 to 2034.

Electric Vehicle Adhesives Market Key Takeaways

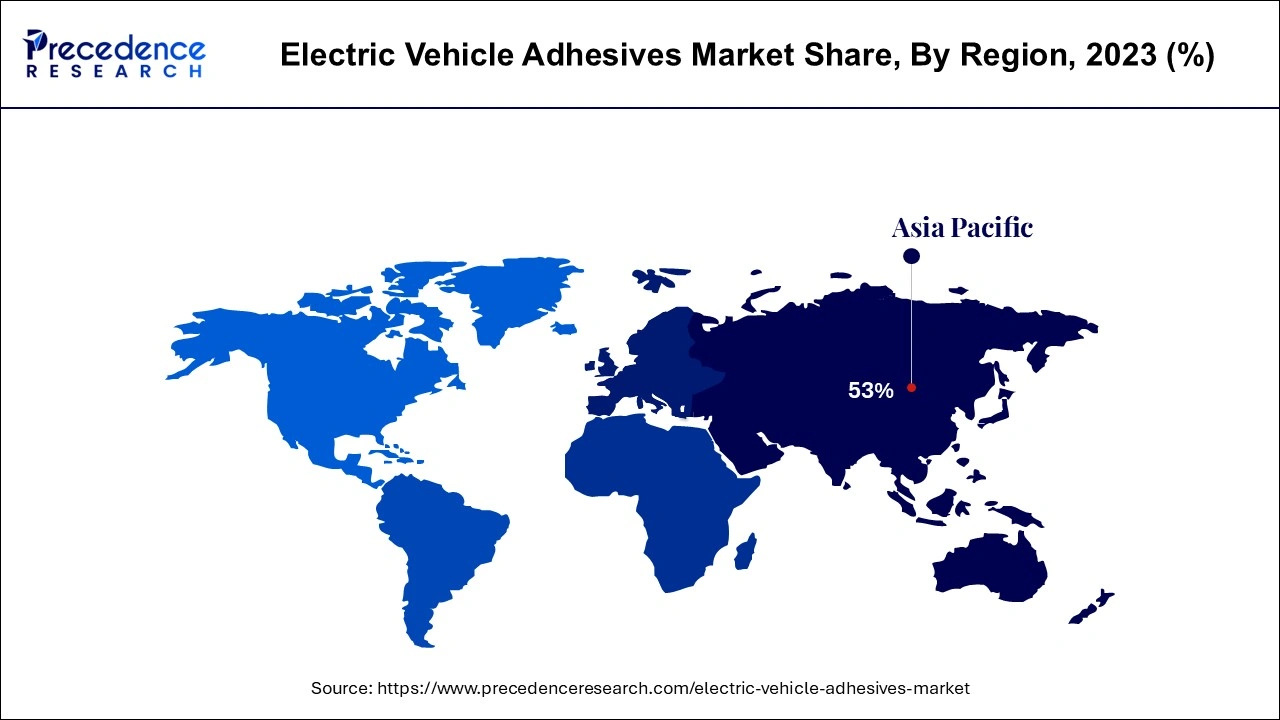

- The Asia Pacific dominated with the largest market share of 53% in 2024.

- By vehicle, the PHEVs contributed the biggest market share of 54% in 2024.

- By application, the pack and module bonding segment captured the major market share of 44% in 2024.

- The battery cell encapsulation application segment is projected to reach the highest CAGR from 2025 to 2034.

Market Overview

There shall be a growth in the demand for oh this is used in the electric vehicles due to the adoption of various initiatives taken by the governments in order to increase the production of the electric vehicles in the developing as well as the developed nations across the globe. Increase in the demand for electric vehicles will increase the demand for the electric vehicle adhesives market. In order to combat the issues related to the environment like the global warming several initiatives were initiated by the governments like the electric vehicle's initiative. This initiative focused on increasing the production of electric vehicles and promoting electric vehicles. As the increased use of electric vehicles will help in reducing the carbon footprint the market for the electric vehicle others is expected to grow during the forecast period.

Due to the outbreak of the COVID-19 pandemic the global market for the electric vehicle adhesives was affected to a great extent. As the manufacturing industries had come to a halt the demand for the electric vehicle adhesives had dropped to a great extent. In order to comply with the policies of the government that restrained the movement of raw materials and prohibited the human contact the market had come to a halt. There were major delays in the production of the vehicles as the supply chain logistics were hampered to a great extent.

There are many reasons why the market growth will be hampered during the forecast period. The expense incurred in the manufacturing of the battery is high due to the use of the technology that makes use of expensive material. The use of this technology which makes use of expensive materials may not be efficient in providing different ranges in the electric vehicles which will hamper the growth of the market. The unavailability of a large number of charging stations for the electric vehicles is another barrier which shall hinder the growth of the market.

The demand for electric vehicles has not grown well as there is of fear of getting stuck at a location which has no charging station. It is estimated that the demand for electric vehicles will grow during the forecast period as there has been an increase in the investment which shall provide a large number of charging stations during the forecast period. Another factor that hampers the growth of the market is that of the lack of standardization. Electric vehicles may not always be compatible with no certain type of charging station. In different countries different voltage is used for fast charging. The electric charger used for the electric vehicles manufactured by Tesla makes use of a supercharger which is not compatible with the other electric vehicles. All of these reasons will restrain the growth of the electric vehicle adhesives market during the forecast period.

How AI is Impacting the Electric Vehicle Adhesives Market?

AI is transforming the electric vehicle adhesives market by optimizing formulation development, enabling manufacturers to design adhesives with enhanced bonding strength, thermal stability, and lightweight properties more efficiently. Predictive analytics powered by AI helps anticipate performance under different operating conditions, reducing trial-and-error testing and speeding up time-to-market. Additionally, AI-driven process automation in production ensures consistent quality, minimizes waste, and supports scalable manufacturing of EV adhesives. Overall, AI accelerates innovation, improves reliability, and reduces costs in the rapidly growing EV adhesives sector.

Electric Vehicle Adhesives Market Outlook

- Industry Growth Overview: The electric vehicle adhesives market is poised for explosive growth from 2025 to 2034, driven by the expanding EV market and the need for lightweight, durable, and reliable bonding solutions. Key growth areas include battery cell encapsulation, pack and module bonding, and bonding of composites and plastics for lightweighting.

- Sustainability Trends: There is a strong focus on developing eco-friendly, sustainable adhesive solutions, with increasing demand for low-VOC adhesives, bio-based polymers, and recyclable formulations. Adhesives are also used to make EVs more sustainable by reducing weight and enabling more efficient manufacturing processes.

- Global Expansion: Market leaders are expanding into high-growth regions such as Asia-Pacific, North America, Latin America, Europe, and MEA, capitalizing on government incentives, rising EV production, and supportive infrastructure development. Asia Pacific is a key market due to significant EV adoption in countries like China and India.

- Major Investors:Large adhesive manufacturers, including Henkel, H.B. Fuller, and Dow, are driving innovation through research and development, strategic acquisitions, and partnerships. Significant investment is also flowing from venture capital firms into the broader EV and battery technology ecosystem, benefiting adhesives innovation.

- Startup Ecosystem:The startup landscape is innovating in advanced adhesive formulations, thermally conductive materials for batteries, and solutions compatible with new lightweight composites. Emerging firms are attracting funding by addressing specific challenges, such as temperature sensitivity, and by enhancing the performance and safety of Electric Vehicle batteries.

Electric Vehicle Adhesives Market Growth Factors

There has been a great demand for electric vehicles in the developed nations. The stringent greenhouse gas emission policies in the developed nations will drive the market growth period in the countries like the United States and Europe many new standards for the emissions have been announced that have come into effect in the recent years period these standards have increased the adoption of electric vehicles in the developed nations. The major automobile manufacturers are increasing their amount of investments for the manufacturing of the electric vehicles. Major manufacturers of electric vehicles are also focusing on expanding their product portfolio by offering different types of models which shall be helpful in creating a larger demand for the product during the forecast. Growing demand for light duty vehicles is also expected to drive the market growth.

Increased use of transport vehicles of the electric form will also drive the market growth during the forecast period. In the recent years there has been a great demand for electric vehicles. Across the globe there are about more than 10 million electric vehicles running on the roads across the globe. And it shall grow in the coming years. That has also been a great demand for electric trucks and bus in order to boost the transport segment.

The presence of various regulatory frameworks that are supportive of the electric vehicles will drive the market growth during the forecast period. There are many initiatives offered by the government that help in the adoption of electric vehicles in many developed nations. Incentives are provided for the consumers that purchase electric vehicles. The availability of such schemes in the developing nations has created a greater demand for electric vehicles. Due to continuous research and development there has been or reduction in the cost of the battery used in the manufacturing of the electric vehicles which has created a greater demand for electric vehicles and it is expected to grow during the forecast period.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 17.53Billion |

| Market Size in 2026 | USD 3.24 Billion |

| Market Size in 2025 | USD 2.62 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 23.50% |

| Dominated Region | Asia Pacific |

| Fastest Growing Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Vehicle, Application, Resin, Substrate, Form, End User, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Vehicle Insights

The electric vehicle batterysegment is expected to dominate the market in the coming years. The plug in hybrid electric vehicles has dominated the market in the past in terms of the market share which accounted for 53%. The demand for battery electric vehicles is expected to grow during the forecast. We shall create a greater demand for additives in this segment.

There is a growing demand for passenger vehicles after battery electric vehicle type. There is been an increase in the investments we shall be helpful in producing large number of light duty vehicles during the forecast period. China is expected to have a great amount of production of battery electric vehicles during the forecast period. There shall be an increase in the demand for the adhesives used in the battery electric vehicles in this region. The global market for the electric vehicles adhesives is expected to have a larger demand through this region.

Application Insights

The exterior application segment is expected to have a dominant position during the forecast period. There has been a growth in the demand for the infotainment systems, batteries, doors, seats and different charging sockets in the electric vehicles. In order to attach all of these there shall be an increased use of adhesives which shall be an alternative to the gaskets, screws as well as the welds which shall be helpful in reducing the weight of the electric vehicles.

As the use of batteries in the electric vehicles increases the weight of the vehicles, adhesives are used to compensate and reduce the weight of the cars. There is an increased use of structural adhesives in the manufacturing of these cars will increase due to constant research and development. The increased use of adhesives in the electric vehicles for the exterior parts will create a greater demand during the forecast period.

- In May 2023, Henkel introduced a new injectable thermally conductive adhesive for EV battery systems. Loctite TLB 9300 APSi is designed to enable high-performance and safe EV battery systems. As a global leader in automotive adhesives, sealants, thermal materials, and functional coatings, Henkel Adhesive Technologies is dedicated to helping solve the challenges of OEMs.

Resins Insights

The polyurethane segment is anticipated to have a dominant position during the forecast period. There are different properties of the due to the type of resins used in its manufacturing. Depending upon the properties of these adhesives they are used in different industries. There shall be a growth in the demand for polyurethane adhesives during the forecast. As it provides and elasticity of about 600% which is an extraordinary quality. This adhesive is extremely strong where it comes to flexibility. There are three different types of the polyurethane adhesive which are used for different applications.

Regional Insights

Asia Pacific Electric Vehicle Adhesives Market Size and Growth 2025 to 2034

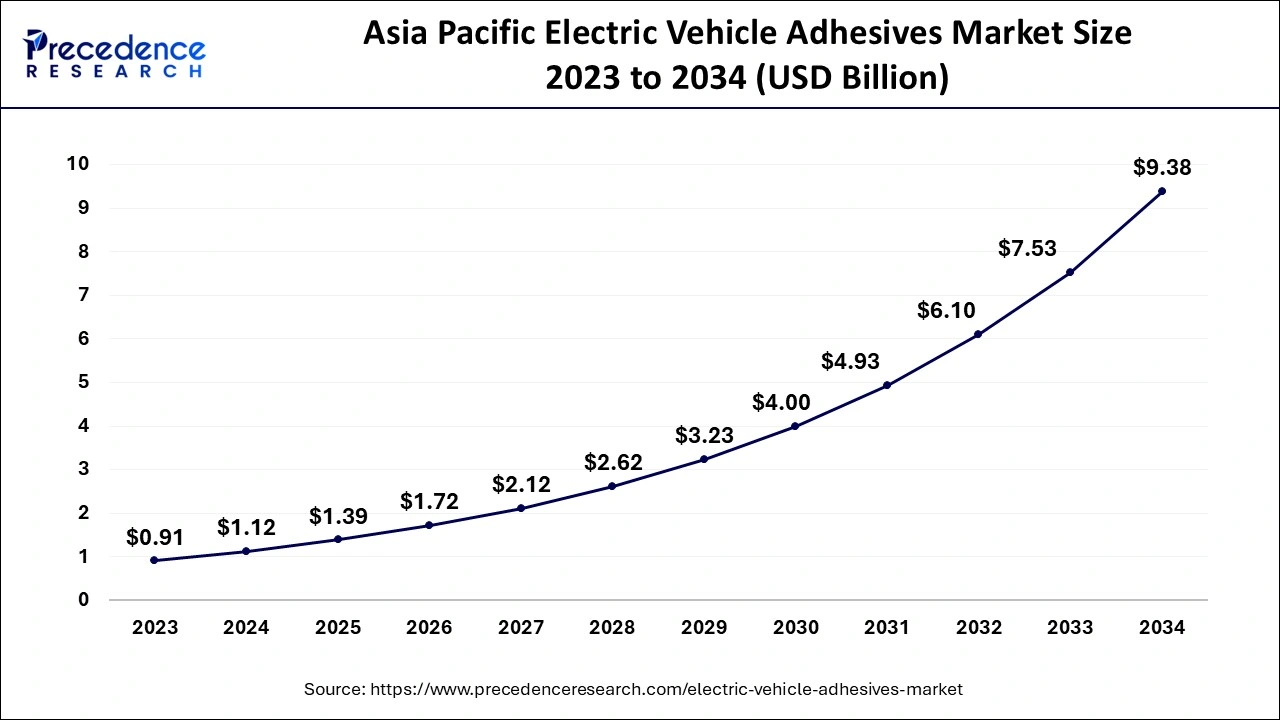

The Asia Pacific electric vehicle adhesives market size is evaluated at USD 1.39 billion in 2025 and is predicted to be worth around USD 9.38 billion by 2034, rising at a CAGR of 23.62% from 2025 to 2034.

The Asia Pacific region is expected to dominate the market during the forecast period. In the recent years there has been an increased sales of electric vehicles in the Asia Pacific region. China is a major manufacturer of these cars. The electric vehicles market was affected to a great extent during the pandemic. As China had taken the worst hit during the COVID-19 pandemic the manufacturing activities had come to a standstill. Restraint in the movement and unavailability of raw material do tourist reigned in the transport affected the market to a great extent. The market for electric vehicles is expected to grow during the forecast and there shall be an increase in the demand for the adhesives in the coming years.

China is the clear leader in the Asia Pacific electric vehicle (EV) adhesives market, primarily due to its enormous EV manufacturing ecosystem and a solid, organized push from the government. In conclusion, China's government initiatives have played a significant role in the rapid growth of the EV market, creating a strong demand for advanced automotive adhesives. Investments in EV battery plants, localizing adhesive materials, and government support, the country is experiencing compelling structural, thermal, and insulating adhesive use from the passenger and commercial EV segments.

Apart from the Asia Pacific region the North American region is also expected to grow well. It is expected to grow at the highest compound annual growth rate during the forecast period. As there has been an increase in the amount of investments made in the manufacturing of the electric vehicles the market is expected to grow well during the forecast period. Major manufacturing companies are setting up factories that shell increase the production of batteries required for the electric vehicles. The market for the electric vehicle adhesives is expected to grow during the forecast period due to an increase in the number of but by the fracturing of electric vehicles.

- In July 2024, Henkel invested in its largest Indian manufacturing facility. The plant will serve Indian businesses, further localize the product portfolio, and decrease dependence on imports. The Kurkumbh site, which was unveiled in 2020, serves the growing demand of Indian industries for high-performance solutions in adhesives, sealants, and surface treatment products.

North America Electric Vehicle Adhesives Market Trends

The U.S. distinguishes itself as the leading market in the North America electric vehicle adhesives market due to rapid growth in EV penetration at the OEM level, significant government rebates for consumers and OEMs alike, and the emergence of businesses like Tesla, Rivian, and GM that accelerate innovation and growth across the entire EV market. These companies are also making considerable investments in and developing an EV ecosystem around charging infrastructure and advancing generation batteries while using high-performance adhesive materials in their manufacturing and assembly processes.

Europe Electric Vehicle Adhesives Market Trends

The European region will also have a steady growth and shall have an increase in the amount of revenue generated through the sales of electric vehicles during the forecast period. It shall be an increase in the demand for adhesives in the European region as there has been an increased adoption of policies that support the manufacturing of electric vehicles and the purchase of electric vehicles. Constant research and development activities are focusing on providing cost effective electric vehicles. Major manufacturing companies are focusing on reducing the price of electric vehicles and bring them down to the fuel based vehicles. All of these factors are expected to create a great demand for electric vehicle or diesels during the forecast period. Many major manufacturers of electric vehicles are also concentrating on improving their technologies for the production of electric vehicles and they're also focusing on coming up with composite materials which shall be helpful in preventing the corrosion.

Germany is the largest country for electric vehicle adhesive in the Europe market. Germany has a highly advanced automotive sector and a commitment to electrification. In June 2025, Germany has launched a comprehensive incentive package to boost electric vehicle (EV) adoption and accelerate the country's climate and infrastructure goals. This government initiatives driving electric vehicle adoption. Companies like Volkswagen, BMW, and Mercedes-Benz need to adopt lightweight and thermally conductive adhesives into their EV platforms to meet emission targets, improve vehicle safety, and enhance battery efficiency and durability.

A Deep Dive into the Latin American Emerging Electric Vehicle Adhesives Market

The Latin American electric vehicle adhesives market is gaining momentum due to rising urbanization, environmental awareness, and supportive government policies promoting EV adoption. Brazil, Mexico, and Argentina are becoming key automotive manufacturing hubs, attracting global OEMs and suppliers to enhance vehicle efficiency and range. Adhesives are increasingly replacing traditional mechanical fasteners across applications such as body panels, interiors, and structural components, driving demand for lightweight, high-performance bonding solutions.

Brazil leads the Latin American electric vehicle adhesives market, fueled by a rebound in vehicle production and supportive policies like the Inovar-Auto program promoting advanced, efficient vehicles. Growing consumer preference for high-performance, durable adhesives that reduce vehicle weight is driving adoption, while manufacturers are introducing innovative bonding solutions. Additionally, regulatory trends toward low-VOC and bio-based chemistries align with global sustainability initiatives, further boosting market growth.

MEA Electric Vehicle Adhesives Market Analysis

The MEA electric vehicle adhesives market is poised for strong growth, driven by efforts to reduce fossil fuel dependence and expand EV infrastructure, including charging networks. South Africa is expected to lead in growth rate, while governments in Saudi Arabia and Morocco are promoting foreign investment and local EV manufacturing hubs. Adoption of advanced adhesives is further supported by the integration of complex electronic components in modern electric and hybrid vehicles.

Saudi Arabia's electric vehicle adhesives market is set for robust growth, fueled by the country's economic diversification and sustainability strategies. Investments in a domestic EV ecosystem, including a new EV company and a local EV metals factory, are strengthening local manufacturing capabilities. Government incentives and rising environmental awareness are accelerating EV adoption, driving demand for high-performance adhesives in critical applications such as battery assembly and sensor integration.

Value Chain Analysis

- Raw Material Supply & Processing

This stage involves producing key chemical components, such as resins and additives.

Key Players: BASF, Evonik, Arkema, Dow, DuPont. - Research and Development (R&D) & Product Formulation

This stage focuses on innovating adhesives tailored for EVs (thermal management, conductivity, etc.).

Key Players: Henkel, Sika, 3M, H.B. Fuller, Wacker Chemie. - Manufacturing and Production

This stage involves the mass production of adhesives in various forms (liquid, film, tape) with quality control.

Key Players: Henkel, H.B. Fuller, Sika, 3M, Wacker Chemie. - Distribution and Supply Chain Management

This stage ensures the delivery of adhesives to manufacturers and suppliers, often through direct collaboration.

Key Players: Henkel and Sika. - Application and Assembly (OEMs and Suppliers)

Adhesives are applied during EV manufacturing for components such as battery assemblies and body frames.

Key Players: Tesla, GM, Ford, BYD; LG Chem.

Top Companies in the Electric Vehicle Adhesives Market and Their Offerings

- Henkel: Structural adhesives and thermal interface materials (TIMs) for battery assembly and cell encapsulation.

H.B. Fuller: Adhesives for battery pack sealing, gasketing, electronics assembly, and lightweight encapsulation foams. - Sika AG: High-performance structural adhesives for body panel bonding, thermal management solutions, and sealing/damping materials.

- 3M: Specialty tapes and adhesives for lightweighting, EMI shielding, thermal management, and flame-retardant sealing solutions.

- Wacker Chemie AG: Silicone-based thermally conductive adhesives (TCAs) and potting compounds for battery systems and power electronics.

Other Key Players

- Ashland

- PPG Industries

- Permabond

- Bostik SA – An Arkema company

- L&L Products

- Jowat SE

Recent Developments

- In February 2025, LG Chem announced that it will collaborate with HL Mando, a leading Korean automotive parts maker, to co-develop adhesives for automotive electronic components. This move aims to expand LG Chem's presence in the automotive adhesive market. (Source:https://www.indianchemicalnews.com )

- In April 2025, Arkema launched a new line of biobased specialty additives aimed at enhancing sustainable coatings and adhesives products. Helene Pernot, Global Sustainability Marketing Director at Coating Solutions, said these innovations help customers meet sustainability and carbon footprint reduction goals. ( Source:https://worldbiomarketinsights.com)

- In April 2025, Covestro will launch an automated laboratory to accelerate the development of coating and adhesive formulations. The new facility will run around the clock and enable tens of thousands of tests per year – with the aim of optimizing formulations faster and more precisely. ( Source:https://www.european-coatings.com )

- In May 2024, Ahlen, Germany-based Polyurethanes Systems House of Dow announced the mechanical completion of its new VORATRONTM Polyurethanes Systems adhesive and gap filler production line. With this move, Dow will double the capacity of its VORATRONTM Polyurethane Systems product family. Allowing it to fulfill the growing demand for these materials in battery assembly solutions catering to the e-mobility market.

Segments Covered in the Report

By Vehicle

- Battery electric vehicle

- Plug in hybrid electric vehicle

By Application

- Exterior

- Interior

- Powertrain

By Resin

- Epoxy

- Silicon

- Polyurethane

- Acrylics

- Others

By Substrate

- Plastic

- Composite

- Metals

- Others

By Form

- Liquid

- Film & Tape

- Others

By End User

- Pack & module bonding

- Thermal interface bonding

- Battery cell encapsulation

- Others

By Geography

- North America

- Latin America

- Europe

- Asia-pacific

- Middle and East Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting