Strapping Materials Market Size and Forecast 2025 to 2034

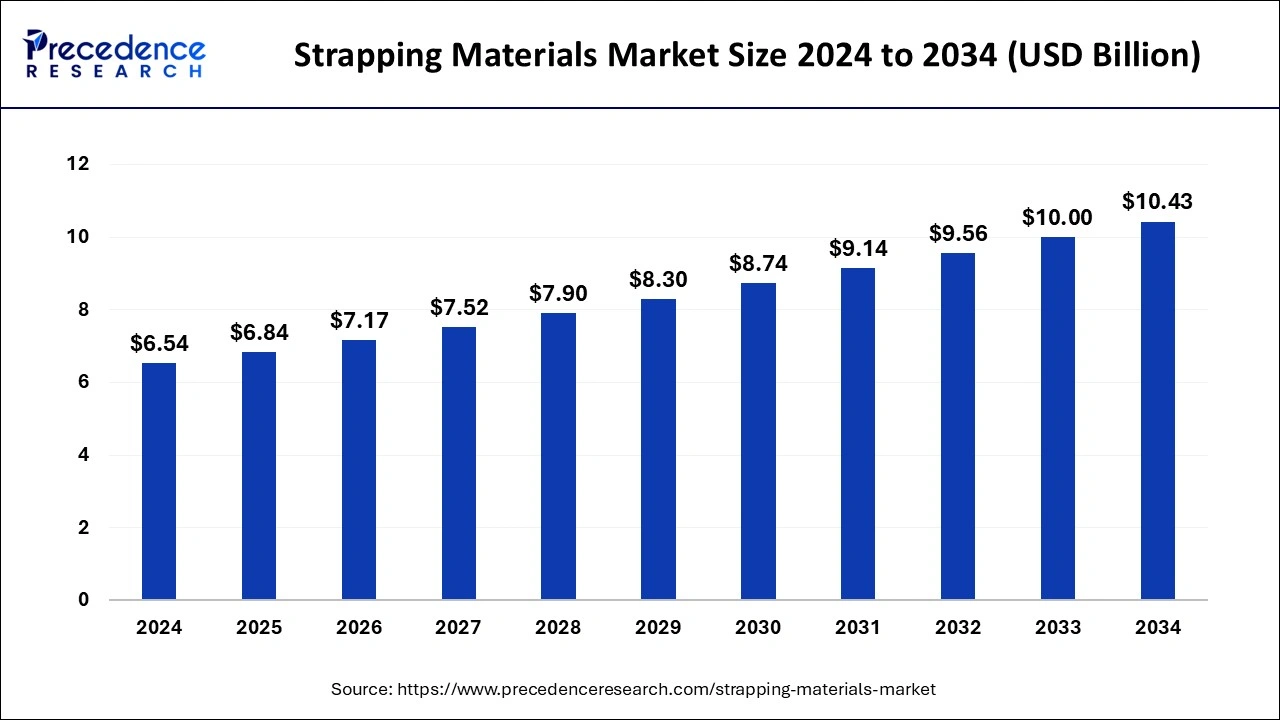

The global strapping materials market size was estimated at USD 6.54 billion in 2024 and is predicted to increase from USD 6.84 billion in 2025 to approximately USD 10.43 billion by 2034, expanding at a CAGR of 4.78% from 2025 to 2034.

Strapping Materials MarketKey Takeaways

- The global strapping materials market was valued at USD 6.54 billion in 2024.

- It is projected to reach USD 10.43 billion by 2034.

- The strapping materials market is expected to grow at a CAGR of 4.78% from 2025 to 2034.

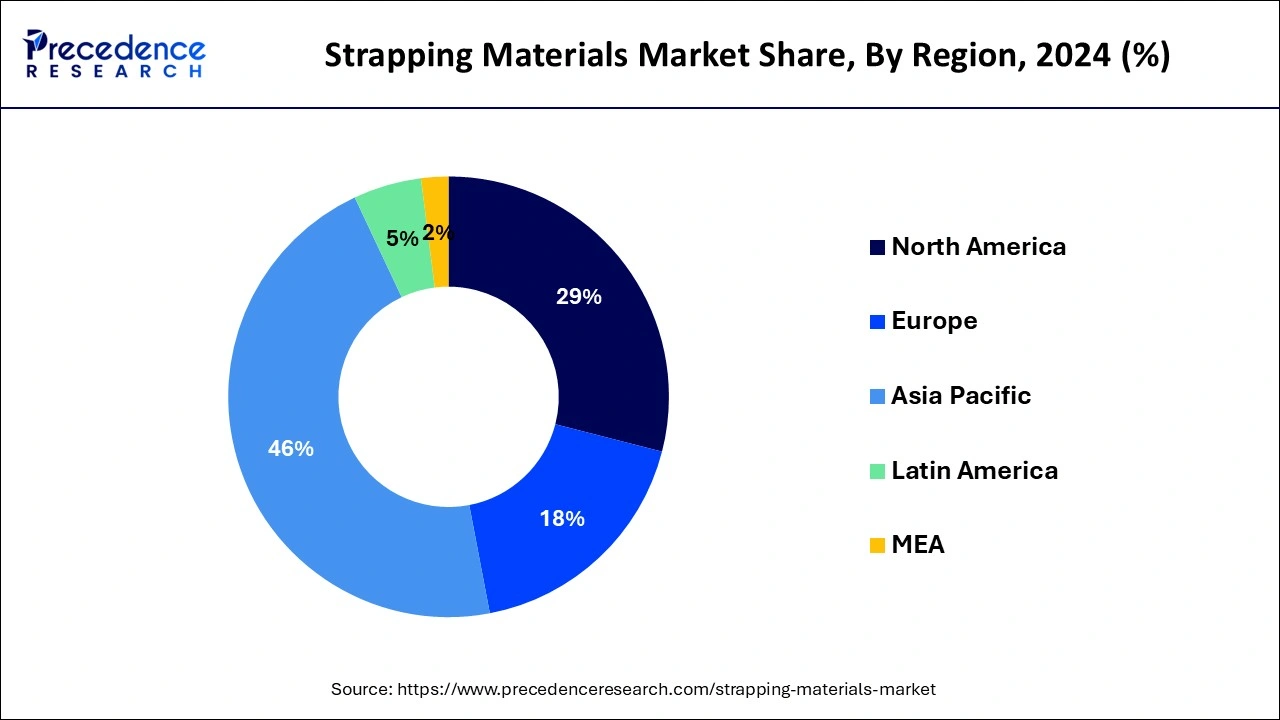

- Asia-Pacific contributed more than 46% of market share in 2024.

- North America is estimated to expand the fastest CAGR between 2025 and 2034.

- By product, the polypropylene (PP) segment generated over 48% of market share in 2024.

- By product, the polyester segment is anticipated to grow at a remarkable CAGR of 6.8% between 2025 and 2034.

- By application, the industrial logistics and warehouse segment generated over 29% of the market share in 2024.

- By application, the food & beverage segment is expected to expand at the fastest CAGR over the projected period.

Asia-PacificStrapping Materials Market Size and Growth 2025 To 2034

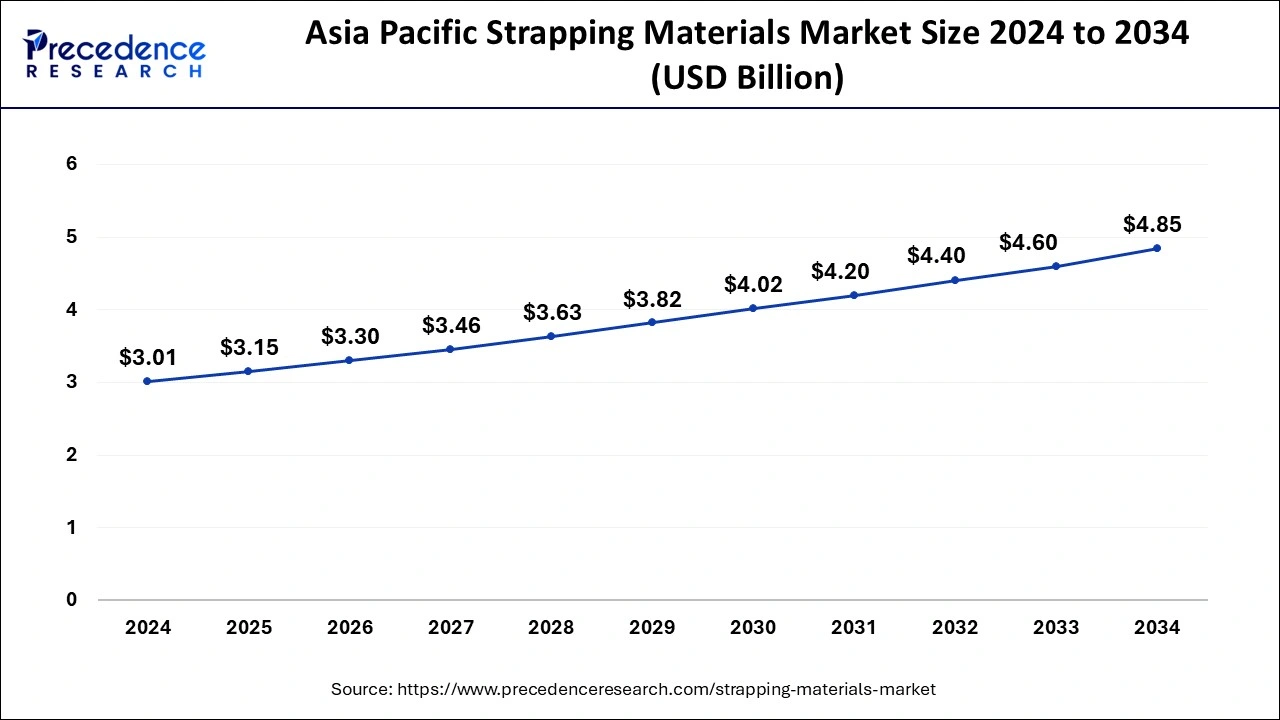

The Asia-Pacific strapping materials market size was valued at USD 3.01 in 2024 and is projected to hit around USD 4.85 billion by 2034, rising at a CAGR of 4.89% from 2025 to 2034.

North America is set for rapid expansion in the strapping materials market, fueled by a resurgence in manufacturing and a thriving e-commerce landscape. The U.S. witnessed a notable 4.9% increase in manufacturing output in 2021, highlighting the sector's strength. Moreover, the region's e-commerce market, with online sales reaching $834 billion in 2020, plays a pivotal role in driving the demand for secure packaging solutions. The growing emphasis on sustainable packaging practices adds an extra layer of opportunity, making North America a focal point for significant growth in the strapping materials industry.

Asia-Pacific held the dominating share of 46% in the strapping materials market, driven by robust economic activities and industrial growth. With Asia-Pacific accounting for 45% of global merchandise exports, the need for reliable strapping materials in international trade cements the region's dominance in the global strapping materials market.

In 2022, China's manufacturing output rose by 5.8%, contributing to increased demand for strapping materials. The region's e-commerce sector, valued at $2.8 trillion in 2021, further propels the market as secure packaging becomes essential for online retail.

Meanwhile, Europe is undergoing substantial growth in the strapping materials market due to a robust manufacturing sector and increased focus on sustainable packaging. The European manufacturing output witnessed a 3.4% rise in 2021, reflecting a strong industrial base. Furthermore, the region's commitment to environmental sustainability is driving the demand for eco-friendly strapping solutions. With the European e-commerce market expanding, reaching €717 billion in 2020, there is an increased need for secure packaging. These factors collectively position Europe as a significant player in the flourishing strapping materials market.

Market Overview

Strapping materials refer to a range of materials used in packaging and shipping to secure and bundle items together. Commonly made from materials like polypropylene, polyester, or steel, strapping is employed to reinforce and stabilize loads during transit. These materials come in various forms, including straps, bands, and tapes, providing versatility to accommodate different packaging needs. Polypropylene strapping is lightweight and suitable for securing light to medium-duty loads, while polyester and steel strapping offer higher tensile strength for more robust applications.

Strapping materials are essential for ensuring the integrity of packages, preventing damage, and facilitating efficient handling in the supply chain. The choice of strapping material depends on factors such as the weight and nature of the items being transported, with each type offering specific advantages in terms of strength, flexibility, and durability in securing goods for transportation and storage.

Strapping Materials Market Data and Statistics

- Germany serves as a crucial logistics center in Europe, capitalizing on its central location to offer logistics services to approximately 500 million residents across the continent.

- In the 2023 Logistics Performance Index report by the World Bank, Germany secured the 4th position, distinguishing itself as one of the top-performing countries with an impressive score of 4.1.

- Anticipated data from the Federal Logistics Association's Statistics Office suggests that Germany is poised for substantial growth in the logistics sector throughout the forecast period, driven by increased activity in air cargo and waterway transport.

Strapping Materials Market Growth Factors

- The boom in e-commerce industry and the rise in online retail activities contribute significantly to the growth of the strapping materials market. As more products are shipped across the globe, the need for reliable and secure packaging using strapping materials has surged.

- The expansion of manufacturing and industrial sectors, including automotive, electronics, and construction, drives the demand for strapping materials to secure and bundle goods for transportation. These materials play a crucial role in maintaining the integrity of products during transit and storage.

- The trend toward globalized supply chains necessitates robust packaging solutions to ensure the safe movement of goods over long distances. Strapping materials provide a reliable means to secure diverse products, fostering their use in international shipping and logistics.

- Ongoing advancements in strapping material technologies, such as the development of high-performance polymers and innovative composite materials, enhance the strength, durability, and sustainability of strapping solutions. These improvements contribute to the overall growth and adoption of strapping materials in various industries.

- Increasing awareness of sustainable packaging practices and stringent regulations regarding the transportation of goods have led to the adoption of strapping materials that are eco-friendly and compliant with regulatory standards. This shift towards environmentally friendly options stimulates market growth.

- The construction industry's expansion, particularly in emerging economies, fuels the demand for strapping materials for packaging construction materials. Straps are widely used to bundle and secure construction components, facilitating safe and efficient transportation to project sites. The construction boom contributes to the overall growth of the strapping materials market.

Market Scope

| Report Coverage | Details |

| Growth Rate from 2025 to 2034 | CAGR of 4.78% |

| Market Size in 2025 | USD 6.84 Billion |

| Market Size by 2034 | USD 10.43 Billion |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | By Product and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Expansion in manufacturing output

The expansion in manufacturing output significantly propels the market demand for strapping materials as industries seek reliable packaging solutions to ensure the secure transportation of their products.

With the global manufacturing output increasing by 3.9% in 2021, a diverse range of goods needs to be efficiently packaged for transit, emphasizing the critical role of strapping materials in this process.

Manufacturing sectors, including automotive, electronics, and consumer goods, rely on strapping materials to bundle and secure products, preventing damage during shipping and storage. Moreover, as manufacturing activities continue to grow, the demand for strapping materials is further heightened by the need for robust and adaptable packaging solutions. Strapping materials play a crucial role in maintaining the integrity of goods, reducing the risk of breakage or deformation, and facilitating streamlined logistics operations. This symbiotic relationship between the expansion in manufacturing output and the demand for strapping materials underscores the vital role these materials play in supporting the global supply chain and ensuring the safe delivery of manufactured goods to end consumers.

Restraint

Fluctuating raw material prices

Fluctuating raw material prices pose a significant restraint on the strapping materials market as they impact the production costs and overall profitability for manufacturers. The strapping industry relies on materials such as plastics and metals, which are susceptible to price volatility influenced by factors like global market conditions, geopolitical events, and supply chain disruptions. These fluctuations create uncertainty in production planning and can result in increased operational costs, subsequently affecting the pricing of strapping materials. Moreover, the ripple effect of fluctuating raw material prices extends to end-users, influencing their purchasing decisions. When manufacturers face increased costs, they may be compelled to pass on the burden to consumers through higher prices for strapping materials. This can lead to a reduced demand for strapping materials as businesses seek cost-effective alternatives or adjust their packaging strategies, impacting the overall market dynamics. The strapping materials industry thus grapples with the challenge of navigating these unpredictable raw material price fluctuations to maintain competitiveness and sustained demand.

Opportunity

E-commerce packaging solutions

The exponential growth of the e-commerce sector is a significant driver of opportunities in the strapping materials market. As e-commerce continues to thrive globally, there is an escalating demand for efficient and secure packaging solutions to safeguard products during transit. Strapping materials play a crucial role in meeting this demand by providing a reliable means to bundle and secure goods, preventing damage and ensuring the integrity of shipments throughout the e-commerce supply chain. The surge in online retail activities necessitates specialized strapping solutions tailored to the unique requirements of e-commerce packaging. With the diverse range of products being shipped, from electronics to apparel, the strapping materials market can capitalize on this trend by offering customizable and high-performance strapping solutions. As e-commerce becomes an increasingly dominant force in retail, the strapping materials industry has the opportunity to grow in tandem with the evolving needs of this dynamic market, providing secure and adaptable packaging solutions for businesses operating in the digital commerce landscape.

Product Insights

In 2024, the polypropylene (PP) segment had the highest market share of 48% on the basis of the product. Polypropylene (PP) strapping is a versatile and widely used segment in the strapping materials market. It is a type of thermoplastic polymer strapping known for its lightweight, cost-effectiveness, and excellent tensile strength. PP strapping finds extensive application in securing light to medium duty loads across various industries. A notable trend in the polypropylene strapping segment is the increasing demand for sustainable and eco-friendly options, driving innovation in the form of recyclable and bio-based PP strapping materials to align with the industry's growing emphasis on environmental responsibility and green packaging solutions.

The polyester segment is anticipated to expand at a significant CAGR of 6.8% during the projected period. The polyester segment in the strapping materials market refers to strapping materials made from polyester, a synthetic polymer known for its high tensile strength and durability. Polyester strapping is widely used for heavy-duty applications, offering excellent resistance to harsh environmental conditions. A notable trend in this segment is the increasing adoption of polyester strapping over traditional materials like steel due to its superior performance, cost-effectiveness, and reduced environmental impact, aligning with the growing demand for sustainable and efficient packaging solutions in various industries.

Application Insights

According to the application, the industrial logistics and warehouse segment has held 29% market share in 2024. In the strapping materials market, the industrial logistics and warehouse segment pertains to the use of strapping materials for securing and bundling goods within industrial settings and storage facilities. This includes applications in logistics operations, where strapping materials play a pivotal role in stabilizing loads for transportation. Current trends in this segment involve the adoption of high-strength and technologically advanced strapping materials to enhance efficiency, reduce product damage, and meet the evolving demands of modern industrial and warehouse logistics.

The food & beverage segment is anticipated to expand fastest over the projected period. In the strapping materials market, the food and beverage segment involves the use of strapping materials for bundling and securing packaging in the production and distribution of food and beverage products. As a critical component of supply chain logistics, strapping materials ensure the safe transport of packaged goods, preventing damage and maintaining product quality. A notable trend in this segment is the increasing adoption of sustainable and food-grade strapping materials, aligning with the industries focus on eco-friendly packaging practices and consumer preferences for safe and environmentally conscious solutions.

Strapping Materials Market Companies

- Signode Packaging Systems

- Crown Holdings, Inc.

- Polychem Corporation

- FROMM Packaging Systems

- Samuel, Son & Co., Limited

- Dynaric, Inc.

- Mosca GmbH

- Teufelberger

- Auto Strap India

- Linder Seevetal

- PAC Strapping Products, Inc.

- Strapex Group

- Midfield Industries

- Messersì Packaging S.r.l.

- Dubose Strapping, Inc.

Recent Developments

- In March 2023, EAM-Mosca Corp., a subsidiary of Mosca GmbH, unveiled a sales and marketing partnership with Spain's Reisopack S.L. Per the agreement, EAM-Mosca exclusively offers Reisopack's strapping systems and OEM parts to clients in the United States, Mexico, Canada, and Brazil.

- In December 2022, Signode launched a new BST battery-powered tool designed for sealless strapping, enhancing load security and stability for heavy-duty tension requirements.

- In February 2023, Samuel Son & Co. announced the inauguration of a cutting-edge 350,000-square-foot Greenfield facility in Mexico, strategically positioned to cater to the growing needs of its expanding customer base.

Segments Covered in the Report

By Product

- Steel

- Polypropylene (PP)

- Polyester (PET)

By Application

- Food & Beverage

- Industrial Logistics & Warehouse

- Corrugated Cardboard & Paper

- Newspaper & Graphics

- Building & Construction

- Metal

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting