What is Plastics Market Size?

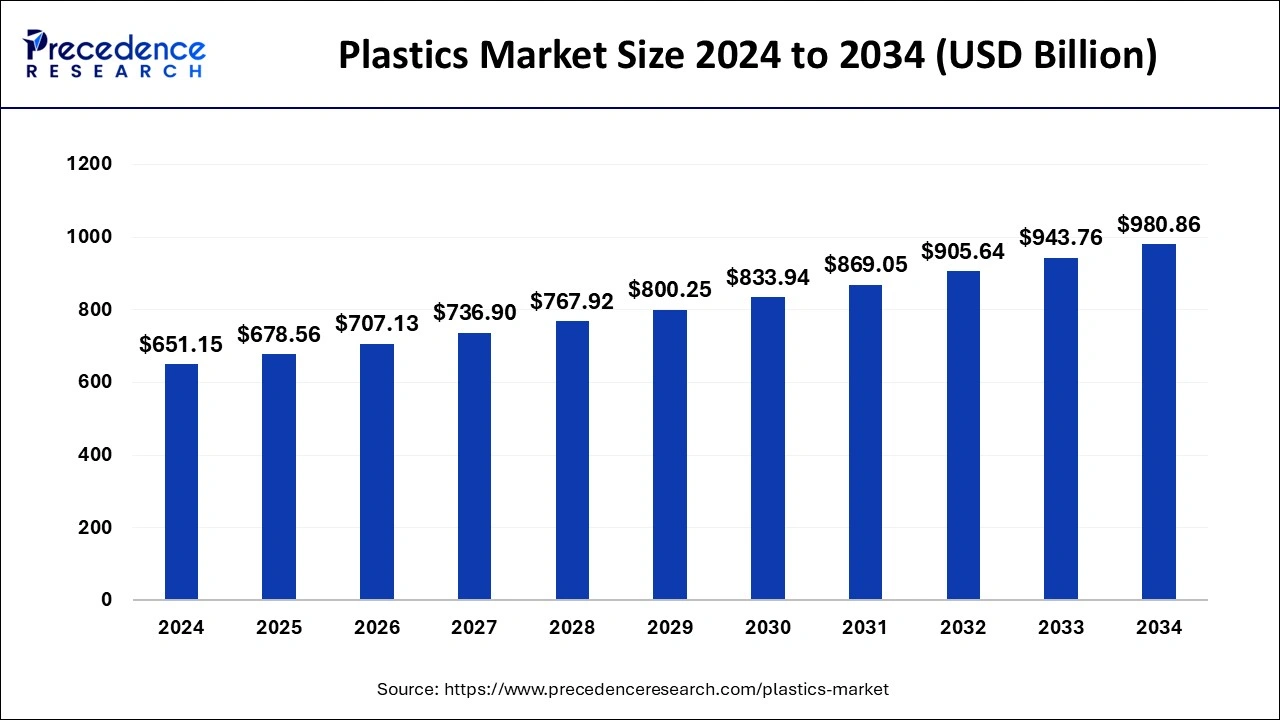

The global plastics market size is estimated at USD 678.56 billion in 2025 and is predicted to increase from USD 707.13 billion in 2026 to approximately USD 980.86 billion by 2034, expanding at a CAGR of 4.18% from 2025 to 2034. The primary reasons behind this market's growth are a rise in the automotive, packaging, manufacturing, and construction industries.

Market Highlights

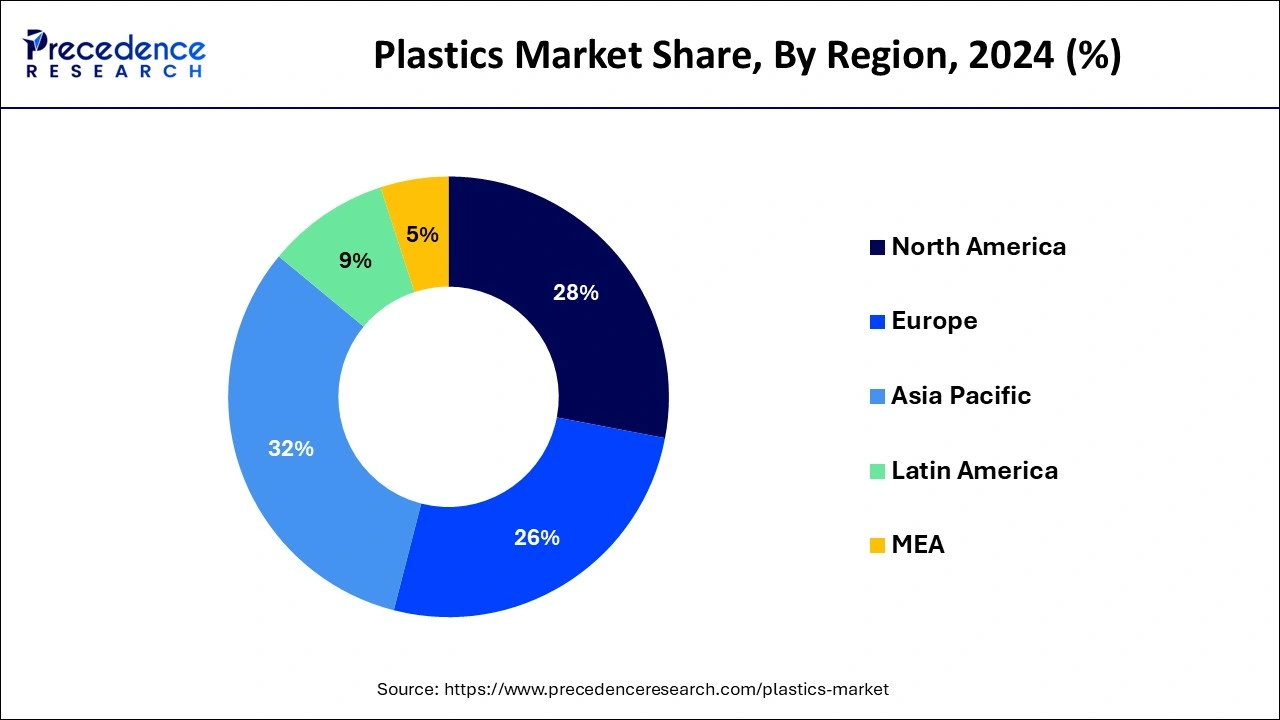

- Asia Pacific dominated the plastics market in 2024.

- Europe will establish a significant presence in the global market during the forecast period.

- By product, the polyethylene segment dominated the market in 2024.

- By product, the polypropylene is projected to be the fastest growing segment in the market.

- By application, the injection molding segment dominated the market by application in 2024.

- By application, the thermoforming segment is expected to witness the fastest growth in the market during the forecast period.

- By end-use, the packaging segment dominated the market in 2024.

- By end-use, the building & construction segment will expand substantially during the forecast period.

Plastics Market: Unlocking the Plastic Potential

Plastics are polymers that are widely used because they are versatile, lightweight, flexible, and easily moldable. Plastics are used in the making of containers, automobiles, stationery items, household items, and construction, and the list of uses is never-ending. Plastics are made of petroleum. There are several advancements that also produce eco-friendly plastics that can be made from corn or cotton cellulose. These plastics are durable and biodegradable as well.

It is lightweight and strong. Research and development are constantly working on improving plastic strength. Being easily moldable, it has many applications. Its flexibility allows innovations in packaging, construction, electronics, and many other industries. Plastics are cost-effective, and the production of plastics can cost less than metal or glass. The cost advantage ensures that plastic is accessible and affordable to many customers and businesses. Hence, it promotes economic development. Plastic containers and packaging are used for food delivery, as they also help preserve the shelf life of food. This quality is helpful for the pharmaceutical industry. Plastic, being lightweight, also saves fuel and reduces transportation costs.

According to data published by the Organisation for Economic Co-operation and Development Report 2023, Plastic consumption has quadrupled over the past 30 years, driven by growth in emerging markets. Global plastics production doubled from 2000 to 2019 to reach 460 million tonnes. Plastics account for 3.4% of global greenhouse gas emissions. Global plastic waste generation more than doubled from 2000 to 2019, to 353 million tonnes. Nearly two-thirds of plastic waste comes from plastics with lifetimes of under five years, with 40% coming from packaging, 12% from consumer goods, and 11% from clothing and textiles. Only 9% of plastic waste is recycled (15% is collected for recycling, but 40% of that is disposed of as residues).

Plastics Market Growth Factors

- Plastic is versatile and light and can be used as a substitute for a wide variety of products.

- Ability to reuse and recycle plastic products to some extent.

- Helps in the growth of a large number of industries due to its multifaceted applications

Plastics Market Outlook: Forecasting the Plastic Trends

- Industry Growth Overview: The growing demand for packaging, healthcare, automotive, and construction is driving the industrial growth in the market.

- Major Investors:Global institutional asset managers and private equity firms are the major investors in the market.

- Startup Ecosystem: The development of bio-based or alternative materials and AI-based waste management systems is the focus of the startup ecosystems.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 678.56 Billion |

| Market Size in 2026 | USD 707.13 Billion |

| Market Size by 2034 | USD 980.86 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 4.18% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | By Product, By Application, and By End-use, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Multipurpose applications

Plastic is heavily used in innumerable places, and the list of uses can be never-ending. We have so much plastic being used around us, but we just don't notice it much. From a plastic pen to a plastic body in a car, there are so many places and things where plastic plays a major role. Plastics are lightweight, and more focus is given to making them stronger and more durable. They are used in aircraft and automobiles to make the vehicles more fuel efficient. Of the entire car volume, 50% is plastic, and it comprises a very small proportion of car weight. When cars consume less fuel, it also contributes to less CO2 emission. Plastics are bad conductors of electricity and are used in electrical appliances to insulate cables and wires.

Restraint

Environmental harm and pollution

The biggest restraint in the plastics market is the pollution it causes. Plastic gained dominance in the 20th century and then gave rise to many problems. This was because plastics decompose at an extremely slow rate (They almost don't decompose at all). There used to be a lack of knowledge regarding plastic recycling; however, even today, a large amount of plastic goes unrecycled and is decomposed. This gives rise to many environmental problems. Many users don't recycle because recycling can be more expensive than producing fresh plastics. The unrecycled plastic keeps accumulating in landfills and can affect aquatic habitats.

According to the Organisation for Economic Co-operation and Development (OECD), there was a plastic waste leakage of 6.1 million tonnes and 1.7 million tonnes into the oceans. At this moment, there are around 30 million tonnes of plastic waste in seas and oceans. There is a further accumulation of 109 million tonnes in rivers.

Limitations in recycling

Although plastics are known for their flexibility and the property of being molded, there are several plastics that cannot be recycled, as they undergo certain chemical changes after being freshly made and can lose their properties if one tries to remold them. Hence, such plastics have to be discarded and cannot be recycled. For example, thermoset plastics have irreversible bonds that cannot be recycled. Such plastics can keep accumulating in the environment and lead to serious environmental problems. Hence, the disposal of such plastics is a challenge in itself.

Opportunities

Growth in the automotive sector

Plastics have a wide range of uses. Apart from the long list of uses where plastic is used, the automotive industry shows a heavy use of plastics. Plastics comprise around 50% of the entire automotive volume and only 10% of the vehicle's weight. Plastic is lightweight and hence reduces fuel consumption, saving money and the environment. The car interior, seat covers, fabrics, and many other components in an automobile are made of high-quality plastic.

A boost in the construction industry

Plastic is irreplaceable in the construction industry. Cables, wires, bathwares, pipes, and many more things in the construction industry are made up of plastics. They are lightweight and strong, so transporting them is an easy task. Unlike metals, they are corrosion resistant. They can be easily installed and fitted, as many plastics have snap-fit-lock systems because of the flexibility offered by plastics. Many pigments can be added to plastics, and they are available in a range of vibrant colors. They are good insulators and are widely used in electric appliances, wires, and cables. Plastics are easy to see and nail, and they can be removed easily as well.

Segment Insights

Product Insights

The plastics market was dominated by the polyethylene segment. Polyethylene is the most common and popular type of plastic. It is used in shopping bags, bottles, and toys, and a large proportion of the plastic market is covered by polyethylene. It is highly ductile and flexible. It gets stretched but does not break because of strength. Polyethylene is water resistant and has a high durability. It is a good insulator and is used in wiring or cables. Low-density polyethylene has good transparency and is used in packaging. Polyethylene can be recycled, too.

The polypropylene segment is projected to be the fastest growing segment in the plastics market. Polypropylene is the second most popular plastic. Polypropylene does not react with acids and, hence, is used as a container for acids. Since it doesn't corrode, polypropylene is used in pipes. It also has a good resistance against freezing. It is easily moldable, and this process of remolding can be done many times. It is highly impermeable to water and is hence used in products like raincoats. Polypropylene is also used to carry huge loads, as it has a high tensile strength.

Application Insights

The injection molding segment dominated the plastics market in 2024. Injection molding is a process where plastic granules or powder are put into a machine, which is then further melted and processed to make finished plastic products. Injection molding has a higher accuracy rate and works at a high efficiency. Every cycle is completed in only around 2 minutes. It is cost-saving as well. Higher efficiency allows the production of more products in a short time. Due to high accuracy and precision, injection molding is used to produce complex machine parts. The parts produced have high strength. Various vibrant colors can be added while processing to produce aesthetic products. Labor costs are low in injection molding.

The thermoforming segment is expected to witness the fastest growth in the plastics market during the forecast period. In this process, plastic is formed into sheets and then trimmed to make products. This process is useful for huge plastic products, and the molding process can be versatile, unlike other processes of plastic molding limited to smaller items. Almost all types of plastics are suitable for thermoforming. Thermoforming is a simpler technology where one can create high-quality products in a short time span.

End-use Insights

The packaging segment dominated the plastics market in 2024. Packaging is a booming market because of a rise in e-commerce business. The packaging industry is expanding in personal and household care, food and beverage, pharma, and several other industries. Plastic is lightweight and flexible, and several e-commerce companies package the goods in high-quality plastic packaging, which ensures that the product is not damaged. Plastics are also engineered so that they can withstand extreme environments and temperatures and preserve product quality. The packages can also be printed, and this makes them good packaging material.

The building & construction segment will expand substantially during the forecast period. Plastic is lightweight and strong. It can be transported easily to construction sites. The products don't corrode easily. Acrylic is highly used because of its optical clarity, resistance to scratches, and rigidness. It is used for LCD screens, windows, and other applications. Composites are made up of two or more constituents that improve the characteristics of the combined product. Polycarbonate is used to create sustainable plastic building supplies. It is a plastic that can be melted and recast several times. It has a high level of optical clarity.

Regional Insights

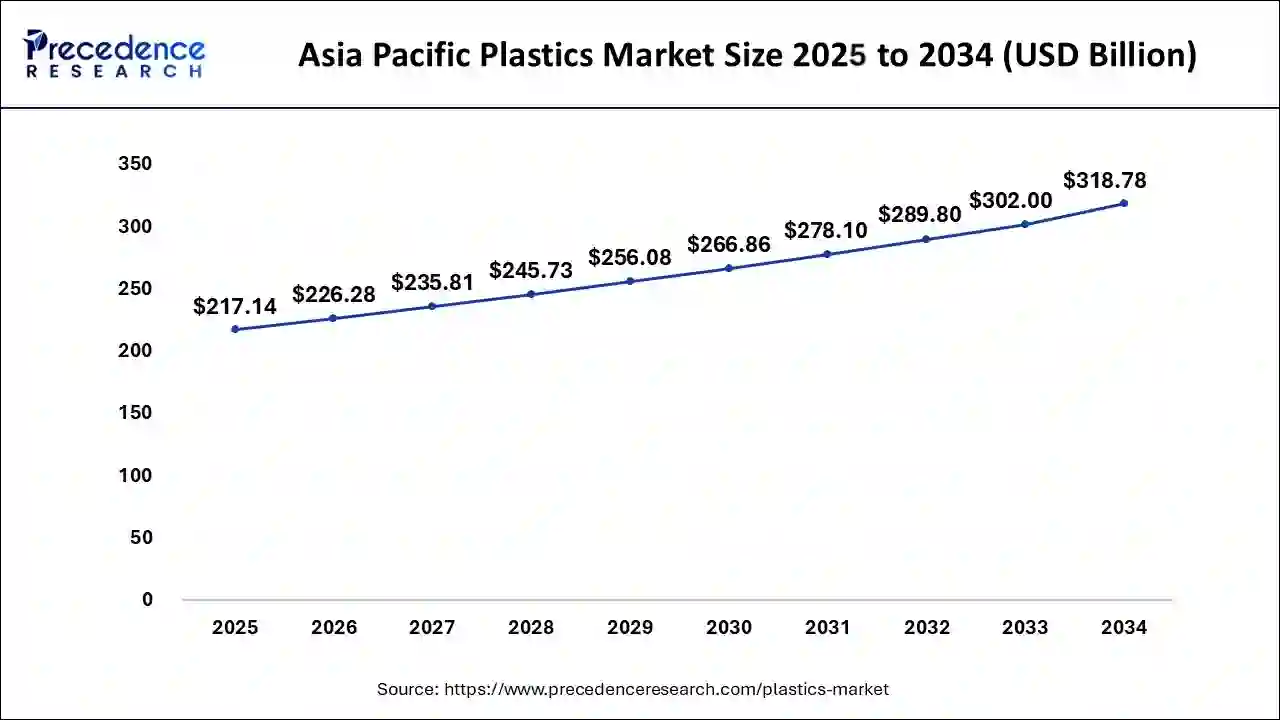

Asia PacificPlastics Market Size and Forecast 2025 to 2034

The Asia Pacific plastics market size is estimated at USD 217.14 billion in 2025 and is predicted to be worth around USD 318.78 billion by 2034, at a CAGR of 4.34% from 2025 to 2034.

Asia Pacific Driven by Growing Population

Asia Pacific dominated the plastics market in 2024. Asia Pacific has countries that are leading in terms of population, like India and China. With a rising population, packaging, manufacturing, automotive, and other industries requiring plastics are in high demand. China is the top manufacturer of EVs, and there is a high need for plastic in making these vehicles.

Expanding E-Commerce Propel India

In India, it can be seen that e-commerce is boosting, as Amazon, Flipkart, and food delivery apps like Zomato and Swiggy have started to give services in rural and remote areas as well. These services require a lot of plastic for packaging purposes and ensure that the product's quality is maintained. Thus boosting the plastics market in the region.

Large Plastic Production Hub Drives Europe

Europe will establish a significant presence in the global plastics market during the forecast period. Europe is one of the largest producers of plastic. In order to prevent plastic pollution, Europe is also getting active in recycling plastic. Recycling plastics is helping to reduce the piles in landfills and keep up with plastic production in Europe. Plastics are in high demand in Europe for packaging, building, development, construction, automotive, and many more industries.

The region actively participating in recycling plastic is expected to propel the market's revenue in the coming years. For instance, according to Plastics Recyclers Europe, as of March 2023, Europe has more than 730 recycling sites, and the total capacity in EU27+3 now stands at 11.3 million tonnes. This shows that the plastic recycling sector is an important employment generator with more than 30,000 persons across Europe, and with €8.7 billion in turnover, it contributes substantially to the socio-economic welfare in the region. Installed plastic recycling capacity has grown by 17% in 2021 in EU27+3, boosted by an estimated €1.75 billion investment.

In total, 26.9% of European plastic waste is now recycled meaning that, for the first time, more plastic waste is recycled than is put into landfills; an important milestone in Europe's plastics circularity journey. The report found that in 2022, circular plastics were produced from several sources: the largest source (13.2% of all plastics produced) was mechanically recycled, while only 1% came from bio-based feedstock, and 0.1% was chemically recycled.

- According to the European Association of Plastic Manufacturers, plastic waste recycling has increased by around 80% in the past ten years in Europe.

In Europe, the UK led the market by holding the largest market share owing to the strong plastic demand from major sectors such as automotive, packaging, and construction, along with the innovations in moulding technologies moulding technologies. Consumers in the region are rapidly seeking eco-friendly and sustainable alternatives impelling major players towards biodegradable plastics and recycled content.

Advanced Industries Drive North America

North America is expected to grow significantly in the plastics market during the forecast period, due to the presence of advanced industries, like construction, healthcare, electronics, automotive, etc. This is increasing use of plastics for various applications is driving their production rates, where plastic from sustainable materials are also being developed, which are supported by government initiatives, promoting the market growth.

Latin America is expected to grow at a notable CAGR over the forecast period. The growth of the region is credited to the growing demand for sustainable and convenient packaging solutions, durable and cost-effective plastic containers, and Innovations in manufacturing technologies. Furthermore, growing automotive manufacturing in countries such as Venezuela and Brazil is driving the demand for blow-moulded plastics.

Growing Populations Spark Brazil Market

Due to a growing population in Brazil, the demand for plastic from packaging to the construction sectors is increasing. The expanding industries are increasing their development, which is further being supplied to the automotive, electronics, and construction industries. The presence of raw materials is enhancing their production.

Domestic Demand Shapes U.S.

The growth in the domestic demand through online platforms is increasing the use of plastic for packaging, medical products, and electronics. They are increasingly being used in the automotive and aerospace sectors. Additionally, biodegradable plastics are also being developed to comply with the government initiatives.

MEA Powered by Petroleum Feedstock

MEA is expected to grow in the plastics market during the forecast period, due to the presence of petroleum feedstock driving the production of plastics. The expanding industries and urbanization are increasing the use of plastics for various purposes. The growing investment and sustainability trends are increasing their advancements as well.

Value Chain Analysis

- Feedstock Procurement The feedstock procurement of plastics involves the procurement of materials like crude oil and natural gas from a global network of energy producers and refiners.

Key players: SABIC, Dow Inc., Exxon Mobil Corporation. - Quality Testing and Certification The quality, safety, performance, and their specific requirements are tested in the quality testing and certification of plastic.

Key players: SABIC, Dow Inc., Exxon Mobil Corporation. - Regulatory Compliance and Safety Monitoring The regulatory compliance and safety monitoring of plastic involves ensuring compliance with standards of health, safety, and the environment.

Key players: SABIC, Dow Inc., Exxon Mobil Corporation.

The Plastics Market Game Changers: Key Players' Offering

- SABIC: The company provides PE, PP, PC, and advanced thermoplastics

- Dow, Inc.: PE, polyurethane components, epoxy resins, acrylics, and silicones are provided by the company.

- Exxon Mobil Corporation: PE, PP, specialty elastomers, and butyl polymers are provided by the company.

- INEOS Group: The company provides PVC, PE, PP, styrenics, and specialty chemicals.

- LyondellBasell Industries Holdings B.V.: The company provides PE, PP, catalysts, and adhesives.

Recent Developments

- In April 2025, India launches plastic parks to boost industry. Under the Scheme for Setting up Plastic Parks, the Department of Chemicals and Petrochemicals aims to create a state-of-the-art infrastructure that supports the domestic downstream plastic processing sector. This initiative not only seeks to increase investment and production but also aims to generate employment.(Source: https://observervoice.com)

- In February 2025, Industry giants launch an automotive plastics recycling project.BASF, Sabic, Covestro, Clariant, LyondellBasell, Mitsubishi Chemical Group, and Solvay join forces with Global Impact Coalition to recycle plastics from end-of-life vehicles in the pilot project.

(Source: https://www.sustainableplastics.com) - In December 2024, Symphony Environmental launched a biodegradable resin for plastics The company says its new resin reduces the fossil content of plastic and can be recycled but biodegrades within months if it escapes into the natural environment. NbR comprises 20 percent non-fossil natural compounds and is suitable for making a wide variety of packaging.(Source: https://www.recyclingtoday.com)

- In April 2023, Kuraray partnered with GC and Sumitomo Corporation to build a highly engineered plastic manufacturing plant to develop Thailand's industrial capabilities in the Eastern Economic Corridor region under the name of Kuraray GC Advanced Materials Co., Ltd. and Kuraray Advanced Chemicals (Thailand) Limited. This facility is likely to support the government's policy of promoting the development of the ECC region to support industrial progress.

- In December 2024, Symphony Environmental Ltd., a United Kingdom-based packaging technology company launched biodegradable resin for plastics industry. The new product, branded NbR, is made with natural minerals to reduce the amount of fossil-derived polyethylene (PE) or polypropylene (PP) used, and it has been formulated to biodegrade safely in nature.

- In April 2025, Engel unveiled an injection molding machine manufacturing plant in Mexico. With a capacity to produce between 180 and 200 injection molding machines per year.

- In August 2024, Igus, a German motion plastics company, announced its plan to invest worth ?100 crore to set up a 92,000 sq ft manufacturing plant in Mandur near Budigere in Bengaluru.

- In April 2024, LyondellBasell revealed the inauguration of a plastic recycling venture in Zhaoqing, Guangdong Province, South China, in collaboration with Genox Recycling. The company will recycle plastic waste and generate new polymers.

Segments Covered in the Report

By Product

- Polyethylene (PE)

- Polypropylene (PP)

- Polyurethane (PU)

- Polyvinyl Chloride (PVC)

- Polyethylene Terephthalate (PET)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polybutylene Terephthalate (PBT)

- Polyphenylene Oxide (PPO)

- Epoxy Polymers

- Liquid Crystal Polymers (LCP)

- Polyether Ether Ketone (PEEK)

- Polycarbonate (PC)

- Polyamide (PA)

- Polysulfone (PSU)

- Polyphenylsulfone (PPSU)

- Others

By Application

- Injection Molding

- Blow Molding

- Roto Molding

- Compression Molding

- Casting

- Thermoforming

- Extrusion

- Calendering

- Others

By End-use

- Packaging

- Building & Construction

- Electrical & Electronics

- Automotive

- Medical Devices

- Agriculture

- Furniture & Bedding

- Consumer Goods

- Utility

- Others

By Region

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting