Aerospace Insulation Market Size and Forecast 2025 to 2034

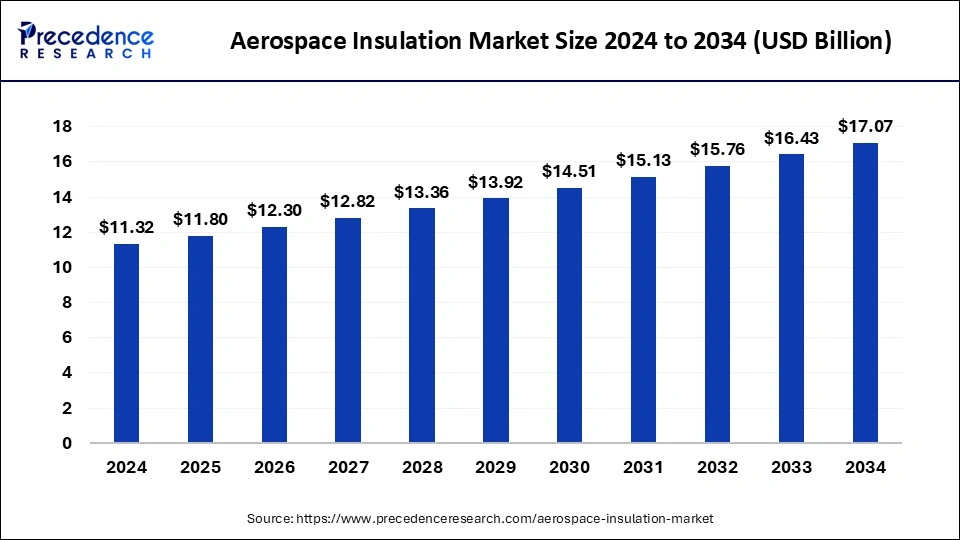

The global aerospace insulation market size was calculated at USD 11.32 billion in 2024 and is predicted to increase from USD 11.80 billion in 2025 to approximately USD 17.07 billion by 2034, expanding at a CAGR of 4.19% from 2025 to 2034. A rise in the fleet replacement rate, which replaces older aircraft with newer innovative models, is estimated to drive the growth of the global aerospace insulation market over the forecast period.

Aerospace Insulation Market Key Takeaways

- The global aerospace insulation market was valued at USD 11.32 billion in 2024.

- It is projected to reach USD 17.07 billion by 2034.

- The market is expected to grow at a CAGR of 4.19% from 2025 to 2034.

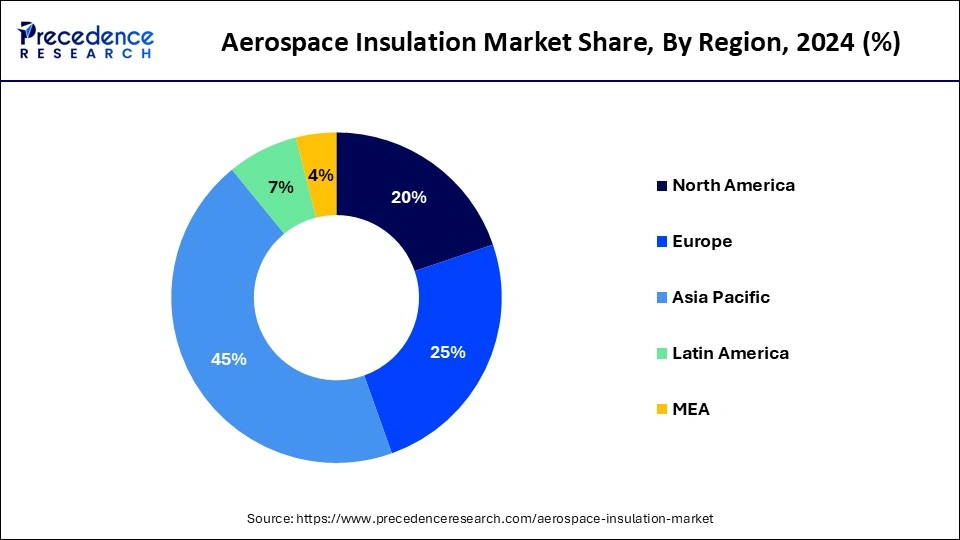

- The North America aerospace insulation market size reached USD 5.09 billion in 2024 and is expected to attain around USD 7.68 billion by 2034, poised to grow at a CAGR of 4.22% between 2025 and 2034.

- North America dominated the global aerospace insulation market with the largest revenue share of 45% in 2024.

- Asia Pacific is expected to fastest growing during the forecast period.

- By material, the ceramic segment has held a major revenue share of 53% in 2024.

- By material, the fiberglass segment is expected to grow at a remarkable CAGR of 4.80% over the forecast period.

- By product, the thermal insulation segment has contributed more than 69% of revenue share in 2024.

- By product, the electric insulation is projected to grow at a solid CAGR of 5.81% in the market over the forecast period.

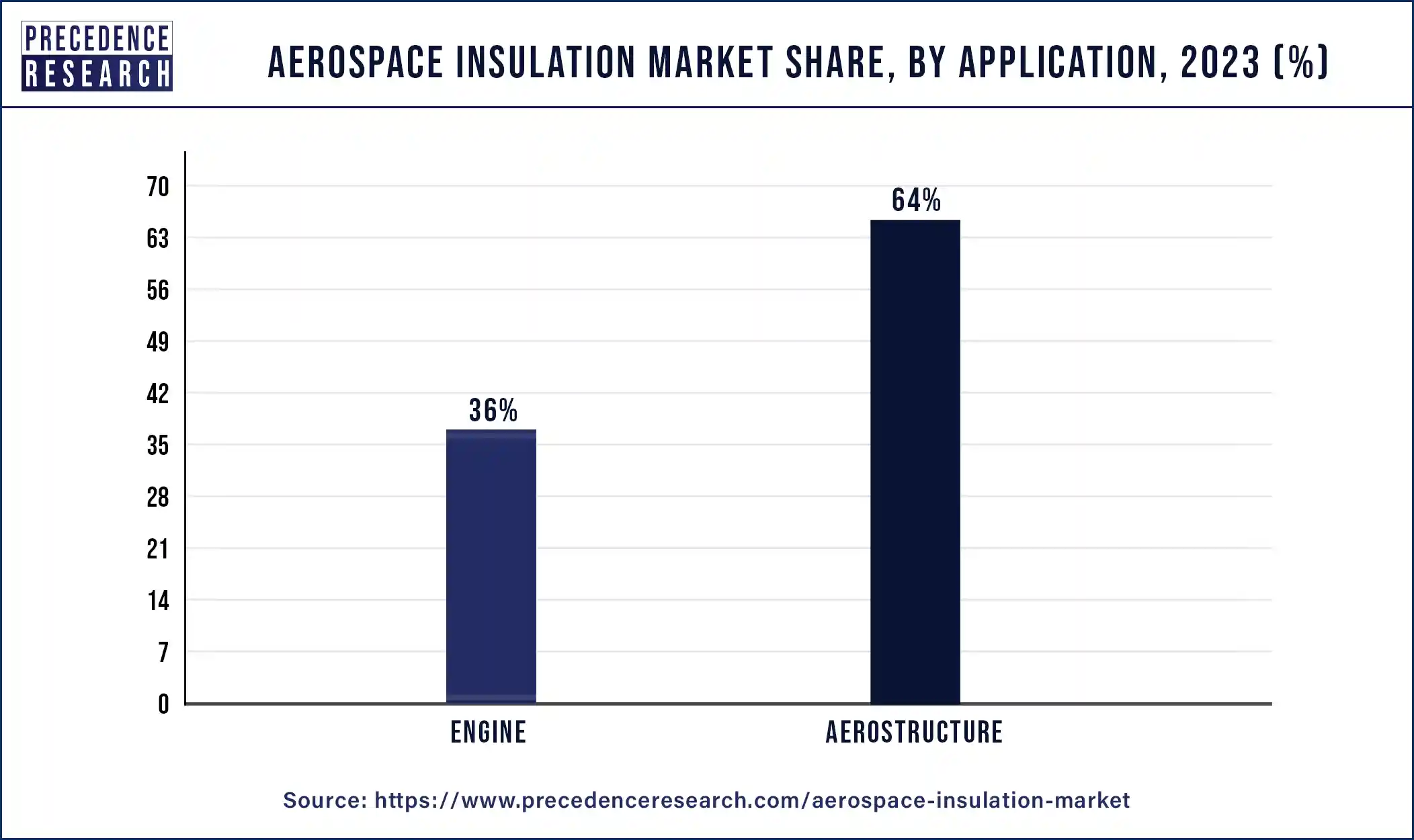

- By application, the aerostructure segment has recorded more than 64% of revenue share in 2024.

- By end-use, the commercial segment has generated more than 69% of revenue share in 2024.

- By end-use, the military segment accounts for a significant share of the market.

U.S. Aerospace Insulation Market Size and Growth 2025 to 2034

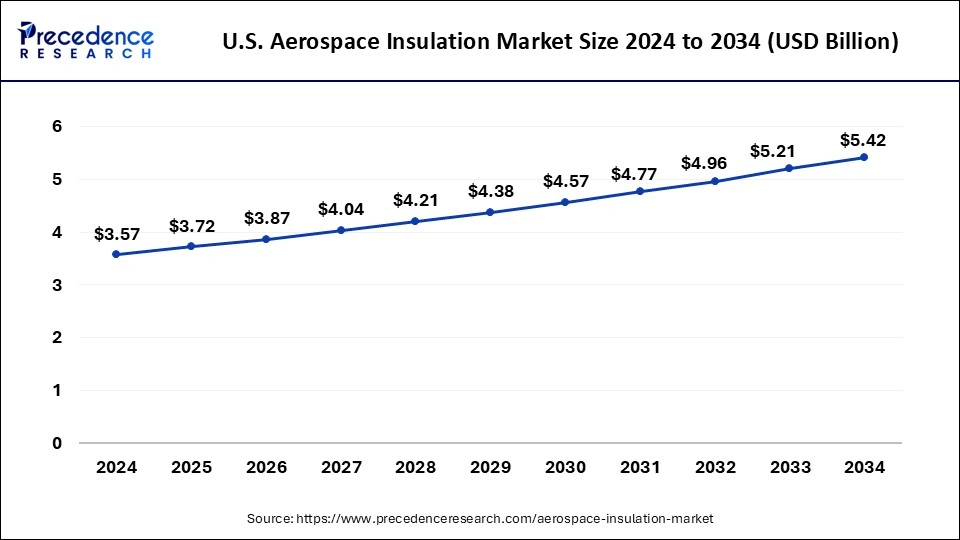

The U.S. aerospace insulation market size was exhibited at USD 3.57 billion in 2024 and is projected to be worth around USD 5.42 billion by 2034, growing at a CAGR of 4.26% from 2025 to 2034.

North America dominated the global aerospace insulation market in 2024. Due to rising fuel prices, the region is projected to see an increase in demand for fuel-efficient aircraft. Throughout the projected period, there will likely be arise in demand for aircraft insulation due to the growth of the developed aerospace industry fueled by the high replacement rate, mostly for regional aircraft.

Air travel is the recommended mode of transportation for travelers longer than 300 miles (480 km), such as business and long-distance vacationers, due to the topography of the United States and the generally great distances between major cities. Increasing research and development activity to meet the rising demand for commercial aircraft is expected to drive the growth of the aerospace insulation market over the forecast period in the region.

- As of 2020, there were 19,919 airports in the United States, of which 5,217 are classified for ‘public use,' which includes general aviation and other uses.

- In January 2024, the National Aeronautics and Space Administration, an independent agency of the U.S. federal government, and Lockheed Martin, a defense and aerospace company, revealed the X-59 quiet supersonic aircraft. With its design, shape, and technologies enabling it to fly at 1.4 times the speed of sound, or 925 mph, the X-59 is at the center of NASA's Quest mission, which focuses on providing data to help regulators reconsider rules that prohibit commercial supersonic flight over land.

Asia Pacific is expected to grow at a significant rate in the aerospace insulation market during the forecast period. Due to the emergence of the aircraft manufacturing industry in the region, emerging economies such as China, India, and Japan are playing a major role in driving the growth of the aerospace industry. This, in turn, is expected to drive the demand for aerospace insulation over the forecast period. Moreover, the increase in terrorist attacks, as well as the threat of war, has raised the demand and innovation of aircraft in the region.

Although aviation-grade aluminum alloy has historically been used extensively in the construction of GA aircraft models, carbon fiber reinforced polymer, or CFRP, is increasingly being used in the production of modern aircraft models. The markets for businesses that produce business aircraft are expanding, and these include China, and India. Improvements made to the interior of the business planes also drew in new clients. This creates a tremendous demand for insulating materials used in the aerospace industry, which are found in many business jet cockpits and other upscale equipment.

- In July 2024, Shenyang Aircraft Corporation (SAC), a manufacturing company, announced the introduction of the new J-31B "Gyrfalcon" stealth fighter. The J-31B has a significantly bigger appearance than the original FC-31 model of fighter aircraft.

- In January 2024, Air India Limited, a subsidiary of Tata Group enterprise, revealed a plan to introduce its newly admitted wide-body Airbus A350 aircraft on international routes by mid-2024.

Europe holds a significant share of the global aerospace insulation market due to the existence of significant manufacturers of corporate, military, and commercial planes. The general aviation sector is currently concentrating on growing its market share in Europe. The use of composite materials by airplane makers to provide noise-free cabins is a response to the growing demand for aircraft and the growth in passenger traffic.

Throughout the course of the forecast period, the expanding usage of aerospace insulation in the manufacturing of airplanes in Germany, France, the U.K., and other European countries is anticipated to fuel the growth of the regional market. Furthermore, increasing government initiatives and funding for the development of advanced technology aircraft is expected to drive the growth of aerospace insulation in Europe.

- In May 2024, Airbus SE, an aircraft manufacturing commercial company, initiated an innovative initiative on aviation hydrogen handling and refueling with cooperation from prominent industry companies, airport operators, and academic partners. Airbus has initiated an innovative initiative on aviation hydrogen handling and refueling to showcase small-scale liquid hydrogen aircraft ground operations at three European airports.

- In July 2024, Stellantis NV, a multinational automotive manufacturing corporation, and Archer Aviation, an aircraft company, revealed that Archer Aviation received an additional USD 55 million in investment funding from Stellantis NV company under the strategic funding agreement. This most recent investment expands upon Stellantis NV's previously disclosed open market acquisition of 8.3 million shares of Archer Aviation company's stock in March 2024.

Market Overview

The atmosphere and space are generally referred to as aerospace. There is a wide range of military, commercial, and industrial uses for aerospace activities. Aeronautics and astronautics are the two branches of aerospace engineering. Organizations dedicated to aerospace research, design, manufacturing, operation, maintenance, and repair of spacecraft and aircraft. Modern airplane designs must use aerospace insulation in order to improve fuel efficiency and guarantee passenger comfort and safety. Alloys made of aluminum, titanium, steel, and composite materials are the primary material types utilized in aeronautical structures. Apart from these materials, alloys based on nickel play a significant role in jet engine structural materials. For aircraft and aerospace vehicles, polymer's open-cell melamine foam offers superior thermal and acoustic insulation.

Some of the leading companies in the airplane insulation market include BASF SE, Polymer Technologies Inc., Triumph Group Inc., Boyd Corporation, and DuPont de Nemours, Inc. New insulating materials and other innovations will help the players land new contracts. Also, the players are concentrating on creating new insulation materials, namely thermal/acoustic insulations, due to the aviation industry's growing emphasis on lightweight components. Some of the top market players manufacturing acoustic insulation have been mentioned here as follows: Saint-Gobain S.A., Armacell International, Owens Corning, Rockwool A/S, Knauf, Kingspan Group, Autex, and Fletcher Insulation, among others.

Aerospace Insulation Market Growth Factors

- Globally, there is a growing need for business jet and general aviation services as a result of rising living standards, rising disposable income, and growing corporate and leisure flying. Consequently, there is now a greater need for light aircraft from the general aviation (GA) sector as well as private and corporate jets.

- Emerging markets are setting new trends for aerospace insulation, which is expected to drive the growth of the global aerospace insulation market over the forecast period.

- Increasing focus on cost reduction and production efficiency can drive the specialty market growth further.

- Increasing regulatory support is estimated to drive the growth of the global aerospace insulation market over the forecast period.

- The increasing launch of the new policy by the government to support aerospace insulation is expected to drive the growth of the market over the forecast period.

- The world's growing economies play a significant role in the market expansion for business jets.

- Increasing adoption of organic strategies like marketing and market expansion by the key companies is estimated to drive the growth of the global aerospace insulation market over the forecast period.

- Increasing adoption of inorganic growth strategies like mergers to launch new aerospace insulation material is estimated to fuel the growth of the market during the forecast period.

- Increasing research study activity for designing new materials for aerospace insulation is expected to drive the growth of the global aerospace insulation market in the near future.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 17.07 Billion |

| Market Size in 2025 | USD 11.80 Billion |

| Market Size in 2024 | USD 11.32 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 4.19% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material, Product, Application, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Increase in both freight and passenger traffic

The increase in aviation traffic has been significantly influenced by globalization. The demand for the aerospace insulation market is rising due to increased global connectivity, promoting trade, tourism, and cross-cultural interactions. The need for air freight services has increased due to the growth of international business. The surge in freight and passenger traffic in the country has led to a rise in MRO–maintenance, repairs, and operations activities for commercial aircraft, which is expected to drive the growth of the global market over the forecast period.

- In March 2024, according to the data published by the International Air Transport Association trade association, it was estimated that domestic air passenger traffic is expected to surpass the pre-COVID levels of 141.2 million and reach 150-155 million in the fiscal year 2024. Investment Information and Credit Rating Agency, a credit ratings organization, predicted that growth would be between 8 and 13 percent.

Restraint

Challenges associated with insulation reliability and fluctuating raw material prices

The aerospace insulation market has been significantly impacted by the pandemic scenario. The airlines are running on minimum profit due to constraints on domestic and international passenger movement, which could impact aircraft orders. It is anticipated that fluctuating raw material prices could negatively impact the market for aircraft insulation. In More Electric Engines (MEE), inorganic materials, like carbon composites, are employed to insulate the wire because standard organic materials cannot withstand temperatures as high as 450°C. While inorganic materials have been used for a long time in high-voltage components outside of the aerospace industry, it is unclear from their behavior how consistent the insulation will be on electrical lines.

Opportunity

Increasing adoption of inorganic growth strategies

There are many different types of jobs and skills associated with working in the aviation industry. These include pilots and air traffic controllers; technicians who build and maintain aircraft; technical engineering jobs, ranging from aircraft and engine design to component production; air traffic control and airspace design planning; and airline and airport logistics. As this list shows, many positions in the aviation industry require a highly skilled workforce and extensive training. The key players operating in the market are focused on adopting inorganic growth strategies like collaboration for launching a new training school of aviation, which is expected to create lucrative opportunities for the growth of the aerospace insulation market over the forecast period.

- In January 2024, the Union Civil Aviation Minister announced the launch of the GMR School of Aviation, set up in collaboration with Airbus SE, an aircraft manufacturing commercial company, on the sidelines of Wings India 2024. GMR School of Aviation is strategically located within the GMR Aerospace and Industrial Park at Rajiv Gandhi International Airport.

Material Insights

The ceramic segment dominated the aerospace insulation market in 2024. Ceramic materials provide advantageous qualities, like their exceptional heat resistance, resistance to corrosion, and lightweight nature, which are the reason for this. These materials are extensively employed in many aerospace applications, such as engines and exhaust systems, heat shields, brakes, bearings, seals, and other wear-resistant parts.

The fiberglass segment is estimated to witness significant growth over the forecast period. This is because the material performs optimally as an acoustical and thermal insulator at temperatures up to 450 °F. It is best utilized for insulating commercial aircraft's fuselage wall cavities.

Tthe fiberglass segment is expected to witness significant growth in the aerospace insulation market over the forecast period. Foamed polymers are often used as insulation in commercial airplanes to increase passenger safety, acoustic comfort, fuel efficiency, and ease of installation and maintenance. The material's outstanding thermal and acoustic properties, fire resistance, and lightweight make it favored.

Product Insights

The thermal segment held a significant share of the aerospace insulation market in 2024 due to the extensive utilization of thermal insulation in aircraft manufacturing. The thermal insulation's main purpose is to act as a heat shield for thrust reversers, ducts, and engine parts. By applying thermal insulation, the components are protected from high temperatures by the essential fire barrier. Fire resistance is provided via thermal insulation in high-intensity settings. The location and kind of aircraft determine the cost-effectiveness of producing a suitable cabin temperature, which is aided by thermal insulation. Fiberglass is utilized for thermal insulation more often than ceramic materials.

The electric insulation is estimated to grow at the fastest rate in the aerospace insulation market over the forecast period due to vital electric systems, such as navigation and communication systems and in-flight control systems, which are equipped with electric insulation. Also, the category will increase faster due to the regular requirement for electrical insulation replacement.

The acoustic insulation segment holds a considerable share of the global aerospace insulation market. Materials for acoustic insulation, including fiberglass and polyimides, block vibrations from moving from one place to another by absorbing sound waves. In order to lessen the impacts of engine vibration, exhaust, and boundary-level excitation, the damping treatment is also applied directly to the skin of an aircraft. They are also used to lessen the effects of noise on the inside trim structure.

Acoustic insulation is utilized to lessen the noise and vibrations caused by engines and aerodynamics and to ensure comfort inside the flight deck and passenger cabin. Although acoustic insulation types differ from aircraft to aircraft, fiberglass is frequently chosen due to its great efficiency as an acoustic attenuator. The increased usage of aerospace insulation in the fuselage for acoustic and anti-vibration qualities is likely to drive considerable growth in the business and general aviation segment throughout the projection period. Additionally, insulation greatly enhances passenger comfort, particularly in the business aviation market.

Application Insights

The aerostructure segment led the global aerospace insulation market in 2024. The segment comprises door pairings, airframe, fuselage, and wings, which require insulation to maintain a safe and secure temperature in the cabin interior and flight deck and cabin interior.

The increasing launch of aerostructure is expected to drive the growth of the segment over the forecast period. For instance, in June 2024, Collins Aerospace, a company focused on providing advanced technology aerostructure, revealed the introduction of the ACES 5 ejection seats.

End-use Insights

The commercial segment held the largest share of the aerospace insulation market in 2024. The aerospace industry uses insulation extensively in the commercial segment, which includes freight liners and passenger aircraft. Aircraft insulation helps with both thermal and acoustic insulation, which enhances passenger comfort and experience even more.

Furthermore, the main purpose of the insulation materials put in freight liners is to enhance thermal insulation, which safeguards the cargo during transportation. Furthermore, increasing adoption of inorganic growth strategies like partnerships for innovating and launching new commercial aircraft training programs to meet the demand of the growing airline industry is expected to drive the growth of the segment over the forecast period.

- In June 2024, Texas State University, a university based in the U.S., signed a partnership with Coast Flight Training, Texas Aviation Partners, a business development service to introduce an innovative new Aviation Science degree program to assist in addressing the growing national demand for commercial and airline pilots.

The military segment accounts for a significant share of the aerospace insulation market due to the growing usage of aerospace insulation for engine bay thermal damping. Additionally, insulation materials, including blankets, lining, firewalls, and seals, are widely used for electrical insulation and fire barriers in military aircraft, including cargo and jets, which will increase their demand throughout the projection period. Furthermore, increasing research and development activity for the launch of new military aircraft equipment is expected to drive the growth of the segment over the forecast period.

- In January 2024, according to the data published by the China Maritime Safety Administration, it was estimated that China's newly innovative and advanced technology aircraft carrier, the Fujain, is under its third sea trial. The Fujian is specially designed for military purposes and equipped with electromagnetic catapults – an advanced technology that allows aircraft to be launched more quickly. The PLAN CV-18 Fujain Aircraft Carrier has undergone a mooring test twice.

- In June 2023, DuPont Aerospace Solutions, a company focused on manufacturing a wide variety of military and commercial aircraft, showcased high-performance solutions for next-generation aerospace technologies at the 54th International Paris Air Show.

- In June 2024, Airbus SE, an aircraft manufacturing commercial company, announced the introduction of the flight test campaign for the prototype of the NH90 Standard 2. One of the newest NH90 versions, this standard is being designed specially to support special forces missions for the French Army Aviation. The French Ministry of Defense has placed an order for eighteen NH90s in standard two configurations.

Recent Developments

- In April 2024, ZeroAvia, a hydrogen-electric aircraft developer, announced the plan for the launch of the hydrogen and electric aviation components. ZeroAvia announced that it will be making some of the essential parts for its hydrogen-electric engines available to other pioneers in clean aviation.

- In January 2024, Indian carriers want to add over 150 aircraft, a 37% increase from the year 2023, as Airbus and Boeing raise up production to fulfill an unprecedented number of orders from the nation's carriers. More planes are scheduled to be introduced this year than were added in 2019 prior to the COVID-19 epidemic, upending the aviation business.

Aerospace Insulation Market Companies

- Duracote Corporation

- Rogers Corporation

- Dupont

- BASF SE

- 3M

- Esterline Technologies Corporation

- Triumph Group Inc.

- Zodiac Aerospace

- Evonik Industries

- Polymer Technologies Inc.

- Zotefoams

- UPF Corporation

- Boyd Corporation

- Johns Manville

- Orcon

- AVS Industries

- Morgan Advanced Materials

Segment Covered in the Report

By Material

- Mineral Wool

- Ceramic Materials

- Fiberglass

- Foamed Plastics

- Others

By Product

- Acoustic Insulation

- Thermal Insulation

- Electric Insulation

By Application

- Aerostructure

- Engine

By End-use

- Military

- Commercial

- Business & General Aviation

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting