What is the Battery Manufacturing Equipment Market?

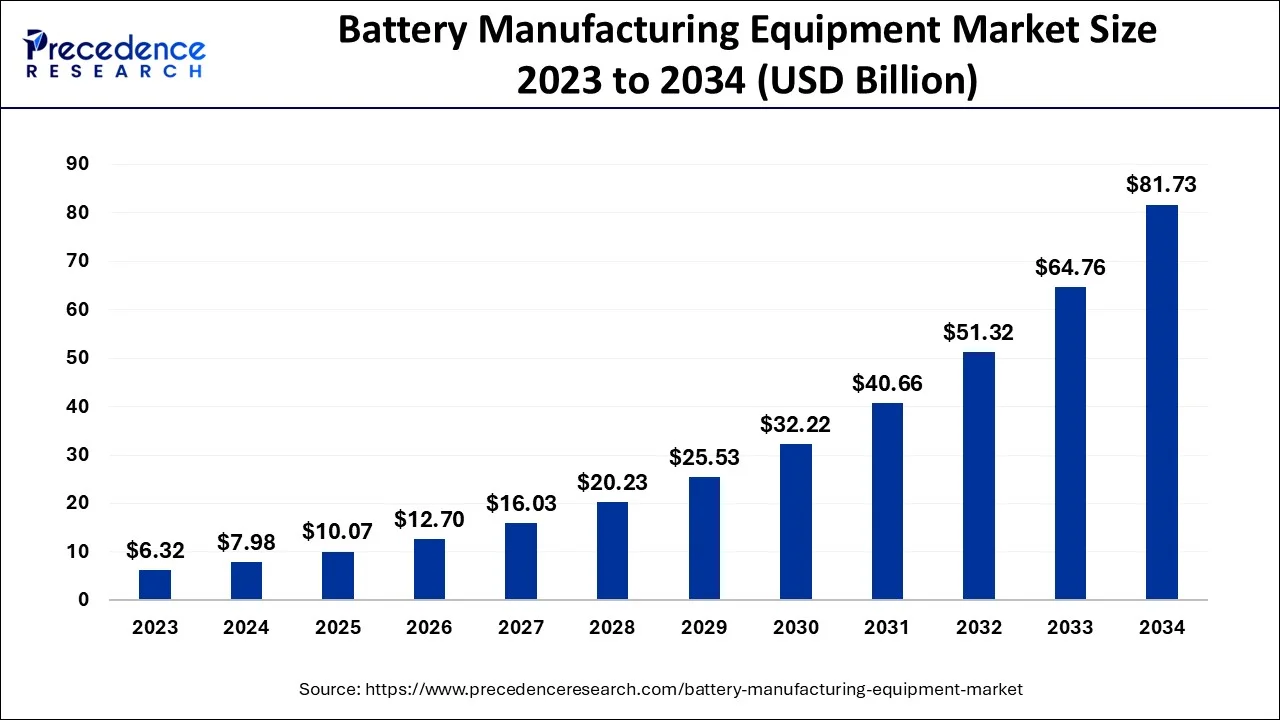

The global battery manufacturing equipment market size is calculated at USD 10.07 billion in 2025 and is predicted to increase from USD 12.70 billion in 2026 to approximately USD 96.35 billion by 2035, expanding at a CAGR of 25.34% from 2026 to 2035.

Battery Manufacturing Equipment Market Key Takeaways

- The Asia-Pacific region has shown the maximum growth in the battery manufacturing equipment market.

- The North American market is the second-highest region and has shown growth in the battery manufacturing equipment market.

- In application, the automotive batteries segments have led the battery manufacturing equipment market.

Market Overview

The rapid increase in the demand for electric vehicles has boosted the use of batteries in recent times. The battery is used in these vehicles are specially made as per the demands and requirements of the power output to be generated by a particular vehicle. The demand for these battery-operated electric vehicles has not been hampered by the covid pandemic caused. The numerous manufacturing companies in this sector are racing with each other in order to fulfill the needs and demands of the automobile industry in order to boost the production of electric vehicles in the market and meet the target set by the companies. Numerous leading battery manufacturing industries and startups have disclosed they are motives to start with plants having greater manufacturing capacity.

The shortage of companies that deal with battery manufacturing equipment has hampered the growth of the market to a great extent. The processes such as electrode manufacturing which forms an integral part of the battery-making process are carried out by a limited number of industries. The shortage in the production of these electrodes hampers the total process of making a battery to its core. Slurry mixing is another sector that helps to form the inner content of the battery which is again available at a very limited scale. The lack of these facilities slows down the process of making which hampers the output of the companies. The battery companies are increasingly inching towards slower production as a result of the shortage in the raw materials that are required in order to manufacture good quality batteries. The assembly of the battery is very important as it forms the final product which is to be sold out in the market to the dealers. This assembling process of batteries is hampered when the accessory parts are unavailable for the same period of time.

The entire process of making a battery is finished when the total assembly goes under a perfect checking procedure. This is known as a battery finishing process which helps to rule out the chances of error in the final product produced. The occurrence of the covid pandemic though showed a considerable effect on the entire market but had not hampered the battery manufacturing equipment market to a great extent as a result of the constant production and demand for the electric vehicle among the people. With the increasing cost of petroleum products and services, the demand for electric vehicles did not notice any decline in the market which helped the battery manufacturing market to maintain its momentum in the declining phase of the market. On the other hand, the market was affected to a certain extent owing to the supply of raw materials which are mainly required for the production of the various battery components which help to produce the final product. Constant strict lockdown and restrictions on movement had made it difficult for the supplies of the raw materials to reach the already limited manufacturing units which made it further difficult for the production of the batteries. This hampered the production process of the companies which did not go hand in hand with the demand of the market.

Battery Manufacturing Equipment Market Growth Factor

The increasing cost of the various types of fuels in the market which are used for commuting by people has helped to boost the demand for suitable alternatives that will be easier on the pocket of middle-class people. The introduction of electric vehicles proved to be this long-awaited alternative that helped the lower to medium socioeconomic class to choose a mode of transport for their daily travel along with a moderate expense on the power or energy required for the functioning of the vehicle.

The rapid demand for electric vehicles has boosted the supply and demand ofelectric vehicle batteriesthat become an integral part of the entire market and the supply chain. Further, the battery market also proves to be a part of the after-sales market as a result of the constant renovation or refilling that will be done by the electric vehicle owners. The different types of vehicles that are produced in the market demand different types and sizes of batteries that ultimately provide a great opportunity to the growing battery manufacturing market. Additionally, the supportive government rules and regulations regarding these battery-operated electric vehicles have helped encourage people to opt for such new advanced innovations which are highly beneficial to society as a whole.

The increasing awareness among people regarding environmental issues and the techniques to improve the constantly deteriorating condition has pushed the battery manufacturing equipment market towards positive boundaries which helps the market to achieve its pre-planned goals in the near future. The various products that include the use of electric batteries have also helped to propel the market for battery manufacturing equipment during the forecast period. The daily basic electric devices used by people include the use of battery which proves to be an integral part.

The battery manufacturing industry has introduced a large variety of options. The battery manufacturing equipment market has also seen its growth as a result of the portability of the devices operated by them which makes it extremely feasible for people to carry them to various places without worrying about the sources of power supply in order to enjoy the facilities provided by the devices. The facilities of recharging which are provided by renewable batteries have helped to reduce the expenses behind these products and thus made it easier for their utilization over a considerably long period of time. This increases the life of the products too which helps to make the entire process quite cheaper as compared to the other sources of energy. In order to boost the usage of renewable sources of energy the use of battery-operated devices and technology has been encouraged by the companies. This reason has also made the government offer lucrative business opportunities to the market in order to protect the environment.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 10.07 Billion |

| Market Size in 2026 | USD 12.70 Billion |

| Market Size by 2035 | USD 96.35 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 25.34% |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered |

|

| Regions Covered |

|

Segment Insights

Type Insights

Lithium-ion batteries have experienced a gradual rise in the market owing to the increasing demand in the automobile industry with the increasing use of electric vehicles. Lead acid batteries are the next type of battery that find their rapid use in industries and companies. This sector is in a state of infiltration by the former type as a result of its feasibility. The rapid demand for interrupted power supply for the smooth functioning of the devices has boosted the demand for these batteries. Nickel metal hydride batteries also provide quality services and are preferred for multiple purposes in the market. Nickel-cadmium batteries also form a major sector in the batteries market along with the nickel metal hydride variants.

Application Insights

Automotive batteries have led the market to great heights on account of their huge demand and supply chain owing to the increasing use of electrically operated vehicles by people. The various types of vehicles introduced by the market have led to the demand for the different types of batteries introduced in the market depending upon the power output expected by the product. Industrial batteries have held the market on strong grounds pertaining to the rapid industrialization in the world. Developing nations include a huge number of upcoming industries and companies that boost the production of industrial battery types.

Portable batteries help to make the devices easy to use and can be carried to places along with their power sources in terms of batteries. These multiple applications help to boost the market for battery manufacturing equipment market which encourages the use of renewable resources.

Regional Insights

What Made Asia Pacific the Dominant Region in the Battery Manufacturing Equipment Market?

On the basis of geography, the Asia-Pacific region has shown the maximum growth in the market for battery manufacturing equipment as a result of the high demand for electric vehicles owing to its recent introduction into the market as a result of the increasing fuel prices. Strong government support, substantial investments in R&D, and the presence of major battery and equipment manufacturers in countries like China, South Korea, and Japan accelerated technological innovation and production capacity. Additionally, the availability of skilled labor and cost-effective manufacturing infrastructure further reinforced Asia Pacific's leading position in the global market.

China Battery Manufacturing Equipment Market Analysis

China dominates the regional market with significant expansions in lithium-ion battery production capacity and aggressive EV industry growth. The country hosts leading global battery manufacturers and invests heavily in advanced coating, calendaring, formation, and assembly equipment. Government incentives, supply chain integration, and technological improvements such as high-speed automation systems enhance China's role as the top buyer of battery manufacturing equipment worldwide.

What Makes North America the Second-Largest Market?

The North American market is the next in line to boost the market size as a result of the high demand for electronic gadgets and devices pertaining to the rapidly developing technologies in the country. The huge number of information technology companies is proving to be a driving force in the battery manufacturing equipment market in this region. The European nations also help to propel the market size with rapid developments in the field of technology.

U.S. Battery Manufacturing Equipment Analysis

The U.S. leads the North American market with major funding for domestic gigafactories and incentives under policies like the Inflation Reduction Act. Demand for battery manufacturing equipment is rising for high-speed assembly, electrode processing, and quality validation technologies. Expansions by automakers and energy storage providers continue to stimulate growth in both new manufacturing facilities and the modernization of existing production lines.

Europe: A Notably Growing Region

Europe is expected to grow at a notable rate during the forecast period, supported by its Green Deal initiatives, EV transition targets, and major investments in sustainable battery ecosystems. The region prioritizes advanced, environmentally compliant manufacturing equipment, including recycling-integrated production lines. European firms are focusing on automation, digitalization, and next-generation solid-state batteries, boosting the need for precise electrode coating, drying, and assembly machinery.

Germany Battery Manufacturing Equipment Market Analysis

Germany drives the European market, as it is a hub for EV manufacturing and engineering innovation. Strong participation from automotive OEMs and battery technology firms creates sustained demand for cutting-edge production equipment. The country's push toward localizing cell manufacturing and integrating high-efficiency, low-emission equipment further strengthens its leadership in Europe's battery manufacturing equipment landscape.

Battery Manufacturing Equipment Market - Value Chain Analysis

- Equipment Manufacturing

Battery manufacturing equipment is produced through processes such as electrode coating system design, slurry mixing unit fabrication, cell assembly line integration, electrolyte filling systems development, formation & aging equipment engineering, and automated quality inspection machinery manufacturing.

Key players: Wuxi Lead Intelligent Equipment, Hitachi High-Tech, Manz AG, Bühler Group - Quality Testing and Certification

Battery manufacturing equipment needs certifications for precise control, electrical safety, automation reliability, material handling safety, and compliance with international battery production standards. Important certifications include CE marking, ISO 9001, ISO 14001, UL machinery safety certification, and SEMI standards.

Key players: ISO (International Organization for Standardization), UL Solutions, CE Marking Authorities, SEMI (Semiconductor Equipment and Materials International) - Distribution to Industrial Users

Battery manufacturing equipment is supplied to lithium-ion battery producers, automotive OEMs, energy storage manufacturers, electronics battery makers, and gigafactories expanding EV battery production capacity.

Key players: CATL suppliers, Panasonic equipment integrators, LG Energy Solution partners, Tesla battery manufacturing associates.

Battery Manufacturing Equipment Market Companies

- Wuxi Lead Intelligent Equipment Co., Ltd. (LEAD): Wuxi Lead is among the world's largest suppliers of lithium-ion battery manufacturing equipment. Its product lineup includes coating machines, calendaring equipment, cell assembly lines, and formation/testing systems. The company supplies high-automation, high-precision solutions to leading EV and energy storage battery manufacturers.

- Hitachi High-Tech Corporation: Hitachi High-Tech offers advanced battery manufacturing equipment, including electrode fabrication systems, inspection machines, and precision measurement tools. The company aims to enhance battery safety, consistency, and high-performance cell production for automotive and industrial uses.

- Buhler Group: Buhler produces mixing, dispersion, and coating equipment commonly used in electrode slurry production for lithium-ion batteries. The company's technologies improve process stability, material consistency, and overall electrode performance, which are vital for high-energy-density cells.

- Manz AG: Manz is a major European provider of automated battery production lines, offering solutions for electrode production, cell assembly, and module/pack assembly. The company focuses on scalable, intelligent manufacturing systems tailored to EV battery and energy storage markets.

- Maccor Inc.: Maccor specializes in battery testing, formation, and measurement equipment used by cell manufacturers, automotive companies, and research laboratories. Its systems support high-precision performance testing and quality assurance across lithium-ion, solid-state, and next-generation battery chemistries.

Other Major Key Factors

- Duracell.

- Johnson Controls

- NEC Corporation,

- GS Yuasa International

- BYD Company

- A123 Systems LLC

- Hitachi Chemical Co.,

- Panasonic Corporation

- Samsung SDI Co.,

- Toshiba Corporation

- LG Chem

- Contemporary Amperex Technology

- Saft

- Sony Corporation

- Eveready Industries

Key Market Developments

- Samsung has been seen to step into the market from the production of batteries to end-user utilization of the devices along with other competitors such as Panasonic.

- M&A and JVs are the various strategies adopted by companies in order to maintain a stable position in the market. Increasing research and development is seen in order to increase production as per the demand in the market.

Segments Covered in the Report

By Type

- Lead Acid

- Lithium Ion

- Nickel Metal Hydride

- Nickel Cadmium

- Others

By Application

- Automotive Batteries

- Industrial Batteries

- Portable Batteries

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (MEA)

Get a Sample

Get a Sample

Table Of Content

Table Of Content