What is Circular Polymers Market Size?

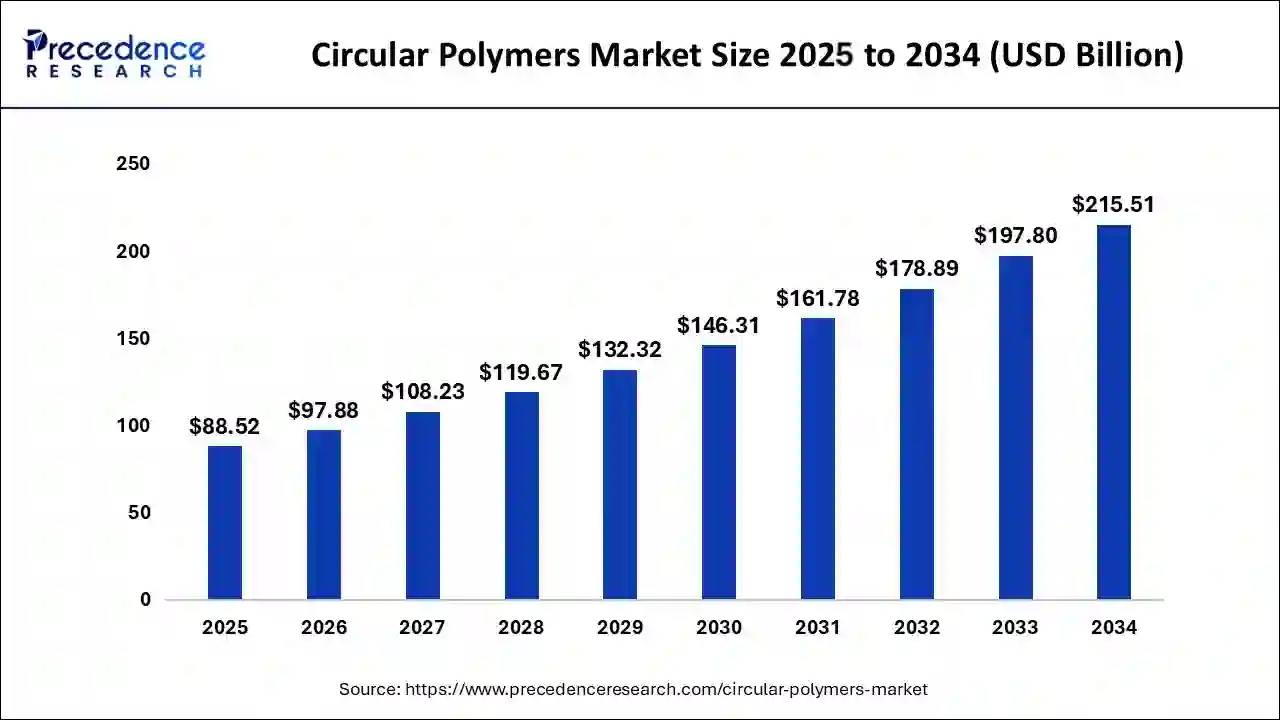

The global circular polymers market size is estimated at USD 88.52 billion in 2025 and is predicted to increase from USD 97.88 billion in 2026 to approximately USD 215.51 billion by 2034, expanding at a CAGR of 10.41% from 2025 to 2034. This market is experiencing propulsive growth owing to increasing strategic initiatives such as new product launches, production expansions, and mergers and acquisitions, among others.

Market Highlights

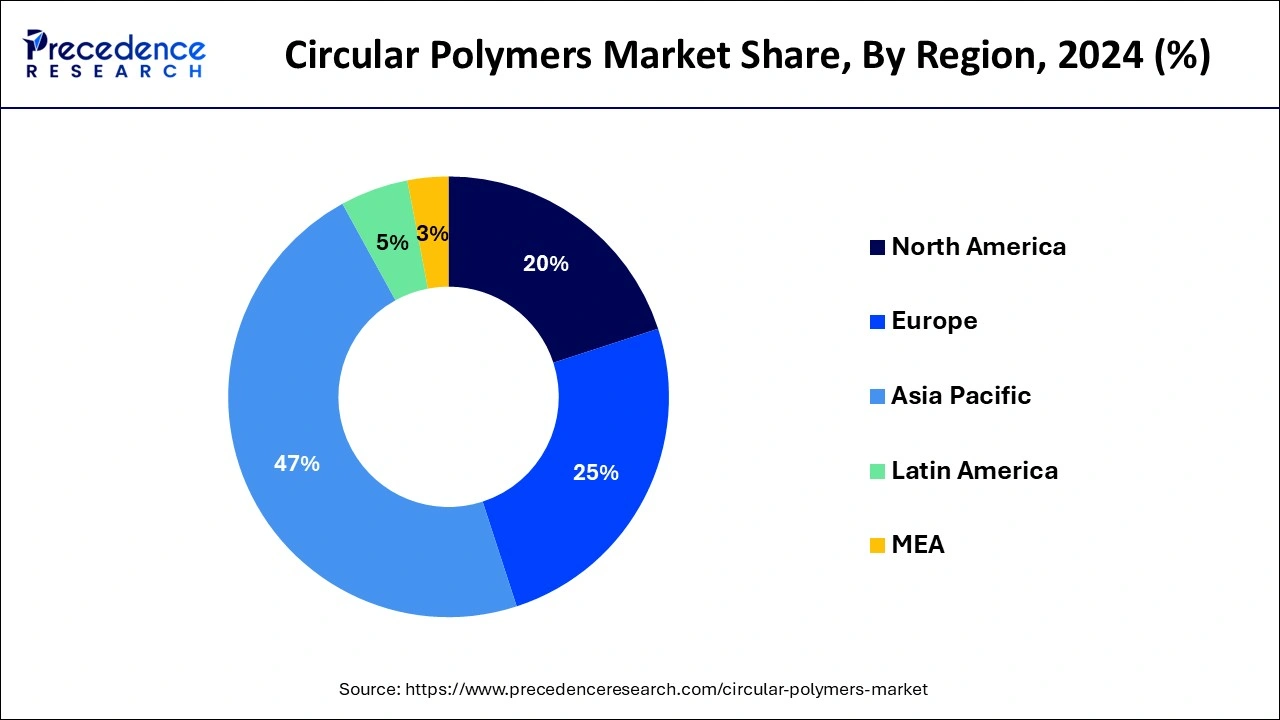

- Asia Pacific dominated the circular polymers market with a market share of 47%.

- North America is expected to secure a significant portion of the market's revenue in the upcoming years.

- By polymer type, the polyethylene (PE) segment has dominated the market in 2024 with a market share of 33%.

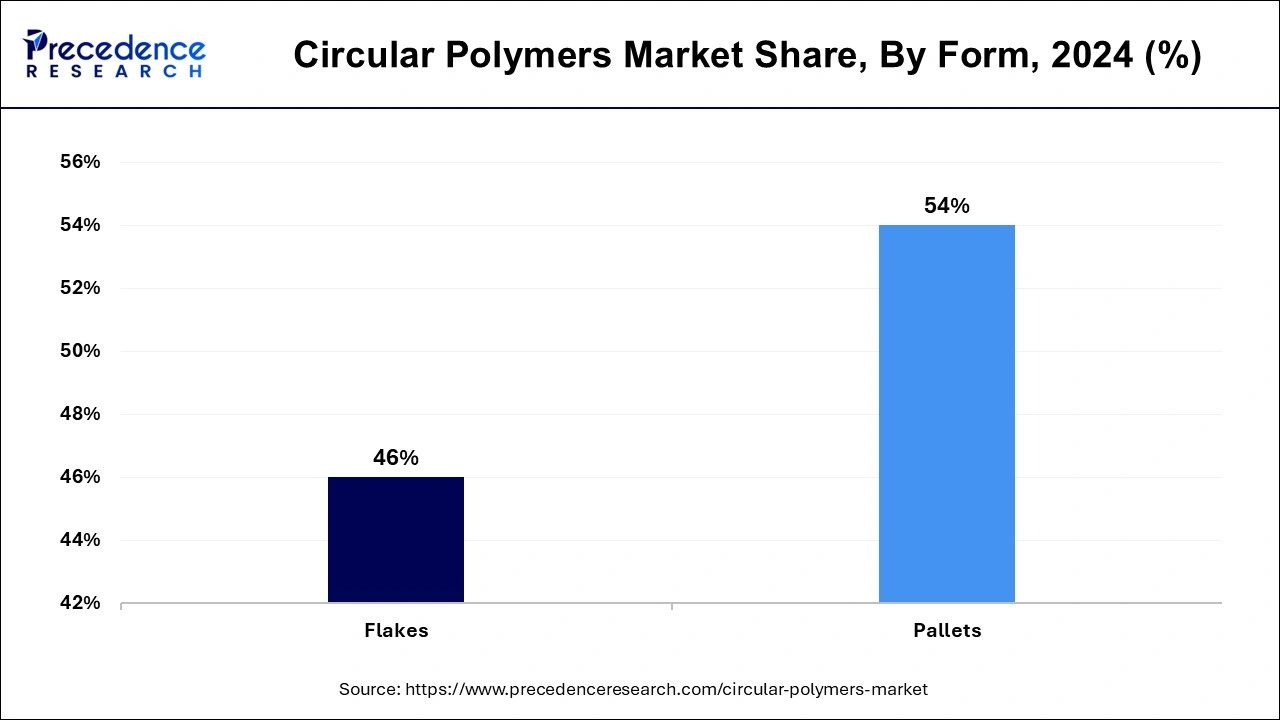

- By form, in 2024, the pellets segment has accounted largest market share of around 54%.

- By form, the flakes segment has captured a market share of around 46% in 2024.

- By application, the food packaging segment dominated the market of circular polymers in 2024 with a 44% revenue share.

- By end use, the packaging segment captured a market share of 54% in 2024.

Market Overview

Circular polymers are unique polymers that can be collected, recycled, and transformed into new polymers without any degradation. They are essential in the circular economy, which aims to minimize waste and maximize resource efficiency. By using circular polymers, we can reduce the need for virgin resources, such as petroleum and natural gas, which promotes resource conservation. Furthermore, recycling plastic waste to create circular polymers produces fewer greenhouse gas emissions than producing virgin polymers, which helps conserve energy and reduce emissions.

Additionally, recycling plastic waste into circular polymers requires less energy and produces fewer greenhouse gas emissions than producing virgin polymers. This makes circular polymers an environmentally preferable option, which further aids in energy conservation and emissions reduction. Using circular polymers also promotes a more sustainable approach to polymer production and waste management by reducing environmental impact and conserving resources.

Circular Polymers MarketGrowth Factors

- Increasing consumer awareness regarding sustainable products is driving the growth of the circular polymers market.

- Rising production of vehicles globally is also expected to boost the demand for the circular polymers market in the future.

- Investments made by various governments across different countries are one of the key factors fueling the circular polymers market growth.

- Extended producer responsibility (EPR) programs are poised to create lucrative opportunities in the circular polymers market.

- Product launches and expansions by key players contribute to the circular polymers market expansion during the forecast period.

Market Outlook

- Industry Growth Overview: As businesses and the government concentrate on cutting plastic aste and encouraging recycling. The market for circular polymers is expanding swiftly. Polymers like PE, PET and nylon are the most widely used in packaging. Due to the increased industrialization and the need for sustainable materials growth is particularly robust in Asia Pacific region. the market outlook is extremely positive with consistent double digital growth anticipated over the next ten years despite ongoing challenges like feedstock supply and rising costs.

- Sustainability Trends: In this market sustainability is a key factor. More plastic types can be effectively reused thanks to developments in chemical and mechanical recycling. While governments impose restrcitions on single use plastics and mandates for recycled content, businesses are creating circular supply chains with traceability and closed loop systems. The main focus is till on high volume polymers and packaging segments which allow plastics to be used for longer periods of time and have a smaller environmental impact.

- Major Investors:All along the value chain, investment in circular polymers is rising. Recycling facilities and cutting-edge polymer technologies are being funded by chemical and plastics corporations like LyondellBasell, SABIC, and ExxonMobile. To secure sustainable feedstock, brands and retailers are also investing in partnerships and startups. In general, circular polymers are viewed as a profitable growth opportunity as well as an environmental necessity, promoting innovation and global expansion.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 88.52 Billion |

| Market Size in 2026 | USD 97.88 Billion |

| Market Size by 2034 | USD 215.51 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 10.41% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | By Polymer Type, By Form, By Application, and By End-use, and region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

The persistent rise in consumer product consumption

The packaging industry is experiencing a rise in demand for circular polymers market because of the increasing consumption of consumer products. With consumers buying more and their spending power growing, there's a greater need for sustainable packaging solutions.

Companies like Patagonia and Danone are leading the way by using recycled materials, including circular polymers, in their packaging. Danone aims to have all its packaging recyclable, reusable, or compostable by 2025 and is exploring the use of circular polymers in its packaging. Coca-Cola is also joining the movement by introducing bottles made from recycled PET in various markets worldwide.

- In April 2022, SABIC or Saudi Basic Industries Corporation, the chemical manufacturer based in Saudi Arabia, announced its plans to commence production of circular polymers for the European market by the end of 2022.

Restraint

Quality and performance requirements

Circular polymers often struggle to meet the quality and performance standards required for certain applications. This is because their mechanical, thermal, or chemical properties may not match those of virgin polymers, limiting their suitability for specific uses. Additionally, circular polymers can face challenges in cost competitiveness compared to traditional linear polymers.

The recycling and processing of plastic waste into circular polymers often involves additional steps and technologies, increasing production costs. Consequently, the higher price of circular polymers may restrict their adoption, particularly in the circular polymers market, which is sensitive to pricing.

Opportunity

Plastic growth

In the packaging industry, a ‘circular economy' involves reusing and recycling plastic in a closed-loop system instead of producing single-use plastic that is discarded after one use. The demand for products made from recyclable plastic has spurred growth in the circular polymers market, driven by customers in the plastic, polymer, and packaging industries in developed countries. The rising volume of plastic waste generated by the food and beverage sectors has led to a greater need for recycling old food packaging, which is projected to increase polymer demand. The use of circular polymers in the packaging sector is expected to be twice the forecast period.

- In 2023, According to the Organization for Economic Co-operation and Development (OECD), over 153 million metric tons of plastics were used in the manufacturing of packaging worldwide. Plastic packaging consumption is anticipated to almost triple by 2060, hitting 380 million tons. Packaging is expected to account for 31% of worldwide plastics usage in that year.

Segment Insights

Polymer Type Insights

The polyethylene (PE)segment dominated the circular polymers market in 2024. This is due to the increasing environmental awareness regarding plastic usage and pollution that the demand for products containing recycled plastics has risen. Polyethylene is a popular polymer among market players and is a key contributor to the market. This factor will fuel segment demand in the future.

The polypropylene (PP) is predicted to be the fastest-growing segment over the projected period. Polypropylene is mainly used in the packaging industry's manufacturing sheets and films because its high resistance to abrasion, chemicals, and thermal bonding is expected to drive the demand for polypropylene throughout the packaging industry.

- In November 2023, Braskem introduced a new polypropylene (PP) grade under the INSPIRE brand designed to replace polyethylene terephthalate (PET) in consumer food packaging applications when higher temperature resistance is needed.

Form Insights

The pellets segment dominated the global circular polymers market in 2024. Pellets are convenient to manage and use in manufacturing processes like injection molding and extrusion. Circular plastics in pellet form are also simpler to transport in large amounts compared to plastics in resin or liquid form.

- In September 2023, Westlake Corporation announced the launch of PIVOTAL™, a line of "one-pellet solutions" for the introduction of post-consumer resin (PCR) into flexible packaging. PIVOTAL™ offers customers a more sustainable material for use in the production of non-FDA applications.

The flakes segment is expected to grow significantly during the period studied. Improvements in recycling infrastructure, such as better collection and sorting systems, can boost the availability of top-notch plastic flakes. Reliable recycling systems ensure a steady supply of raw materials for manufacturing circular polymers. These developments are expected to drive growth in the segment.

Application Insights

The food packaging segment dominated the market of circular polymers in 2024. This is because consumer preferences are shifting more towards eco-friendly and sustainable products, including food packaging. Circular polymers derived from recycled materials are aligned with these preferences, and brands are adopting them to meet customers' demand for eco-friendly packaging. This factor will help to boost the demand for a segment of the market.

End-use Insights

The packaging segment captured the dominant share of the circular polymers market in 2024, driven by increasing demand for luxury personal care and cosmetic products. These premium items rely on exceptional packaging to attract consumers. Research indicates that appealing packaging plays a crucial role in captivating the target audience, serving as the initial impression, particularly for high-value cosmetics and personal care goods.

Regional Insights

Asia PacificCircular Polymers Market Size and Growth 2025 to 2034

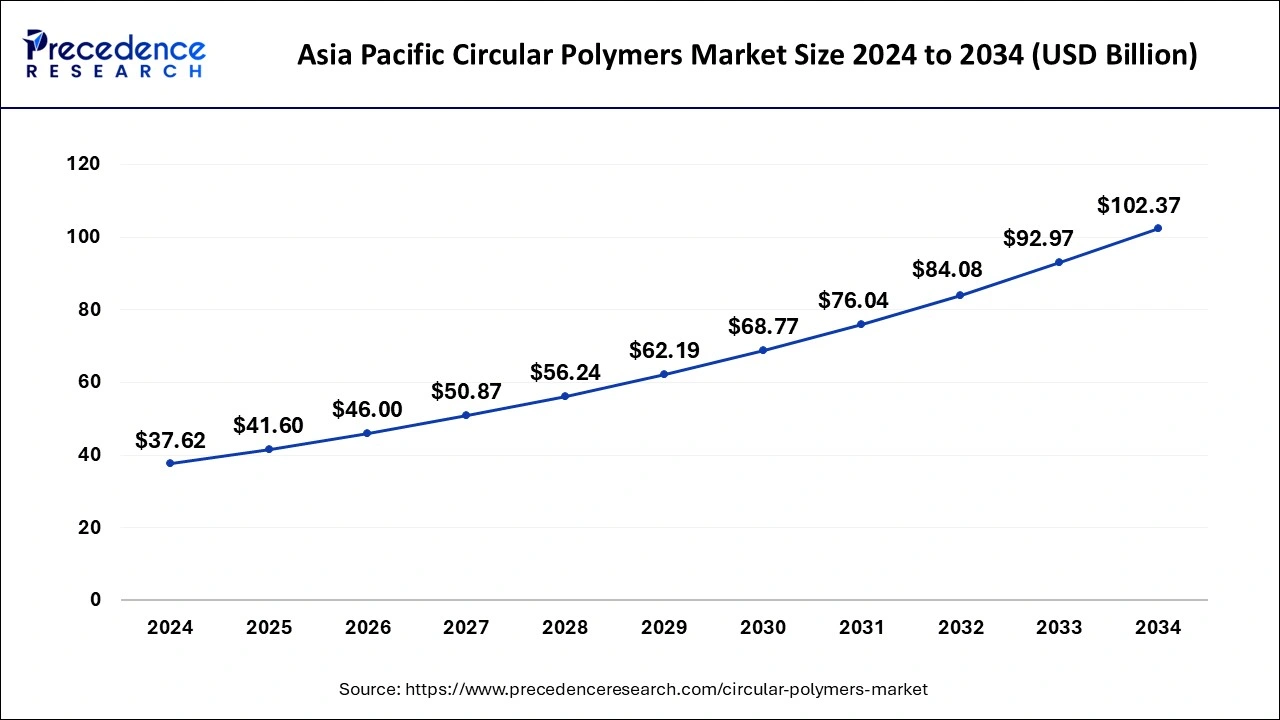

The Asia Pacific circular polymers market size is estimated at USD 41.60 billion in 2025 and is projected to surpass around USD 102.37 billion by 2034 at a CAGR of 10.53% from 2025 to 2034.

Asia Pacific dominated the circular polymers market and is expected to maintain its position throughout the forecast period.The region's growth is anticipated to be steady, driven by rising disposable incomes in emerging economies, which spur demand for convenient products and contribute to the global expansion of circular polymers. Furthermore, the consumer goods sector has experienced significant growth in recent years, emerging as a key market for circular polymers, particularly in packaging applications. Companies like Jindal Films play a crucial role in producing plastics, especially for packaging purposes.

- In October 2023, Germany-based polycarbonate manufacturer Covestro started operating a new compounding line in Shanghai. It is the company's first dedicated mechanical recycling compounding line for polycarbonates in China.

North America has accounted for 20% of revenue share in 2024and is expected to secure a significant portion of its revenue in the upcoming years. The growing recognition of the harmful environmental effects of plastic pollution has prompted both businesses and consumers in North America to explore alternative plastic materials that diverge from traditional practices. Circular polymers, sourced from recycled materials, align with initiatives aimed at tackling plastic waste problems. These factors are expected to drive increased demand within North America.

- In July 2023, TotalEnergies, Aramco, and SABIC have, for the first time in North Africa, successfully converted oil derived from plastic waste into ISCC+-certified circular polymers. The plastic pyrolysis oil, also called plastic waste-derived oil (PDO), was processed at the SATORP refinery jointly owned by Aramco and TotalEnergies in Jubail, Saudi Arabia. It was then used as a feedstock by Petrokemya, a SABIC affiliate, to produce certified circular polymers.

Circular Polymers Market Companies

- LyondellBasell Industries Holdings B.V.

- SABIC

- Ascend Performance Materials Operations, LLC

- Advanced Circular Polymers

- Borealis AG

- Veolia

- Exxon Mobil Corporation

- The Shakti Plastic Industries

- Chevron Phillips Chemical Company, LLC

- Suez Group

Recent Developments

- In October 2024, Magpet Polymers announced a ₹205 crore (USD ~24 million) investment from British International Investment (BII) to scale up its bottle-to-bottle food-grade recycling plant in Kharagpur, West Bengal, with a capacity of 45,000 tonnes/year. This plant will convert post-consumer PET bottles into rPET pellets using advanced European recycling technology, helping India build a robust circular plastics ecosystem.

(Source: https://www.business-standard.com) - In December 2023, Reliance Industries announced that it had started chemically recycling plastic waste to produce ISCC-Plus certified circular polymers“CircuRepol” (polypropylene) and “CircuRelene” (polyethylene) by converting plastic waste into pyrolysis oil at its Jamnagar refinery. This demonstrates their commitment to turning unrecyclable plastic into high-quality circular polymer resins.

- In February 2025, researchers at the Indian Institute of Science (IISc), Bengaluru, announced a breakthrough recycling method that significantly improves the mechanical strength and purity of recycled PET by effectively removing contaminants from post-consumer waste, potentially enabling its use in applications currently reserved for virgin polymers.(Source: https://www.polymerupdate.com)

- In September 2023, Chevron Phillips Chemical Company LLC collaborated with Danimer Scientific, formerly known as Meridian Holdings Group Inc., and MHG, a biopolymer manufacturer. This collaboration aimed to utilize Rinnovo polymers produced in a loop slurry reactor process to create biodegradable cast extrusion films, blown extrusion films, injection molded parts, and rational molded parts.

- In July 2023, TotalEnergies SE collaborated with Aramco, SABIC (Saudi Arabia Basic Industries Corporation), a chemical manufacturer. This collaboration aimed to convert oil derived from plastic waste into circular polymers.

- In June 2023, Circular Polymers by Ascend introduced Cerene, a line of recycled polymers and materials made from the company's proprietary carpet reclaiming technology. The launched product would be available as polyamide 6 and 66, PET, polypropylene, and calcium carbonate as a consistent, sustainable feedstock for many applications consisting of molding and compounding.

- In June 2023, Borealis AG took over Rialti S.p.A., a polypropylene (PP) compounder of recyclates based in the Varese area of Italy. This acquisition aimed to expand Borealis's PP compounding business and, in particular, increase its volume of PP compounds based on mechanical recyclates.

- In May 2023, Borealis AG launched Bornewables, a line of Queo, a range of plastomers and elastomers based on renewable feedstock. The launched product would allow Borealis to meet increasing customer demand for sustainable solutions that don't compromise on quality or performance.

Segments Covered in the Report

By Polymer Type

- Polyethylene (PE)

- Polypropylene (PP)

- Polyethylene Terephthalate (PET)

- Polyvinyl Chloride (PVC)

- Polyamide (PA)

- Others

By Form

- Pellets

- Flakes

By Application

- Food Packaging

- Adhesives & Sealants

- Interior & Exterior Components

- Wires & Cables

- Others

By End-use

- Packaging

- Building & Construction

- Automotive

- Electrical & Electronics

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting