What is Dental 3D Printing Devices Market Size?

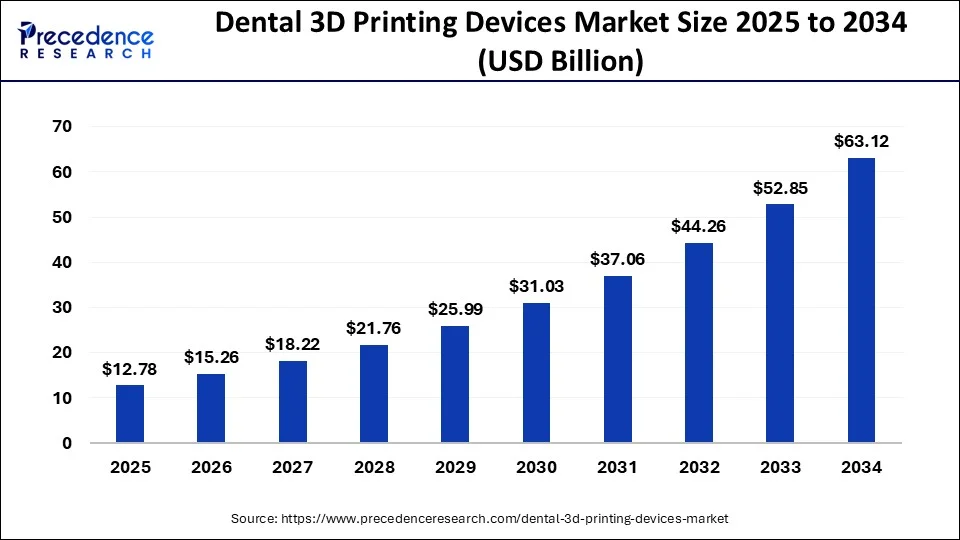

The global dental 3D printing devices market size is valued at USD 12.78 billion in 2025, and is projected to hit around USD 15.36 billion by 2026, and is anticipated to reach around USD 63.12 billion by 2034, growing at a double-digit CAGR of 19.42% from 2025 to 2034. The growth of the dental 3D printing devices market is attributed to a potential footprint and the combination of state-of-art technology. The development and designs of advanced products, including delivery positioning, advanced fabrication to provide an aesthetic look, and invisible aligners, are the major factors increasing the adoption and demand for dental 3D printers.

Market Highlights

- North America dominated the global dental 3D printing devices market in 2024.

- Asia Pacific is expected to grow at the fastest CAGR during the forecast period.

- By equipment, the 3D scanner segment has held the largest market share in 2024.

- By technology, the stereolithography segment led the market in 2024.

- By application types, the orthodontics segment generated the highest market share in 2024.

- By application types, the prosthodontics segment is expected to grow rapidly during the forecast period.

- By end-use types, the dental segment accounted for the biggest market share in 2024.

- By end-use types, the dental clinics segment is expected to grow significantly during the forecast period.

Revolutionizing Dentistry: Precision and Customization with 3D Printing Technology

Dental 3D printing devices are revolutionizing the field of dentistry by enabling customizable, efficient, and precise solutions for several dental procedures. Dental 3D printers can create accurate and detailed surgical guides, dentures, bridges, crowns, and dental models, using advanced additive manufacturing technologies. The process begins with digital scans of a patient's mouth, which are then utilized to design a 3D model via specialized software.

- In addition, the major factor driving the dental 3D printing devices market growth is the increasing adoption of digital dentistry solutions and the growing demand for personalized dental care. Furthermore, the expanding elderly population and increasing prevalence of dental disorders require more dental interventions.

HowArtificial Intelligence is Changing the Dental 3D Printing Devices Market?

3D printing allows dental professionals to develop highly accurate dental appliances, which include bridges, implants, crowns, and guards. The dental 3D printing devices market appliances are designed and manufactured using digital scans and AI technology instead of traditional molds. Artificial Intelligence helps ensure that dental restorations and aids in analyzing data are tailored precisely to the individual's needs. There are various advantages of 3D printing devices and AI in dental treatments, such as personalization, reduced weight times, increased accuracy, greater comfort and restorations, and prosthetics. 3D printing devices allow accurate and faster production of dentures, bridges, and crowns. AI can help in designing restorations that fit the patient's bite and anatomy.

Dental 3D Printing Devices Market Growth Factors

- The increasing of highly tailored dental, implants, and appliance restorations is made possible by 3D printing devices, which improves patient comfort and outcomes.

- The ongoing developments in 3D printing materials, devices, software, and technology enhance the dental 3D printing devices market growth.

- The dental manufacturing process can be streamlined with 3D printing devices to cut production time and expenses and further drive market growth.

- The increasing need for dental treatments, especially those made possible by 3D printing devices, is enhanced by rising awareness of oral health, and the aging of the world population is expected to boost market growth.

- Dental practitioners are utilizing 3D printing device technology in their practices and are becoming increasingly accustomed to it, which is further anticipated to enhance the market growth during the forecast period.

Market Outlook

- Industry Growth Overview-The dental 3D printing devices market is growing rapidly due to increasing demand for personalized dental restorations, technological advancements in 3D printing, and adoption of digital workflows in clinics and labs for faster, precise, and cost-effective solutions.

- Global Expansion- The global market is expanding as clinics and labs worldwide adopt advanced 3D printing technologies, driven by growing demand for customized dental restorations, efficiency, and precision in restorative and orthodontic treatments.

- Startup Ecosystem- The startup ecosystem in the dental 3D printing devices market is thriving, with innovative companies developing advanced printers, biocompatible materials, and software solutions to offer precise, cost-effective, and customizable dental restorations, attracting investments and partnerships worldwide.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 12.78 Billion |

| Market Size in 2026 | USD 15.36 Billion |

| Market Size by 2034 | USD 63.12 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 19.42% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Equipment, Technology, Material, Application, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East, and Africa |

Market Dynamics

Drivers

Increasing awareness and training about 3D printing devices

Dental associations and educational establishments are incorporating 3D printing technology into their curricula as dental practitioners grow increasingly conscious of the uses and benefits of this technology. Technicians and dentists can better capture 3D printing devices' advantages and capabilities over conventional processes by participating in certification programs, webinars, and workshops. Dental professionals can share their knowledge more easily via online forums, professional associations, and social media groups. By allowing practitioners to exchange best practices, learn from one another, and talk about their experiences, these devices provide more possibilities for training and raising awareness.

Restraints

Technological complexity

Complex software is frequently needed for the dental 3D printing devices market to construct and create dental structures. Software platform compatibility issues may cause mistakes and inconsistencies. Dental businesses are subject to 3D-printed goods, and stringent regulations have to address health requirements and safety. Navigating these regulations might take a lot of complexity and effort. Standards for safety and quality are predicted to change as the market develops, making it challenging for practices to stay up to date without ongoing investments in training and equipment.

Opportunity

Increasing awareness and accessibility

The usage of dental 3D printing devices market has the capacity to increase dental care accessibility to underserved regions and remote areas where conventional dental services and laboratories may be restricted. The development of cost-effective and portable 3D printer devices in various locations can improve the on-site fabrication of dental devices, thereby driving access to vital dental care. In addition, the expeditious production of physical prototypes by dental professionals allows prompt refinement and evaluation, thereby decreasing the time-to-market and accelerating development cycles for novel dental devices.

Segment Insights

Equipment Insights

The 3D scanner segment held the largest dental 3D printing devices market share in 2024. 3D scanners are pieces of hardware that capture 3D shapes utilizing projected lasers or light and cameras. 3D scanners can be used in a clinical laboratory, chairside setting, or dentistry. There are types of 3D scanners in dental 3D printing devices such as intraoral 3D scanners and desktop 3D scanners. Intraoral 3D dental scanners are handheld applications that 3D scan directly inside a patient's mouth, and desktop dental scanners are stationary devices utilized for efficiently scanning items such as models and impressions. Various major manufacturers of 3D dental scanners, such as Medit, Shining 3D, Dental Wings, and 3Shape, offer both desktop and intraoral scanners.

Technology Insights

The stereolithography segment dominated the dental 3D printing devices market in 2024. It is often referred to as ‘SLA printing' and has rapidly become the most widely adopted 3D printing technology across the dentistry field. This prevalence is due to its exceptional ability, versatility, and precision to produce high-quality dental prosthetics and restorations. Unlike other 3D printing devices, SLA uses a laser to cure liquid resin layer by layer, resulting in highly intricate, accurate models. The dental industry has adopted SLA printing for a variety of applications, such as creating orthodontic appliances, surgical guides, dentures, bridges, and crowns. The technology's capability to produce complex geometries with fine details is instrumental in crafting restorations that seamlessly integrate with patients' surrounding tissues and natural teeth. In addition, SLA's efficiency and speed have significantly streamlined the fabrication process, enabling improved patient satisfaction and faster turnaround times.

Application Insights

The orthodontics segment held the largest share of the dental 3D printing devices market in 2024. Advancements have enhanced the aesthetics and functionality of orthodontic devices in biocompatible materials, including dental resins explicitly created for orthodontic uses. These materials are accurate for personalized solutions since they are appropriate, flexible, and strong for long-period intraoral use. Orthodontists can improve patient communication and involvement with the ability to graphically display patients' treatment progress. Patient trust and loyalty have increased due to being able to offer accurate, faster treatments.

The prosthodontics segment is expected to grow rapidly in the dental 3D printing devices market during the forecast period. Dental prostheses such as dentures, bridges, crowns, and veneers are fitted and designed by prosthodontists. 3D printing device technology, which is necessary in prosthodontics, makes high degrees of customization possible. Despite conventional techniques, 3D printing devices enable the production of personalized prosthetics that are anatomically suited to each patient and improve functioning, comfort, and fitness.

End-use Insights

The dental segment dominated the dental 3D printing devices market in 2024. Dental laboratories are innovative When creating personalized dental prostheses, such as implants, dentures, bridges, and crowns. There is a great demand for individualized solutions, and 3D printing technology makes it possible to precisely create, fit, and customize patient-specific designs that are complex to develop with conventional techniques. High production capabilities can be achieved by printing many parts at once, which is very useful for large laboratories that manage a large number of cases regularly. Due to its scalability, labs can make dental restorations faster than ever without reducing quality.

The dental clinics segment is expected to grow significantly in the dental 3D printing devices market during the forecast period. The dentistry sector is witnessing a transition to digital operations, with 3D printing devices at its center. Digital dentistry enhances patient care by enabling a smooth transition from diagnostic to treatment creation and planning. Insurance companies' refund policies have been gradually enhancing as they become aware of the benefits of 3D-printed dental device items. This assistance motivates clinic adoption by increasing patient access to 3D-printed treatments and reducing costs.

Regional Insights

North America dominated the global dental 3D printing devices dental 3D printing devices market in 2024. Technicians and dentists proficient in utilizing advanced technologies are broadly available in the U.S. and Canada. Integrating and adopting 3D printing devices in dental practices is contingent upon having a skilled workforce. The dentists in the region had an early benefit in the market since they were the first to use 3D printing devices for orthodontic products, dental implants, dentures, bridges, and crowns.

- In March 2023, 3Shape and Stratasys jointly launched an advanced automated digital color workflow. This is specially designed for dental 3D printing devices. The aim behind this launch was to streamline the color customization process in dental applications, improving accuracy and efficiency.

3D Printing: Booms Of Dental Innovation in the U.S

The U.S. market is growing due to increasing demand for customized dental solutions such as crowns, bridges, and dentures. Advancements in additive manufacturing technologies enable faster, more accurate, and cost-effective production. Additionally, the rising adoption of digital dentistry, growing dental care awareness, and the need to improve efficiency in dental clinics and laboratories are driving the widespread use of 3D printing devices across the country.

China Market Grows with Precision and Innovation

The China market is growing due to rising demand for personalized dental treatments, increasing prevalence of oral health issues, and the expansion of dental clinics and laboratories. Technological advancements in 3D printing, supportive government initiatives for digital dentistry, and the need for faster, accurate, and cost-effective dental solutions are further driving market adoption across the country.

Europe Embraces 3D printing for Advanced and Personalized Dental Care

The Europe market is growing due to increasing demand for customized dental restorations, a rising geriatric population requiring advanced dental care, and widespread adoption of digital workflows in clinics and laboratories. Technological advancements, such as high-precision printers and biocompatible materials, along with the need for faster, cost-effective, and accurate dental solutions, are further driving the market growth across European countries.

UK Dental Care Transformed 3D Printing at the Forefront

The UK dental 3D printing devices market is increasing as more dental professionals adopt advanced technologies to deliver precise, customized treatments. Rising focus on efficiency, reduced production times, and improved patient outcomes is driving adoption in clinics and laboratories, while innovations in 3D printing materials and workflows make these devices increasingly accessible and practical for everyday dental applications.

Asia Pacific is expected to grow at the fastest rate in the dental 3D printing devices market during the forecast period. The market growth in the region is enhanced by increased investments in 3D printing technology research and development from the private and public sectors. South Korea and Japan are two countries making significant investments in 3D printing devices for dentistry and other medical industries. Cosmetic dentistry is becoming more and more popular in the area as people become more aware of their appearance. Dental 3D printing technology is essential to provide visually beautiful and accurate dental restorations.

Value Chain Analysis

- Clinical Trials

Clinical trials for 3D-printed dental devices, including implants, crowns, and bridges, assess their safety, effectiveness, and performance versus traditional restorations.

Key Players: Straumann, Dentsply Sirona, Align Technology, Nobel Biocare, and 3M Oral Care. - Regulatory Approvals

Regulatory approval for dental 3D printing devices ensures manufacturers demonstrate the safety and effectiveness of printers, materials, and software.

Key Players: Straumann, Dentsply Sirona, Align Technology, Nobel Biocare, and 3M Oral Care. - Distribution to Hospitals, Clinics

Dental 3D printing devices and materials are distributed through specialized dental suppliers to clinics and labs, either for in-house printing or outsourced production.

Key Players: Straumann, Dentsply Sirona, Align Technology, Nobel Biocare, and 3M Oral Care.

Kry Players in Dental 3D Printing Devices Market and their Offerings

- 3D Systems: Provides dental 3D printers, software, and materials for creating crowns, bridges, dentures, surgical guides, and orthodontic models with high precision and efficiency.

- Sprintray: Offers desktop dental 3D printers and biocompatible resins for crowns, bridges, and orthodontic appliances.

- Ackuretta: Supplies dental 3D printing systems, materials, and software for accurate restorations and models in clinics and labs.

- Asiga: Delivers high-speed, precise dental 3D printers and materials for crowns, bridges, dentures, and surgical guides.

- Renishaw: Provides metal and dental 3D printing solutions, including printers, software, and services for customized dental implants and prosthetics.

Recent updates on dental 3D printing devices

Personalized Dentistry and Same-Day Solutions Drive Growth

- On 19 March, the market for dental 3D printing equipment kept expanding due to the trend toward chairside customized dentistry. On-demand production of crowns, bridges, aligners, and dentures has greatly shortened turnaround times and enhanced patient satisfaction. Dental labs and clinics are spending more money on internal 3D printing systems to provide same-day care and cut down on outsourcing expenses.

Material Advancements and Digital Workflow Integration Boost Efficiency

- In April 2025, the range of printable dental applications has been increased by developments in ceramic-based materials, biocompatible resins, and hybrid composites. From impression to finished prosthetic, digital workflows have been expedited through integration with intraoral scanners and CAD/CAM software. This smooth transition between diagnosis design and fabrication is increasing restoration and orthodontic device accuracy and decreasing manual errors.

Latest Announcement by Industry Players

- In February 2024, an innovative solutions provider for dental 3D printing, LuxCrea, Inc., added Kevin Dillon to lead its dental sales team to enhance the market expansion of LuxCreo's innovative dental 3D printing workflow.

Recent Developments

- On 21 February 2025, Formlabs launched its next-generation dental 3D printer, Form 4B, featuring faster print times, improved resolution, and compatibility with over 15 dental resins. The device supports the production of surgical guides, splints, and permanent crowns, targeting high-volume dental labs.

- In March 2025, 3D Systems introduced a new line of high-speed dental printers under the NextDent series, incorporating AI-assisted print monitoring and automated calibration. These printers are tailored for multi-patient batch printing and are optimized for orthodontic models and RPD (removable partial denture) frameworks.

- Also in March 2025, Stratasys announced a strategic partnership with leading dental scanner manufacturer Medit to offer an integrated digital dentistry ecosystem. The partnership enhances precision in the scanning-to-printing pipeline, reducing workflow complexity for dental professionals.

- In March 2025, SprintRay expanded its presence in Europe by opening a new dental printing innovation center in Germany. The facility will support clinical trials, resin development, and practitioner training, strengthening its footprint in the rapidly growing EU dental market.

- In March 2024, an experienced global leader in stereolithography, UnionTech launched its new fully automated 3D printer EvoDent D300 at Dental South China. The machine is designed for medium and large denture processing factories, utilizes digital light processing (DLP) 3D-printing technology, and targets restoration and implant model applications.

- In February 2024, a U.S.-based 3D printer manufacturer, 3D Systems launched its new multi-material 3D printed denture offering. This is being advertised as the industry's first solution for monolithic, jetted, and multi-material 3D-printed dentures.

- In May 2024, SprintRay, a Dental 3D printing brand launched its Pro 2 line of desktop 3D printing systems alongside two new resins from the company's BioMaterial Innovation Lab.

- In July 2024, a new high-speed 3D printer, the DentalJet XL was launched by Stratasys. The aim behind this launch was to reduce costs and improve dental lab productivity.

- In August 2024, Premium Teeth Resin, Formlabs received FDA 510(k) Medical Device Clearance for the 3D printing of several dental devices. The material can be used to 3D print natural-looking teeth for temporary single-unit restorations, temporary full-arch implant-supported restorations, and digital dentures.

Segment Covered in the Report

By Equipment

- 3D Scanner

- Printer

By Technology

- Stereolithography

- LCD

- FDM

- SLS

By Material

- Plastics

- Metals

By Application

- Prosthodontics

- Orthodontics

- Implantology

By End-use

- Dental Labs

- Hospitals

- Clinics

By Region

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting