What is the Single-Use Filtration Assemblies Market Size?

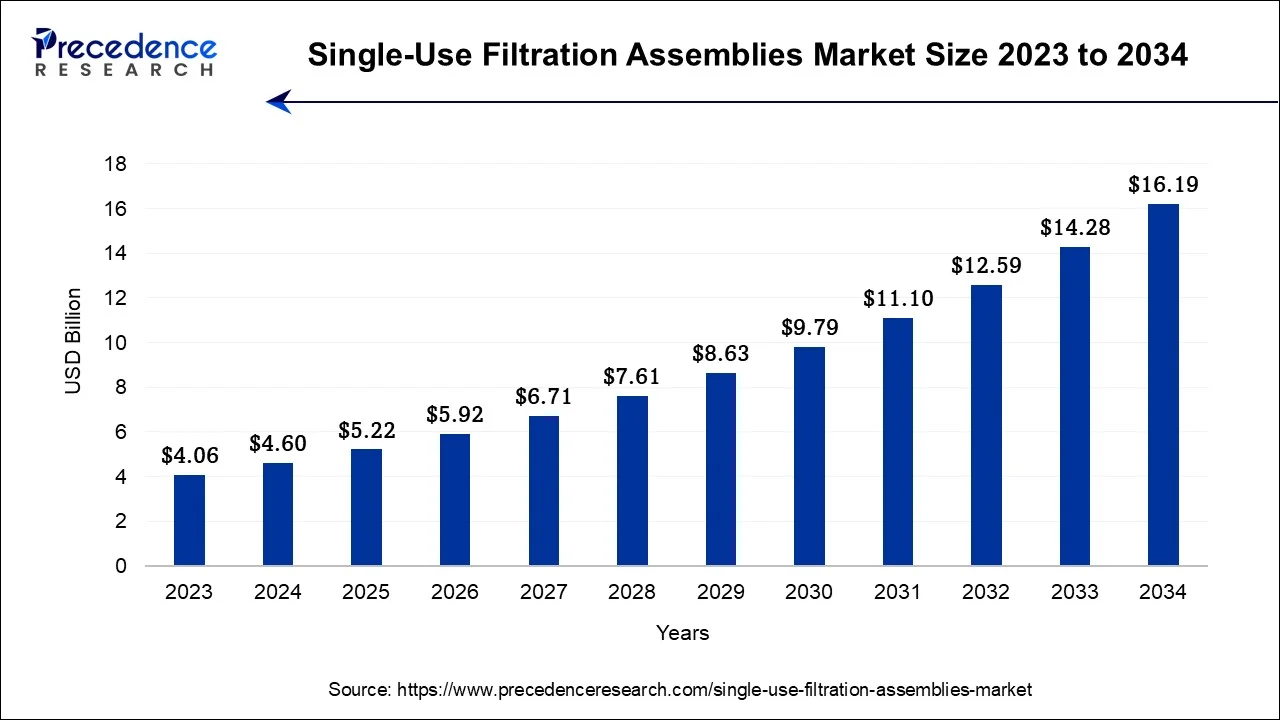

The global single-use filtration assemblies market size is calculated at USD 5.22 billion in 2025 and is projected to reach around USD 16.19 billion by 2034, ragistaring a healthy CAGR of 13.40% from 2025 to 2034.

Market Highlights

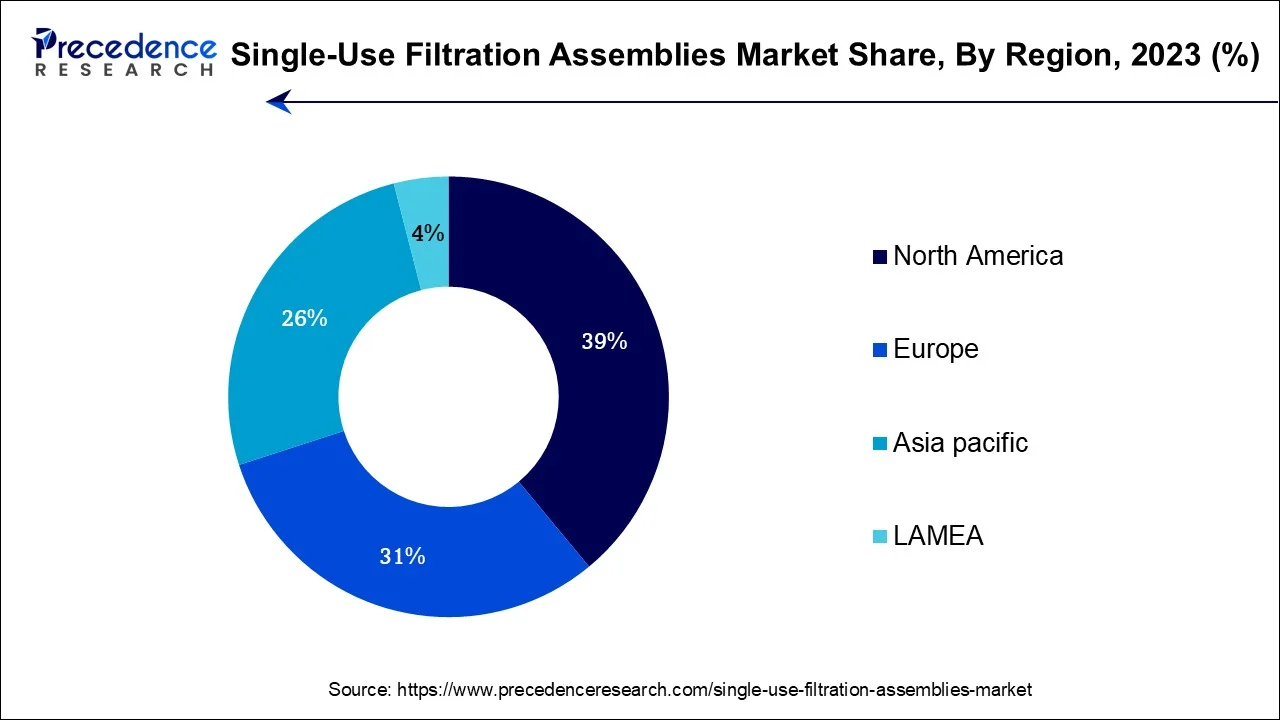

- North America contributed the largest revenue share of 39% in 2025.

- Asia-Pacific region is expected to expand at the fastest CAGR from 2025 to 2034.

- By Type, the membrane filtration segment has held the highest market share of 51% in 2025.

- By Type, the depth filtration segment is expected to expand at the fastest CAGR of 16.8% during the projected period.

- By Application, the bioprocessing/biopharmaceuticals segment captured more than 43% of revenue share in 2025.

- By Application, the laboratory use segment is expected to grow at the fastest rate over the projected period.

- By Product, the filters segment had the largest market share of 26.8% in 2025.

- By Product, the cartridges segment is anticipated to expand at the fastest CAGR over the projected period.

Market Size and Forecast

- Market Size in 2025: USD 5.22 Billion

- Market Size in 2026: USD 5.92 Billion

- Forecasted Market Size by 2034: USD 16.19 Billion

- CAGR (2025-2034): 13.40%

- Largest Market in 2024: North America

- Fastest Growing Market: Asia Pacific

Market Overview

The single-use filtration assemblies market is a sector within the biopharmaceutical and pharmaceutical industries. It focuses on disposable filtration systems comprising filters and related components tailored for one-time usage.

These systems are primarily employed in applications like bioprocessing and pharmaceutical manufacturing, offering a convenient and efficient solution to meet the industry's stringent requirements for sterile filtration and separation processes. They are crucial for achieving sterile filtration, clarification, and separation of biomolecules, vaccines, and pharmaceutical products.

This market is characterized by its emphasis on reducing cross-contamination risks, enhancing operational efficiency, and meeting stringent regulatory standards in biomanufacturing, making it an essential component of modern bioprocessing.

Single-Use Filtration Assemblies Market Growth Factors

- The single-use filtration assemblies market is a vital component of the biopharmaceutical and pharmaceutical sectors, specializing in disposable filtration systems. These assemblies are meticulously designed for one-time use, primarily in bioprocessing and pharmaceutical manufacturing. They play a pivotal role in achieving sterile filtration, biomolecule separation, and clarification of pharmaceutical products, ensuring product quality, and mitigating cross-contamination risks.

- Several key trends and growth drivers are shaping the market. Including there is a notable shift towards adopting single-use technologies across the biopharmaceutical industry. This transition enhances operational flexibility, minimizes cleaning validation efforts, and significantly reduces the risk of product cross-contamination.

- Despite its growth prospects, the single-use filtration assemblies industry faces certain challenges. Ensuring the robustness and integrity of single-use components, especially during critical processes, is essential. Maintaining regulatory compliance, validation protocols, and quality assurance are paramount due to the impact of filtration on product quality and patient safety. Additionally, some traditionalists in the industry may require time to fully embrace single-use technologies, creating an adoption curve.

- The market presents numerous business opportunities. Companies can invest in research and development to enhance the design and performance of single-use filtration assemblies, meeting evolving industry needs. Collaborations with biopharmaceutical manufacturers to offer customized solutions can be advantageous. Additionally, expanding into emerging markets with a growing biopharmaceutical sector and emphasizing the environmental sustainability of single-use products aligns with broader industry trends.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 5.22 Billion |

| Market Size in 2026 | USD 5.92 Billion |

| Market Size by 2034 | USD 16.19 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 13.40% |

| Largest Market | North America |

| Base Year | 2025 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Application, Product, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Flexibility for smaller batches and operational flexibility

The flexibility offered by single-use filtration assemblies for smaller batches is a significant market driver. As the demand for niche and personalized medicine markets grows, manufacturers require cost-effective solutions that can efficiently process smaller production runs. Single-use filtration assemblies enable precisely that, making them a compelling choice for pharmaceutical companies seeking to meet the needs of these specialized markets while maintaining operational efficiency and cost-effectiveness.

Moreover, Operational flexibility is a driving force behind the increased demand for single-use filtration assemblies. These assemblies simplify processes, reduce downtime, and minimize the need for extensive cleaning and validation procedures. This flexibility allows biopharmaceutical manufacturers to adapt swiftly to changing production requirements and accommodate diverse products and batch sizes. As a result, companies can enhance efficiency, reduce costs, and respond more effectively to market dynamics, making single-use filtration assemblies a preferred choice in the industry.

Restraints

Limited compatibility and complex processes

Limited compatibility, paradoxically, drives market demand for single-use filtration assemblies. As biopharmaceutical processes become more diverse and specialized, manufacturers seek adaptable solutions. The exclusivity of single-use systems for certain applications fosters demand as companies recognize the need for a versatile portfolio of filtration options. While not universally compatible, single-use filtration assemblies cater to specific requirements, providing tailored solutions for processes where traditional systems fall short, ultimately enhancing their appeal in niche segments of the industry.

Moreover, Complex biopharmaceutical processes drive the demand for single-use filtration assemblies. These processes require advanced filtration solutions capable of meeting intricate manufacturing needs. Single-use assemblies offer the flexibility to adapt to complex workflows, reducing downtime associated with cleaning and validation in comparison to traditional stainless-steel systems. Consequently, they enhance operational efficiency, making them an attractive choice for biopharmaceutical companies navigating intricate production processes while ensuring cost-effectiveness.

Opportunities

Diversification, customization and specialization

Diversification within the single-use filtration assemblies market fuels demand as it caters to a wide array of applications. These assemblies can be customized to suit various processes, from large-scale bioprocessing to smaller niche markets. This adaptability ensures that single-use filtration solutions are relevant across diverse sectors of the biopharmaceutical and pharmaceutical industries, making them a preferred choice for manufacturers seeking versatile and efficient filtration solutions for different production needs.

Moreover, Customization and specialization are significant drivers of demand in the single-use filtration assemblies market. Manufacturers require tailored solutions that align precisely with their unique bioprocessing needs and product requirements. Single-use filtration assemblies offer the flexibility to customize components and configurations, optimizing performance and efficiency for specific applications. This ability to address diverse and specialized processes effectively makes single-use systems a compelling choice for biopharmaceutical companies, propelling market growth.

Segments Insights

Type Insights

The membrane filtration segment has held a 51% revenue share in 2025.Membrane filtration is a critical type within the single-use filtration assemblies market. It involves using semipermeable membranes to separate particles, microorganisms, and contaminants from liquids or gases in pharmaceutical and bioprocessing applications. Recent trends indicate a growing preference for membrane filtration due to its effectiveness in achieving precise separations, enhanced product quality, and reduced maintenance compared to traditional methods. Moreover, advancements in membrane materials and designs are continually improving filtration efficiency and expanding the scope of applications, reinforcing its pivotal role in the single-use filtration assemblies market.

The depth filtration segment is anticipated to expand at a significant CAGR of 16.8% during the projected period. Depth filtration, a key type in the single-use filtration assemblies market, involves the use of porous matrices to trap particles and contaminants. This method is widely employed in biopharmaceutical manufacturing to remove impurities from liquids and gases. Current trends in depth filtration include the development of enhanced filter media for greater efficiency, scalability, and reduced maintenance. Single-use depth filtration assemblies are gaining popularity due to their flexibility and cost-effectiveness, enabling seamless integration into bioprocessing operations while meeting stringent regulatory standards.

Application Insights

The bioprocessing/biopharmaceuticals segment is anticipated to hold the largest market share of 43% in 2025. Within the context of the single-use filtration assemblies market, "bioprocessing" refers to their application in the biopharmaceutical industry. This usage encompasses filtration and separation processes integral to producing biologics, monoclonal antibodies, and other biopharmaceutical products. Noteworthy trends in this sector include a rising demand for biologics, personalized medicines, and biosimilars. Additionally, the industry is increasingly favoring cost-effective, scalable manufacturing approaches, with a demonstrated need for rapid scale-up capabilities during critical situations such as the COVID-19 pandemic. These factors are driving the heightened adoption of single-use filtration assemblies in bioprocessing.

The Laboratory Use segment is projected to grow at the fastest rate over the projected period. In laboratory use, single-use filtration assemblies refer to disposable filtration systems employed for various applications, such as sample preparation, clarification, and sterilization. A notable trend in this segment is the increasing preference for single-use systems in laboratory workflows. Laboratories are adopting these assemblies to streamline processes, reduce contamination risks, and enhance operational efficiency. The convenience, cost-effectiveness, and scalability of single-use filtration solutions align well with the evolving needs of laboratories, making them an integral component of modern research and development practices.

Product Insights

The filters segment had the highest market share of 26.8% in 2025. In the single-use filtration assemblies market, filters play a central role in separating particles and contaminants from pharmaceutical and biopharmaceutical products. Recent trends in filter technology include the development of high-capacity, high-flow filters to accommodate larger batches and faster processing times. Moreover, there's a growing emphasis on improving the filtration of smaller particles, such as viruses and nanoparticles, to enhance product purity. Additionally, there is a shift toward using innovative materials that offer enhanced biocompatibility and reduced extractables, ensuring the highest product quality and patient safety.

The cartridges is anticipated to expand at the fastest rate over the projected period. In the single-use filtration assemblies market, cartridges are essential components used for the filtration of liquids and gases. These disposable filtration units consist of filter media encased in a housing and are designed for one-time use. Cartridges are available in various sizes and configurations to accommodate diverse biopharmaceutical and pharmaceutical applications. Trends in cartridge technology include the development of high-capacity and high-efficiency designs, customization options, and the integration of advanced materials to enhance filtration performance. These trends cater to the growing demand for efficient and precise filtration solutions in bioprocessing and pharmaceutical manufacturing.

Regional Insights

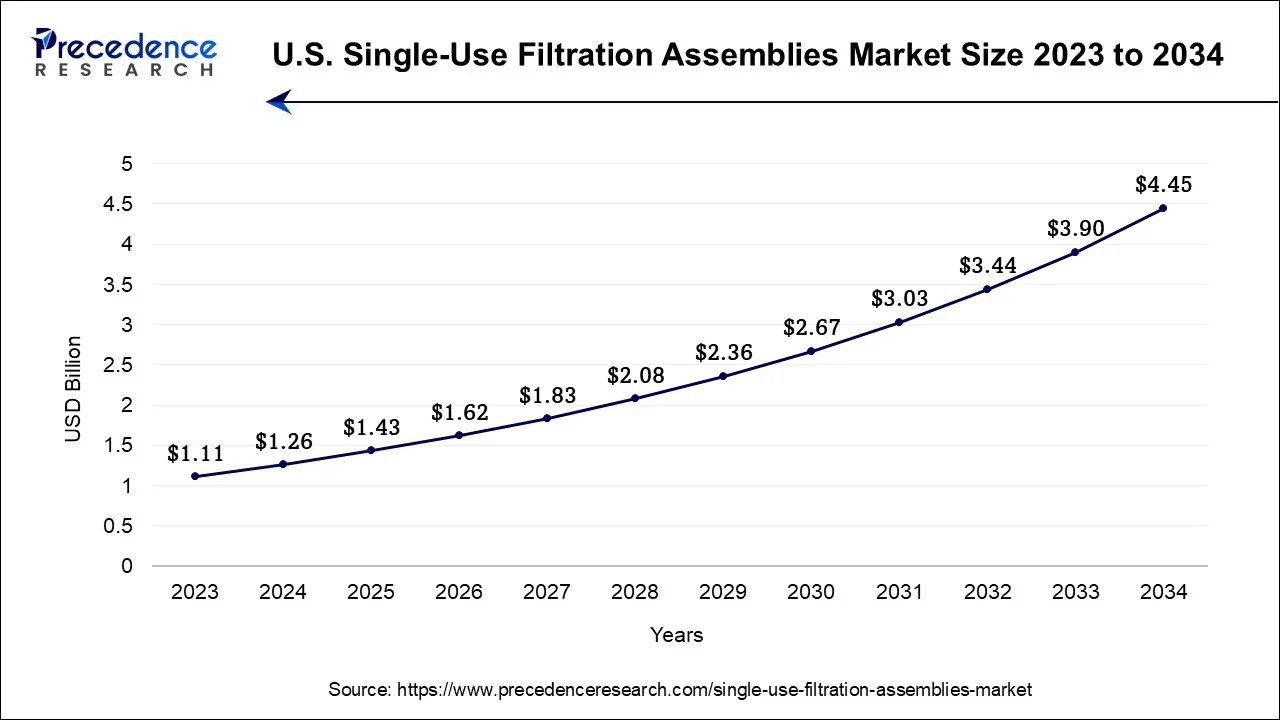

U.S. Single-Use Filtration Assemblies Market Size and Growth 2025 to 2034

The U.S. single-use filtration assemblies market size was exhibited at USD 1.43 billion in 2025 and is estimated to to be worth around USD 4.45 billion by 2034, growing at a CAGR of 13.44% from 2025 to 2034.

North America has held the largest revenue share of 39% in 2025. In North America, the single-use filtration assemblies market is marked by several noteworthy trends. The region exhibits a strong emphasis on biopharmaceutical research and manufacturing, driving the demand for efficient and flexible single-use filtration solutions. Regulatory compliance and adherence to stringent quality standards remain paramount. The COVID-19 pandemic accelerated the adoption of these systems, with pharmaceutical companies seeking rapid production of vaccines and therapeutics. Furthermore, there is a growing focus on sustainability, prompting innovations in recyclable single-use components to address environmental concerns while maintaining the market's growth trajectory.

Asia-Pacific is estimated to observe the fastest expansion in the Asia-Pacific region, the single-use filtration assemblies market is witnessing notable trends. The expansion of the biopharmaceutical industry in nations such as China and India are propelling the need for cost-efficient and effective filtration solutions. Moreover, the emphasis on quality and regulatory compliance in pharmaceutical manufacturing is fueling the adoption of single-use systems. As the region becomes a global hub for pharmaceutical production, single-use filtration assemblies are increasingly recognized as essential components in ensuring sterile and efficient bioprocessing operations, further contributing to market growth.

In Europe, the single-use filtration assemblies market is witnessing notable trends. Stringent regulatory standards and a focus on product quality are driving the adoption of single-use systems in biopharmaceutical manufacturing. Additionally, the region's commitment to environmental sustainability is promoting the development of eco-friendly single-use components. The COVID-19 pandemic has accelerated the acceptance of these systems, particularly in vaccine production. Europe's growing biopharmaceutical sector, along with an emphasis on cost-effective and flexible manufacturing processes, further contributes to the demand for single-use filtration assemblies in the region.

Single-Use Filtration Assemblies Market Companies

- Pall Corporation (a part of Danaher Corporation)

- Merck KGaA (EMD Millipore)

- Sartorius AG

- Thermo Fisher Scientific Inc.

- 3M Company

- GE Healthcare (Cytiva)

- Parker Hannifin Corporation

- Eaton Corporation

- Repligen Corporation

- Meissner Filtration Products, Inc.

- Entegris, Inc.

- Amazon Filters Ltd.

- Advantec MFS, Inc.

- Graver Technologies LLC

- Sterlitech Corporation

Recent Developments

- In 2022, Merck has committed approximately €100 million to expedite single-use manufacturing in China. In collaboration with the Administrative Management Committee of Wuxi National High-Tech Industrial Development Zone, they aim to foster and strengthen the life science ecosystem in Wuxi.

- In 2021, Pall Corporation and Cytiva jointly invested USD 1.5 billion to address the increasing demand for biotechnology solutions. This significant investment demonstrates their commitment to expanding capacity and capabilities in the rapidly growing biopharmaceutical industry.

Segments Covered in the Report

By Type

- Membrane Filtration

- Depth Filtration

- Centrifugation

- Others

By Application

- Pharmaceuticals Manufacturing Market

- Bioprocessing/Biopharmaceuticals Market

- Laboratory Use

By Product

- Filters

- Cartridges

- Membranes

- Manifold

- Cassettes

- Syringes

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting