Healthcare Additive Manufacturing Market Size and Forecast 2025 to 2034

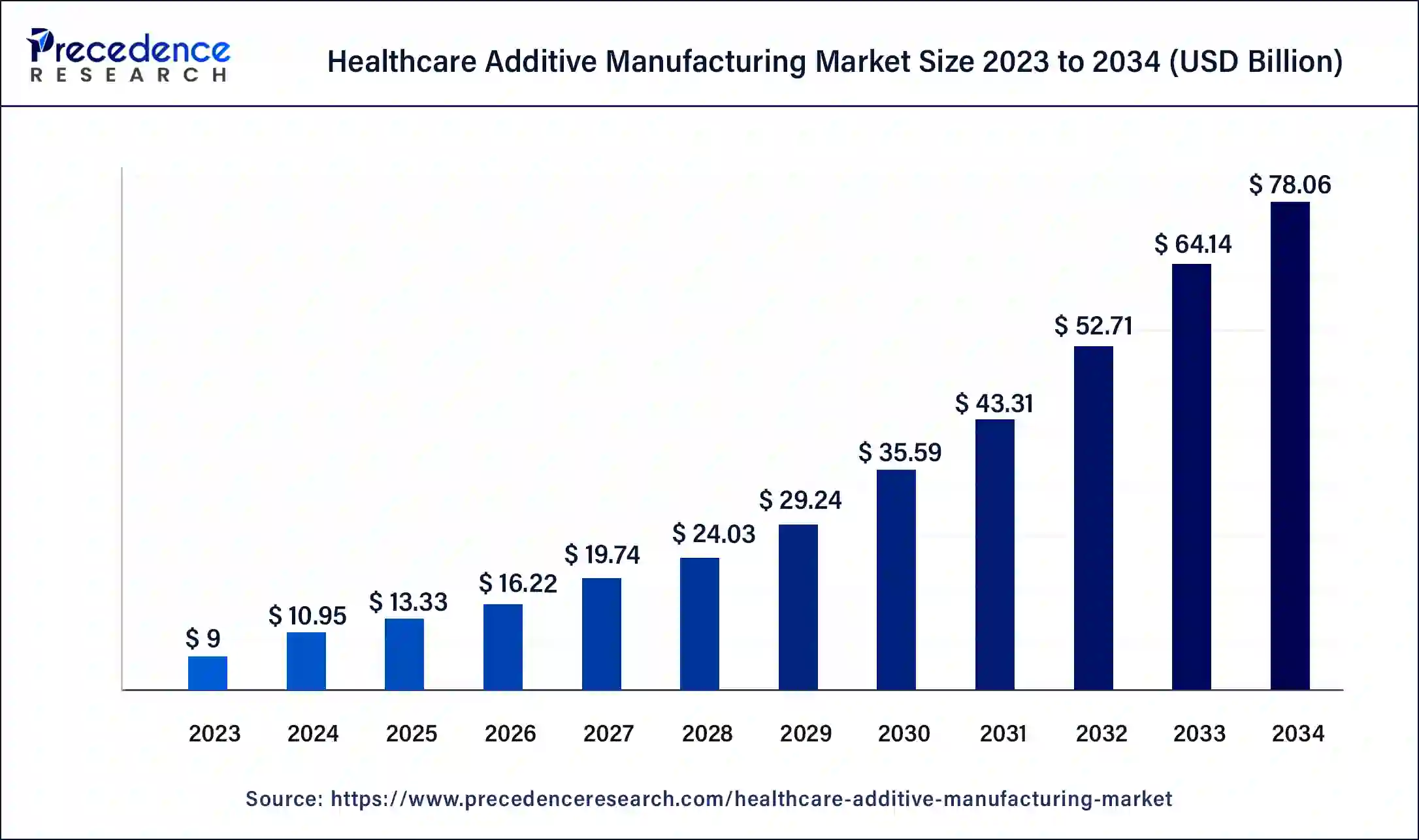

The global healthcare additive manufacturing market size was estimated at USD 10.95 billion in 2024 and is predicted to increase from USD 13.33 billion in 2025 to approximately USD 78.06 billion by 2034, expanding at a CAGR of 21.70% from 2025 to 2034.

Healthcare Additive Manufacturing Market Key Takeaways

- In terms of revenue, the healthcare additive manufacturing market is valued at $13.33 billion in 2025.

- It is projected to reach $78.06 billion by 2034.

- The healthcare additive manufacturing market is expected to grow at a CAGR of 21.70% from 2025 to 2034.

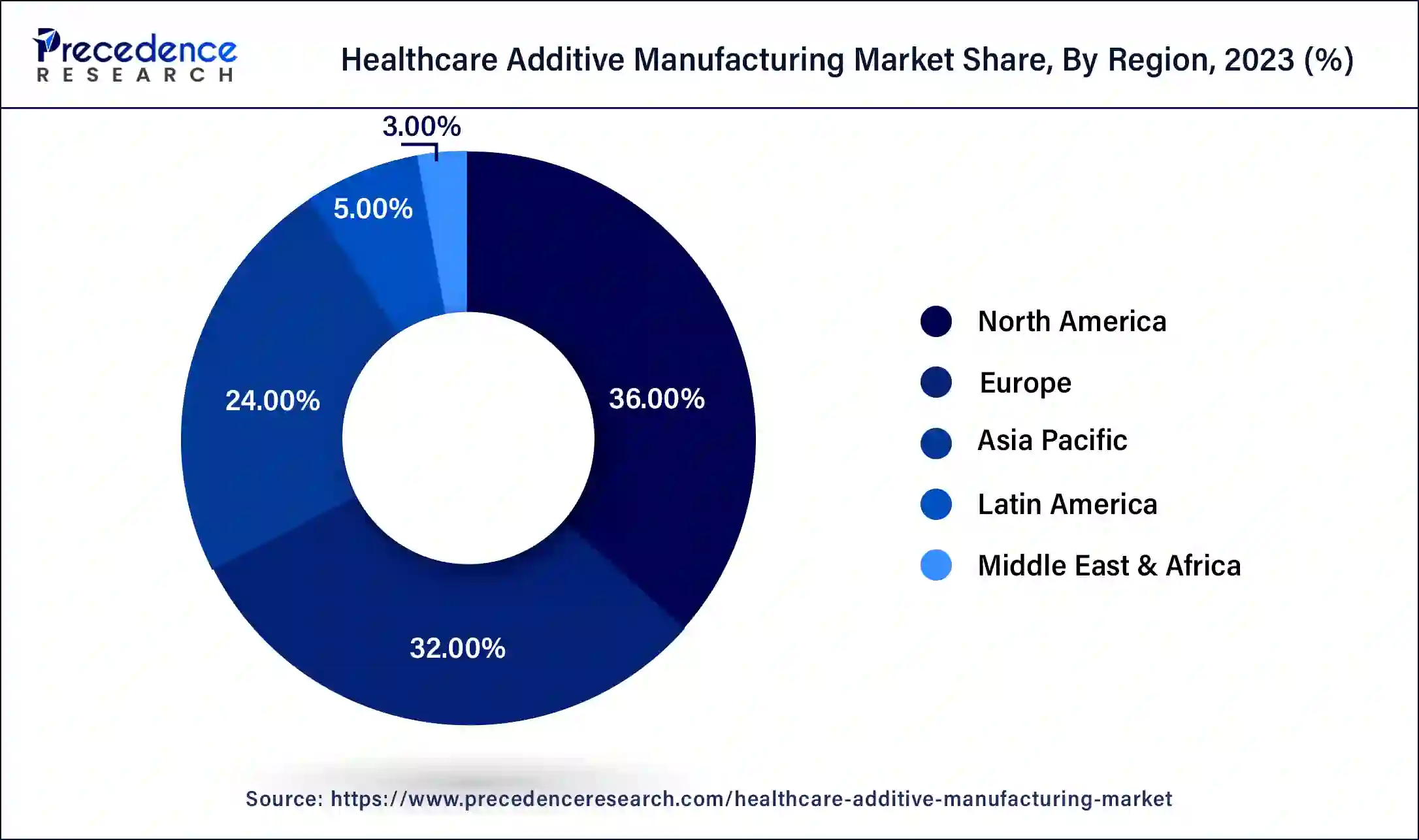

- North America generated more than 36% of revenue share in 2024.

- Asia-Pacific is expected to expand at the fastest CAGR during the forecast period.

- By Technology, the laser sintering segment has held a market share of 31.5% in 2024.

- By Technology, the deposition modeling segment is anticipated to grow at the fastest CAGR during the projected period.

- By Material, the polymer segment had the largest market share of 55% in 2024.

- By Application, the medical implant segment contributed more than 32% of revenue share in 2024.

How has AI benefited the market?

All in all, artificial intelligence (AI) in healthcare additive manufacturing enjoys several advantages: optimal designs, enhanced quality controls, ease of production, and better patient outcomes. AI algorithms optimize designs by contemplating thousands of parameters and thus allow them to be made most efficiently, saving materials, simplifying production, and ultimately lowering the cost. AI vision systems detect defects as they occur, foresee problems in production, or carry out analyses concerning very complex geometries designed to be lightweight and best performing in their specific applications. Hence, from the conversion of designs into production, automation reduces labor costs, increases efficiency, and minimizes downtime. AI assists pharma companies in drug discovery by spotting drug candidates from massive databases. For personalized healthcare, AI considers patient records, genetics, and health monitoring so as to predict their response to treatment and recommend a tailored treatment plan. Surgical assistance implies employing AI to generate highly accurate 3D models of patient anatomy.

U.S. Healthcare Additive Manufacturing Market Size and Growth 2025 to 2034

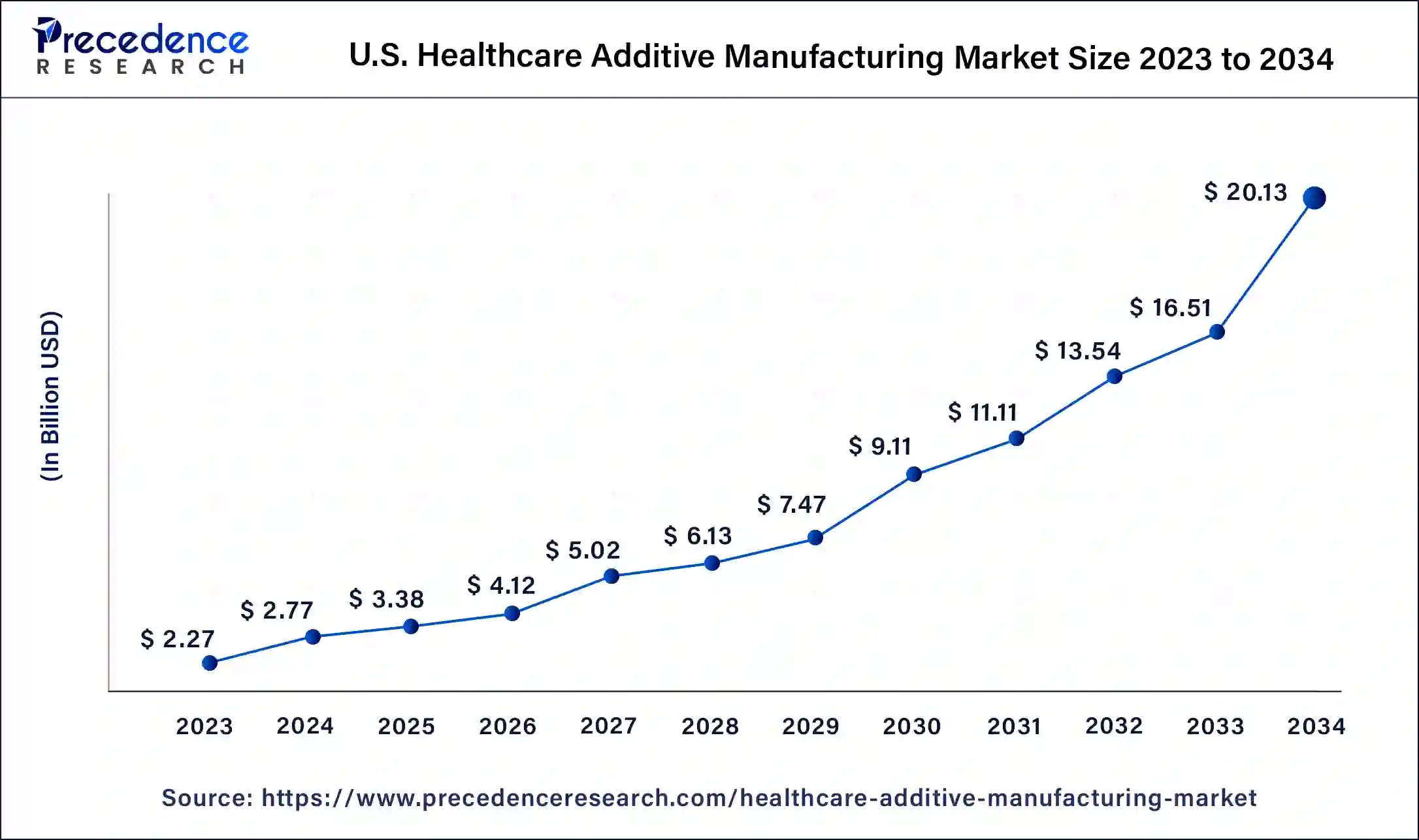

The U.S. healthcare additive manufacturing market size was estimated at USD 2.77 billion in 2024 and is predicted to be worth around USD 20.13 billion by 2034, at a CAGR of 21.94% from 2025 to 2034.

North America is expected to dominate the market with a revenue share of more than 36% in 2024 and is expected to grow significantly during the forecast period owing to the presence of major market players in the region such as GE Additive, 3D Systems, Inc., Stratasys Ltd., and many others investing heavily in research and development of new technology healthcare devices. Also, the favorable Government regulations in the U.S. are fostering the market growth. For instance, On 8th September 2021, 3D Systems has acquired Oqton, a software business that is a pioneer in the development of an intelligent, cloud-based Manufacturing Operating System (MOS) platform. This acquisition will aid 3D Systems in the development of flexible production environments that increasingly include a variety of advanced manufacturing and automation technologies, including additive manufacturing (AM) solutions, into their manufacturing processes.

Asia Pacific is also anticipated to be the fastest growing market in the upcoming years due to the presence of developing economies and the availability of large population in India and China that requires advanced medical facilities. Moreover, the demand in dental 3D printing due to the rise in people count undergoing tooth replacement surgeries will fuel the market growth. Also, the rising cases of arthritis and the fast growing healthcare infrastructure are estimated to drive the growth of the Healthcare Additive Manufacturing Market in the Asia Pacific region.

Healthcare Additive Manufacturing Market Growth Factors

The increasing need for customization of medical products such as implants is expected to drive the market growth. The advent of advanced technologies such as 3D printing is expected to provide cost-effective ways to produce complex medical components and parts. The growing demand and the unmet needs due to an increase in the number of procedures and hospitalizations in the healthcare sector the surge in chronic disorders are the factors that are expected to fuel the growth of the healthcare additive manufacturing market.

Additive Manufacturing (AM) permits the manufacturing of complex designs that are difficult or expensive to be developed using the traditional machinery, molds, milling, and dies. It helps in rapid prototyping and offers a dynamic and design-driven process. Additive manufacturing is suitable for prototyping using CAD, as it removes the time-consuming procedure and higher costs involved with the production of complicated devices.

Polymers are extensively used additive manufacturing materials because of its potential to be used in various applications of the healthcare industry. This factor is expected to drive the growth of the market.

- Market is growing on account of increased demand for customized medical products, such as implants, supported by the growing procedures and surgical cases.

- Technologies such as 3D printing make it cheaper to manufacture complicated medical parts and address the healthcare demand.

- Additive manufacturing aids in rapid prototyping from computer-aided design, thereby cutting down production time and cost for complex medical devices.

- This is a technology that can produce complex designs with greater ease and at a lesser cost compared to traditional manufacturing techniques such as milling or molds.

- The market further expands owing to the widespread use of polymers in additive manufacturing because of their varied usages in healthcare.

Trends in the Healthcare Additive Manufacturing Market

- Integration of AI with additive manufacturing/3D printing gives more precise results than manual efforts. It helps predict how material will react, makes a more efficient map, and suggests customization for medical devices. Machine learning makes production more efficient and reduces costs, which supports faster iterations with precise and better results. Additive manufacturing is efficient only when done with accuracy, which is offered by artificial intelligence nowadays.

- Hospitals are inclined to set up additive manufacturing on-site. This trend will help hospitals and professionals to create the required medical tools and implants at an early stage. This offers customization and helps surgeons to achieve optimum results within a shorter timeframe. Such a change saves operation time and costs as well.

- Healthcare additive manufacturing companies are trying to cut down on waste materials. To achieve this, recycling is a good option, which will make new medical equipment. The use of materials that are sustainable and eco-friendly for additive manufacturing is another factor supporting the market's expansion on a large scale. By leveraging this idea, researchers are expecting to generate human organs that will be completely functional on their own with the help of bioprinting methods, aiming to support organ transplant surgeries on a larger scale, which is crucial to achieve due to ongoing health conditions across the globe.

Market Scope

| Report Highlights | Details |

| Growth Rate from 2025 to 2034 | CAGR of 21.70% |

| Market Size in 2024 | USD 10.95 Billion |

| Market Size in 2025 | USD 13.33 Billion |

| Market Size by 2034 | USD 15.35 Billion |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Largest Market | North America |

| Fastest Growing Market | Asia Pacific |

| Segment Covered | By Technology, By Material, By Application, and By Region |

| Regions Covered | Asia Pacific, North America, Europe, Latin America, Middle East and Africa |

Market Dynamics

Drivers

Technological Advancements

Greater control over the 3D printing process and technical enhancement of bioprinting now allow exceedingly complicated medical devices and implants to be personalized per need, with more precision and faster output. Innovations in smart materials and AI-assisted design tools lead to higher device accuracy and cost reduction, while they also speed up development. In essence, rapid prototyping and patient-specific solutions are enabling revolutionary designs in healthcare manufacturing. Improved printing techniques, with intelligent materials and AI-driven optimization methods, culminate in a faster, more precise, and highly personalized production of medical devices to improve treatment outcomes and explore applications of additive manufacturing in medicine.

Restraining Factors

Availability of Expertise

The AM field for healthcare is facing an acute shortage of people trained in design, operation/production, and quality control aspects in AM for medical applications. Such niche expertise is necessary for a design to be safe, compliant with regulations, and manufactured efficiently. Having this minuscule talent pool continues to constrain the embracement and scaling up of AM technology for healthcare purposes. Closing the gap would entail concerted training efforts, cross-sector collaboration, and investment in developing the workforce. For now, with less-than-qualified personnel availability, it can be said to be the greatest bottleneck of additive manufacturing being geared up for medical device production on a wide scale.

Opportunity

Customized Imants and Prosthetics

Additive manufacturing enables the fabrication of patient-specific implants and prosthetics tailored to individual anatomy, thereby enhancing fit and, consequently, comfort and functionality. Such customization creates fewer complications and leads to faster recovery from the iatrogenic interventions compared to standard devices. 3D printing in terms of rapid prototyping and urgent delivery plays a key role wherever the need is critical. There have been advancements with regard to biocompatible materials that simultaneously increase implantation durability and biocompatibility. The growing demand for personalized medical solutions, therefore, opens up large avenues for customization in implants and prosthetics via additive manufacturing in healthcare.

Technology Insights

The Healthcare Additive Manufacturing Market is divided into Stereolithography, Deposition Modeling, Electron Beam Melting, Laser Sintering, Jetting Technology, Laminated Object Manufacturing and Others.

Laser sintering technology segment dominated the market in 2024 accounting for more than 31.5% revenue share and is expected to grow significantly during the forecast period. The Laser Sintering (SLS) method is used to produce several pieces at a time without the need for any support to build objects to be used un the healthcare industry. This factor drives the market growth.

The deposition modeling segment is expected to increase at the fastest rate during the forecast period, allowing for the production of precise prototypes and complex forms out of photosensitive resins. Stereo lithography Technology segment is also predicted to make a significant contribution to market expansion because to its effectiveness in producing orthodontic and prosthetic parts that provides precise models with fine features and a smooth surface aspect.

Material Insights

TheHealthcare Additive Manufacturing Market is divided into Metals & Alloys, Polymers, Biological Cells and Others.

The polymer material segment dominated the market in 2024 contributing more than 55% of revenue share and is anticipated to grow remarkably during the forecast period. The polymer materials are widely used in the healthcare industry to create medical instruments, prosthetic limbs and related accessories. Some of the appealing characteristics that have made polymers the most widely used kind of material for AM techniques include Synthetic versatility & adaptability and numerous other properties of polymer materials. For medical education purpose Polymer-based models are extensively utilized. The Polymer-based models assist in implant designing, diagnosis and training & preoperative planning. Models of different body organs and body parts can be developed using the polymers and these models are used for practicing various delicate surgical operations.

Due to their increased use in surgical implants, the metal and alloys material category also contributed considerably in 2023 and will continue to do so in the future years. Due to their advantageous properties such as corrosion resistance, biocompatibility, and high strength, metals and alloys such as stainless steel, titanium, and cobalt-based alloys are commonly employed in the healthcare business. Medical implants made from cobalt chrome metal powder offer a good biocompatibility and a hardness that ensures long-term function. All of these factors are propelling the Healthcare Additive Manufacturing Market forward.

Application Insights

The Healthcare Additive Manufacturing Market is divided Prosthetics, Wearable Devices, Medical Implants, Tissue Engineering and Others. The medical implant segment contributed the largest share in 2024 accounting for more than 32% revenue share and is expected to grow significantly in the upcoming years because of the rise in adoption of orthopedic implants. The surge in geriatric population across the world has led to the rise in demand for orthopedic procedures, such as knee & hip replacements. Also, the increasing demand for trauma-associated devices, such as spinal implants has positively impacted the growth of the Healthcare Additive Manufacturing Market.

In the dental industry, Additive manufacturing is also increasingly used in scanning the mouth of the patient to develop accurate and customized solutions to fix problems associated with dental care. Also, many machines and materials are developed especially for dental treatments. All these attributes are expected to foster the market growth.

Healthcare Additive Manufacturing Market Companies

- GE Additive (General Electric)

- 3D Systems Inc.

- EnvisionTEC GmbH

- RegenHU

- Allevi Inc.

- EOS GmbH (Electro Optical Systems)

- Materialise N.V.

- Stratasys Ltd.

- Nanoscribe GmbH

- GPI Prototype and Manufacturing Services LLC.

Recent Developments

- In April 2025, the 3D System worked in collaboration with the Switzerland-based university Hospital Basel. This company's unique offering of point-of-care additive manufacturing solutions has been leveraged to produce a precisely designed medical device, regulation-compliant 3D printed PEEK facial implant. This implant was also successfully used for a surgery completed on 18th March 2025, highlighting its effective results.

- In February 2024, Spherene produced metamaterials with geometry presented by spheres. Spherene Inc. has developed an algorithm that creates adaptive density minimal surfaces that can support independent infill strategies, which are further used to lower mass and are able to manage material properties in 3D printed parts.

Segments Covered

By Technology

- Stereolithography

- Deposition Modeling

- Electron Beam Melting

- Laser Sintering

- Jetting Technology

- Laminated Object Manufacturing

- Others

By Material

- Metals & Alloys

- Polymers

- Biological Cells

- Others

By Application

- Medical Implants

- Prosthetics

- Wearable Devices

- Tissue Engineering

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting