What is the Non-Stick Conveyor Belt Market Size?

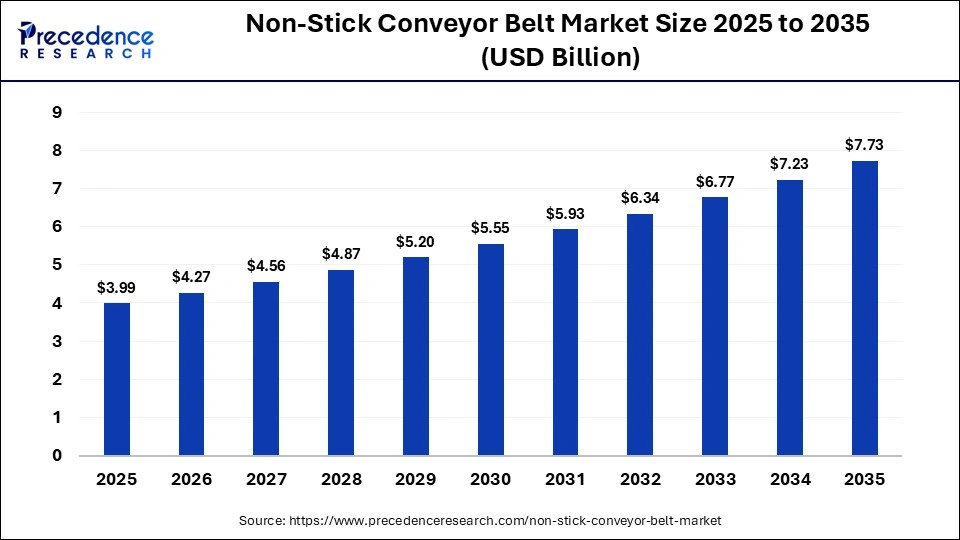

The global non-stick conveyor belt market size was calculated at USD 3.99 billion in 2025 and is predicted to increase from USD 4.27 billion in 2026 to approximately USD 7.73 billion by 2035, expanding at a CAGR of 6.82% from 2026 to 2035. This market is growing due to increasing demand for hygienic and efficient material handling solutions in various industries.

Market Highlights

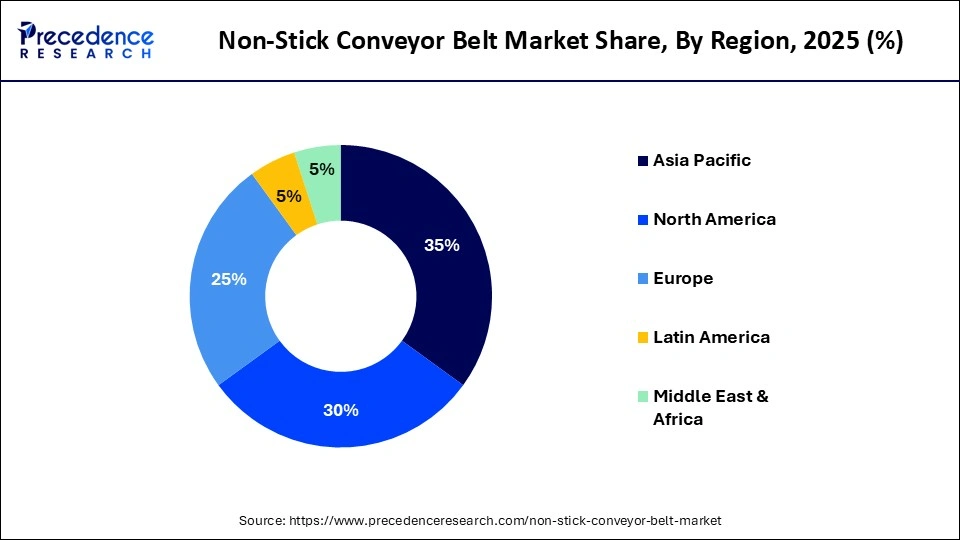

- Asia Pacific dominated the global non-stick conveyor belt market with a major share of approximately 35% in 2025.

- North America is expected to grow at the fastest CAGR between 2026 and 2035.

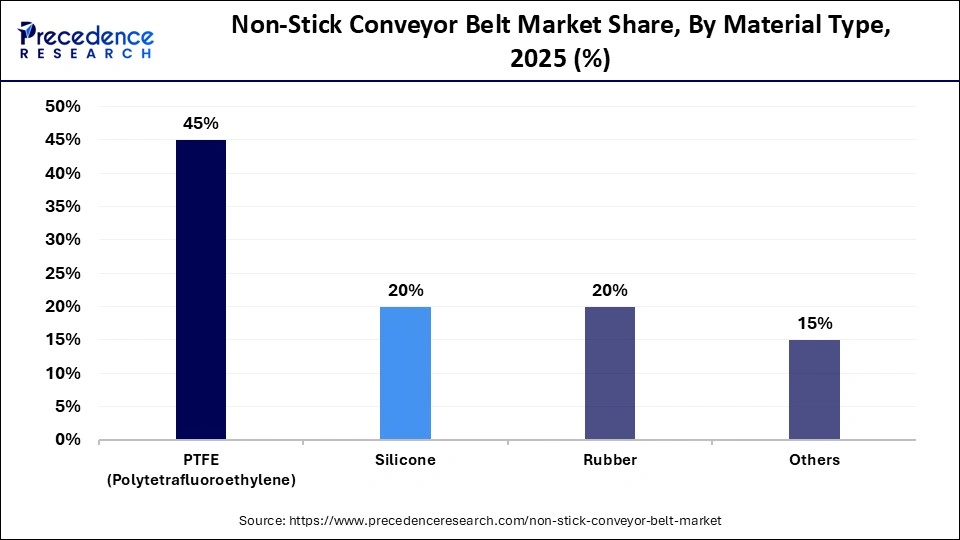

- By material type, the PTFE segment generated the biggest market share of approximately 45% in 2025.

- By material type, the silicone segment is expected to expand at the fastest CAGR of 6.3% between 2026 and 2035.

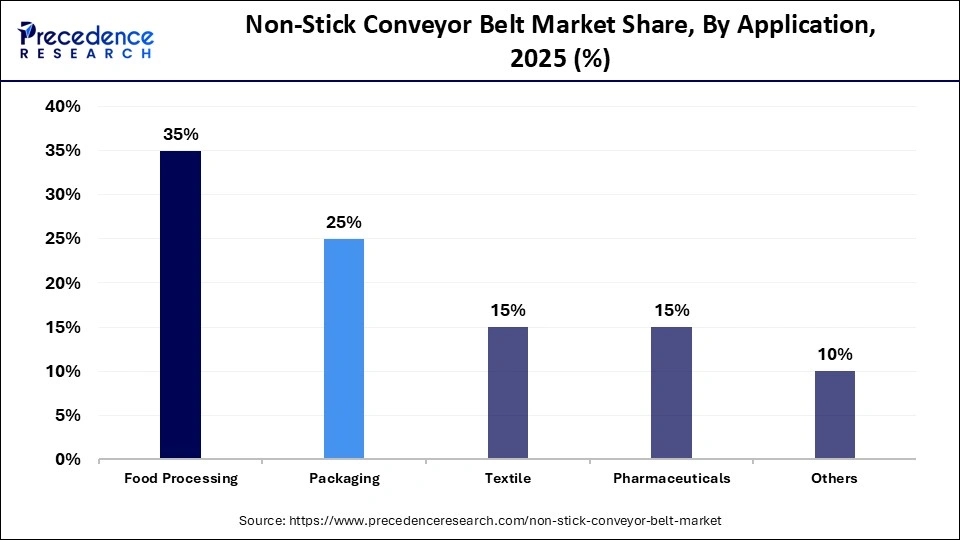

- By application, the food processing segment contributed the highest market share of approximately 35% in 2025.

- By application, the packaging segment is expected to grow at a strong CAGR between 2026 and 2035.

- By end-use industry, the food & beverage segment held a major market share of approximately 40% in 2025.

- By end-use industry, the pharmaceuticals segment is expected to expand at a significant CAGR from 2026 to 2035.

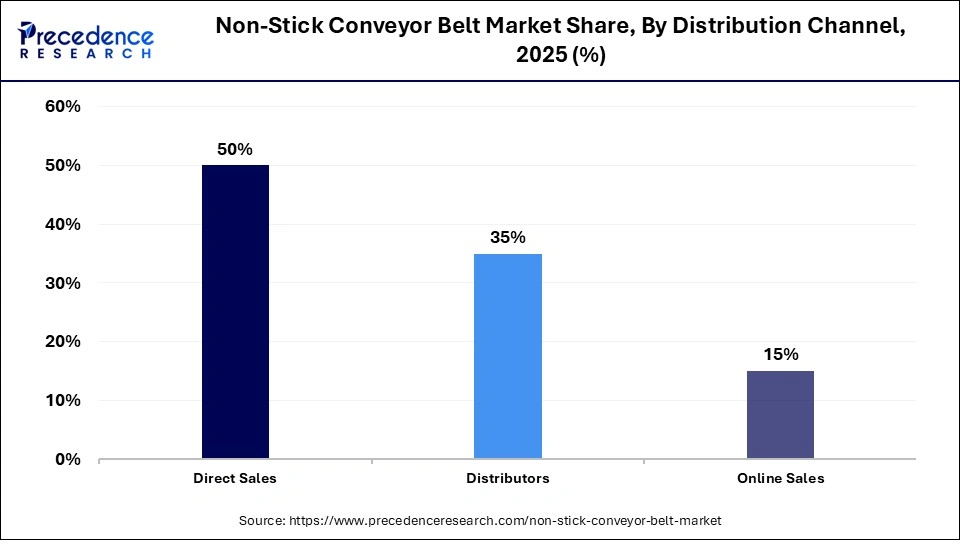

- By distribution channel, the direct sales segment generated the biggest market share of approximately 50% in 2025.

- By distribution channel, the online sales segment is expected to expand at the fastest CAGR of 5.9% between 2026 and 2035.

Why Is the Non-Stick Conveyor Belt Market Gaining Momentum?

The non-stick conveyor belt market is experiencing steady growth due to its growing use in the manufacturing, food processing, packaging, and pharmaceutical sectors, where easy material handling, hygienic compliance, heat resistance, and less maintenance downtime are critical to operational effectiveness. The market includes belts designed with surface coatings or materials that prevent adhesion of conveyed products, improving sanitation, reducing waste, and enhancing throughput in industrial processes. These belts find high demand in food processing, packaging, pharmaceuticals, textiles, and other sectors that require contamination‑free material handling. Additionally, the need for robust low-friction conveyor solutions is increasing due to the increased emphasis on automation and high-speed production lines. Market expansion is also being accelerated by strict food safety regulations and the need to reduce product contamination.

How is AI Transforming the Non-Stick Conveyor Belt Market?

Artificial intelligence (AI) is transforming the non-stick conveyor belt market by enabling real-time performance monitoring, predictive maintenance, and early wear and tear detection, all of which help to minimize scheduled downtime. Higher efficiency, lower operating cost, and more intelligent automated production environments are supported by AI-powered vision systems and sensors that also enhance quality control and optimize conveyor speed and load handling. Additionally, AI assists in customizing belt performance for specific industrial processes, optimizing temperature control, coating application, and throughput, ultimately enhancing productivity and reducing material waste.

Key Trends Shaping the Non-Stick Conveyor Belt Market

- Rising adoption of non-stick belts in food processing due to stricter hygiene and safety regulations.

- Increasing use of PTFE and silicone coated belts for high-temperature and non-contaminating applications.

- Growing integration of automation and smart manufacturing systems across industries.

- Demand for lightweight, durable, and low-friction conveyor materials to improve energy efficiency.

- Expansion of the pharmaceutical and bakery industries is driving specialized conveyor belt requirements.

- Custom-designed conveyor belts are gaining popularity for specific production needs.

- Increased focus on easy-to-clean and maintenance-free conveyor solutions to reduce downtime.

Future Market Opportunities

- Growing demand from emerging economies is due to rapid industrialization and food processing expansion.

- Rising adoption of AI-enabled and sensor-based conveyor systems for predictive maintenance.

- Increasing investments in automated packaging and material handling solutions.

- Opportunities in frozen food, ready-to-eat, and bakery product manufacturing sectors.

- Development of eco-friendly and recyclable non-stick conveyor belt materials.

- Expansion of e-commerce logistics and high-speed sorting facilities.

- Rising demand for customized conveyor solutions in niche industrial applications.

How are Government Initiatives Supporting the Non-Stick Conveyor Belt Market?

Government initiatives promoting manufacturing growth, automation, and food safety are indirectly boosting demand for non-stick conveyor belts. Advanced material handling system adoption is being accelerated by policies that support industrial modernization and domestic production, while the food and pharmaceutical industries are moving toward high-performance, easily cleaned conveyor belt solutions due to more stringent hygiene regulations.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 3.99 Billion |

| Market Size in 2026 | USD 4.27 Billion |

| Market Size by 2035 | USD 7.73 Billion |

| Market Growth Rate from 2026 to 2035 | CAGR of 6.82% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Material Type, Application, End User Industry, Distribution Channel, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segment Insights

Material Type Insights

What Made PTFE the Dominant Segment in the Non-Stick Conveyor Belt Market?

The PTFE segment dominated the market with a 45% share in 2025, driven by its exceptional chemical inertness, high heat resistance, and superior non-stick qualities. PTFE conveyor belts can withstand elevated temperatures while ensuring smooth product release, making them highly preferred in industries such as food processing, electronics, and packaging. Their long service life, minimal maintenance requirements, and compliance with food safety regulations have established PTFE as the material of choice for high-volume industrial applications.

The silicone segment is expected to grow at the fastest CAGR of 6.3% in the coming years, driven by rising demand for lightweight, flexible, and cost-effective conveyor belt solutions. Silicone belts offer superior performance in delicate handling applications, particularly in the processing of baked goods and confections, due to their enhanced elasticity and excellent heat resistance. The adoption of silicone-based non-stick conveyor belts is further accelerating, thanks to innovations in silicon-coated fabrics and the growing demand for customizable belt designs.

Application Insights

Why Did the Food Processing Segment Dominate the Non-Stick Conveyor Belt Market?

The food processing segment dominated the market with a 35% share in 2025 and is expected to continue its growth trajectory in the upcoming period. The dominance is ascribed to the extensive use of non-stick conveyor belts in operations related to meat processing, baking, freezing, cooking, and drying. The need for contamination-free material handling, strict hygiene regulations, and growing automation in the food manufacturing industry all greatly increased demand for non-stick conveyor belts.

The packaging segment is expected to grow at a significant rate in the coming years, driven by the quick growth of the e-commerce, pharmaceutical, and packaged food sectors. The use of non-stick conveyor belts for labeling, sealing, and wrapping in high-speed packaging lines is growing. The segment growth is also driven by the increase in demand for effective material flow, decreased product sticking, and enhanced operational efficiency.

End Use Industry Insights

Why Did the Food & Beverage Segments Dominate the Non-Stick Conveyor Belt Market?

The food & beverage segment dominated the market with a 40% share in 2025, driven by strict sanitary regulations and ongoing production cycles. When it comes to handling sticky, greasy, and temperature-sensitive food items, non-stick conveyor belts are essential. The segment's dominance in the market is further strengthened by investments in contemporary food manufacturing facilities and rising consumption of processed foods.

The pharmaceuticals segment is expected to grow at the fastest CAGR of 5.7% in the coming years, driven by increased pharmaceutical manufacturing and stringent cleanroom operating regulations. Blister packaging, tablet coating, and sterile material handling procedures are using non-stick conveyor belts more and more. Demand from this end-use sector is increasing due to growth in biologics drug manufacturing and medical packaging.

Distribution Channel Insights

What Made Direct Sales the Leading Segment in the Non-Stick Conveyor Belt Market?

The direct sales segment led the market with a 50% share in 2025 because direct procurement is preferred by manufacturers and major industrial buyers for specialized solutions and technical assistance. Direct sales channels are perfect for industrial automation projects and large-scale food processing because they allow for improved pricing control, product customization, and after-sales services.

The online sales segment is expected to grow at the fastest CAGR of 5.9% in the coming years, fueled by growing digitalization and the accessibility of product data. Non-stick conveyor belts are becoming increasingly popular among small and mid-sized businesses that buy them online because of the competitive pricing, quicker delivery, and availability of standardized products. Another factor bolstering this growth trend is the proliferation of B2B e-commerce platforms.

Regional Insights

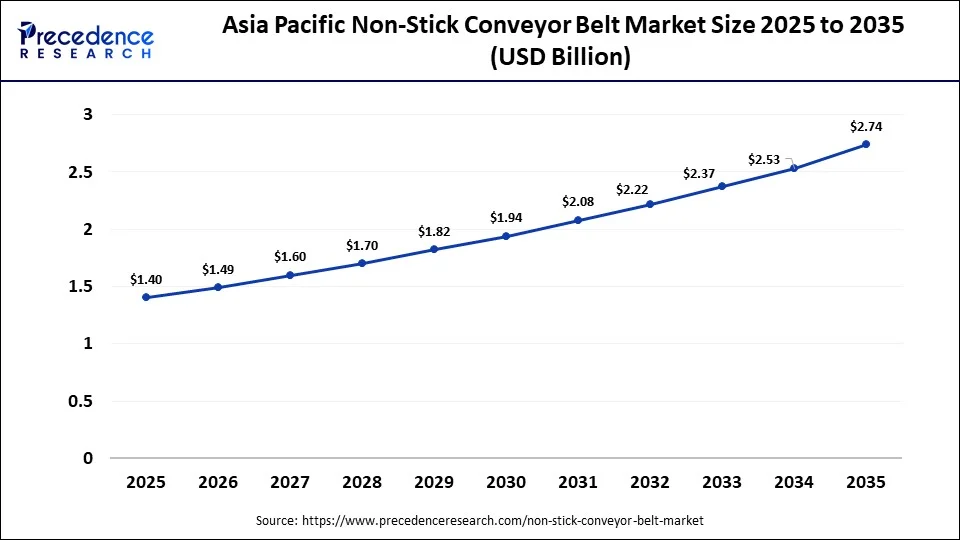

What is the Asia Pacific Non-Stick Conveyor Belt Market Size?

The Asia Pacific non-stick conveyor belt market size is expected to be worth USD 2.74 billion by 2035, increasing from USD 1.40 billion by 2025, growing at a CAGR of 6.95% from 2026 to 2035.

What Made Asia Pacific the Dominant Region in the Non-Stick Conveyor Belt Market?

Asia Pacific dominated the market with a major share of 35% in 2025. The region's leadership in the market is driven by the fast pace of industrialization, the growth of the food processing sector, and the expansion of manufacturing centers in other nations. Growing consumption of packaged foods, increased automation investments, and more affordable manufacturing capabilities all contributed to the region's dominance. Additionally, the availability of cost-effective raw materials and expanding industrial infrastructure have accelerated adoption across multiple end-use sectors.

India Non-Stick Conveyor Belt Market Trends

India is emerging as a high-growth market for non-stick conveyor belts, driven by the rapid expansion of the bakery, packaged food, and food processing industries. Initiatives like Make in India and increased investments in organized food production have accelerated the adoption of PTFE and silicone-based belts across processing and packaging lines. Rising demand for automation, cost-efficient production, and compliance with food safety standards, along with significant contributions from the FMCG and pharmaceutical sectors, are positioning India as a key growth hub within Asia Pacific.

Why is North America Considered the Fastest-Growing Region in the Market?

North America is expected to grow at the fastest CAGR in the coming years. This is mainly due to its well-developed food processing and pharmaceutical industries. Technological advancements, coupled with a focus on automating processes to comply with stringent food safety regulations and replacing conventional conveyor systems with advanced non-stick belts, are key factors driving the region's rapid market expansion.

U.S. Non-Stick Conveyor Belt Market Trends

The U.S. market for non-stick conveyor belts is mature and technology-driven, fueled by strong demand from the packaging, pharmaceutical, and food & beverage industries. Growth is driven by extensive automation, strict FDA regulations, and continual upgrades to processing equipment. While PTFE belts remain widely used for their durability and hygienic benefits, silicone belts are gaining popularity in specialized food applications. Additionally, the rapid adoption of high-performance, customized conveyor solutions is contributing to the faster growth of this developed market.

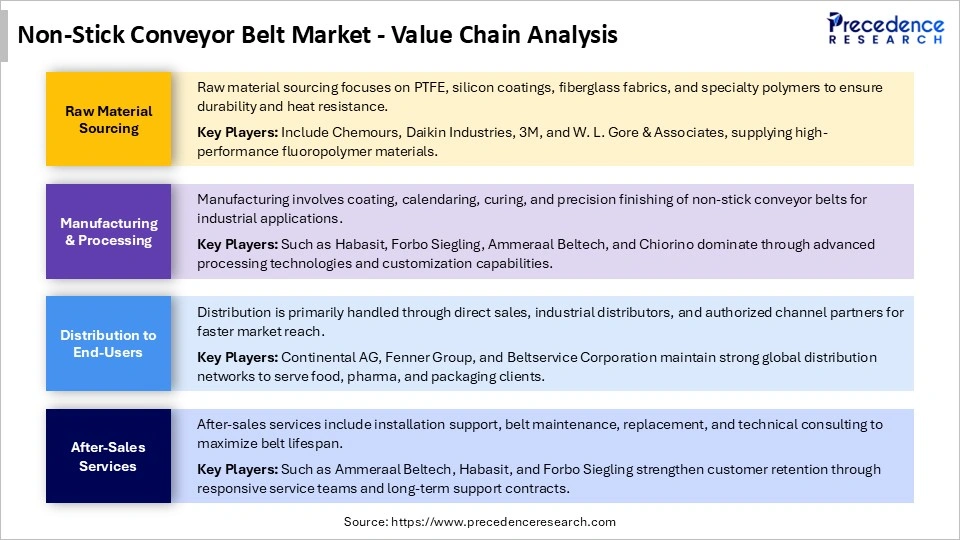

Non-Stick Conveyor Belt Market Value Chain Analysis

Who are the Major Players in the Global Non-Stick Conveyor Belt Market?

The major players in the non-stick conveyor belt market include Habasit AG, Ammeraal Beltech, Forbo Movement Systems, Fenner Dunlop, Mitsuboshi Belting Ltd., Intralox, Bando Chemical Industries, Ltd., ContiTech AG, Esbelt S.A., Sampla Belting, Volta Belting Technology Ltd., Chiorino S.p.A., Nitta Corporation, Sparks Belting Company, and YongLi Belting.

Recent Developments

- In September 2025, Shanghai Puteken Transmission System Co., Ltd. announced the launch of an advanced Silicone Timing Belt series utilizing high-grade silicone elastomers. The belts are designed for thermal stability and low-noise operation in automation and robotics, offering jointless construction for enhanced durability and precision in multi-axis machinery.(Source: https://www.openpr.com)

- In January 2025, Shanghai Puteken Transmission System Co., Ltd. launched a durable conveyor belt designed for biscuit and dough processing with high heat resistance and anti-static features. The new belt addresses the challenges of sticky food products by offering improved durability and process efficiency. This development reflects product innovation in food manufacturing conveyors.(Source: flokii.com)

- In October 2025, the PTFE-Teflon Conveyor Belts Industry Coverage industry insight highlighted the superior industrial performance of PTFE-Teflon conveyor belts in extreme conditions. The analysis noted their exceptional heat resistance, chemical inertness, and durability for high-temperature applications.(Source:https://www.bcflon.com)

Segments Covered in the Report

By Material Type

- PTFE (Polytetrafluoroethylene)

- Silicone

- Rubber

- Others

By Application

- Food Processing

- Packaging

- Textile

- Pharmaceuticals

- Others

By End User Industry

- Food & Beverage

- Automotive

- Textile

- Pharmaceuticals

- Others

By Distribution Channel

- Direct Sales

- Distributors

- Online Sales

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting