What is the Plastic Additives Market Size?

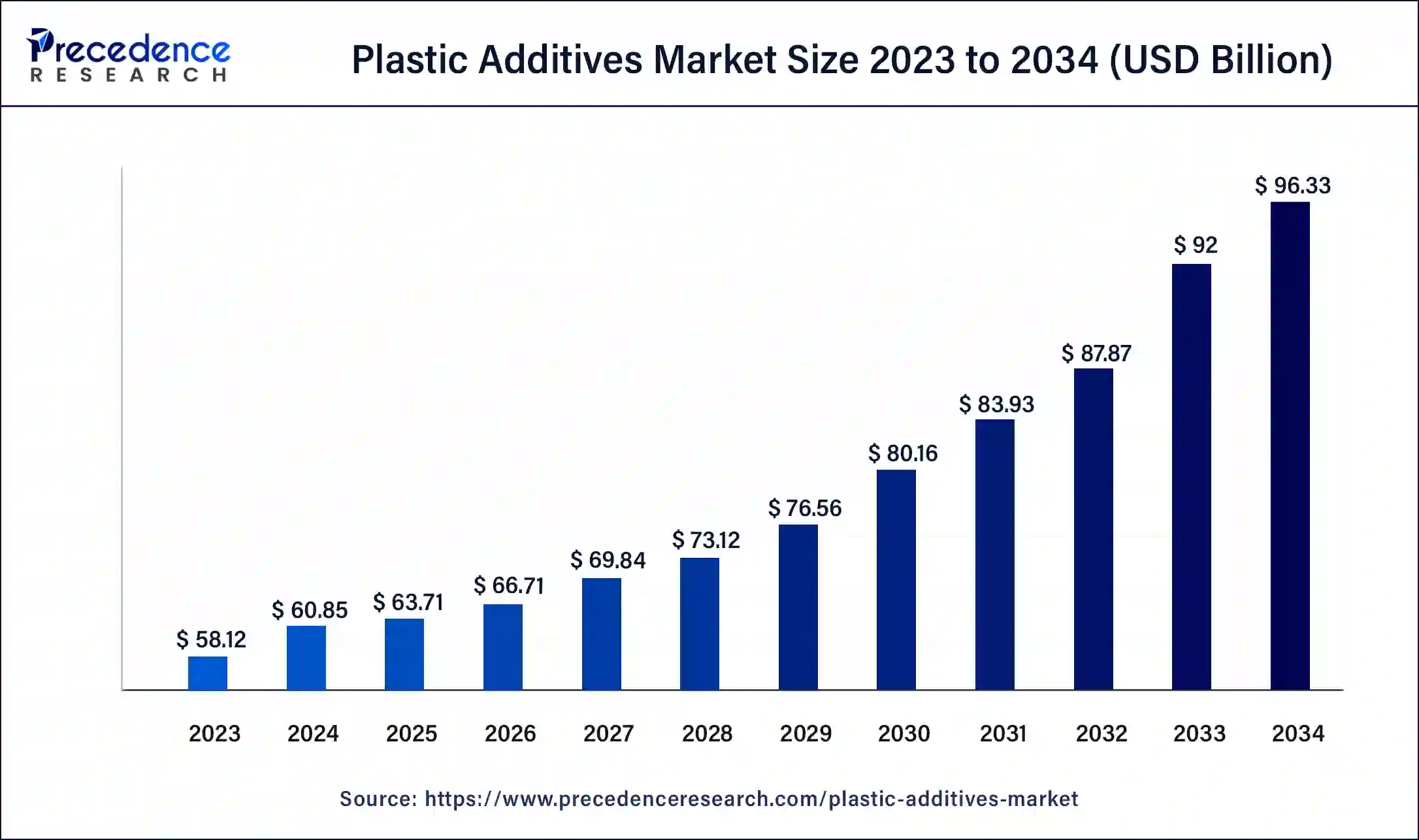

The global plastic additives market size was valued at USD 63.71 billion in 2025, accounted for USD 66.71 billion in 2026, and is expected to reach around USD 96.33 billion by 2034, expanding at a CAGR of 4.7% from 2025 to 2034. The plastic additives market is observed to be driven by the expansion of the automotive sector.

Market Highlights

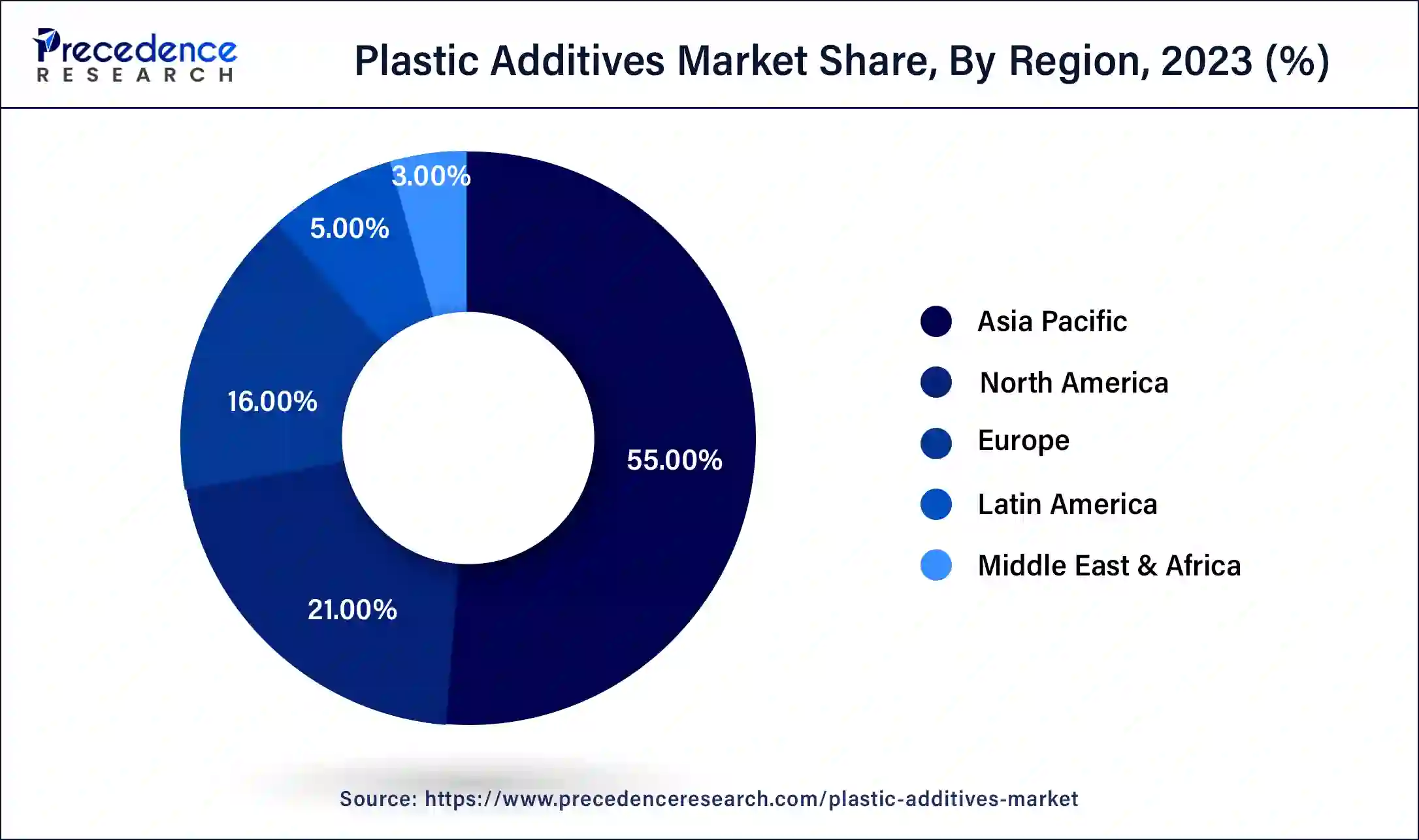

- Asia Pacific held the largest market share of 55% in 2024.

- North America is observed to grow at a significant rate during the forecast period.

- By type, the plasticizers segment dominated the market with the largest share in 2024.

- By type, the stabilizers segment is observed to witness the fastest rate of expansion during the forecast period.

- By plastic type, the polypropylene segment held the largest share of the market in 2024.

- By end-use, the automotive segment held the largest share of the market in 2024.

Market Size and Forecast

- Market Size in 2025: USD 63.71 Billion

- Market Size in 2026: USD 66.71 Billion

- Forecasted Market Size by 2034: USD 96.33 Billion

- CAGR (2025-2034): 4.7%

- Largest Market in 2024: Asia Pacific

- Fastest Growing Market: North America

Market Overview

The plastic additives market refers to the industry involved in the manufacturing, distribution, and sale of various chemical additives used in plastics to enhance their properties or performance during processing, fabrication, or end-use applications. Plastic additives are the materials that are added to the plastics at the time of the manufacturing process, they provide the optimal performance of the material at the time of molding and use. Plastic additives are also used for enhancing the properties of polymer to meet specific performance from the plastics. Additives increase the lifecycle of plastics and allow them to be used in many processes. Plastic additives are found in three different variants that are liquid, powder, and pallet.

Plastic additives are used in the plastic compounding process, additives are the chemical that help to modify the plastic combined with raw materials, to meet the required properties, color, and performance. Additives also help to fight against extreme weather conditions like exposure to UV lights or water that help to extend the lifecycle and durability of plastic products. The rising industrialization and the higher demand for the additives are driving the growth of the plastic additives market.

Plastic Additives Market Growth Factors

- The increasing demand for plastic additives or polymers as the replacement of conventional material in industries is driving the growth of the market. The rising use of plastic in every sector is also accelerating the growth of the market.

- Plastic is replacing traditional materials like glass, metal, wood, paper, etc due to its exceptional durability, strength, resistance, dependability, and flexibility all these factors are contributed in the higher adoption of plastic material in the various industrial use which drives the growth of the plastic additives market.

- Increasing use of plastic material in the industries like automotive, construction, electric and electronic, textile, agriculture, and packaging is boosting the demand for the plastic material which drive the growth of the market.

- The increasing demand for the plastic additive material from the automotive industry due to its durability, strength, and cost-effectiveness is boosting the growth of the market.

- The rising investments in industrialization by the private and public sectors are positively impacting the demand for plastic material or products which anticipated the growth of the plastic additives market.

Market Scope

| Report Coverage | Details |

| Global Market Size in 2025 | USD 63.71 Billion |

| Global Market Size in 2026 | USD 66.71 Billion |

| Global Market Size by 2034 | USD 96.33 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 4.55% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Plastic Type, End-use, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Expansion of the automotive industry

The increasing adoption of plastic materials in the automotive industry is driving the growth of the plastic additives market. Automotive plastics are also known as engineering plastics with high performance, which make them compatible for the growing demand from the automotive industry. Automotive plastics play an important role in the manufacturing of various automotive parts. Polypropylene is one of the types of automotive plastics which is widely applicable in the vehicle manufacturing due to its heat resistance, it is used in the manufacturing of automotive parts such as gas cans, bumper fascia, cable insulation, engine covers, and instrument panels.

Polyurethane is another type of high-performance plastic polymer which have higher insulative properties, resilience, strength, and moldability. This type of polymer is used in the manufacturing of headrests, seats, bumpers, soundproof and air filtering systems, and tires. Thus, the higher demand for plastic materials in the automotive sector is boosting the demand for the plastic additives market.

According to the data published by the Society of Indian Automobile Manufacturers (SIAM), Passenger Vehicles (PV) witnessed their highest ever sales in FY 2024-25 of 4.3 million units, with a growth of 2% as compared to FY 2023-24. Passenger Vehicles also experienced their highest ever exports in FY 2024-25 of 0.77 million units, registering a growth of 14.6% as compared to FY 2023-24.

Restraint

Environmental concerns

Several environmental concerns are observed to act as a major restraint for the plastic additives market. The widespread use and disposal of plastic products have led to environmental issues, including plastic pollution in oceans, rivers, and landfills. Concerns about the environmental impact of plastic waste, such as wildlife entanglement, habitat destruction, and microplastic contamination, have prompted calls for reducing plastic consumption and finding alternatives to conventional plastics.

Many companies across industries are prioritizing environmental sustainability and corporate social responsibility as integral parts of their business strategies. Using plastic additives associated with environmental concerns may tarnish a company's brand reputation and undermine its commitment to sustainability goals. As a result, businesses may seek to avoid or minimize the use of problematic plastic additives and adopt more sustainable practices throughout their supply chains.

Opportunity

Rising utilization of cost-effective materials

The growing utilization of cost-effective materials is driving innovation and collaboration across the plastic value chain. Manufacturers, material suppliers, additive producers, and end-users are collaborating to develop new formulations, technologies, and applications for recycled and bio-based plastics. Plastic additives play a crucial role in these collaborative efforts by enabling the optimization of material properties, processing parameters, and performance characteristics. By working together to overcome technical challenges and scale up production of cost-effective materials, stakeholders can unlock new opportunities for growth and innovation in the plastic additives market.

Segments Insights

Type Insights

The plasticizers segment held the largest share of the plastic additives market in 2024. The most commonly utilized additives in plastics are plasticizers. Typically, they come in the form of colorless, non-volatile liquids. Plasticizers work by reducing the viscosity of the polymer melt, which increases the flow and thermoplasticity of the polymer. Plasticizers improve the mechanical properties of plastics, such as tensile strength, elongation at break, impact resistance, and flexibility. They help reduce the glass transition temperature (Tg) of polymers, making them softer and more pliable. This enhancement in mechanical properties makes plasticizers indispensable in applications where flexibility and durability are essential, such as in PVC pipes, flooring, cables, and automotive interiors.

Plasticizers improve the processability of plastics by reducing melt viscosity, improving flow properties, and facilitating easier processing and molding. They enhance the compatibility between polymer chains and fillers or reinforcements, leading to improved dispersion and homogeneity in the final product. This compatibility and processability contribute to the widespread adoption of plasticizers across various manufacturing processes, including extrusion, injection molding, and blow molding.

The stabilizers segment is observed to witness a significant expansion in the plastic additives market during the forecast period. Stabilizers are widely used in enhancing the stability of chemical bonding in order to maintain their physical properties. Stabilizers are additives used to enhance the performance and durability of plastic materials, particularly in challenging environmental conditions. They help prevent degradation caused by exposure to heat, light, oxygen, and other environmental factors, thereby extending the lifespan of plastic products and maintaining their mechanical properties over time.

With increasing consumer demand for high-quality and long-lasting plastic products, manufacturers are under pressure to incorporate effective stabilizers into their formulations. Stabilizers contribute to the overall quality, performance, and reliability of plastic materials, thereby meeting consumer expectations for durable and sustainable products.

The flame retardants segment is observed to witness growth at a notable rate during the forecast period. Flame retardants play a crucial role in enhancing the fire safety properties of plastic materials, making them compliant with stringent safety regulations and standards. Governments and regulatory bodies worldwide impose strict fire safety requirements for various applications, such as building materials, automotive components, electronics, and consumer goods. As a result, there is a high demand for flame retardant additives to meet these regulatory requirements and ensure product safety.

- In January 2024, LyondellBasell (LYB) unveiled an all-in-one flame-retardant compound, petrothene T3XL7420, which is expected to deliver considerable cost savings while streamlining manufacturing processes. The new product offering also improves the quality of end products for wire producers in the automotive and appliance industries.

Increasing awareness of fire safety risks among consumers has led to growing demand for flame retardant products in the market. Consumers prioritize safety and reliability when purchasing plastic products for residential, commercial, and industrial use. Manufacturers and brands respond to consumer preferences by incorporating flame retardant additives into their products to enhance fire resistance and meet market expectations for quality and safety.

Plastic Type Insights

The polypropylene segment held the largest share of the market in 2024. Polypropylene is a highly versatile polymer used in a wide range of applications, including packaging and automotive parts along with textiles industry. Such widespread applications create a high demand for additives to enhance their properties. Polypropylene-based additives can significantly improve the strength and flexibility of materials. These enhancements make polypropylene more suitable for diverse applications and industries.

- In February 2025, Bharat Petroleum Corporation Ltd (BPCL) announced its plan to set up a new polypropylene unit in Kochi with an investment of ₹5,000 crore.

End-use Insights

The automotive segment held the dominating share of the plastic additives market in 2024. With the increasing regulatory pressure to reduce emissions and improve fuel efficiency, automakers are turning to lightweight materials like plastics to meet these standards. Thereby, the application of plastic additives in the automotive industry is observed to be more significant. Plastic provides greater design flexibility compared to metal, allowing for more intricate shapes and designs, which is important for both aesthetic and functional purposes.

- According to the China Association of Automobile Manufacturers (CAAM) in May 2025, in April, vehicle production and sales volumes totaled 2.619 million units and 2.59 million units, up 8.9% y/y and 9.8.% % y/y, respectively.

Regional Insights

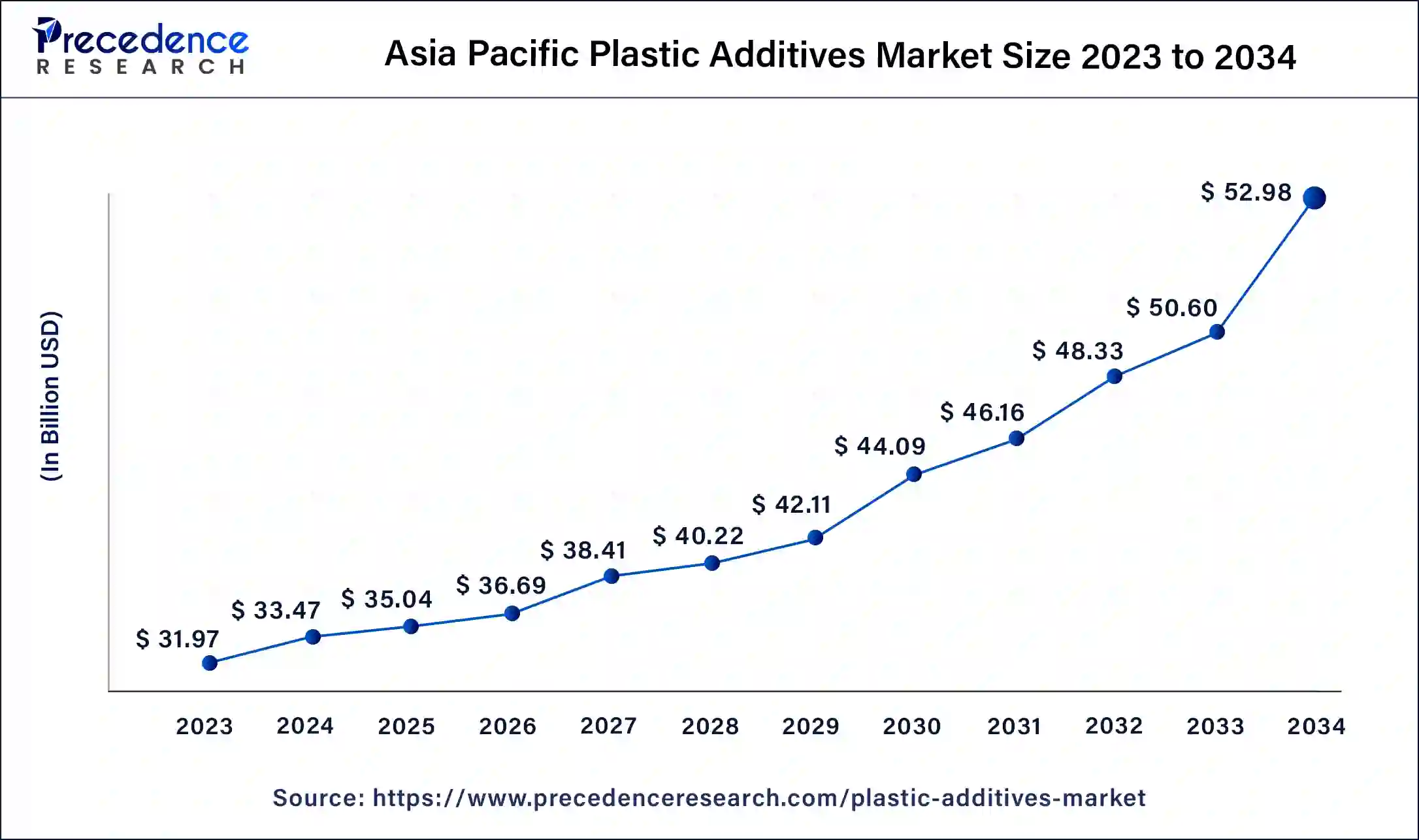

Asia Pacific Plastic Additives Market Size and Growth 2025 to 2034

The Asia Pacific plastic additives market size is estimated at USD 35.04 billion in 2025 and is predicted to be worth around USD 52.98 billion by 2034, at a CAGR of 4.9% from 2025 to 2034.

Asia Pacific held the dominating share of the plastic additives market with the largest share of 55% in 2024. Asia Pacific is experiencing rapid industrialization and urbanization, leading to increased demand for plastics in construction, infrastructure development, and consumer products. Plastic additives play a crucial role in enhancing the performance, durability, and aesthetic properties of plastics used in these applications, further driving market growth in the region.

Asia Pacific is witnessing significant investments in research and development (R&D) and technological advancements in the field of plastic additives. Manufacturers in the region are focused on developing innovative additives that offer improved performance, sustainability, and cost-effectiveness, driving market competitiveness and growth.

North America is expected to witness a significant rate of growth during the forecast period in the plastic additives market. North America has a significant manufacturing base for plastics, including industries such as automotive, packaging, construction, and consumer goods. These industries use plastic additives extensively to enhance the performance, durability, and aesthetic properties of plastic materials. The high demand for plastic additives from various manufacturing sectors contributes to North America's dominance in the market.

With increasing awareness of environmental issues and sustainability concerns, there is a growing demand for sustainable plastic additives in North America. Additives that improve the biodegradability, recyclability, and environmental performance of plastics are in high demand. North American manufacturers are at the forefront of developing eco-friendly additives and sustainable plastic solutions to address these demands, further solidifying the region's dominance in the market.

Plastic Additives Market Companies

- Songwon Industries Co. Ltd.

- Exxon Mobil Corporation

- KANEKA CORPORATION

- Clariant Ltd.

- Dow

- Albemarle Corporation

- Nouryon

- Lanxess Corporation

- BASF SE

- Evonik Industries AG

Recent Developments

- In April 2024, Finolex announced the launch of sustainable and flame-retardant wires. The halogen-free and flame-retardant industrial cables under FinoGreen are designed to mitigate safety risks in electrical installations and avert accidents, particularly fires.

- In April 2025, R�nesans Holding, one of Europe's leading contracting and investment groups, announced the investment of USD 2 billion in T�rkiye's largest private PP plant. The construction of a new Polypropylene (PP) Production Plant and Liquid Bulk Terminal in Ceyhan with a total investment of $2 billion, these strategic projects aim to increase T�rkiye's industrial self-sufficiency, reduce foreign dependency, and enhance the country's position in global trade.

- In April 2025, Sky Peak Capital announced the acquisition of TriStar Plastics Corp., a leading provider of engineered plastic solutions and self-lubricating bearings.

- In February 2022, BASF launched the latest service named, �RegXcellence� it is the digital solution to access regulatory documents and the worldwide community of regularity experts that analyze relevant environment, safety data, and health.

- In October 2022,�KraussMaffei� plastic processing machinery firm launched their first two manufacturing platform precisionPrint small-format machines and powerPrint large-format at the K 2022 show booth.

- In March 2023, Gerdau Graphene, the largest steel producer of Brazil and major steel producer of America launched first graphene enhanced PE additive masterbatch. The organization comes in the collaboration with the conglomerate Sumitomo Corp. for the graphene enhanced PE additive masterbatch distribution in Japan.

- In February 2024,Evonik is launched �INFINAM FR 4100L� a photopolymer resin which is mechanical durable and flame retardant, designed for the use with the digital light processing 3D printers.

Segments Covered in the Report

By Type

- Stabilizers

- Antioxidants

- Plasticizers

- Antistatic agents

- Anti-scratch additives

- Rheology/Thickners

- Flame retardants

By Plastic Type

- Polystyrene

- PVC

- Polypropylene

- Polyethylene

- Engineering plastics

- Others

By End-use

- Automotive

- Construction

- Textiles

- Electric and electronics

- Packaging

- Agriculture

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Get a Sample

Get a Sample

Table Of Content

Table Of Content