What is the Precision Reduction Gears Market Size?

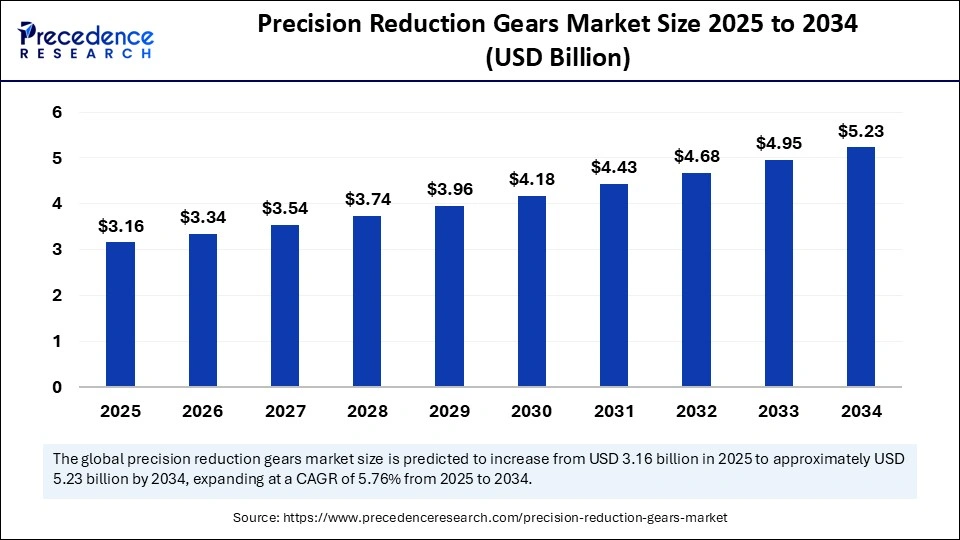

The global precision reduction gears market size accounted for USD 2.99 billion in 2024 and is predicted to increase from USD 3.16 billion in 2025 to approximately USD 5.23 billion by 2034, expanding at a CAGR of 5.76% from 2025 to 2034.

Market Highlights

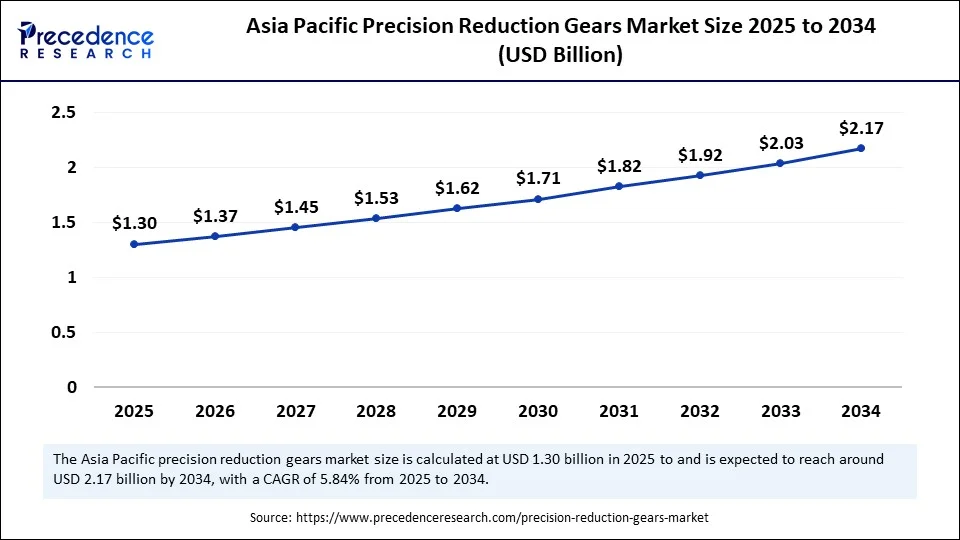

- Asia Pacific dominated the precision reduction gears market with the largest market share of 41% in 2024.

- North America is expected to expand at the fastest CAGR between 2025 and 2034.

- By gear type, the strain wave gears segment held the biggest market share in 2024.

- By gear type, cycloidal reduction gears are expected to grow at a remarkable CAGR between 2025 and 2034.

- By precision level type, the standard precision segment captured the highest market share in 2024.

- By precision level type, high precision is expected to grow at a remarkable CAGR between 2025 and 2034.

- By configuration type, the inline reduction gears segments contributed the highest market share in 2024.

- By configuration type, right-angle reduction gears are expected to grow at a remarkable CAGR between 2025 and 2034.

- By application type, the robotics segment accounted for the significant market share in 2024.

- By application type, medical devices are expected to grow at a remarkable CAGR between 2025 and 2034.

- By end-user type, the healthcare and medical segment generated the major market share in 2024.

- By end-user type, industrial automation is expected to grow at a remarkable CAGR between 2025 and 2034.

Market Size and Forecast

- Market Size in 2024: USD 2.99 Billion

- Market Size in 2025: USD 3.16 Billion

- Forecasted Market Size by 2034: USD 5.23 Billion

- CAGR (2025-2034): 5.76%

- Largest Market in 2024: Asia Pacific

- Fastest Growing Market: North America

How Precision Reduction is Gearing up for Growth?

The precision reduction gears market refers to the industry of high-precision gear mechanisms, such as strain wave gears, planetary gears, and cycloidal gears, that are used to achieve accurate speed reduction, torque amplification, and smooth motion control in robotics, machine tools, aerospace, medical equipment, and automation systems. These gears are critical for applications requiring high positioning accuracy, compact size, and long operational life.

The precision reduction gears market is experiencing strong growth, fueled by automation, robotics, and digital manufacturing trends. Rising demand in high-growth industries such as electric vehicles, semiconductor equipment, and defense systems further expands its scope. Market players are increasingly focusing on lightweight materials, high durability, and integrated control solutions to stay competitive. In addition, the transition to Industry 4.0 has created new avenues for innovation, with smart factories embracing precision reduction systems for efficiency. The market also reflects systems for efficiency. The market also reflects a globalized supply chain, with the Asia Pacific taking a leading role in production and North America and Europe strengthening high-value adoption. Collectively, these forces are setting the market on a path of consistent expansion.

How AI Is Reshaping the Precision Reduction Gears Market?

Artificial Intelligence is bringing a paradigm shift to precision reduction by enhancing design, testing, and predictive maintenance. AI algorithms are being leveraged to optimize gear geometry, stimulate stress loads, and improve overall efficiency. Predictive analytics powered by AI ensures a longer lifespan and minimizes unplanned downtime in critical industries like aerospace and robotics. Machine learning is enabling manufacturers to tailor products for specific applications with unprecedented precision. AI-driven automation also reduces production errors, thereby lowering costs and boosting scalability. Ultimately, AI transforms precision reduction from mechanical components into a digitally intelligent asset.

Market Key Trends

- Miniaturization of gears to suit compact robotics and medical devices is emerging as a strong trend.

- Lightweight and eco-friendly materials are being adopted to meet sustainability mandates.

- Hybrid systems that integrate sensors and IoT connectivity are redefining performance monitoring.

- Companies are increasingly shifting towards modular designs for flexible assembly and quicker customization.

- The influence of EV adoption and smart factories is creating high-volume demand.

- Overall, the trend is toward convergence of mechanical strength with digital intelligence.

Market Scope

| Report Coverage | Details |

| Market Size in 2024 | USD 2.99 Billion |

| Market Size in 2025 | USD 3.16 Billion |

| Market Size by 2034 | USD 5.23 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 5.76% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Gear type, Precision Level, Configuration, Application, End-user Industry, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Growing automation across industries is the primary driver of the precision reduction gears market. Robotics in manufacturing, logistics, and healthcare rely heavily on accurate torque transmission. The rising penetration of electric vehicles demands advanced motion control for power efficiency. Aerospace and defense sectors are investing in high-reliability gear systems for mission-critical operations. Miniaturization in medical devices and semiconductor equipment further drives demand. Together, these drivers make precision reduction indispensable to modern industry.

Restraints

High initial costs remain a major challenge for widespread adoption, especially among SMEs; technical complexities in design and assembly limit market penetration in low-capability regions. Dependence on specialized raw materials makes the industry vulnerable to supply chain disruptions. Heat generation and lubrication issues pose engineering limitations for extended operations. Additionally, the lack of standardization in precision gear manufacturing slows global interoperability. These factors collectively restrain the pace of market expansion.

Opportunities

The surge in collaborative and service robotics offers lucrative avenues for the precision reduction gears market. Expanding EV production globally provides a strong growth corridor. Integration of AI and IoT opens opportunities for smart precision systems with predictive capabilities. Growing medical technology innovations, including surgical robots, create new demand pockets. Sustainability goals also drive opportunities for eco-friendly, lightweight designs. These opportunities position the market for sustained long-term growth.

Segment Insights

Gear Type Insights

How Strain Wave Gears Is Dominating the Precision Reduction Gears Market?

Strain wave gears dominate the precision reduction gears market due to their compact design and unrivalled torque-to-weight ratio. They are indispensable in robotics, aerospace, and semiconductor manufacturing, where precision and minimal backlash are non-negotiable. Their ability to deliver high reduction ratios within a small footprint makes them irreplaceable in space-constrained applications. As collaborative robots multiply in industrial settings, strain wave gears provide the quiet, smooth motion control needed for safe human-robot interaction. Moreover, their proven durability and long operating life strengthen their leadership position. In effect, strain wave gears remain the undisputed backbone of modern motion control engineering.

The dominance of strain wave gears also stems from continuous refinement in material science and lubrication technologies. Advanced alloys and composites have enhanced their wear resistance and reduced heat buildup during extended cycles. Manufacturers are also integrating smart sensors into these gears to monitor strain, vibration, and fatigue in real time. This digitalization not only improves reliability but also helps industries achieve predictive maintenance goals. As industries lean toward zero downtime, such innovations reinforce the indispensability of strain wave designs. Their role is expanding from robotics into next-generation aerospace and even renewable energy systems.

Looking forward, the future of strain wave gears will be shaped by convergence with AI-driven optimization. Gear geometry is being digitally modelled to push efficiency beyond current limits. Additive manufacturing is enabling bespoke strain wave gears tailored for specific robotic joints and surgical devices. The miniaturization trend, especially in medical robotics, will further entrench their relevance. Furthermore, eco-friendly lubricants and recyclable components are aligning these gears with sustainability mandates. Altogether, strain wave gears are not only dominant today but also architecting the precision reduction systems of tomorrow.

Cycloid reduction gears are witnessing the fastest growth in the precision reduction gears market, propelled by their robustness and shock-resistant design. Unlike strain wave gears, they excel in applications demanding higher load-bearing capacity and extended operational durability. Their unique motion principle ensures smoother distribution of stress across contact surfaces, reducing wear. Industries such as heavy robotics, machine tools, and packaging machinery are increasingly embracing this gear type. Their ability to handle higher torque with compact dimensions is fueling their adoption. Consequently, cycloid gears are rapidly carving a strong niche within precision reduction.

The scalability of cycloid gears is particularly attractive in cost-sensitive industries. Their relatively simpler design and ability to withstand misalignment make them more forgiving in practical operations. Manufacturers are increasingly marketing them as reliable solutions for semi-automated factories in emerging economies. In addition, recent advances in surface finishing and coating technologies have significantly improved their energy efficiency. As precision requirements broaden beyond elite sectors, cycloid gears find themselves well-positioned. This trajectory ensures a growing share of the overall market.

Prospects for cycloid reduction gears are tied to their adaptability in new domains. Compact medical devices and logistics robots are beginning to incorporate cycloid mechanisms. Their potential for hybrid integration with digital monitoring systems will further boost relevance. Increasing R&D is pushing designs toward reduced noise levels, addressing one of their traditional drawbacks. Furthermore, localized production in Asia is reducing costs and expanding global accessibility. In sum, cycloid gears may soon become the dynamic counterweight to strain wave dominance.

Precision Level Insights

Why Is High Precision Dominating the Precision Reduction Gears Market?

High-precision gears dominate the precision reduction gears market due to their indispensable role in robotics, aerospace, and semiconductor manufacturing. Their minimal backlash and exact torque delivery make them the gold standard for industries demanding flawless motion control. In satellite positioning, robotic surgery, and wafer fabrication, they provide unparalleled reliability. Their adoption is driven by the need for error-free operations under extreme conditions. This dominance is further cemented by continuous innovation in micro-machining and smart monitoring. As industries prioritize accuracy above cost, high-precision gears remain irreplaceable.

High-precision reduction gears dominate the market as they are essential in robotics, aerospace, and semiconductor fabrication, where accuracy cannot be compromised. These gears deliver consistent motion with negligible backlash, ensuring error-free operations in critical applications. Robotic surgery and space navigation systems particularly rely on such accuracy. The manufacturing of semiconductors, where tolerances are measured in nanometers, further cements their indispensability. Continuous innovation in micro-machining techniques has enhanced their performance and efficiency. As industries increasingly pursue perfection, high-precision gears remain irreplaceable at the core of advanced technologies.

Standard precision gears are gaining traction as industries seek cost-effective yet reliable solutions. They are increasingly deployed in general machinery, packaging equipment, and logistics automation. These gears meet good enough tolerances without the premium price of high-precision systems. Emerging economies are fueling their adoption due to budget constraints. Their scalability and availability make them attractive for SMEs. Hence, standard precision gears are emerging as the fastest-growing category.

Standard precision reduction gears are the fastest-growing segment, providing affordable yet reliable motion solutions for general machinery and cost-sensitive industries. They strike a balance between functional precision and affordability, making them highly appealing to small and mid-sized manufacturers. Packaging, logistics, and agricultural automation systems rely on these gears for dependable operations. Their scalability across different industries makes them versatile and adaptable. With the rise of SMEs in emerging markets, demand for standard precision gears is soaring. As global industries adopt automation at all scales, this segment is expected to witness exponential growth.

Configuration Insights

Why Are Inline Reduction Gears Dominating the Precision Reduction Gears Market?

Inline reduction gears dominate the precision reduction gears market because of their widespread use in robotics, CNC machines, and automation systems. Their compact alignment and efficiency make them a default choice for precision-driven setups. Industries value their ability to deliver consistent torque without spatial complications. Their modular design also simplifies integration into complex machinery. With robotics expanding globally, inline gears continue to reinforce their dominance. Their adaptability across sectors cements their leadership.

Inline reduction gears dominate configuration preferences due to their compatibility with robotic joints, CNC machines, and industrial automation setups. Their straightforward alignment simplifies integration while maintaining efficiency and precision. Inline systems also offer design modularity, allowing manufacturers to easily adapt them to diverse machine layouts. Their adoption is further reinforced by the proliferation of collaborative robots across factories. Inline gears are widely recognized for delivering reliable performance without occupying excessive space. Consequently, they remain the cornerstone of industrial gear configurations.

Right-angle reduction gears are gaining rapid traction, particularly in compact, space-constrained applications. Their ability to redirect motion flow without compromising accuracy makes them invaluable in medical devices and packaging systems. The rise of miniaturized robotics is further accelerating their adoption. Their flexibility in unconventional layouts gives them an edge in next-generation automation. As demand for ergonomic machine design grows, right-angle systems are positioned for exponential growth. Thus, they represent the fastest-emerging gear configuration.

Right-angle reduction gears are gaining rapid adoption as industries demand more compact and flexible machine layouts. They enable motion redirection without compromising torque or accuracy, making them invaluable in medical devices and packaging systems. With the miniaturization trend in robotics and healthcare equipment, their adoption is accelerating. These gears allow engineers to optimize space without reducing functionality. Their adaptability to unconventional designs makes them attractive for next-generation machinery. As compact automation systems proliferate, right-angle reduction gears are projected to outpace traditional configurations in growth rate.

Application Insights

Why Robotics Is Dominating the Precision Reduction Gears Market?

Robotics is the single largest application area, as precision reduction gears form the very heart of industrial and collaborative robots, driving growth in the precision reduction gears market. They ensure smooth articulation, accurate torque, and safe human-robot interaction. As robotics expands from manufacturing to logistics and healthcare, demand keeps multiplying. Strain wave and cycloid systems find maximum deployment in robotic joints. The robotics revolution is inseparable from precision reduction. Hence, this segment stands as the uncontested leader.

Medical devices are the fastest-growing application area due to the rise of surgical robots and diagnostic automation. Precision gears enable delicate, controlled motion crucial in minimally invasive procedures. Their adoption reflects the broader push for technology-assisted healthcare. From robotic surgery to automated imaging, precision gears play a vital enabling role. Miniaturization and sterility-friendly materials further accelerate this trend. Thus, healthcare emerges as the most dynamic growth frontier.

End-User Industry Insights

Why Industrial Automation Is Dominating the Precision Reduction Gears Market?

Industrial automation remains the largest end-user industry in the precision reduction gears market, integrating precision reduction across CNC, packaging, robotics, and material handling. The global march toward Industry 4.0 has entrenched its relevance. Precision gears ensure efficiency, reliability, and scalability for factories worldwide. As manufacturing becomes smarter and leaner, demand in this segment remains resilient. Automation giants continue to rely on these systems for mission-critical operations. Therefore, industrial automation secures the dominant share.

The healthcare sector is witnessing exponential growth in precision reduction adoption. The rise of robotic surgery, prosthetics, and diagnostic automation drives this surge. Hospitals and clinics increasingly demand reliability, compactness, and sterility in motion systems. Precision reduction offers all three, making it a natural fit. The broader healthcare technology wave further amplifies this need. As a result, healthcare is the fastest-expanding end-user segment.

Regional Insights

Asia Pacific Precision Reduction Gears Market Size and Growth 2025 to 2034

The Asia Pacific precision reduction gears market size was evaluated at USD 1.23 billion in 2024 and is projected to be worth around USD 2.17 billion by 2034, growing at a CAGR of 5.84% from 2025 to 2034.

How is Asia Pacific the Powerhouse Precision?

Asia Pacific dominates the global precision reduction gears market, with largest market share of 41% in 2024, driven by its manufacturing prowess and large-scale automation adoption. Countries like China, Japan, and South Korea serve as key production hubs, supplying to both domestic and global industries. The rapid growth of EV production, coupled with government support for robotics, has strengthened regional demand. In addition, expanding semiconductor and electronics industries further boost consumption. The region also benefits from lower production costs and robust supply chains, giving it a competitive edge. Asia Pacific is thus not just a production center but also a driver of global demand.

In its next phase, the region is expected to deepen innovation in miniaturized and smart precision systems. Japanese and Korean companies are investing heavily in AI-driven motion control solutions. China, with its large EV and robotics market, will remain the largest consumer. India, too, is emerging as a promising market with growing automation in manufacturing. The increasing localization of component production reduces dependence on imports. Together, these developments cement Asia Pacific's position as the anchor of the global market.

How is North America Fastest Growing?

North America and Europe are emerging as the fastest-growing regions in the precision reduction gears market. Their growth is underpinned by the rapid expansion of robotics in healthcare, defense, and manufacturing. Strong investments in EV production and aerospace technologies also contribute to rising demand. Both regions are leading in the integration of AI and IoT into mechanical systems, fostering innovation. Additionally, the focus on sustainability drives the adoption of lightweight and recyclable materials in gear systems. The presence of high-end R&D centers ensures steady innovation pipelines.

The growth trajectory is expected to accelerate as smart factories become mainstream. Europe, with its strong automotive and industrial base, is rapidly scaling precision gear adoption. North America is particularly advanced in robotics, AI integration, and defense applications. High demand for customized, high-reliability systems provides lucrative opportunities. Government initiatives supporting advanced manufacturing also provide a favorable ecosystem. Collectively, these factors position North America and Europe as innovation-driven growth engines of the global market.

Precision Reduction Gears Market Companies

- Harmonic Drive Systems Inc.

- Nabtesco Corporation

- Sumitomo Heavy Industries

- WITTENSTEIN SE

- Cone Drive

- Neugart GmbH

- Spinea s.r.o.

- Onvio LLC

- Beijing CTKM Harmonic Drive Co., Ltd.

- Leaderdrive (China)

- GAM Enterprises, Inc.

- KOFON Motion Group

- DieQua Corporation

- Zhejiang Laifual Drive Co., Ltd.

- APEX Dynamics, Inc.

Recent Developments

- In September 2025, the product page for this sleek black-and-white mouse is now live, and it's generating buzz for a major innovation: replacing traditional mechanical switches on the left and right buttons with a Haptic Inductive Trigger System. Similar to the technology behind magnetic keyboards, this analog induction mechanism introduces “instant actuation,” significantly enhancing responsiveness. By minimizing delay, it reduces latency by an impressive 9 to 30 milliseconds, setting a new benchmark for speed and precision in gaming peripherals.(Source: https://www.tweaktown.com)

Segments Covered in Report

By Gear Type

- Strain Wave Gears (Harmonic Drive)

- Planetary Reduction Gears

- Cycloidal Reduction Gears

By Precision Level

- Standard Precision

- High Precision

By Configuration

- Inline Reduction Gears

- right-angle reduction gears

By Application

- Robotics (Industrial Robots, Service Robots, Collaborative Robots)

- Machine Tools

- Semiconductor Equipment

- Aerospace & Defense

- Medical Devices

- Automotive & Transportation

- Packaging & Printing Machinery

- Others

By End-user Industry

- Automotive

- Electronics & Semiconductor

- Healthcare & Medical

- Aerospace & Defense

- Industrial Automation

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting