High Power Graphite Electrode Market Revenue and Forecast by 2033

High Power Graphite Electrode Market Revenue and Trends 2025 to 2033

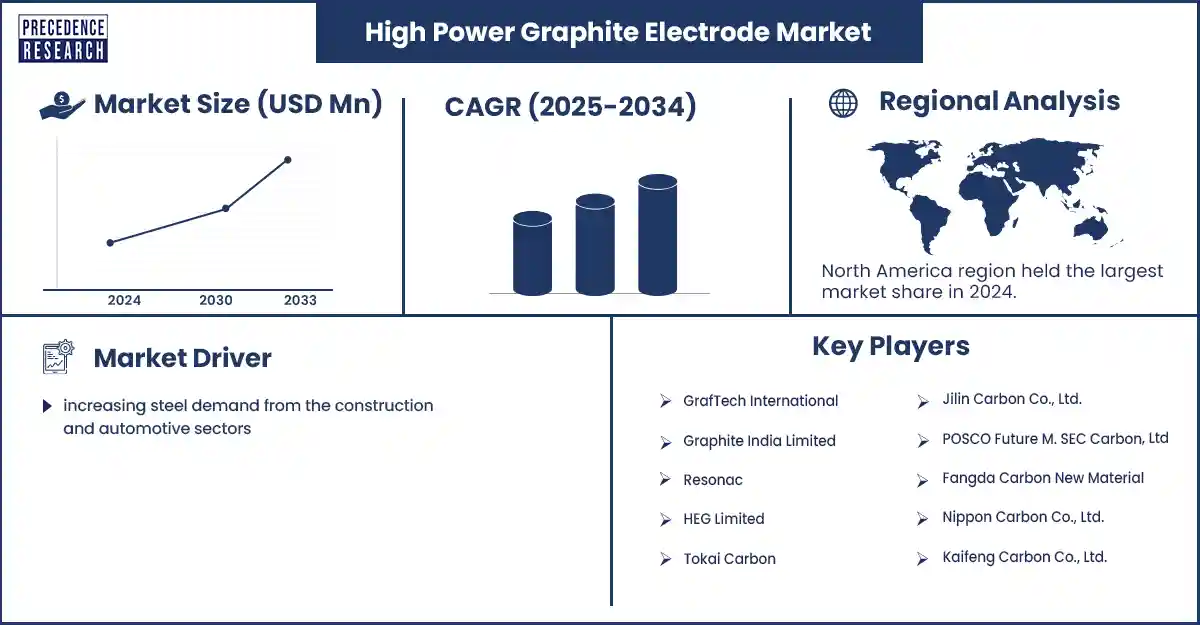

The global high power graphite electrode markets environmental impact of high power graphite electrode production and the industry's efforts towards sustainability, including recycling initiatives and emissions reduction strategies.The growth of the market is driven by rising global demand for steel from the construction and automotive sectors, the increasing adoption of steel recycling, the expansion of EAF-based production, and technological advancements.

High Power Graphite Electrode Market: Key Drivers & Emerging Opportunities

The high-power graphite electrode market focuses on the production and use of high-quality, durable graphite electrodes that are essential for the Electric Arc Furnace (EAF) steelmaking process. These electrodes conduct electricity to melt scrap metal at high temperatures. The growing demand for graphite electrodes is driven by several factors, including the increasing adoption of EAF technology in steel production, which offers energy efficiency and environmental benefits.

Additionally, the demand for high-quality steel in construction, automotive, and aviation industries is rising, fueled by urbanization and industrialization. The expansion of steel recycling and advancements in graphite electrode manufacturing also contribute to market growth. Furthermore, the increasing demand for graphite in lithium-ion batteries for electric vehicles is creating a significant new market for graphite electrodes.

Segment Insights

- By product type, the high power (HP) graphite electrode segment led the market due to its balance of performance and cost-effectiveness, particularly as the use of EAF technology in steel production continues to grow alongside global demand for high-quality steel.

- By application, the Electric Arc Furnace (EAF) segment dominated the market, primarily due to its increasing use in recycling scrap steel, which is a more sustainable and environmentally friendly method of steel production compared to traditional blast furnaces.

- By end-user industry, the steel industry is the primary consumer of graphite electrodes and dominates the market due to high demand for quality steel, rapid industrialization, and a shift toward more sustainable scrap-based production methods.

- By electrode size, the 400–600 mm electrode size segment held a significant market share because it offers a versatile balance of power, performance, and cost-effectiveness, making it suitable for a wide range of steelmaking requirements in electric arc furnaces.

- By distribution, the direct sales segment led the market due to the relationship-driven nature of the industry, the need for customized solutions, and the limited number of large-scale buyers.

Regional insights

Asia Pacific region accounts for the majority of the high-power graphite electrode market, largely due to massive steel production via EAFs that rely heavily on these electrodes. Rapid urbanization, extensive infrastructure development, and a push towards cleaner steelmaking methods in countries like China, India, and Japan have further fueled this demand. Many countries are encouraging a shift from traditional, more polluting blast furnaces to more energy-efficient EAFs, thereby boosting the market for high-power graphite electrodes, which offer superior performance and durability.

North America is expected to be the fastest-growing region in the high-power graphite electrode market due to increased adoption of EAF technology for sustainable steel production. The region has robust local natural graphite reserves, significant infrastructure investments, and a growing demand for high-grade graphite in electric vehicle battery manufacturing. Canada and the U.S. possess substantial natural graphite deposits, providing a stable and local source of raw materials for electrode manufacturers, thus reducing reliance on imports, and enhancing supply chain stability.

High Power Graphite Electrode Market Coverage

| Report Attribute | Key Statistics |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa |

High Power Graphite Electrode Market Key Players

- GrafTech International

- Graphite India Limited (GIL)

- Resonac

- HEG Limited

- Tokai Carbon

- Jilin Carbon Co., Ltd.

- POSCO Future M. SEC Carbon, Ltd

- Fangda Carbon New Material

- Nippon Carbon Co., Ltd.

- Kaifeng Carbon Co., Ltd.

- Zhongze Group

- SGL Carbon

- Fangda Carbon New Material

- Energoprom Group

- Kaifeng Carbon.

Recent Development

- In October 2024, graphite electrode manufacturer HEG Ltd. acquired an 8.23% stake in GrafTech International Ltd., a publicly listed graphite electrode manufacturing company on the New York Stock Exchange. HEG Ltd. invested in GrafTech shares through secondary market transactions as part of the Overseas Portfolio Investment (OPI) scheme under the Foreign Exchange Management Rules, 2022. (Source: https://www.cnbctv18.com)

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape overview @ https://www.precedenceresearch.com/sample/6908

You can place an order or ask any questions, please feel free to contact us at sales@precedenceresearch.com |+1 804 441 9344