What is the Radiation Curable Coatings Market Size?

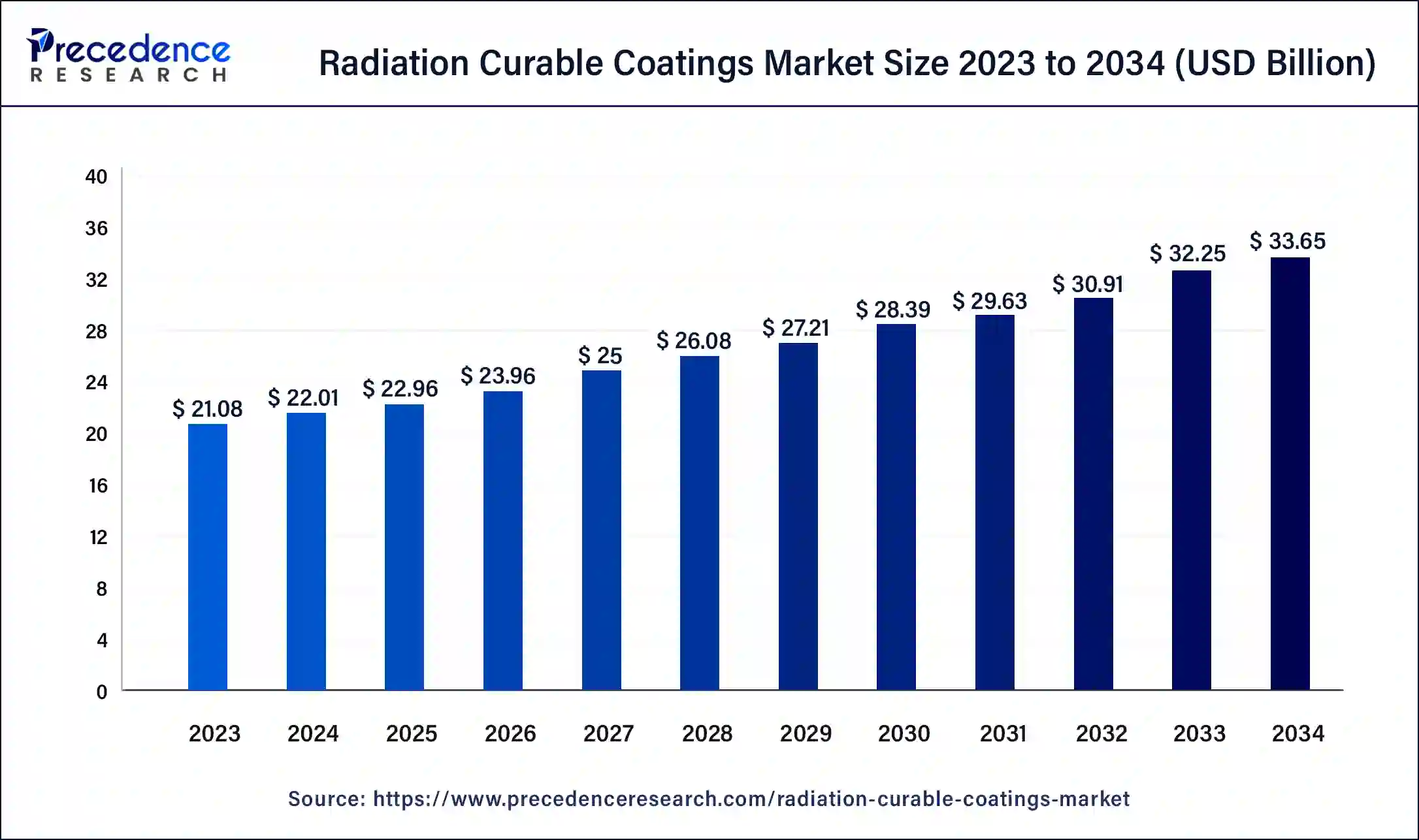

The global radiation curable coatings market size was calculated at USD 22.96 billion in 2025 and is predicted to increase from USD 23.96 billion in 2026 to approximately USD 33.65 billion by 2034, growing at a CAGR of 4.34% over the forecast period 2025 to 2034. The need for high-performance coatings in the consumer goods, infrastructure, and building industries are the key drivers for the radiation curable coatings market.

Radiation Curable Coatings Market Key Takeaways

- The global radiation curable coatings market was valued at USD 22.01 billion in 2024.

- It is projected to reach USD 33.65 billion by 2034.

- The radiation curable coatings market is expected to grow at a CAGR of 4.34% from 2025 to 2034.

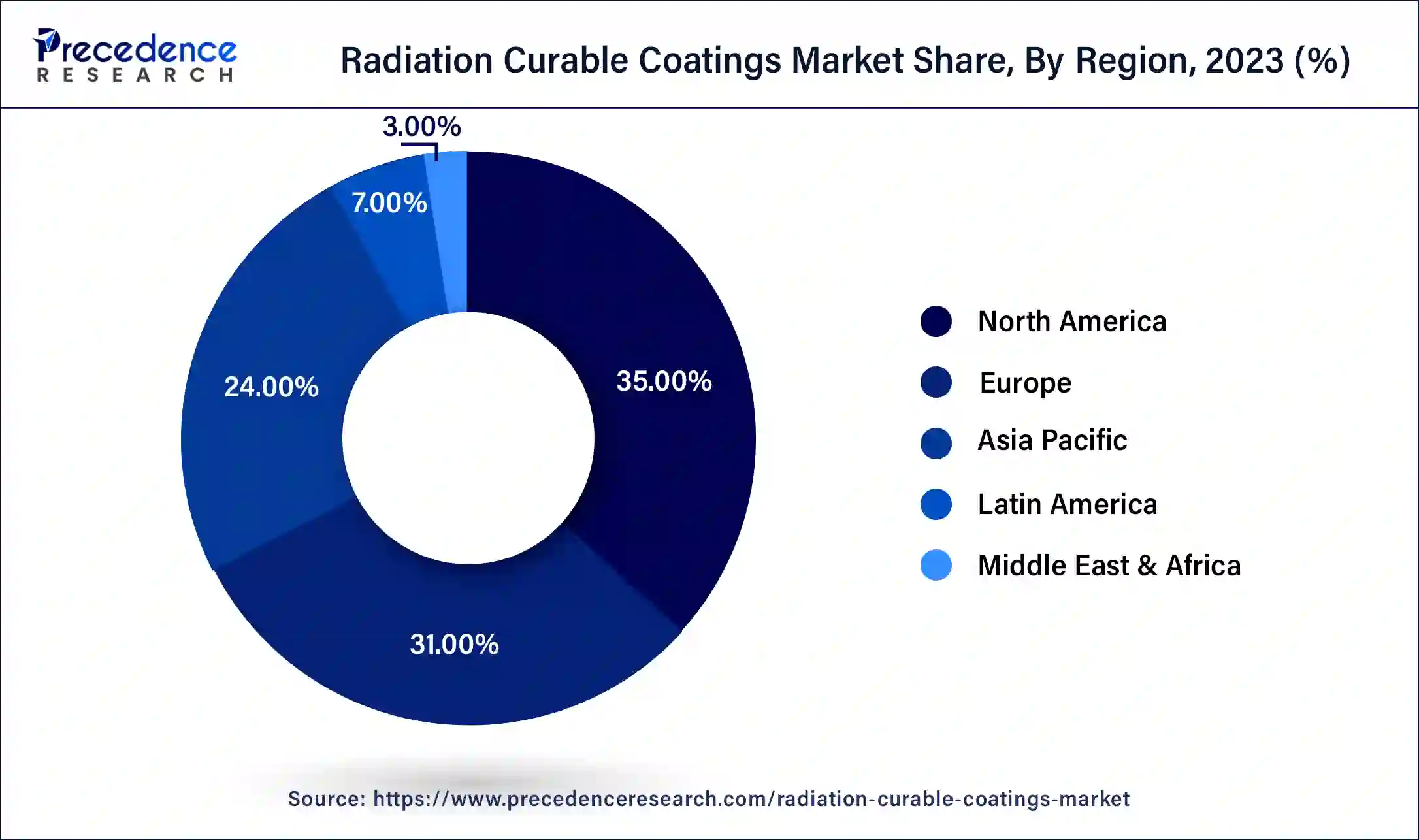

- Europe dominated the radiation-curable coatings market in 2024.

- By product, the UV curable coatings segment dominated the market in 2024.

- By product, the EB curing coatings segment is expected to grow at the fastest rate in the market over the forecast period.

- By function, the scratch-resistant segment led the market in 2024.

- By function, the UV protection segment is anticipated to grow at the fastest rate in the market during the forecast period.

- By application, the paper & film coating segment dominated the market in 2024 and is expected to grow at a significant rate over the forecast period.

Role of AI in the Radiation Curable Coatings Market

Emerging computational technologies have the potential to drive innovation by leading to higher-performance coatings and more efficient processes in the radiation curable coatings market. For artificial intelligence (AI) to be truly effective, extensive data aggregation is required, which requires a significant shift in organizational practices. In the radiation coatings sector, AI could advance to predict various failure modes, such as crack propagation, corrosion, creep, fatigue, color fading, and material diffusion. By analyzing thousands of tagged images of specific coatings labeled by human experts, AI systems can accurately diagnose and prevent flaws in existing products.

What are radiation-curable coatings?

Radiation-curable coatings are specially formulated materials that undergo cross-linking or curing through high-intensity radiation. These coatings are made from a reactive liquid vehicle, pigments, and various conventional additives. They are applied to a wide range of surfaces, including wood, glass, plastics, and paper. Also, they serve as both temporary and permanent protective coatings for metal tubes, pipes, fence posts, electrical conduits, and sprinkler system tubing. The radiation curable coatings market products are also used as protective films for construction steel and aluminum. UV technology in radiation-curable coatings provides benefits such as the ability to coat heat-sensitive materials and improved performance, including improved scratch and stain resistance to plastics.

Market Outlook

Industry Growth Overview:

The radiation curable coatings market is growing, driven by an increasing shift towards environment-friendly coatings and rising adoption in industries such as packaging, automotive, and electronics

Global Expansion:

The radiation-curable coatings market is growing worldwide, driven by rising demand for eco-friendly, high-performance products, driven by strict regulatory policies on volatile organic compounds (VOCs) and technological development. Europe is dominated in the market by increasing industrialization, burgeoning automotive and electronics production.

Major investors:

Major investors in the radiation-curable coatings market such as The Sherwin-Williams Company, PPG Industries, Akzo Nobel, BASF SE, and 3M Company.

Radiation Curable Coatings Market Growth Factors

- Rising sustainability and environmental rules are expected to fuel the radiation curable coatings market growth.

- Growing urbanization and industrialization can drive the radiation curable coatings market growth further during the forecast period.

- The strong Performance and Durability of radiation-curable coatings can boost market growth.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 33.65 Billion |

| Market Size in 2025 | USD 22.96 Billion |

| Market Size in 2026 | USD 23.96 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 4.34% |

| Largest Market | Europe |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product Type, Function, Application, End use, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Driver

Increasing demand from various industries

Several factors drive the growth of the radiation-cured coatings market, including low energy consumption, minimal volatile organic compounds (VOCs), consistent coating quality, and rapid curing and drying. These coatings also offer superior hardness and abrasion resistance. Increased demand for steel, driven by growth in the automotive, chemical, oil, construction, and heavy engineering sectors, further fueling the need for radiation-cured coatings. Additionally, radiation-cured coatings are utilized in the food and beverage industry due to their ability to protect the metal from high temperatures, which enhances dimensional stability, provides a glossy finish, and ensures a smooth metal surface. This drives the growth of radiation curable coatings market.

- In December 2023, AkzoNobel's Coil and Extrusion Coatings business signed a strategic agreement with the hi-tech specialists to develop a pioneering process that uses electron beams to cure coatings on metal substrates. Electron beams are being explored as a potential alternative for curing coatings via a new partnership between AkzoNobel and China's Wuxi El Pont Radiation Technology Co., Ltd.

Restraint

Health and safety concerns

Adhering to strict safety protocols is important when handling or being exposed to radiation sources to avoid health risks. This necessity can complicate the implementation process and may prevent some companies from using these coatings. Additionally, the range of applications for radiation-curable coatings is somewhat restricted, as they are not compatible with all substrates. This limitation could hinder the growth of the radiation curable coatings market.

Opportunity

3D printing and additive manufacturing

The growth of 3D printing and additive manufacturing gives a significant opportunity for the radiation curable coatings market. These coatings play a crucial role in achieving instant curing, which is essential for the efficient layer-by-layer process in 3D printing. Furthermore, Companies like Carbon and Formlabs are already utilizing UV-curable resins in their stereolithography (SLA) printers. As 3D printing moves beyond prototyping to full-scale production in industries such as dental, medical devices, and customized consumer products, the demand for fast-curing, high-performance materials is expected to rise substantially.

- In December 2022, Arizona-based 3D printing start-up Mechnano brought a tough new electrostatic dissipative (ESD) photopolymer to market. Formulated using Mechnano's carbon nanotube technology (CNT), Tough ESD is designed to yield vat polymerization 3D printed parts with enhanced impact resistance and isotropic ESD properties.

Product Insights

The UV curable coatings segment dominated the radiation curable coatings market in 2024. UV curing enables both spot curing and staged curing, which is especially useful in intricate assembly processes. This technology is commonly applied in areas like printing inks, electronics, and automotive coatings, where precision and detailed surface work are essential. As advancements in light sources and photoinitiator systems continue, UV curing technologies are anticipated to evolve by broadening their application in more specialized and high-precision fields.

- In August 2023, Elkem launched UV Hg and UV LED curable silicone solutions for sustainable release coatings. Specially designed for the release coating of thermal labels that are self-wound without a separate release liner. It guarantees the desired level of performance during the manufacturing, cutting, converting, and printing stages, making it possible to develop sustainable thermal printed linerless labels and enable a circular economy.

The EB curing coatings segment is expected to grow at the fastest rate in the radiation curable coatings market over the forecast period. Curing is preferred for its efficient curing of coatings without the need for photoinitiators, which simplifies formulations and reduces costs. This method excels in applications where high throughput and Immediate curing is essential. It offers exceptional finish quality and improved resistance to scratches, solvents, and abrasions, which makes it particularly suitable for high-end industrial uses.

Function Insights

The scratch-resistant segment led the radiation curable coatings market in 2024. Coating materials are consistently needed for both protective and decorative purposes. However, many available coatings are prone to scratches and abrasion. To address this, there is growing popularity in incorporating nanoparticles into coatings to enhance their resistance to scratches and wear. Moreover, the rising interest in radiation-curing technology is driven by stringent regulations and environmental concerns, which are likely to contribute to segment growth.

The UV protection segment is anticipated to grow at the fastest rate in the radiation curable coatings market during the forecast period. The ionization process generates free radicals that trigger the light-induced polymerization of the reactive double bonds in the coating formulation, leading to UV-cured coatings. NANOMYTE UVP coatings shield surfaces from UV radiation by blocking its penetration, which helps maintain the material's strength, adhesion of the coating, and appearance.

Application Insights

The paper & film coating segment dominated the radiation curable coatings market in 2024 and is expected to grow at a significant rate over the forecast period. Coatings for paper and film enhance both durability and visual appeal, whereas coatings for plastic and electronic products need to provide precision and withstand environmental stresses. These varied applications demonstrate the versatility and critical role of radiation-cured coatings across different industries. The widespread use of these coatings in industrial settings underscores the continued demand for efficient, long-lasting, and eco-friendly coating solutions.

Regional insight

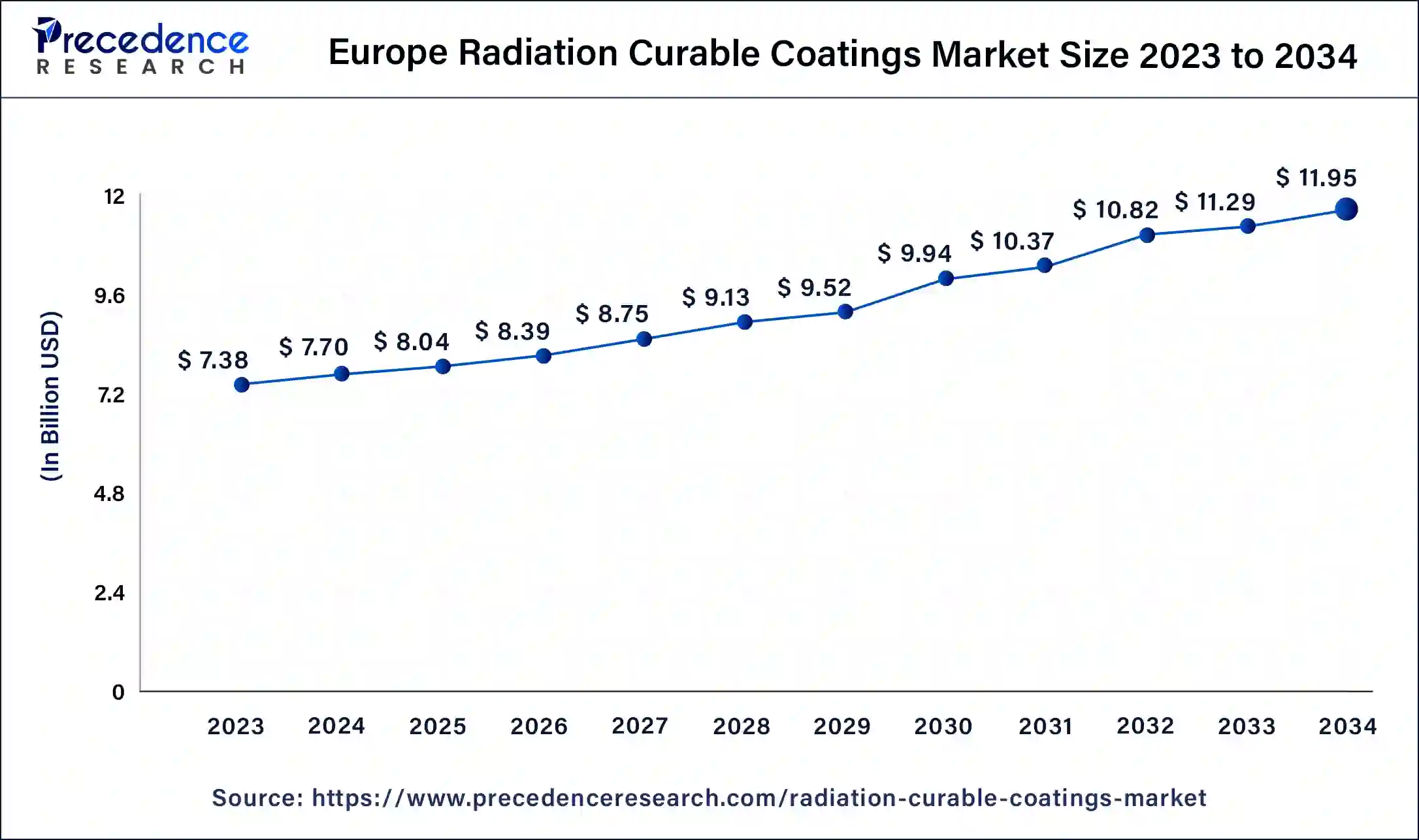

Europe Integration of advanced coating technologies

The Europe radiation curable coatings market size was valued at USD 8.04 billion in 2025 and is predicted to surpass around USD 11.95 billion by 2034, at a CAGR of 4.49% from 2025 to 2034.

Europe led the radiation curable coating market in 2024. The growth in this region is driven by the integration of advanced coating technologies in the automotive and manufacturing sectors, and by strict environmental regulations. The European market for radiation-curable coatings caters to a range of industries, including automotive, electronics, packaging, wood coatings, and graphic arts, by providing fast-curing and eco-friendly solutions. A key application is in the automotive sector, where these coatings are applied to both exterior and interior components.

- In October 2023, Covestro's revenue climbed back to €230 million, reflecting a 9.5% growth from July. This rebound was driven by increased demand in North America and Europe, supported by strategic pricing and expanded distribution channels.

UK: Increasing sustainability and green initiatives

In the UK, the presence a strong regulatory push for eco-friendly, low-VOC products, an emphasis on sustainability, and an increasing demand from significant industries such as automotive and packaging. There is an increasing prominence of sustainability, both from regulatory initiatives such as the European Green Deal and from public demand, which drives the market growth.

Asia Pacific: Industrial and manufacturing expansion

Asia Pacific is observed to grow at the fastest rate during the forecast period in the radiation curable coatings market. The expansion of the market is supported by increased investment in the industrial sector and infrastructure development in emerging countries like China, India, and Indonesia. Moreover, Radiation-curable coatings are gaining popularity across various niche applications due to their ease of use, quick curing, and low-temperature healing. The market's growth is further fueled by the economic advantages of these coatings, including rapid curing and drying, reduced energy consumption during production, and enhanced hardness and abrasion resistance.

- In January 2024, hubergroup Chemicals will present its Portfolio at Paint India. hubergroup Chemicals will showcase its portfolio of resins, colorants and pigments, laminations, adhesives, and monomers. In addition, hubergroup Chemicals will present its capabilities in custom manufacturing. A particular focus will be placed on inks, overprint varnishes, and industrial coatings. Sustainability and environmental protection are an integral part of the daily business.

India: Increasing government initiatives

In India, quick industrial growth, specifically in the electronics, automotive, and packaging fields, is combined with helpful environmental policies. Massive growth in sectors like automotive, electronics, and packaging increases the essential for high-performance coatings. Increasing government initiatives such as "Make in India" spurred local manufacturing and growing demand for effective and high-performance coatings.

North America: Strong manufacturing sector

North America is significantly growing in the market with its strong production base, strict government guidelines preferring low-VOC products, and the demand for high-performance, maintainable coatings in sectors such as printing, automotive, and wood finishing. Strict environmental laws and a strong focus on sustainability make low-volatile organic compound (VOC) radiation-cured coatings a favored choice over traditional solvent-based ones, which drives the growth of the market.

U.S.: Technological advancements

The U.S. has a massive, established production sector that increases demand for modern coating technologies in the major industries. Stricter government guidelines and an increasing industry focus on lowering volatile organic compounds (VOCs) have created a strong market for solvent-free, radiation-cured coatings.

Radiation Curable Coatings Market- Value Chain Analysis

Raw Material Sourcing:

Radiation-curable coatings are composed of four significant types of raw materials, such as oligomers, monomers, photoinitiators for UV curing, and additives.

Key Players: Dymax and Sartomer

Package Design and Prototyping:

These coatings are used to improve the appearance and durability of packaging materials, and the technology is employed in modern technologies such as 3D printing.

Key Players: Akzo Nobel and BASF SE

Recycling and Waste Management:

Materials coated with radiation-curable coatings, like cardboard, paper, and certain plastics, are usually compatible with current recycling processes.

Key Players: Sherwin-Williams and PPG Industries

Top Vendors in the Radiation Curable Coatings Market & Their Offerings

|

Company |

Headquarters |

Key Strengths |

Latest Info (2025) |

|

Akzo Nobel N.V. |

Netherlands |

Advance innovation and sustainability. |

In April 2025, AkzoNobel bonds with IPG Photonics over laser curing for powder coatings |

|

PPG Industries, Inc. |

Pennsylvania |

Diverse and Innovative Product Portfolio |

In September 2025, PPG to show advanced coatings, EV total system solutions at The Battery Show North America. |

|

Sherwin-Williams Company |

United States |

Controlled distribution network |

RadGuard is a urethane resin system that boasts long-lasting performance. |

|

Axalta Coating System |

United States |

Innovation in sustainable and high-performance coatings. |

In April 2025, Axalta announced the launch of its next-generation patented Fast Cure Low Energy System (FCLE) clearcoat and surfacer products. |

|

Hempel A/S |

Denmark |

Innovation and R&D excellence |

Hempadur Avantguard 750 Pro is a fast-drying, high solids activated zinc-rich epoxy primer based on Hempel's proprietary technology. |

Recent Developments

- In November 2023, Beckers Group will bring radiation-curable technologies to coil coatings. The company has developed the first commercial paint formulations for dual ultraviolet and electron-beam curing in the coil coating market.

- In January 2023, Bayer Material Science AG reported monthly revenue of €220 million in the radiation-cured coatings market. This performance marked a steady start to the year, driven by robust demand in the European automotive and electronics sectors, reflecting a 5% increase from December 2022.

Segments Covered in the Report

By Product Type

- Electro Beam Curing

- Ultraviolet Curing

By Function

- Scratch Resistance

- UV Protection

- Chemical Resistant

- High Gloss

- Matte & Station

By Application

- Industrial

- Wood

- Printing Inks

- Paper & Film

- Plastic

- Electronic Products

- Others

By End use

- Wood Coatings

- Metal Coatings

- Printed Materials

- Optical Coating

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting