What is the Steam Methane Reforming Market Size?

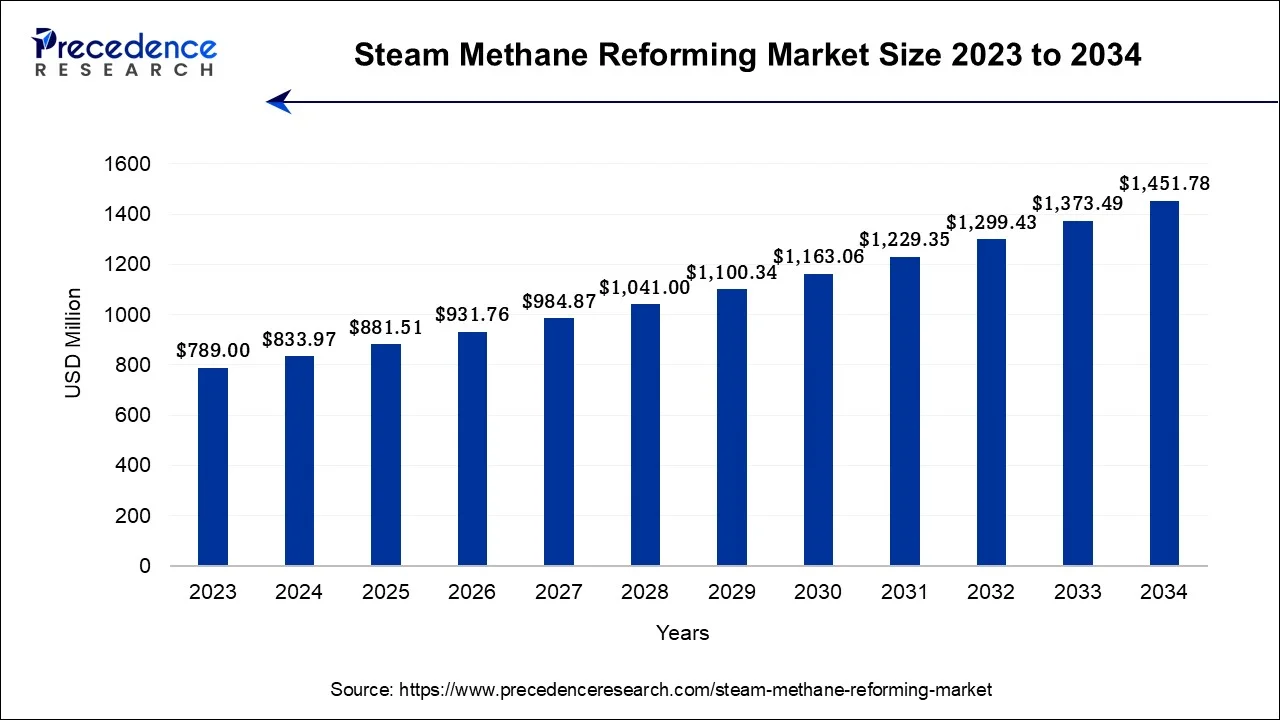

The global steam methane reforming market size is calculated at USD 881.51 million in 2025 and is predicted to increase from USD 931.76 million in 2026 to approximately USD 1,527.25 million by 2035, expanding at a CAGR of 5.65% from 2026 to 2035.

Market Highlights

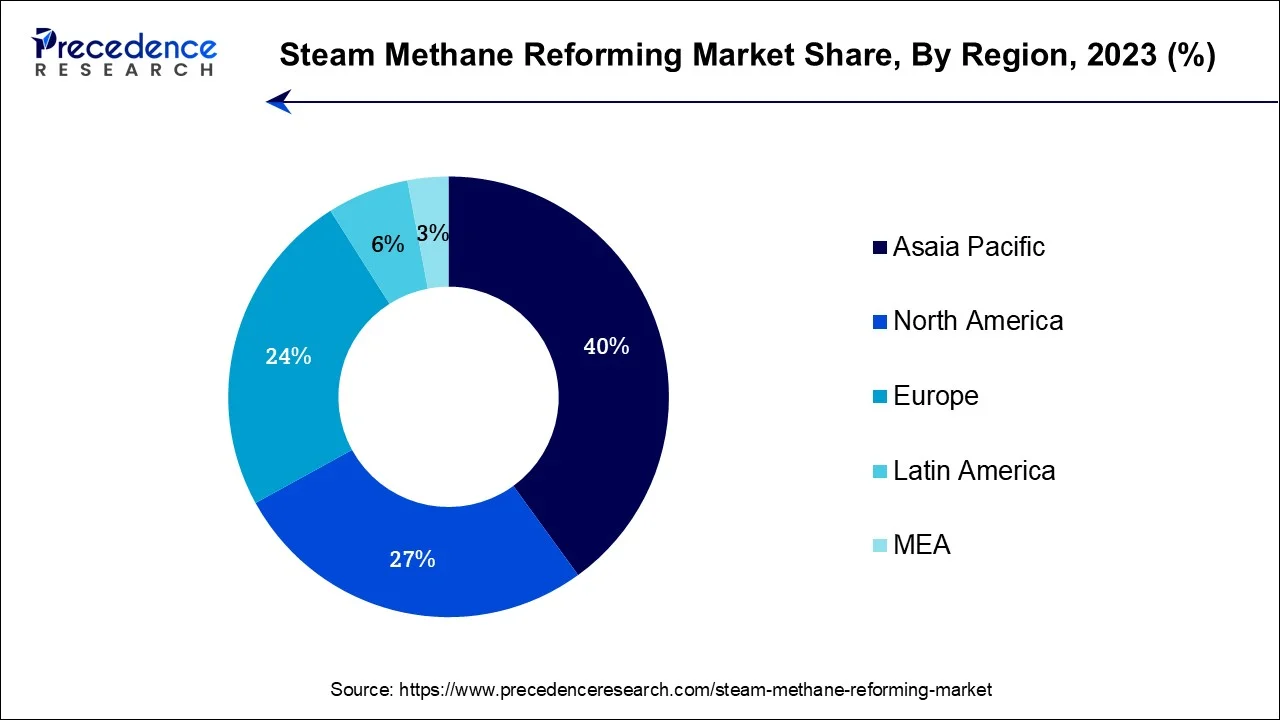

- Asia Pacific contributed more than 35% of revenue share in 2025.

- By Technology, the steam methane reforming segment is expected to dominate the steam methane reforming market.

- By System, the merchant segment is expected to hold the dominating share of the market during the forecast period.

- By Application, the methanol production segment is expected to dominate the steam methane reforming market.

What is Steam Methane Reforming?

The steam methane reformer market revolves around resolving issues with storing and transporting hydrogen cylinders. Steam methane reforming (SMR) is the most popular and practical approach for producing hydrogen gas compared to all other known technologies. For the steam methane reforming industry to expand, a robust supply chain for hydrogen generation must be established, including infrastructure for transportation and distribution. Steam methane reforming hydrogen can also fuel power plants, particularly gas turbines and fuel cells. This application is becoming more popular, particularly in areas prioritizing renewable energy alternatives.

How is AI contributing to the Steam Methane Reforming Industry?

The artificial intelligence is to streamline the steam methane reforming process and operations by means of process modelling, real-time optimization, predictive maintenance, digital twins, catalyst discovery, carbon capture integration, and intelligent control systems. This will lead to safer operations, higher hydrogen efficiency, reduced emissions, improved reliability, and informed decision-making through the entire industrial reforming process, which is very complex.

Steam Methane Reforming Market Growth Factors

- A greater demand for low-carbon and renewable energy sources is being seen as the globe works toward decarbonization. SMR-produced hydrogen is regarded as a crucial component of this shift. SMR technology has advanced owing to ongoing research and development activities in hydrogen production.

- These developments improve SMR's efficiency and lower associated costs, increasing its competitiveness. The creation of low-carbon or blue hydrogen is made possible by integrating carbon capture and storage technologies with SMR. This strategy promotes the steam methane reforming industry and is consistent with the carbon reduction objectives.

- Green hydrogen can be created using steam methane reforming in combination with renewable energy sources such as solar or wind energy. This strategy, also referred to as power-to-gas, supports the expansion of SMR while stabilizing the intermittent character of renewable energy sources.

- Numerous countries worldwide are putting policies and regulations in place to promote the use of hydrogen as a sustainable energy source, including targets, incentives, and subsidies for hydrogen generation, all of which positively impact the steam methane reforming market.

Market Outlook

- Industry Growth Overview: Steam methane reforming continues to be the major method of hydrogen production in the industry because it is the most economical and therefore the most used method when demand is high.

- Sustainability Trends: The industry is focusing on carbon capture integration, which will allow the production of blue hydrogen with lower emissions.

- Global Expansion: The industrialization of the Asia Pacific region is speeding up the adoption process, while North America is still the strongest leader in production.

- Major Investors: The principal investors are Linde, Air Liquide, and KBR, who are backing reforming technologies all over the world.

Market Scope

| Report Coverage | Details |

| Market Size by 2035 | USD 1,527.25 Million |

| Market Size in 2025 | USD 881.51Million |

| Market Size in 2026 | USD 931.76 Million |

| Market Growth Rate from 2026 to 2035 | CAGR of 5.65% |

| Largest Market | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Technology, System, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Expanding hydrogen generation industry

The demand for hydrogen has grown due to the worldwide movement towards decarbonization and the shift to a low-carbon economy. SMR is the central low-emission technology used to create hydrogen, a versatile and clean energy source. SMR can be used in many businesses because they already have well-established infrastructure and knowledge in managing natural gas. By converting to hydrogen production via SMR, proficiency in operating natural gas can be used to lower entry barriers for this technology. SMR has proven economically viable, especially in areas with significant natural gas deposits.

This method makes it possible to produce hydrogen cheaply, making it a desirable alternative for businesses and governments looking to invest in hydrogen as part of their clean energy initiatives. Governments worldwide are implementing rules and offering incentives to help the hydrogen economy thrive. This comprises monetary rewards, research funding, and legal frameworks that support the creation and application of SMR technology.

One of the most popular processes for producing hydrogen on an industrial scale is steam methane reforming. At high temperatures and pressures, methane and steam react to produce hydrogen and carbon dioxide. This method is well-known for its effectiveness and is easily expandable to handle the rising demand for hydrogen. The energy and environmental performance of SMRs are constantly being improved through ongoing research and development. The SMR market is expanding and becoming more competitive thanks to advancements in catalyst technology, reactor design, and process optimization.

Restraint

Complexities in decarbonization

Hydrogen, an essential component in numerous industrial processes, is produced using the widely utilized SMR technique. However, because CO2 is a byproduct, it is inherently carbon-intensive. Removing CO2 from SMR becomes a key constraint as worldwide worries about climate change and the need to minimize greenhouse gas emissions grow. Governments enact strict rules to reduce CO2 emissions and advance greener technologies globally. This directly impacts the SMR sector since businesses must reduce their emissions or switch to more environmentally friendly options.

Organizations are under increasing pressure to adopt cleaner practices as consumers and organizations prioritize sustainability more. This includes hydrogen synthesis, a vital part of numerous sustainable technologies, including fuel cells. The operating expenses of SMR facilities rise when carbon pricing mechanisms like carbon taxes or cap-and-trade programs are implemented. Due to the need to account for CO2 emissions and pay for their environmental impact, this puts additional financial strain on businesses that use SMR.

Natural gas, mainly composed of methane (CH4), is the fuel source for SMR. Methane is transformed throughout the process into hydrogen and carbon monoxide (CO), which releases CO2. This results in a significant carbon footprint, especially considering the extensive hydrogen production necessary for sectors including refining, chemicals, and ammonia manufacture.

Opportunity

Emergence of blue hydrogen

Steam methane reforming, which generates blue hydrogen, also collects and stores carbon dioxide emissions. This means that compared to conventional grey hydrogen, which is produced without carbon capture, the creation of blue hydrogen generates much fewer greenhouse gases. Blue hydrogen can be essential in the transition as the world advances towards a low-carbon economy. It serves as a bridge to a future with cleaner energy by replacing fossil fuels in several sectors, including transportation, electricity generation, and industrial activities. The technology of steam methane reforming is well-established and advanced. Because they can adjust their current processes, industries that already use natural gas as a feedstock can switch to blue hydrogen quite smoothly.

The infrastructure now in place for natural gas extraction, storage, and transport can be used to produce blue hydrogen. This reduces the need for significant new infrastructure investments, making it a more affordable choice for producers and consumers. The smaller carbon footprint of blue hydrogen can give enterprises looking to cut their emissions and adhere to regulatory standards a competitive edge in a market where carbon pricing and emissions trading systems are becoming increasingly important.

Segment Insights

Technology Insights

The steam methane reforming segment is expected to be dominated in the steam methane reforming market during the predicted period. SMR begins with natural gas, mostly made up of methane (CH4). The usual source of this natural gas is fossil fuel deposits. Natural gas is desulfurized before entering the reformer to eliminate sulfur compounds, which can be bad for catalysts. With an extensive record of industrial uses, SMR is an established and mature technology, giving it a substantial edge in scalability, efficiency, and dependability.

Methane and steam (H2O) react at a high temperature within the reformer with the help of a catalyst. The reforming reactions must be accelerated by catalysts, which are commonly made of nickel. They aid in reducing the activation energy needed for the responses to take place, improving the effectiveness of the process. By capturing and storing the CO2 emissions generated during the reforming process, SMR can be combined with carbon capture and storage (CCS) technologies to produce low-carbon or blue hydrogen. SMR units are already present in many industrial sites, particularly those in the petrochemical and refining industries. Utilizing existing infrastructure eliminates the requirement for significant capital expenditures on new technology.

System Insights

The merchant segment is expected to hold the dominating position during the forecast period. It has made significant progress toward raising the productivity, sustainability, and efficiency of SMR processes. This can entail advancements in the design of reactors, the creation of catalysts, the integration of heat, or other methods. It would probably strongly emphasize environmental sustainability, including carbon capture and storage (CCS) technologies or looking into additional low-carbon energy sources for the reforming process.

It would also adhere to all pertinent safety, environmental, and quality standards and be accredited by trade associations or regulatory bodies, which could enhance its reputation and gain the trust of its clients. A dominant retailer would be skilled at adjusting their tactics and offers to correspond with shifting market conditions because they regularly monitor market trends, client wants, and technological improvements.

Application Insights

The methanol production segment is expected to dominate the global steam methane reforming market during the forecast period. Methanol is a chemical substance with a wide range of applications. It is used as a feedstock to make a variety of compounds, including acetic acid, formaldehyde, and olefins. Additionally, it plays a crucial role in producing fuels like dimethyl ether and biodiesel. This adaptability drives the demand for the manufacturing of methanol. Because it burns more cleanly than conventional hydrocarbons, methanol is a desirable fuel for achieving legal criteria and environmental objectives.

Methanol fits into this transformation as governments and businesses explore more fuel substitutes. The SMR procedure is well-known and has been improved and refined over many years. Due to the process's cost-effectiveness, dependability, and technological maturity, its market dominance is further cemented.

Natural gas is plentiful and available in many parts of the world, with methane serving as the primary feedstock for the manufacture of methanol by SMR, which guarantees a consistent and accessible raw material supply for methanol synthesis. The infrastructure for extracting, moving, and processing natural gas is well-established worldwide. This indicates that the tools and knowledge required to support industrial-scale SMR methanol synthesis are available.

Region Insights

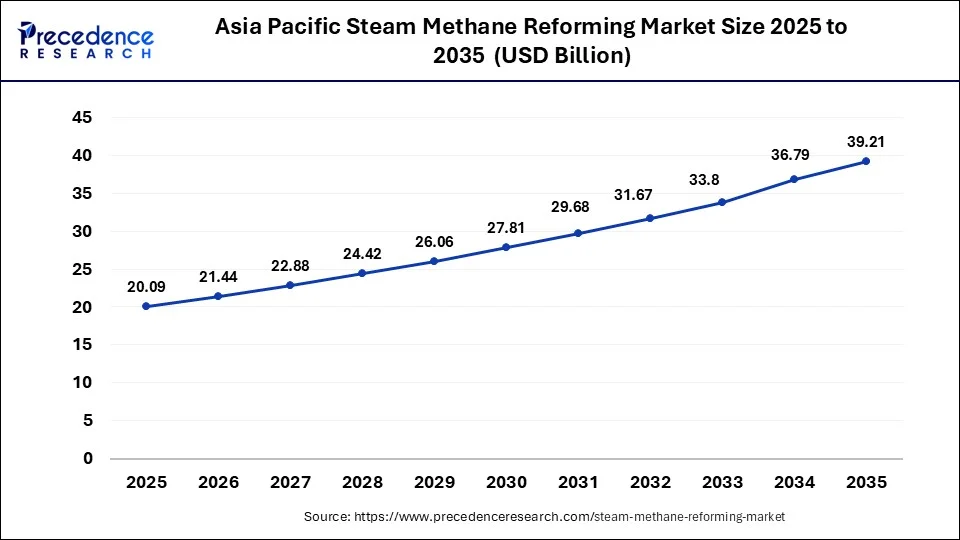

Asia Pasific Steam Methane Reforming Market Size and Growth 2026 to 2035

The Asia Pacific steam methane reforming market size was evaluated at USD 20.09 million in 2025 and is estimated to reach around USD 39.21 million by 2035, expanding at a CAGR of 6.22% from 2026 to 2035.

Asia Pacific carried the largest share in 2025, the region is expected to grow at a significant rate throughout the forecast period. Natural gas resources abound in the area, with significant deposits held by nations like China, and India acts as major contributor to the growth of the market in Asia Pacific. Natural gas is readily available, offering a solid base for advancing SMR technology. Asia-Pacific region has been at the vanguard regarding the worldwide movement toward a hydrogen-based economy. Given that it may be used in transportation, manufacturing, and power generation, hydrogen produced from steam methane reforming is crucial to this transformation. Many nations in Asia are eager to develop local hydrogen sources to cut their reliance on imports, gain a competitive edge in the global hydrogen market, and address the geopolitical significance of energy security. All these elements supplement the market's expansion in Asia Pacific.

China Steam Methane Reforming Market Trends

The Chinese steam methane reforming market is driven by the increasing need for clean energy sources and government initiatives to decrease carbon emissions. As the leading manufacturer of hydrogen globally, China is leveraging SMR technology to meet industrial and energy sector needs.

North America is steadily growing in the steam methane reforming market during the forecasted timeframe. Natural gas, the principal fuel for steam methane reforming, is abundant in North America. The region's plentiful natural gas supply gives SMR production a competitive edge. Significant investments have been made to build hydrogen production plants, including SMR ones. Funding initiatives about sustainable energy and hydrogen generation have attracted interest from the governmental and private sectors. The sustainability of hydrogen generation can be improved by combining SMR with renewable energy sources like solar and wind. Such integrated systems have been actively investigated and implemented in North America.

The move towards a low-carbon economy in the region is likely to depend heavily on hydrogen. It is employed in several sectors, including transportation, chemicals, and refining. With an emphasis on lowering carbon emissions and fulfilling sustainability objectives, North America has seen a rise in hydrogen consumption. Steam methane reforming technology advancements have improved the process's effectiveness and cost-efficiency. These upgrades have facilitated the expansion of SMR facilities in North America.

What Are the Driving Factors of The Steam Methane Reforming Market in Europe?

Europe is a mature steam methane reforming market that is more and more on the side of decarbonization, where the combining of carbon capture, utilization, and storage (CCUS) is the future relevance that keeps supporting industrial hydrogen demand, regulatory compliance, and transition strategies that are gradual within the already established energy and chemical infrastructure ecosystems.

The UK Steam Methane Reforming Market Trends:

The UK is still setting good momentum as a result of governmental support, the availability of offshore carbon storage, and the development of industrial clusters that together are making it possible for the adoption of blue hydrogen, the optimization of steam methane reforming and the integration of carbon capture mainly to support domestic decarbonization, the resilience of the industry, and long-term pathways to energy security.

Canada Steam Methane Reforming Market Trends

Canada, with its abundant natural gas reserves, provides a strategic advantage in producing hydrogen at scale. Emerging demands in the market include developments in the efficiency of SMR processes and even the integration of carbon capture technologies to decrease environmental impact.

Hydrogen Production Dynamics: Latin America Steam Methane Reforming Market

Latin America's market shows notable growth during the forecast period. It is driven by high regional need for industrial hydrogen in refining, along with chemical production, leveraging abundant, low-cost natural gas. Increased focus on decarbonization in Latin America is driving the integration of carbon capture, utilization, and storage (CCUS) with existing SMR plants to manufacture blue hydrogen, balancing emissions reduction with expense.

Brazil Steam Methane Reforming Market Trends

Brazil's steam methane reforming market is popular due to high demand in industrial sectors, primarily for hydrotreating in refineries, creating up 87% of local hydrogen production. Abundant natural gas resources and even established, cost-effective infrastructure keep SMR dominant, while increasing fertilizer production and industrial need, e.g., steel, chemical, further drive the market.

Steam Methane Reforming Market-Value Chain Analysis

- Resource Extraction: identifying, buying, and handling primary energy resources for the reforming operations

Key players: Rostec, Adani Enterprises, CSIR-National Institute of Oceanography - Power Generation: changing primary fuels into electrical energy and supplying the industrial processes

Key players: General Dynamics Corporation, Northrop Grumman Corporation, BAE Systems - Distribution Network Management: providing electricity to industrial users through the grids in a reliable manner

Key players: Olin Corporation (Winchester Ammunition), General Dynamics Corporation

Top Companies in the Steam Methane Reforming Market and Their Offerings

- Plug Power Inc.:Plug Power Inc. is primarily targeted on replacing conventional fossil fuel-based hydrogen production methods, which include steam methane reforming, with green hydrogen generated through electrolysis.

- Air Liquide: Air Liquide offers comprehensive steam methane reforming solutions, including technology licensing, design, and construction of small-to large-scale units for hydrogen and even syngas production. Their providing features high-efficiency, flexible, along with low-carbon technologies such as SMR-X (zero-steam production) and integrated CO2 capture, programmed for reliability and reduced operating expenses.

- Topsoe: Topsoe offers a comprehensive suite of technologies, catalysts, along with equipment for the steam methane reforming market, targeted at hydrogen and syngas production with an aim on efficiency, sustainability, along with flexibility. Their solutions range from conventional reforming furnaces to developed electrified reactors and autothermal technologies.

- CALORIC: CALORIC involves the manufacture of modular cylindrical reformers and gas generators, which provide compact, efficient hydrogen production solutions with a high level of cost-effectiveness and flexibility, along with being scalable and performing well in various industrial applications around the world.

- Air Products and Chemicals, Inc.: Air Products and Chemicals has the large-scale steam methane reforming plants that provide outsourced hydrogen supply, integrated carbon capture solutions, operational expertise, reliability, and long-term industrial gas partnerships worldwide.

- Linde plc: Linde plc is the company that designs and builds complete steam reformer plants and furnaces, thus providing advanced design, global project execution, and reliable large-scale hydrogen production technologies throughout the industry

Recent Developments

- In October 2025, European Energy launched bio-methanol via electrified steam methane reforming (e-SMR), advancing decarbonization efforts. This innovative method supports low-cost green methanol production for the shipping and aviation sectors. (Source: https://fuelcellsworks.com )

- In July 2025, the METH2GEN project, launched by JSW, aims to reduce methane emissions from mines and produce inexpensive hydrogen, backed by over €20 million from the company and €25.6 million total budget, with EU support. (Source: https://gmk.center )

- In September 2022, the outcomes of a field test of the non-combustion balance Steam/CO2 Reforming SR2 unit, developed by the renewable fuels company Raven SR Inc., showed that it could produce transportation-grade hydrogen from methane faster than other commercially available methods. Steam Methane Reformation (SMR), which has a typical first-pass conversion efficiency of about 75-80%, is used to manufacture almost 95% of the hydrogen utilized throughout the United States.

- In April 2022, according to a conventional hydrogen production plant, Wood's revolutionary steam methane reforming (SMR) technology can reduce CO2 emissions by 95%. With over half of all greenhouse gas emissions coming from inefficient energy, heat, and industrial operations, the technique tries to reduce these inefficiencies. Wood thinks that lowering the carbon footprint of hydrogen production is the key to lowering these emissions, fostering a more sustainable future, and meeting rising energy demand.

Segments Covered in the Report

By Technology

- Coal Gasification

- CALORIC

- Air Products and Chemicals, Inc.

- Linde plc

- Plug Power Inc.

- Air Liquide

- Topsoe

- Messer

- Steam Methane Reforming

By System

- Merchant

- Captive

By Application

- Methanol Production

- Ammonia Production

- Petroleum Refinery

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting