What is the Styrene Butadiene Latex Market Size?

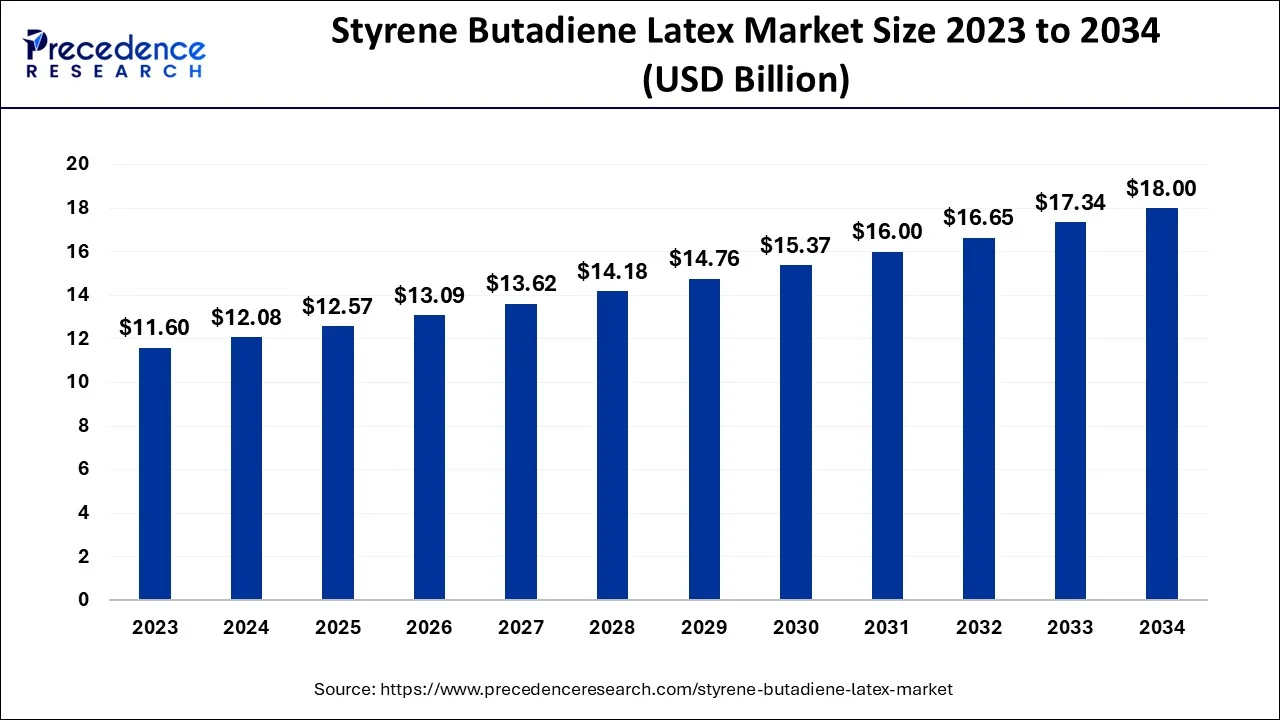

The global styrene butadiene latex market size is valued at USD 12.57 billion in 2025 and is predicted to increase from USD 13.09 billion in 2026 to approximately USD 18.66 billion by 2035, expanding at a CAGR of 4.03% from 2026 to 2035.

Styrene Butadiene Latex Market Key Takeaways

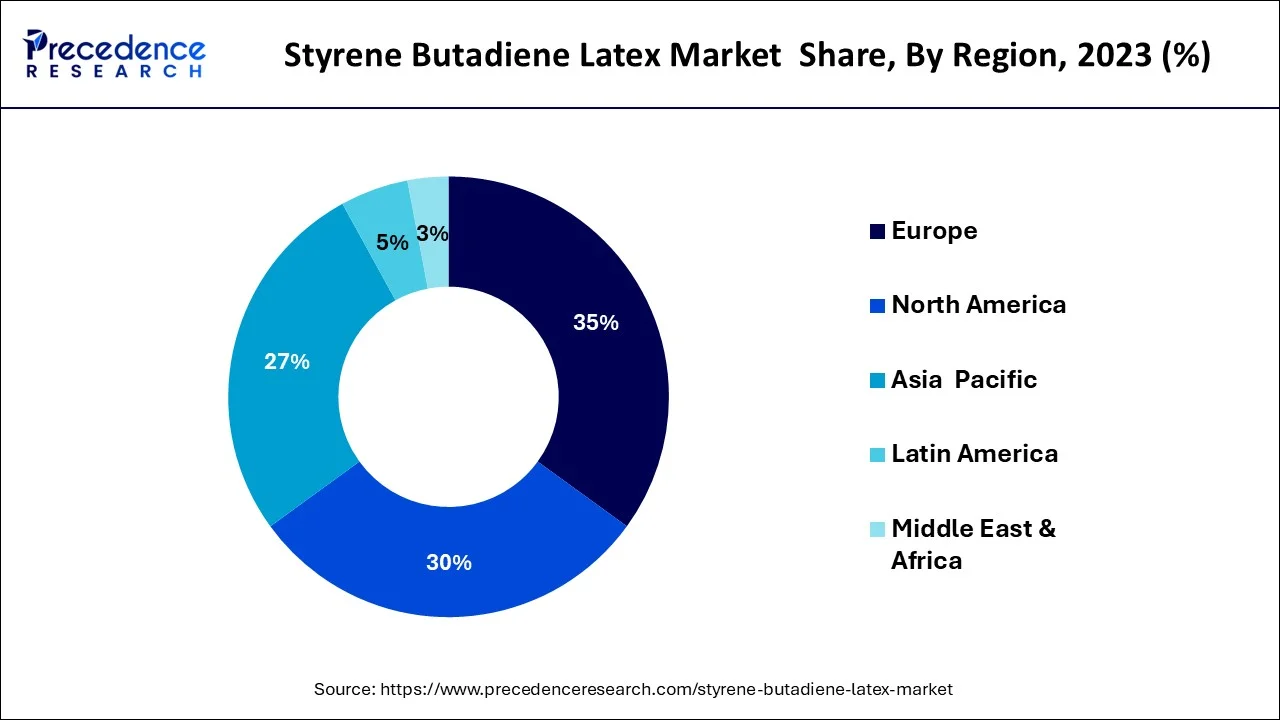

- Europe contributed more than 35% of revenue share in 2025.

- North America is estimated to expand the fastest CAGR between 2026 and 2035.

- By type, the emulsion styrene butadiene latex segment has held the largest market share of 72% in 2025.

- By type, the solution styrene butadiene latex segment is anticipated to grow at a remarkable CAGR of 5.9% between 2026 and 2035.

- By application, the paper processing segment generated over 28% of revenue share in 2025.

- By application, the mortar additives segment is expected to expand at the fastest CAGR over the projected period.

- By butadiene content, the low segment generated over 38% of revenue share in 2025.

- By butadiene content, the high segment is expected to expand at the fastest CAGR over the projected period.

Market Overview

Styrene butadiene latex (SBL) is a synthetic polymer emulsion that combines the strength of styrene with the flexibility of butadiene. This unique blend results in a versatile latex with excellent adhesion, abrasion resistance, and water resistance. SBL is widely utilized in the production of coatings, adhesives, sealants, and paints owing to its ability to create durable and elastic films on surfaces.

Its application extends to paper coatings, where it improves print quality and enhances paper strength. SBL is also a popular choice for carpet backings, providing stability and durability to the end product. Its cost-effectiveness and wide range of uses make styrene butadiene latex an essential component in various industries, contributing to the creation of high-performance materials in diverse sectors.

Styrene Butadiene Latex Market Growth Factors

- Increasing Construction Activities: Growing construction projects worldwide drive demand for Styrene Butadiene Latex (SBL) in applications such as adhesives and coatings.

- Rising Demand in Paper and Packaging Industry: The expanding paper and packaging sector fuels the need for SBL, employed for its advantageous properties in paper coatings.

- Automotive Industry Growth: SBL finds use in automotive applications, benefiting from the expanding automotive sector due to its adhesive and sealing capabilities.

- Growing Textile Industry: The textile industry's expansion boosts SBL demand, particularly in carpet backing applications, where it enhances stability.

- Surge in Infrastructure Development: Increased infrastructure projects globally drive the demand for SBL in construction materials like sealants and adhesives.

- Preference for Water-Based Products: The shift towards environmentally friendly water-based products favors SBL, known for its waterborne nature.

- Advancements in Paints and Coatings: Ongoing developments in the paints and coatings industry increase the adoption of SBL for its film-forming and protective properties.

- Rising Environmental Awareness: The increasing emphasis on eco-friendly materials benefits SBL, known for its lower environmental impact compared to some alternatives.

- Growth in the Furniture Industry: The expanding furniture sector drives demand for SBL in adhesives, coatings, and sealants used in furniture manufacturing.

- Expansion of Packaging Industry: SBL's excellent adhesion and water resistance contribute to its increased usage in the packaging industry.

- Demand for High-Performance Adhesives: The need for high-performance adhesives in various applications, including aerospace and electronics, boosts the market for SBL.

- Asia-Pacific Market Expansion: Rapid industrialization and construction activities in the Asia-Pacific region propel the demand for SBL in diverse applications.

- Technological Advancements in Manufacturing: Continuous advancements in SBL manufacturing processes enhance product quality and broaden its applications.

- Growing Emphasis on Green Building Materials: SBL aligns with the trend towards sustainable and green building materials, fostering its use in construction.

- Increasing Disposable Income: Higher disposable income levels drive consumer spending on products like carpets and textiles, benefiting the SBL market.

- Preference for Lightweight Automotive Materials: The automotive industry's inclination towards lightweight materials boosts SBL demand for its lightweight and durable properties.

- Expansion of Renewable Energy Sector: The growth of renewable energy projects drives the demand for SBL in applications such as sealants and coatings for solar panels.

- Infrastructure Rehabilitation Projects: Rehabilitation projects for existing infrastructure create opportunities for SBL applications in repair and maintenance materials.

- Growing E-commerce Industry: The rise of e-commerce increases the demand for packaging materials, favoring SBL applications in the packaging sector.

- Research and Development Initiatives: Ongoing research and development efforts to enhance SBL properties and discover new applications contribute to market growth.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 12.57 Billion |

| Market Size in 2026 | USD 13.09 Billion |

| Market Size by 2035 | USD 18.66 Billion |

| Growth Rate from 2026 to 2035 | CAGR of 4.03% |

| Largest Market | Europe |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Type, Application, Butadiene Content, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Construction boom and green building trends

The construction boom and green building trends synergistically propel the demand for styrene butadiene latex (SBL) in the market. As the construction industry experiences robust growth globally, SBL finds extensive use in various construction materials such as adhesives, sealants, and coatings. Its unique properties contribute to the durability and resilience of these materials, meeting the stringent requirements of modern construction projects.

Simultaneously, the emphasis on green building practices aligns perfectly with SBL's environmentally friendly characteristics. Green building trends prioritize sustainable and eco-friendly construction materials, and SBL, being water-based and having a lower environmental impact, emerges as a preferred choice. As architects and developers increasingly prioritize sustainability in construction projects, the demand for SBL is on the rise, reflecting a harmonious relationship between the construction boom and the growing preference for environmentally conscious building solutions.

Restraint

Competition from alternatives

Competition from alternative products serves as a significant restraint on the growth of the styrene butadiene latex market. Various latex alternatives, including acrylic, vinyl, and polyurethane-based formulations, offer competing properties and may be preferred by industries based on factors such as cost-effectiveness, performance attributes, or environmental considerations. Customers seeking specific characteristics, such as enhanced durability or reduced environmental impact, may opt for alternatives that align more closely with their requirements.

Moreover, advancements in technology continually introduce new formulations and materials that challenge the market position of SBL. As industries become increasingly focused on sustainability and eco-friendly solutions, alternatives that boast superior environmental profiles may gain traction, posing a threat to SBL's market share. To address this challenge, SBL manufacturers must emphasize innovation, efficiency, and differentiation to maintain their competitive edge in an evolving landscape of latex-based products.

Opportunity

Infrastructure development in emerging markets

Infrastructure development in emerging markets is a key catalyst for creating opportunities in the styrene butadiene latex market. As these markets experience rapid urbanization and industrialization, there is a growing demand for construction materials, including adhesives, coatings, and sealants, where SBL finds versatile applications. The expansion of transportation networks, residential complexes, and commercial spaces in emerging economies provides a substantial platform for the use of SBL in various construction projects.

Additionally, the development of infrastructure-related industries, such as manufacturing and automotive, further amplifies the demand for SBL in adhesives and sealants. By tapping into these opportunities, SBL manufacturers can establish a strong foothold in emerging markets, contributing to both the economic development of these regions and the global growth of the styrene butadiene latex market.

Type Insights

In 2023, the emulsion styrene butadiene latex segment had the highest market share of 72% based on the type. Emulsion styrene butadiene latex (ESBL) is a type within the styrene butadiene latex market, characterized by its polymer emulsion formulation of styrene and butadiene. ESBL offers enhanced stability, excellent adhesion, and versatility, making it a preferred choice in applications like paints, coatings, adhesives, and paper coatings.

A notable trend in the ESBL segment includes the increasing demand for environmentally friendly water-based coatings, aligning with the broader market shift towards sustainable solutions, particularly in the construction and packaging industries. This trend underscores the prominence of ESBL in meeting both performance and eco-conscious criteria.

The solution styrene butadiene latex segment is anticipated to expand at a significant CAGR of 5.9% during the projected period. Solution styrene butadiene latex (S-SBL) is a type within the styrene butadiene latex market characterized by a homogeneous liquid state. This form offers advantages such as improved stability, higher solids content, and better film-forming properties compared to its counterparts.

In recent trends, there is a noticeable increase in the demand for solution styrene butadiene latex, driven by its application versatility in paints, coatings, adhesives, and sealants. The market trend reflects a preference for S-SBL due to its superior performance characteristics in various end-use industries.

Application Insights

According to the application, the paper processing segment has held a 28% revenue share in 2023. The paper processing segment in the styrene butadiene latex market involves the application of SBL in coatings for paper products. SBL is utilized to enhance print quality, improve paper strength, and provide water resistance to paper coatings. A notable trend in this segment is the increasing demand for eco-friendly and sustainable paper solutions. As environmental concerns rise, SBL's water-based nature and lower environmental impact make it an attractive choice, aligning with the growing preference for greener alternatives in the paper processing industry.

The mortar additives segment is anticipated to expand fastest over the projected period. In the styrene butadiene latex market, the mortar additives segment involves the incorporation of SBL into mortar formulations to enhance performance. This application enhances mortar's adhesive properties, flexibility, and durability. A notable trend in this segment is the increasing demand for SBL-based mortar additives in the construction industry, driven by the pursuit of high-performance building materials. The trend reflects a shift towards more advanced and reliable mortar formulations, addressing the evolving needs of the construction sector for improved adhesion and flexibility in various building applications.

Butadiene Content Insights

According to the butadiene content, the low segment has held a 38% revenue share in 2023. In the styrene butadiene latex market, the low butadiene content segment refers to formulations with a lower proportion of butadiene relative to styrene. This segment is characterized by improved hardness and abrasion resistance, making it suitable for applications requiring enhanced durability, such as carpet backing and paper coatings. The trend in this segment involves a growing demand for cost-effective solutions without compromising on performance, driving manufacturers to develop SBL formulations with optimized butadiene content to meet the specific needs of industries seeking durable and resilient materials.

The high segment is anticipated to expand fastest over the projected period. In the styrene butadiene latex market, the high segment is defined by latex formulations with elevated butadiene content. This segment is characterized by increased flexibility and resilience, making it suitable for applications demanding superior durability. Trends in this high butadiene content segment involve a growing demand for specialty coatings, adhesives, and sealants in industries like automotive and construction. As end-users seek enhanced performance and versatility, the high butadiene content in SBL formulations continues to drive innovation, aligning with evolving market preferences for robust and flexible materials.

Regional Insights

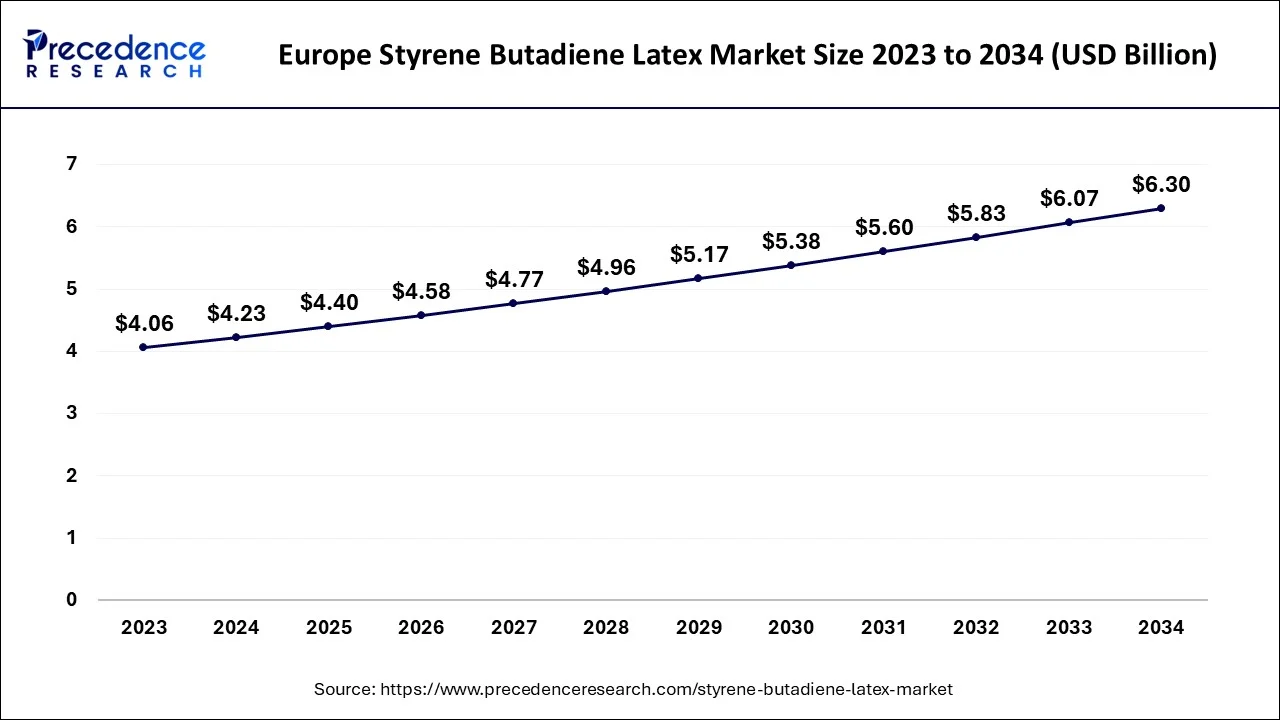

Europe Styrene Butadiene Latex Market Size and Growth 2026 to 2035

The Europe styrene butadiene latex market size is valued at USD 4.40 billion in 2025 and is expected to be worth around USD 6.53 billion by 2035, rising at a CAGR of 4.00% from 2026 to 2035.

Europe has held the largest revenue share 35% in 2025. Europe holds a major share in the styrene butadiene latex market due to robust demand across diverse industries and a well-established infrastructure. The region's emphasis on sustainable construction and stringent environmental regulations favors the adoption of SBL, known for its eco-friendly characteristics. Additionally, the thriving automotive and textile sectors contribute to the substantial market share, with European industries valuing SBL for its versatility in applications such as adhesives, coatings, and sealants, thereby driving the sustained prominence of SBL in the European market.

Germany Market Trends

Germany is a major contributor to the European styrene butadiene latex market due to its large industrial base and high demand from sectors like automotive, coatings, and packaging. Its advanced chemical manufacturing infrastructure allows both significant domestic consumption and export of SBL products. Additionally, strict European environmental regulations have encouraged the adoption of eco-friendly latex formulations, further boosting Germany's role in the market.

What Makes North America the Fastest-Growing Market?

North America is estimated to observe the fastest expansion. North America holds a major growth in thestyrene butadiene latex market due to robust demand across diverse industries. The region's thriving construction sector, coupled with a well-established automotive and textiles industry, drives significant utilization of SBL in applications such as adhesives, coatings, and carpet backing.

Moreover, stringent environmental regulations promoting water-based and low-VOC materials further contribute to the dominance of SBL in North America, reflecting a preference for sustainable and eco-friendly solutions in the market.

Canada Market Trends

The styrene butadiene latex market in Canada is growing due to strong government support for decarbonization and clean energy, which drives demand for sustainable, low-VOC latex in adhesives, coatings, and construction. Growth is also fueled by increased use in high-performance tires, interior components, and synthetic rubber applications, along with advancements in SB latex offering superior durability, printability, and binding properties.

What Potentiates the Market in Asia Pacific?

The styrene butadiene latex market in Asia Pacific is primarily driven by the region's rapid industrialization and urbanization, which drive demand in sectors like construction, automotive, paper, and adhesives. Growing packaging and coating industries, especially in China and India, also contribute significantly due to rising consumer goods production. Additionally, increasing investments in infrastructure projects and the availability of cost-competitive raw materials further strengthen market growth in the region.

Japan Market Trends

The market in Japan is driven by a strong demand for bio-based and eco-friendly SBL as industries, especially paper, shift from traditional synthetic latex due to consumer preference and stricter environmental regulations. Innovations in formulations are enhancing the durability, flexibility, and overall performance of SBL, enabling its use in a wider range of applications. Additionally, the expansion of high-solids SBL products is contributing to market growth in the country.

How is the Opportunistic Rise of Latin America in the Market?

Latin America is experiencing an opportunistic rise in the styrene butadiene latex market due to increasing demand from the construction, paper, and adhesive industries, driven by urbanization and infrastructure development. Growing awareness and adoption of eco-friendly and high-performance latex formulations are creating new opportunities for manufacturers in the region. Additionally, investments in local production and high-solids SBL products are helping Latin America capture a larger share of the global market, supporting steady growth.

What Opportunities Exist in the Middle East & Africa for the Market?

The Middle East & Africa (MEA) offers immense opportunities in the market due to rapid industrialization, urban infrastructure projects, and growth in the construction and automotive sectors. Increasing adoption of eco-friendly and high-performance latex products is also driving demand, particularly in coatings, adhesives, and paper applications. Furthermore, investments in local manufacturing and high-solids SBL formulations offer potential for market expansion and improved regional supply chains.

Value Chain Analysis

- Feedstock Procurement

It includes sourcing raw materials, such as styrene monomer and butadiene monomer. Both are byproducts of petroleum refining as well as petrochemical processes.

Key Players: BASF SE, Trinseo, Dow Chemical Company - Chemical Synthesis and Processing

Styrene butadiene latex is manufactured through a chemical synthesis process called emulsion polymerization, in which styrene and butadiene monomers are polymerized in water.

Key Players: Synthomer plc, Asahi Kasei Corporation, LG Chem - Compound Formulation and Blending

It is the post-polymerization procedure of adding numerous chemical additives and a few materials to the base styrene butadiene latex to monitor its final properties for specific end-use applications such as paper coatings, carpet backing, and adhesives.

Key Players: BASF SE, Dow Chemical Company, Asahi Kasei Corporation

Styrene Butadiene Latex Market Companies

- BASF SE

- Styron LLC (Trinseo)

- Dow Chemical Company

- Synthomer plc

- LANXESS AG

- Omnova Solutions Inc.

- LG Chem Ltd.

- JSR Corporation

- Wacker Chemie AG

- Sibur International GmbH

- Zeon Corporation

- Kumho Petrochemical Co., Ltd.

- Eastman Chemical Company

- Arkema S.A.

- Daelim Industrial Co., Ltd.

Recent Developments

- In July 2023, Synthomer, a prominent player in specialty chemicals, revealed its acquisition of Kraton Performance Polymers, a leading producer of styrene block copolymers (SBCs) and engineered polymers. This strategic move is anticipated to bolster Synthomer's position in the Styrene Butadiene (SB) latex market by broadening its product portfolio and geographical reach.

- In June 2023, Trinseo, a global leader in latex binders and polymers, joined forces with BASF, a major chemical company, to collaborate on developing next-generation Styrene Butadiene Rubber (SBR) tailored for the paper and packaging industry. This collaborative partnership aims to innovate and introduce new SBR formulations with enhanced performance and a focus on sustainability, signaling a commitment to advancing materials in the evolving landscape of the latex market.

Segments Covered in the Report

By Type

- Emulsion Styrene Butadiene Latex

- Solution Styrene Butadiene Latex

By Application

- Paper Processing

- Fiber and Carpet Processing

- Glass Fiber Processing

- Paints and Coatings

- Adhesives

- Mortar Additives

- Foams and Mattresses

- Others

By Butadiene Content

- Low

- Medium

- High

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting