What is the Torque Sensor Market Size?

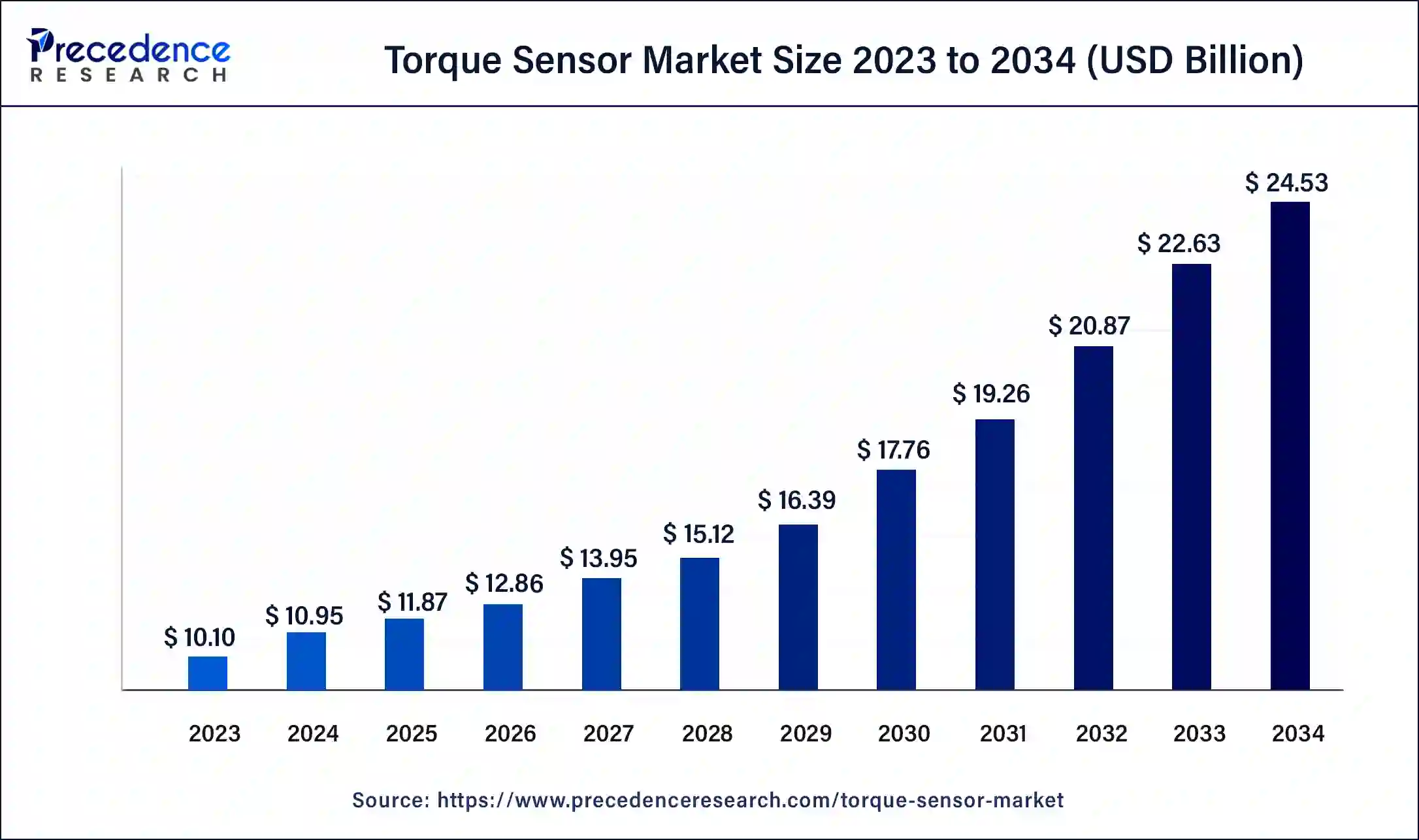

The global torque sensor market size is valued at USD 11.87 billion in 2025 and is predicted to increase from USD 12.86 billion in 2026 to approximately USD 24.53 billion by 2034, expanding at a CAGR of 8.40% from 2025 to 2034. The increasing demand for automobile, aerospace, and robotic sectors, rising investments, and government policies drive the torque sensor market.

Torque Sensor Market Key Takeaways

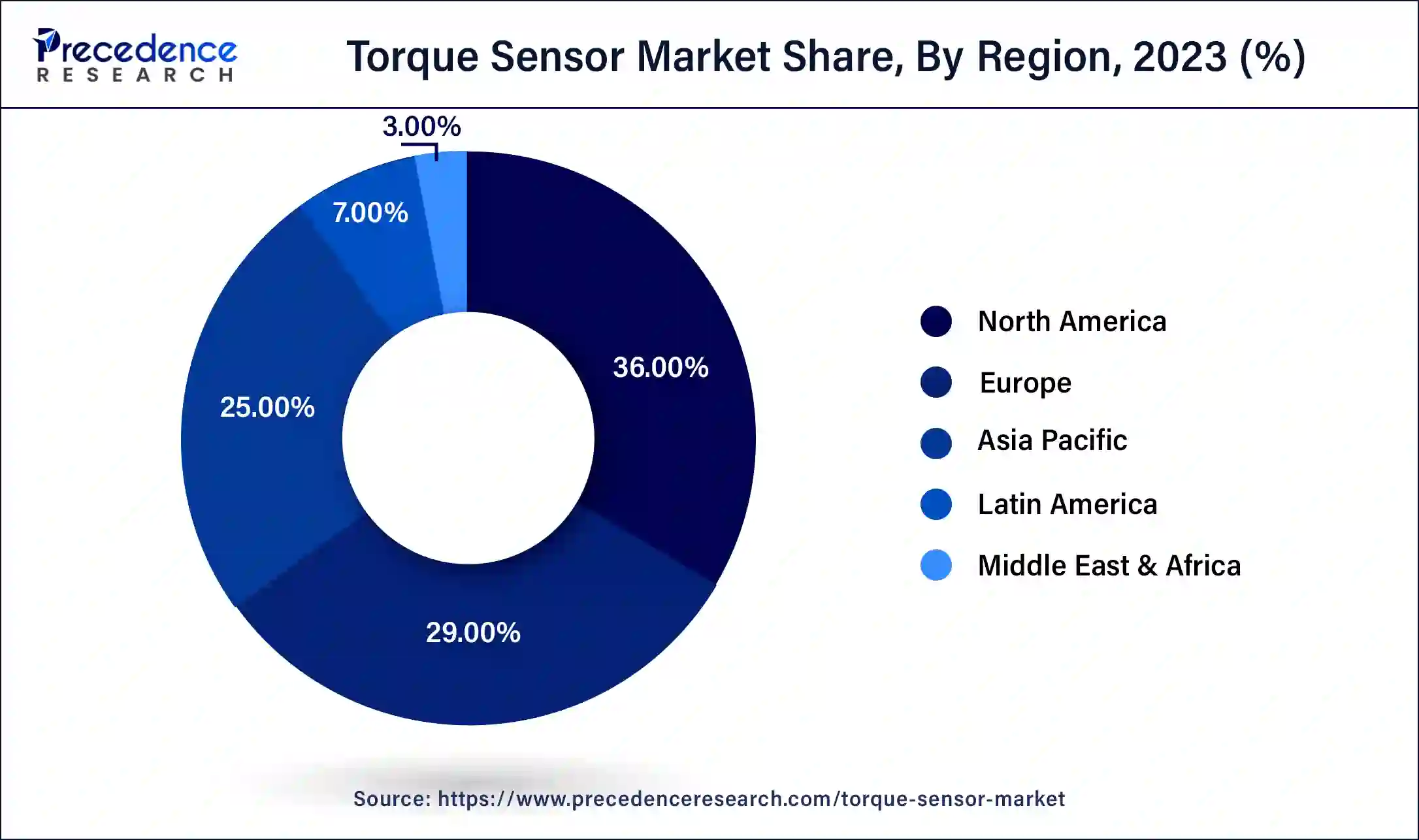

- Asia Pacific dominated the market with the largest share of 36% in 2024.

- North America is anticipated to grow at the fastest rate in the market during the forecast period.

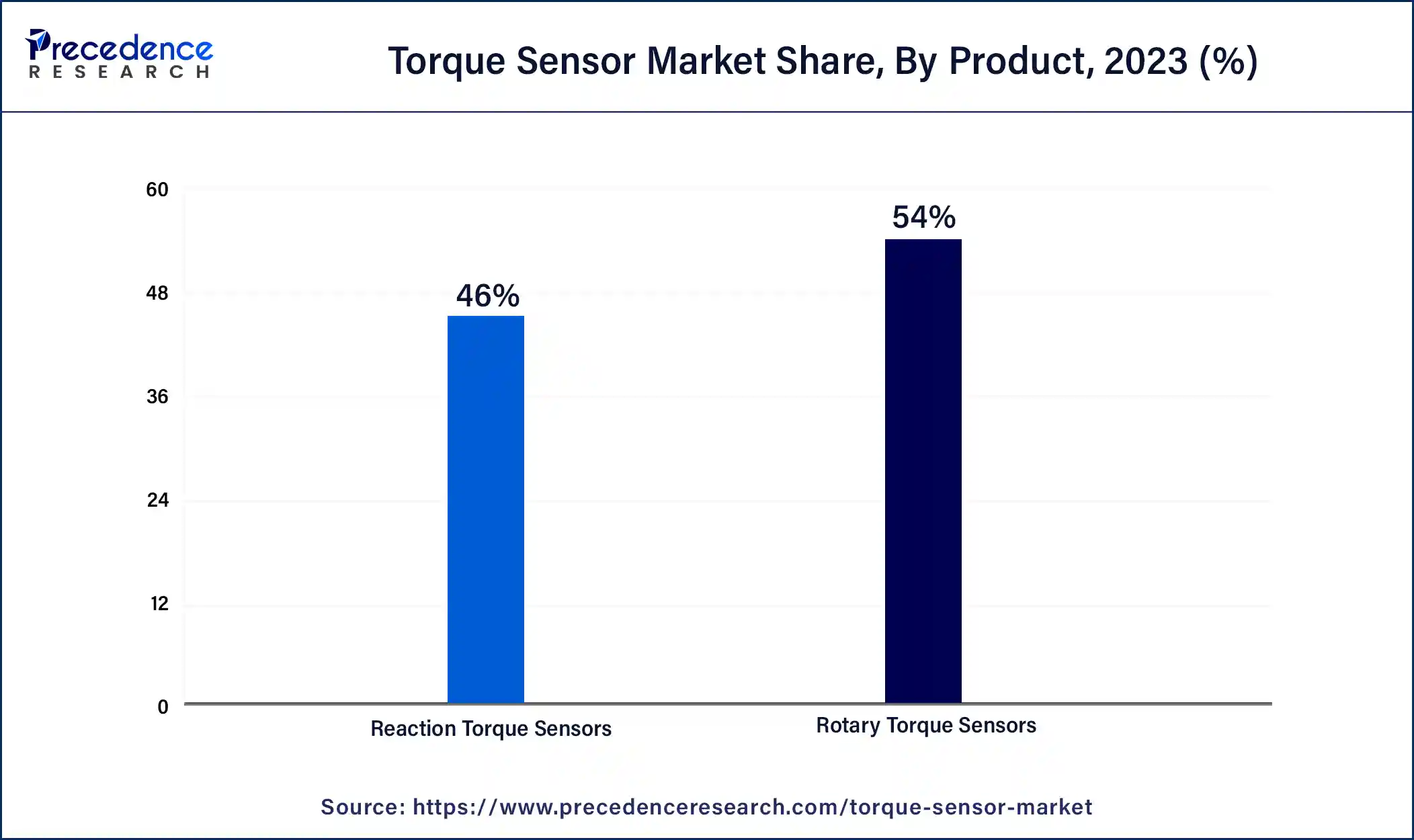

- By product, the rotary torque sensors segment contributed more than 54% of market share in 2024.

- By product, the reaction torque sensors segment is expected to grow at the fastest rate in the market during the forecast period of 2025 to 2034.

- By technology, the strain gauge segment generated the highest market share of 41% in 2024.

- By application, the automotive segment accounted for the highest market share of 34% in 2024.

- By application, the test & measurement segment is anticipated to grow with the highest CAGR in the market during the studied years.

What are Torque Sensors?

A torque sensor measures the torque applied to a rotary shaft by converting the torque into an electrical signal. Torque sensors are generally of two types: reaction and rotary. The reaction torque sensor measures static torque, and the rotary torque sensor measures dynamic torque. These sensors are used to control the speed of motors, monitor the functioning of machinery, and guarantee the safety of industrial processes. Hence, they can be used to identify any potential defect and optimize the performance of the system. This facilitates improved efficiency and reduced running costs over time. They determine the condition and performance of many mechanical measurement systems like pumps, rotational cutting equipment, gearbox shafts, vehicle axles, and electric motors. They are also used to develop new technologies and improve existing ones by monitoring the performance and behavior of the systems. The torque sensors are commercially used in the aerospace, automobile, manufacturing, robotics, and medical industries.

How Can AI Revolutionize the Torque Sensor Market?

Integrating artificial intelligence (AI) into torque sensors can boost their functionality, turning them into smarter and more effective components. AI can be used to analyze data obtained from sensors, providing more accurate and faster outcomes. AI with torque sensors can predict a machine's performance and suggest measures for its repair and maintenance. Neural-network-based calibration methods can calibrate force/torque sensors to accurately interpret the relationships between sensor readings and their represented outputs. AI can also facilitate contact detection, terrain classification, object recognition, and robust grasping.

Furthermore, AI can be integrated into the manufacturing process of torque sensors to enhance efficiency and reproducibility and incorporate automation. AI can potentially benefit supply chain management by planning and optimizing supply chain activities. Hence, the use of AI can help enterprises become more resilient and sustainable, thereby providing cost-effective solutions.

Torque Sensor Market Outlook

- Industry Growth Overview: The market is set for strong growth from 2025 to 2034, driven by the rapid adoption of electric vehicles (EVs) and the expansion of industrial automation and robotics. The rising need for precision measurement and real-time feedback in applications like engine testing, power steering systems, and robotic control further fuels this growth.

- Major Trends:There is a rising adoption of non-contact torque sensor technologies across a range of applications. Non-contact sensors such as Surface Acoustic Wave (SAW) and optical sensors offer improved durability and accuracy. Another key trend is the miniaturization and integration of sensors into compact systems with wireless connectivity and IoT capabilities, enabling seamless data analysis in smart factory environments.

- Global Expansion:The market is expanding worldwide, driven by increasing industrialization and growing automotive manufacturing. Emerging regions present significant opportunities due to increasing investments in manufacturing infrastructure, electric vehicles, and automation, which are accelerating market penetration.

- Major Investors:Large technology and industrial companies like Honeywell International Inc., Kistler Group, TE Connectivity, and ABB are major investors. Investment is also being driven by ongoing R&D initiatives from global automotive manufacturers and government-backed research in aerospace and defense applications.

- Startup Ecosystem:A vibrant startup ecosystem is emerging, focusing on niche innovations in specialized sensor design and software integration. Startups are attracting funding to develop highly accurate, multi-axis force/torque sensors for cobots and to create AI-enabled control software and analytics platforms for predictive maintenance.

Torque Sensor Market Growth Factors

- The increasing demand for electric power steering in electric vehicles and the automobile industry drives the torque sensor market.

- The need for torque sensors is increasing due to advancements in technology and the demand for robotics and automation.

- Torque sensors are commonly used in the aerospace industry to measure the torque of aircraft engines, thereby monitoring performance and operational safety.

- Rapid industrialization leads to the development of advanced tools and an increase in manufacturing, leading to increased demand for torque sensors.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 24.53 Billion |

| Market Size in 2026 | USD 12.86 Billion |

| Market Size in 2025 | USD 11.87 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 8.40% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, Technology, Application and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Drivers

Demand for miniature torque sensors

The demand for miniature torque sensors is increasing rapidly with the growth of different manufacturing industries. Miniature torque sensors are small sensors that measure torque in mechanical systems. These sensors can provide real-time measurements of torque and are hence used in quality control to optimize product quality. It can optimize motor performance, leading to improved efficiency, longer lifespan, and reduced maintenance. They are commonly used in test bench applications, screwdriver calibration, and twist measurement. Other potential applications of miniature torque sensors include tire braking and friction-skid test measurement. Hence, they have diverse applications in producing and designing automotive and vehicle components, machines and lab equipment, robotics, medical devices, and in testing the viability, durability, and safety of consumer products.

Restraints

Torque sensors have posed challenges in the automotive sector. The primary challenge is the higher price of a torque sensor e-bike. The advanced sensor technology and integration make the price higher, limiting the affordability to a larger consumer base. The next challenge is the high rotational speeds of electric drives in vehicles, creating a challenge for the torque measurement technology. Another challenge is the measurement of torque in CV (constant velocity) joints due to space constraints.

Opportunity

Rising Demand for Robotics

Torque sensors are potentially used in diverse industries. However, their use and demand in collaborative robotics are escalating. Rapid industrialization has increased the demand for robotics globally. The most common application of torque sensors in robotics is the angle measurement of a typical robotic arm. A robotic arm assists in material handling, inspection, and picking and placing applications. Torque sensors can also measure the torque of the motor and gearbox within the joint unit of a cobot. Hence, they lead to safer and more reliable robotic systems with increased worker safety.

The U.S. companies are heavily investing in robotics to boost productivity. The International Federation of Robotics provided a detailed analysis of the use of industrial robots based on applications, customer industries, types of robots, and other technical aspects. The industrial robot density i.e. number of robots per 10,000 employees in the manufacturing industry of 40 countries was compared and reported. The Republic of Korea reported the highest number of industrial robots in the manufacturing sector.

Segment Insight

Product Insights

The rotary torque sensors segment held a dominant presence in the torque sensor market in 2024. A rotary torque sensor is a torque transducer that measures the torque of a rotating system. It measures torque by connecting to the object that is receiving the torque and the object itself. The electrical signal is transmitted to the measurement equipment via slip rings or electric induction, providing real-time data. They not only measure torque but also give idea about position and rpm feedback. The rotary torque sensor is used in sectors that require accurate control and optimization of their processes. Hence, they are used in a wide range of applications, from robotics and automation to renewable energy sources.

- In May 2024, Forsentek Co. Ltd. announced the launch of their latest cutting-edge products: the Miniature Load Cell, the 3-Axis Load Cell, and the Rotary Torque Sensor. The rotary torque sensor provides precise and accurate measurements in automotive testing, industrial automation, and energy systems.

The reaction torque sensors segment is expected to grow at the fastest rate in the torque sensor market during the forecast period of 2025 to 2034. Reaction torque sensors are the sensors that measure the torque of a static system or non-rotating shaft. They are cost-effective and require fewer considerations. Unlike the rotating torque sensor, the reaction sensor does not require rpm considerations. These sensors are widely used in process control and testing. Hence, it can provide information about product consistency, performance, safe operating limits, maximum loads, and breaking points. They are also used in manufacturing industries, such as steel and paper. Furthermore, they are used in rolling mills to measure load and hence material properties.

Technology Insights

The strain gauge segment registered its dominance over the global torque sensor market in 2024. A strain gauge is a technology that measures the strain on a given object. It is widely used in torque sensors as it is a reliable, stable, sensitive, robust, and cost-effective torque measurement method. Another advantage is that it can be applied to any shaft without any shaft modification. They are employed in all types of torque sensors and used on drive shafts of power plants, refineries, fans, turbines, etc. It has a huge potential in the aerospace, automotive, rail, maritime, medical, and household applications.

- In April 2024, Sensor Technology Ltd. launched its new TorqSense SGR530/540 series of torque sensors with a sensing head and electronics model in separate housings. They operate on the principle of a strain gauge bridge. The sensing head can probe deep into machinery and electronics, which can be located in a position where they are protected from physical damage, moisture, electromagnetic forces, etc.

Application Insights

The automotive segment led the global torque sensor market in 2024. Torque sensors are widely used in the automotive sector. They are used to measure torque produced by the engine to track its performance. They also measure the torque generated from the steering wheel. Additionally, they are used to test clutch, gearboxes, powertrain, brake, and suspension systems. The horsepower is measured to improve fuel efficiency. The rapid growth in the automobile sector and increasing demand for electric vehicles drive the market. The market is also driven by the increasing global investment in automobile R&D in the automotive industry.

- In July 2022, McLaren Applied, an electronics specialist, delivered its next-generation surface acoustic wave torque sensor to an undisclosed motorsport client for all the participants of its race series. The new sensor is a non-contact measurement device that is small, lightweight, and robust and provides accurate wireless measurement.

The test & measurement segment is anticipated to grow with the highest CAGR in the torque sensor market during the studied years. The test & measurement sector provides tools that analyze, test, measure, display, and record electrical data. Torque measurement is used in the test and measurement to monitor the force required to open child-proof containers, calibrate torque wrenches, and determine fastener breaking torque. In materials testing, torque can even predict the onset of plastic deformation.

Regional Insights

Asia-Pacific Torque Sensor Market Size and Forecast 2025 to 2034

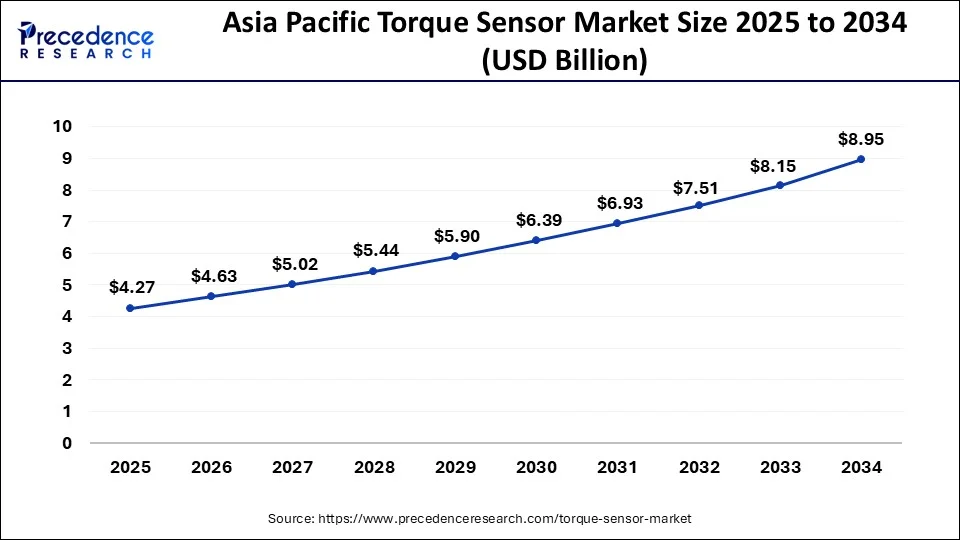

The asia-pacific torque sensor market is estimated at USD 4.27 billion in 2025 and is projected to grow to USD 8.95 billion by 2034, rising at a compound annual growth rate CAGR of 8.55% from 2025 to 2034.

Asia-Pacific held the largest share of the market in 2024. The rapid growth in the manufacturing industry potentiates torque sensor market growth. The torque sensor is used in the manufacturing industry to measure the torque applied to different components during assembly. China is the global leader in the manufacturing sector. China contributed around 35% of the global gross production in 2023. Additionally, India and South Korea are amongst the top five countries with the highest gross production globally, with a 3% contribution each in 2023. This surge is due to the Indian government's “Make in India” policy to boost the country's manufacturing sector. Additionally, the rising automobile sector augments the market. Chinese automakers account for more than half of the electric vehicles produced in the world.

- In December 2023, Mihogo One launched a folding e-bike with a 270 km range and new features. The bike has a hub wheel motor that is controlled by a torque sensor and has a maximum output of 750W.

India is a rapidly growing market driven by increased adoption of torque sensors in its expanding automotive and industrial sectors. Demand is boosted by rapid industrialization, significant growth in electric vehicle (EV) production, and the increasing adoption of Industry 4.0 initiatives, positioning India for considerable growth in domestic applications.

North America is observed to grow at the fastest rate in the torque sensor market during the forecast period. The rapid growth in the aerospace sector drives the market growth. The increasing investments, state-of-the-art R&D, and presence of key players also boost the market. Countries like the US and Canada are at the forefront of potentiating the market. The United States is the leading nation in the aerospace sector globally.

- According to the International Trade Administration, the foreign direct investment (FDI) in the U.S. aerospace industry was around $21 billion. The aerospace sector in Canada contributed around $28.9 billion to GDP in 2023.

Also, Canada is ranked in the top 5 countries globally across civil flight simulators, engines, and aircraft segments. The torque sensor market is also driven by rapid growth in the automobile, medical, and robotic sectors.

- In January 2024, Propella started shipping its new Propella 9S Pro V2, a low-cost torque sensor-enabled electric bike. The torque sensor is incorporated to provide the most natural and responsive pedal-assist experience.

U.S. Torque Sensor Market Trends

The market in the U.S. is characterized by its technological leadership and focus on high-precision applications, particularly in aerospace, automotive testing, and industrial automation. The presence of major industry players and an emphasis on advanced, non-contact sensor technologies solidifies the country's leadership in innovation. The market in the U.S. is growing due to the increasing demand for precise, real-time measurement of rotational force across industries such as automotive, aerospace, and industrial automation.

Why is Europe Considered a Notably Growing Region in the Torque Sensor Market?

Europe is expected to grow at a notable rate in the market. The market in Europe is characterized by its high-performance standards and established infrastructure in the automotive and industrial sectors. There is a strong focus on advanced R&D, particularly on the development of highly accurate and intelligent autonomous systems for robotics, logistics, and test-and-measurement applications. Strict safety regulations, the need for enhanced performance optimization, and the presence of leading sensor manufacturers like Kistler Group, HBM, and Infineon Technologies AG are also contributing to market growth.

Germany Torque Sensor Market Trends

Germany is leading the European torque sensor market, thanks to its large, established automotive and industrial sectors and the presence of global industry leaders such as Infineon Technologies AG, Bayer AG's former subsidiary, and other specialized manufacturers. The market focuses heavily on precision engineering, quality control, and integrating sensors into advanced manufacturing and robotics applications. R&D in wireless and non-contact sensor technologies is a key trend.

What Factors Boost the Growth of the Market in Latin America?

The torque sensor market in Latin America is driven by increasing industrial automation and the expanding automotive sector. There is a growing demand for vehicle safety systems as the region sees growth in car sales and urbanization. The rising development of electric power steering (EPS) and general industrial machinery, along with growing investments in manufacturing infrastructure, is boosting the demand for precise measurement solutions. Brazil is a major player in the market, with strong demand in the automotive and industrial automation sectors. Government regulations encouraging energy efficiency and the increasing adoption of electric and hybrid vehicles are also driving the market.

How is the Opportunistic Rise of the Middle East and Africa in the Torque Sensor Market?

The Middle East and Africa region is experiencing an opportunistic rise in the global market, driven by industrial diversification, investments in oil and gas exploration, and a growing focus on renewable energy projects. The expanding automotive and manufacturing sectors, especially in the Gulf Cooperation Council (GCC) countries, are creating profitable growth opportunities. The market is adopting advanced systems in response to increasing demand for smart manufacturing solutions and the need for precision in heavy industries.

Saudi Arabia Torque Sensor Market Trends

Saudi Arabia leads the market within the Middle East and Africa, driven by its large automotive sector and national development programs focused on industrial diversification. The country is investing in quality control infrastructure and advanced testing laboratories, increasing demand for precise force and torque measurement tools. The market is expanding in applications such as automotive parts manufacturing, oilfield equipment, and industrial machinery, as the nation advances toward higher production standards and technological modernization.

Value Chain Analysis

Research & Development (R&D)

This stage focuses on innovating sensors for higher accuracy, durability, and integration.

- Key Players: Infineon Technologies AG, Honeywell International Inc., Kistler Group, HBK, ABB Ltd., FUTEK Advanced Sensor Technology Inc.

Component Sourcing and Manufacturing

Sourcing specialized materials and precision manufacturing of sensor elements and complete products.

- Key Players: TE Connectivity Ltd., General Dynamics Corporation, Teledyne Technologies Inc., Vishay Intertechnology Inc.

Quality Assurance and Certification

Rigorous testing, calibration, and compliance with industry standards and regulatory bodies.

- Key Players:ABB, Honeywell, and Siemens.

Distribution and Sales

Global distribution through B2B partnerships, distributors, and online platforms.

- Key Players: Mouser Electronics, Honeywell, Siemens, and ABB.

Maintenance, Support, and Lifecycle Services

Ensuring long-term performance through post-sales support, calibration, and predictive maintenance.

- Key Players:HBK, Siemens, and Kistler Group.

Top Companies in the Torque Sensor Market and Their Offerings

- Honeywell International: Wide range of high-capacity rotary and reaction torque sensors for aerospace, industrial automation, and automotive use.

- FUTEK Advanced Sensor Technology, Inc.: High-precision, miniaturized force and torque sensors for medical robotics, aerospace, and test and measurement applications.

- Crane Electronics: Measurement instruments, transducers, and analyzers for manufacturing, quality assurance, and fastening operations in industrial settings.

- S. Himmelstein and Co.: High-accuracy non-contact rotary and reaction torque sensors for motor, pump, and drivetrain test and measurement systems.

- Sensor Technology Ltd: Non-contact, wireless SAW technology torque sensors for automotive, industrial, and renewable energy sectors, known for accuracy and easy integration.

Other Key Players

- Althen Sensors & Controls

- Bota Systems AG

- Datum Electronics

- HITEC Sensor Developments

- Lorenz Messtechnik

- Mountz Torque

- Omega Engineering

- PCB Piezotronics

- Quality Sense Technologies

- Welan Technologies

Recent Developments

- In June 2023, ABB launched two new variants of its GoFa collaborative robot, GoFa 10 and GoFa 12, to leverage cobot automation for enhanced efficiency. The ABB's motion control technologies and GoFa's intelligent torque sensors ensure smooth movements needed for high-precision surface finishing, fastening, assembly, and testing tasks.

- In March 2024, Bota Systems AG launched SenseONE T5 with three to five times higher sensitivity than its predecessor. The compact and lightweight sensor offers optimal sensitivity for small robots.

- In April 2024, Bota Systems AG launched PixONE, a torque sensor that combines high-performance electronics with a compact, lightweight design. The new sensor can connect a robot's arm and end-of-arm tooling while maintaining the integrity of internal cable routing.

Segments Covered in the Report

By Product

- Rotary Torque Sensors

- Reaction Torque Sensors

By Technology

- Strain Gauge

- Surface Acoustic Wave (SAW)

- Optical

- Magnetoelastic

By Application

- Automotive

- Test & Measurement

- Industrial

- Aerospace & Defense

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting