What is the Advanced Recycling Market Size?

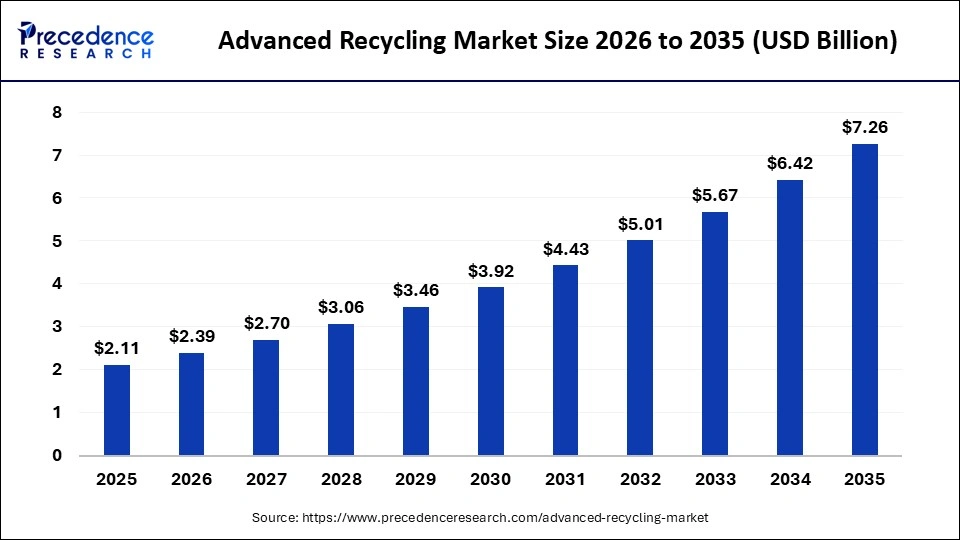

The global advanced recycling market size accounted for USD 2.11 billion in 2025 and is predicted to increase from USD 2.39 billion in 2026 to approximately USD 7.26 billion by 2035, expanding at a CAGR of 13.16% from 2026 to 2035. The strong regulatory and corporate circularity targets primarily drive the advanced recycling market.

Market Highlights

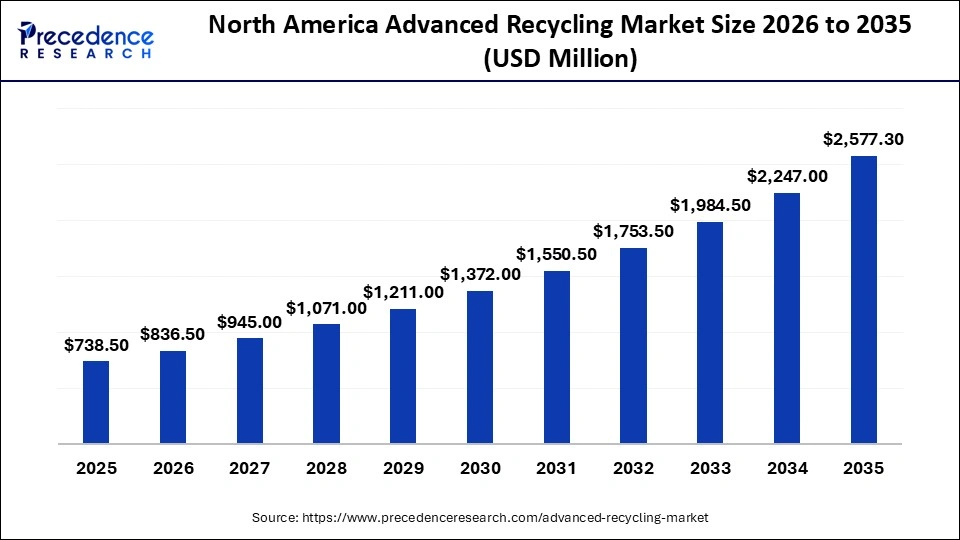

- North America dominated the market, holding the largest market share of 35% in 2025.

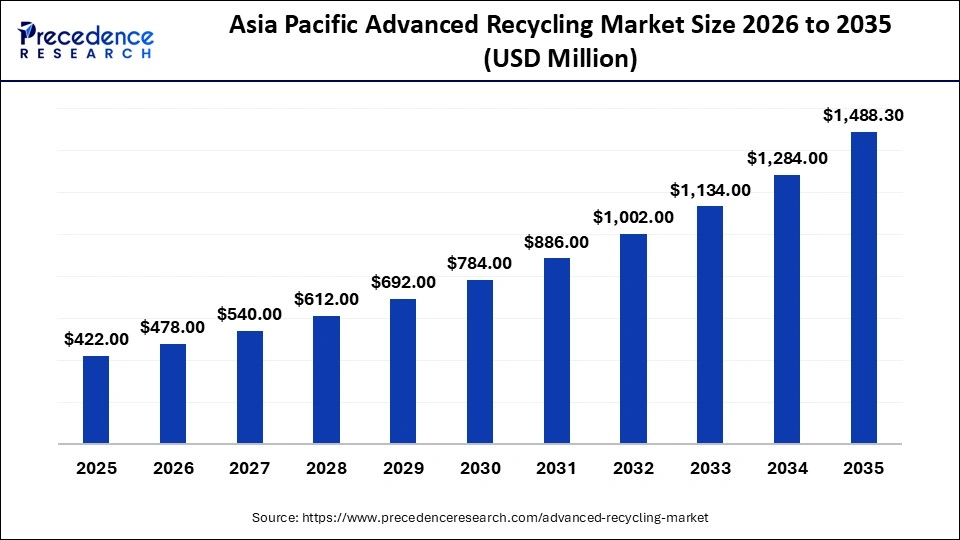

- The Asia Pacific is expected to grow at the fastest CAGR between 2026 and 2035.

- By technology, the pyrolysis segment held the largest market share of 40% in 2025.

- By technology, the depolymerization (including glycolysis, methanolysis) segment is expected to grow at a strong CAGR between 2026 and 2035.) segment held the largest market share of 40% in 2025.

- By feedstock, the polyethylene (PE) segment is expected to grow at a significant CAGR of 18% between 2026 and 2035.

- By application/end-use industry, the packaging (rigid & flexible) segment contributed the biggest market share of 38% in 2025.

- By application/end-use industry, the building & construction materials segment is growing at a remarkable CAGR between 2026 and 2035.

- By product output/ end-product, the recycled feedstock oils & fuels (pyrolysis oil) segment held the major market share of 35% in 2025.

- By product output/ end-product, the recovered monomers / chemical intermediates segment is expected to expand at a remarkable CAGR between 2026 and 2035.

Advanced Recycling Market Overview

The advanced recycling market encompasses technologies that convert post-consumer and post-industrial plastic waste, as well as other challenging-to-recycle feedstocks, into useful chemical building blocks, monomers, polymers, fuels, or specialty materials. It includes thermal processes (pyrolysis, gasification), depolymerization (glycolysis, methanolysis, enzymatic), hydrothermal and solvolysis approaches, and integrated systems that combine feedstock pre-treatment, chemical conversion, purification, and polymerization. Advanced recycling targets mixed, contaminated, and multi-layer plastics unsuitable for mechanical recycling, enabling circularity for materials such as PE, PP, PET, multi-layer films, and styrenics.

According to the World Bank, the world produces nearly 2 billion metric tons of waste each year. With the increasing pace of urbanization, this amount could almost double by 2050. 37% of this waste ends up in landfills, where it pollutes the environment, lowers property values, poses health risks, and produces greenhouse gas emissions. Only about 19% of waste is recycled globally.

How Are AI-Driven Innovations Reshaping the Advanced Recycling Market?

In today rapidly evolving technological landscape, Artificial Intelligence (AI) is a transformative force, with great potential to accelerate the growth of the advanced recycling market by enhancing the accuracy, efficiency, and profitability of material recovery and conversion processes. Modern waste facilities are increasingly incorporating AI into their systems using robots equipped with AI-powered computer vision systems to identify and sort various materials with higher accuracy and speed than human capabilities. Robots equipped with high-speed cameras and sensors are cheaper than humans. Humans typically sort 50 to 80 items each hour, while an AI robot with optical sensors can sort up to 1,000 items per hour with greater accuracy. Therefore, robotic arms integrated with these AI systems can significantly reduce labor costs and exposure to hazardous materials.

Advanced Recycling Market Outlook

Between 2025 and 2030, the industry is expected to experience accelerated growth. The market is driven by rising plastic pollution, increasing demand for high-quality recycled materials across sectors, heightened environmental concerns, stringent regulatory policies, a growing need for sustainable waste management solutions, and rising investment in chemical recycling technologies.

Leading players are increasingly expanding their geographic presence through strategic investments, partnerships, and joint ventures. For instance, in November 2025, ExxonMobil plans to invest more than USD 200 million to expand its advanced recycling operations at its sites in Baytown and Beaumont, Texas. The new operations are expected to start up in 2026 and can help increase advanced recycling rates and divert plastic from landfills. The company plans to build additional units to reach a global recycling capacity of 1 billion pounds per year by 2027. Additional advanced recycling units are scheduled for North America, Europe, and Asia.

Several large petrochemical companies, specialized technology companies, and venture capital firms are heavily investing in advanced recycling to meet sustainability goals and generate high-quality recycled materials. For instance, in April 2025, Brightmark, a plastic recycling company, announced plans to invest nearly USD 1 billion in Middle Georgia to build a factory that will take used plastic and turn it into the building blocks to make new plastics, while diverting hundreds of thousands of tons of waste each year from landfills. Brightmark plans a large facility to convert plastic waste into materials for new plastic.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 2.11 Billion |

| Market Size in 2026 | USD 2.39 Billion |

| Market Size by 2035 | USD 7.26 Billion |

| Market Growth Rate from 2026 to 2035 | CAGR of 13.16% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Technology, Feedstock, End-Product, Application, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Advanced Recycling Market Segmental Insights

Technology Insights

Pyrolysis: The pyrolysis segment held the largest market share, at 40%, in 2025. The segment includes thermal pyrolysis (plastic-to-oil) and catalytic pyrolysis. Pyrolysis is a dominant technology, owing to its effectiveness in processing a wide range of plastics, including Polyethylene (PE), Polyethylene Terephthalate (PET), Polypropylene (PP), and Polystyrene (PS), into valuable outputs such as oil and chemical feedstocks. Pyrolysis technology can efficiently process mixed and contaminated plastic waste, which is oftens difficult to process through traditional mechanical recycling.

Depolymerization (including glycolysis, methanolysis): This segment is expected to grow at a remarkable 25% CAGR between 2025 and 2034. The segment includes PET depolymerization to monomers and Polyurethane/nylon depolymerization. Depolymerization targets condensation polymers such as nylon, PET, and polycarbonate, breaking chemical bonds to recover the original monomers through processes such as glycolysis, hydrolysis, and methanolysis. These recovered monomers can then be purified and repolymerized into new virgin-quality plastic materials.

Feedstock Insights

Mixed plastic waste (unsorted municipal plastic): The mixed plastic waste (unsorted municipal plastic) segment dominates the advanced recycling market, accounting for 40% of the market share. Advanced recycling technologies are gaining immense popularity, owing to their ability to process diverse and lower-quality unsorted municipal plastic waste as feedstocks. Moreover, technological innovations such as AI-driven sorting robotics, sensor-based systems, and improved catalysts are significantly improving the efficiency and quality of processing mixed plastics.

Polyethylene (PE): This segment is the fastest-growing in the advanced recycling market, with a CAGR of 18%. Corporate sustainability commitments, rising regulatory pressure, and growing demand for sustainable, recycled materials primarily drive the segments growth. Advanced recycling methods, particularly pyrolysis, are crucial for processing complex, contaminated, and diverse PE waste streams that mechanical recycling struggles to handle efficiently.

Application Insights

Packaging (rigid & flexible): This segment dominates the advanced recycling market, accounting for 38% of the market share. The segments growth is driven by rising regulatory pressure to reduce plastic waste and by increasing demand for sustainable packaging solutions. Advanced recycling provides effective solutions for complex packaging that traditional mechanical recycling struggles to process.

Building & construction materials (incl. composite products): On the other hand, the building & construction materials segment is the fastest-growing in the advanced recycling market, with a CAGR of 10%, owing to the rising need to meet the increasing regulatory standards and increasing consumer demand for recycled materials like concrete, asphalt, plastics, metals, and wood. Several companies are increasingly leveraging advanced recycling technologies to keep materials in the loop for longer and align with the circular economy principles.

End-product Insights

Recycled feedstock oils & fuels (pyrolysis oil): The recycled feedstock oils & fuels (pyrolysis oil) segment dominates the advanced recycling market, holding a 35% share owing to the stringent environmental regulations, growing demand for recycled content in new polymers, and increasing demand for sustainable energy solutions. Moreover, the continuous innovations in catalysts and process efficiency are significantly improving oil yield and quality.

Recovered monomers/chemical intermediates: On the other hand, the recovered monomers/chemical intermediates segment is the fastest-growing in the advanced recycling market, projected to grow at a CAGR of 25%. Advanced recycling is an emerging opportunity, providing a sustainable source of raw materials. The recovered monomers and chemical intermediates produced through advanced recycling are integrated into various industries, including packaging, textiles, automotive, electronics, and construction.

Advanced Recycling Market Regional Insights

The North America advanced recycling market size is estimated at USD 738.50 million in 2025 and is projected to reach approximately USD 2,577.30 million by 2035, with a 13.31% CAGR from 2026 to 2035.

How Can North America Dominate the Advanced Recycling Market?

North America dominates the advanced recycling market, accounting for 35% of the market. The regions leadership position is driven by increasing investment in waste management infrastructure, growing environmental concerns, rising regulatory pressures,rising demand for recycled plastics, and increasing interest and investment from both the private and public sectors in chemical recycling solutions. Moreover, the rising transition toward the circular economy is expected to spur the adoption of advanced recycling technology in the North American region. Advanced recycling technology has the potential to complement existing mechanical recycling by enabling the processing of hard-to-recycle plastics and paving the way for mixed-plastic processing. Such supportive factors bolster the region growth during the forecast period.

In May 2025, Dow and Freepoint Eco-Systems Supply & Trading LLC announced an agreement for an estimated 65,000 metric tons per year of certified-circular, plastic waste-derived pyrolysis oil to produce new, virgin-grade equivalent plastics in Dows U.S. Gulf Coast operations. Both Dow and Freepoint Eco-Systems are building recycling systems that convert plastic waste into valuable materials and foster a circular economy for plastics in North America.

The U.S. advanced recycling market size is calculated at USD 516.95 million in 2025 and is expected to reach nearly USD 1,817.00 million in 2035, accelerating at a strong CAGR of 13.39% between 2026 and 2035.

How Is the United States Transforming the Advanced Recycling Market?

The United States leads the advanced recycling market. The countrys growth is driven by regulatory pressure to reduce plastic waste, rising investment in advanced recycling technologies, a growing emphasis on circular economy principles, corporate sustainability commitments, and increasing demand for sustainable recycled materials. Additionally, the governments active participation in waste management including the introduction of regulations and policies to curb plastic waste and the promotion of sustainable practices across the country.

The U.S. generates 1,800 pounds of waste per capita annually, more than any other country. The U.S. national recycling goal of 50% by 2030 will be difficult, if not impossible, to achieve with the current standard recycling methods.

The Asia Pacific advanced recycling market size is expected to be worth USD 1,488.30 million by 2035, increasing from USD 422.00 million by 2025, growing at a CAGR of 13.43% from 2026 to 2035.

How Is the Asia Pacific Region the Fastest-Growing in the Advanced Recycling Market?

Asia Pacific is the fastest-growing region in the advanced recycling market, with a CAGR of 30%, fuelled by rising concerns about plastic waste pollution, stringent government regulations, rapid urbanization & industrialization, rapid technological innovation in advanced recycling, and the rising need for sustainable waste management solutions. Several major brands in the region have set ambitious environmental, social, and governance (ESG) targets to utilise more recycled plastic, which creates significant demand for advanced recycling solutions. Such a combination of factors is expected to drive growth in the advanced recycling market in the Asia Pacific region.

India Advanced Recycling Market Analysis

Indias advanced recycling market is experiencing growth. Indias advanced recycling market is expanding rapidly, supported by rapid urbanization, a surge in plastic waste, rising investments in waste management technologies, stringent regulatory standards, growing environmental concerns, and a growing demand for high-quality recycled materials. Moreover, supportive government regulations, such as Extended Producer Responsibility (EPR), and initiatives, such as the Swachh Bharat Mission, are promoting waste management and sustainability in the country.

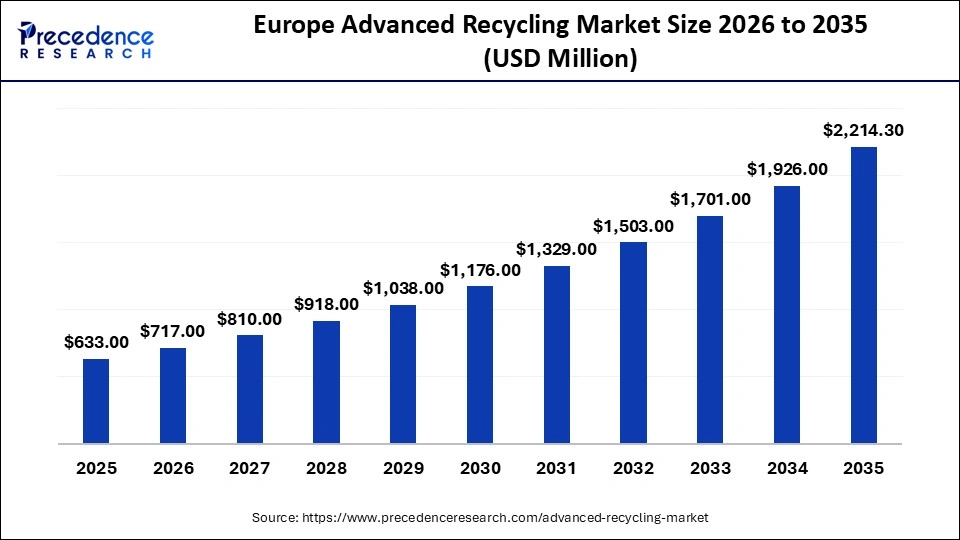

The Europe advanced recycling market size has grown strongly in recent years. It will grow from USD 633.00 million in 2025 to USD 2,214.30 million in 2035, expanding at a compound annual growth rate (CAGR) of 13.37% between 2026 and 2035.

Is the Europe Region Responsible for Growth in the Advanced Recycling Market?

The European market is experiencing notable growth. The region is undergoing a significant transformation driven by growing demand for sustainable solutions to curb plastic waste and stringent regulatory mandates. The market is gaining considerable attention as the region leads the way in transitioning to a more sustainable, circular plastics economy. The European Union (EU) is taking a remarkable step towards reducing plastic waste by banning single-use plastics by 2030. The ongoing technology maturation (depolymerization, improved pyrolysis, catalytic processes) is improving yields and product quality, along with growing end-market demand from the packaging, automotive, and textile sectors for lower-carbon feedstocks and recycled monomers/resins, driving the regions growth during the forecast period.

Germany Advanced Recycling Market Analysis

Germany is experiencing significant growth, driven by rising demand for recycled content, the growing popularity of eco-friendly construction, stricter regulations, and increased government initiatives toward sustainability. The market is experiencing increasing demand from various industries such as automotive, construction, packaging, and consumer electronics to reduce their carbon footprint and comply with regulations. Moreover, the rising partnerships among key industry players, governments, large petrochemical companies, and specialized technology companies are fuelling innovation and boosting the adoption of efficient advanced recycling technologies in the country.

The advanced recycling market is expected to grow at a notable rate in the Middle East & Africa region. The regions growth is fuelled by rising plastic waste, increasing environmental concerns, a greater focus on aligning with circular economy principles, and increased investment in developing modern waste management and recycling infrastructure. Moreover, the upward trend is driven by sustainability initiatives and the growing desire to reduce environmental impact, which is expected to boost the markets growth in the coming years. Governments stringent regulations on waste management and recycling have substantially increased the adoption of advanced recycling technologies to meet compliance standards.

South Africa Advanced Recycling Market Analysis

The country is experiencing remarkable growth due to a combination of factors, including growing public awareness of plastic pollution and climate change, stringent regulatory mandates, rising consumer demand for recycled content, and advances in recycling technologies. Governments are increasingly implementing a range of long-term strategies to increase recycling rates and reduce reliance on landfills. Additionally, rising investments and vertical integration by petrochemical, plastics, and waste-management companies are anticipated to drive the countrys growth during the forecast period.

Advanced Recycling Market Companies

- Plastic Energy

- Mura Technology

- Quantafuel

- Agilyx

- Loop Industries

- Carbios

- Brightmark

- Enerkem

- Pyrowave

- Polystyvert

- GreenMantra Technologies

- Recycling Technologies

- Ioniqa Technologies

- BlueAlp Innovations

- Gr3n Recycling

- Renewlogy

- LyondellBasell

- BASF

- ExxonMobil Chemical

- Shell

Recent Developments

- In August 2025, Mura Technology announced expansion into Singapore with a new advanced recycling facility. The company plans to develop a 50-kilotonne-per-annum (kta) facility in Singapore. This marks a significant milestone in the companys expansion across Asia.(Source:https://www.muratechnology.com)

- In September 2025, Greenback Recycling Technologies announced the first UK deployment of its Enval advanced recycling module at Amcors facility in Heanor, Derbyshire, where it will undergo a six-month commissioning and trial phase. The partnership with Amcor aims to showcase the potential for co-locating modular recycling units within existing industrial infrastructure, bringing the circular economy closer to reality.(Source:https://interplasinsights.com)

Advanced Recycling Market Segments Covered in the Report

By Technology

- Pyrolysis

- Thermal pyrolysis (plastic-to-oil)

- Catalytic pyrolysis

- Depolymerization (including glycolysis, methanolysis)

- PET depolymerization to monomers

- Polyurethane/nylon depolymerization

- Gasification

- Syngas production for chemicals/fuels

- High-temp gasification of mixed feedstock

- Solvolysis / chemical solvolysis

- Solvent-based recycling of polymers

- Hydrothermal liquefaction (HTL)

- Wet waste/biomass co-processing

- Enzymatic / biochemical recycling

- Enzyme-assisted depolymerisation pilots

- Other / emerging technologies

By Feedstock

- Mixed plastic waste (unsorted municipal plastic)

- Polyethylene (PE)

- Polypropylene (PP)

- Polyethylene terephthalate (PET)

- Multi-layer films & flexible packaging

- Styrenics, ABS & other engineering plastics

By End-Product

- Recycled feedstock oils & fuels (pyrolysis oil)

- Recovered monomers / chemical intermediates

- rPET / recycled resin pellets

- Performance/engineering polymers

- Waxes & specialty chemicals

- Energy / cogeneration outputs

- Other outputs

By Application

- Packaging (rigid & flexible)

- Automotive & transportation

- Consumer goods & electronics

- Building & construction materials

- Textiles & fibers

- Industrial & oilfield applications

Other end-uses

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

Get a Sample

Get a Sample

Table Of Content

Table Of Content