Automotive Engine Valve Market Size and Forecast 2025 to 2034

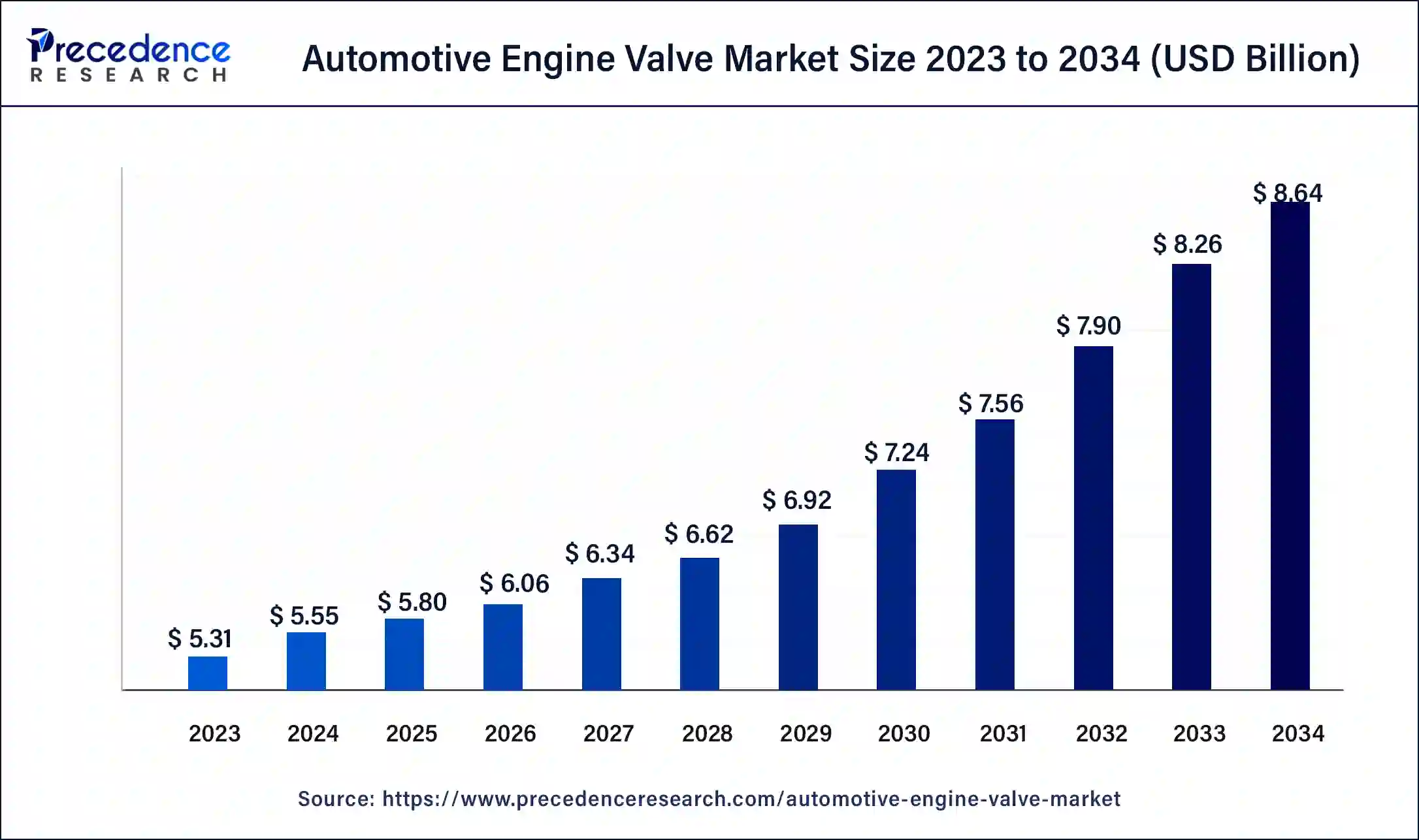

The global automotive engine valve market size is projected to be worth around USD 8.64 billion by 2034 from USD 5.55 billion in 2024, at a CAGR of 4.53% from 2025 to 2034. The rising demand for commercial and passenger vehicles is driving the growth of the market.

Automotive Engine Valve Market Key Takeaways

- In terms of revenue, the automotive engine valve market is valued at $5.80 billion in 2025.

- It is projected to reach $8.64 billion by 2034.

- The automotive engine valve market is expected to grow at a CAGR of 4.53% from 2025 to 2034.

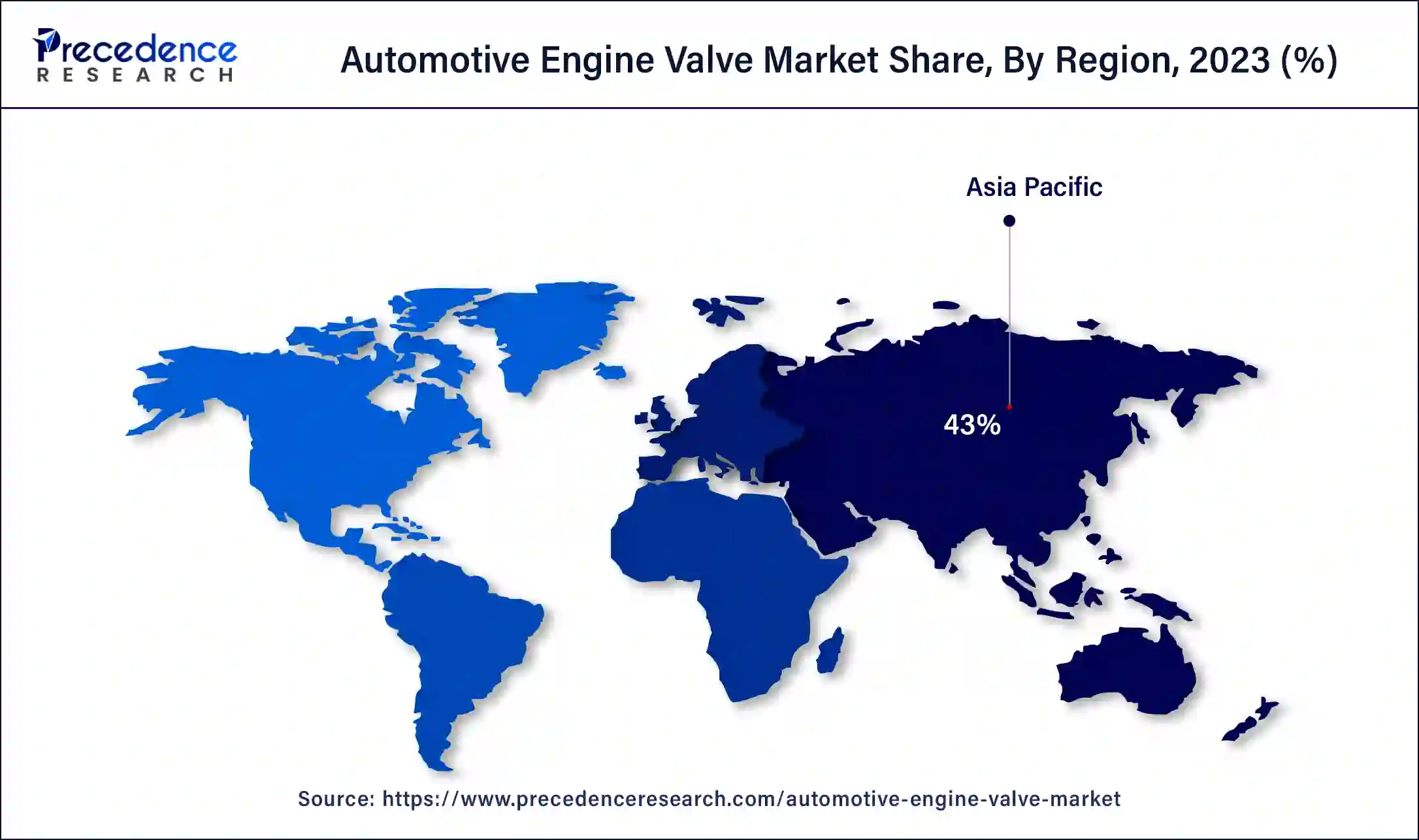

- Asia Pacific dominated the automotive engine valve market with the largest market share of 43% in 2024.

- North America is expected to have the fastest growth in the market during the forecast period.

- By product type, the bimetallic engine valves are projected to capture the largest share of the market during the forecast period.

- By material type, the titanium segment is expected to have the largest share of the market during the predicted period.

- By vehicle type, the compact passenger cars segment is expected to have the largest share of the automotive engine valve market during the predicted period.

- By sales channel, the OEM segment is expected to hold the largest share of the market during the forecast period.

How can AI impact the automotive engine valve?

Artificial intelligence and electric vehicles are transforming the automotive sector in the future. The implementation of artificial intelligence (AI) into the internal combustion engine of vehicles is driving the enhancement in the consumer experience. The AI algorithms can detect data from several sources and sensors to fine-tune engine performance. It helps in ignition timing, air-fuel mixture, and valve timings in the internal combustion engine. Artificial intelligence plays an important role in reducing harmful emissions from vehicles. It controls the selective catalytic reduction (SCR) systems and exhaust gas recirculation (EGR) in petroleum engines to minimize nitrogen oxide emissions. It provides real-time insights about adjustments to reduce emissions by monitoring the emitted engine and gas parameters.

- In May 2024, Preferred Networks, Inc. (PFN), and ENEOS Corporation (ENEOS) announced the agreement of continuous autonomous operation facilitated by AI system atmospheric in distillation unit for crude oil processing since January 2024. The operations are underway at the ENEOS Kawasaki Refinery.

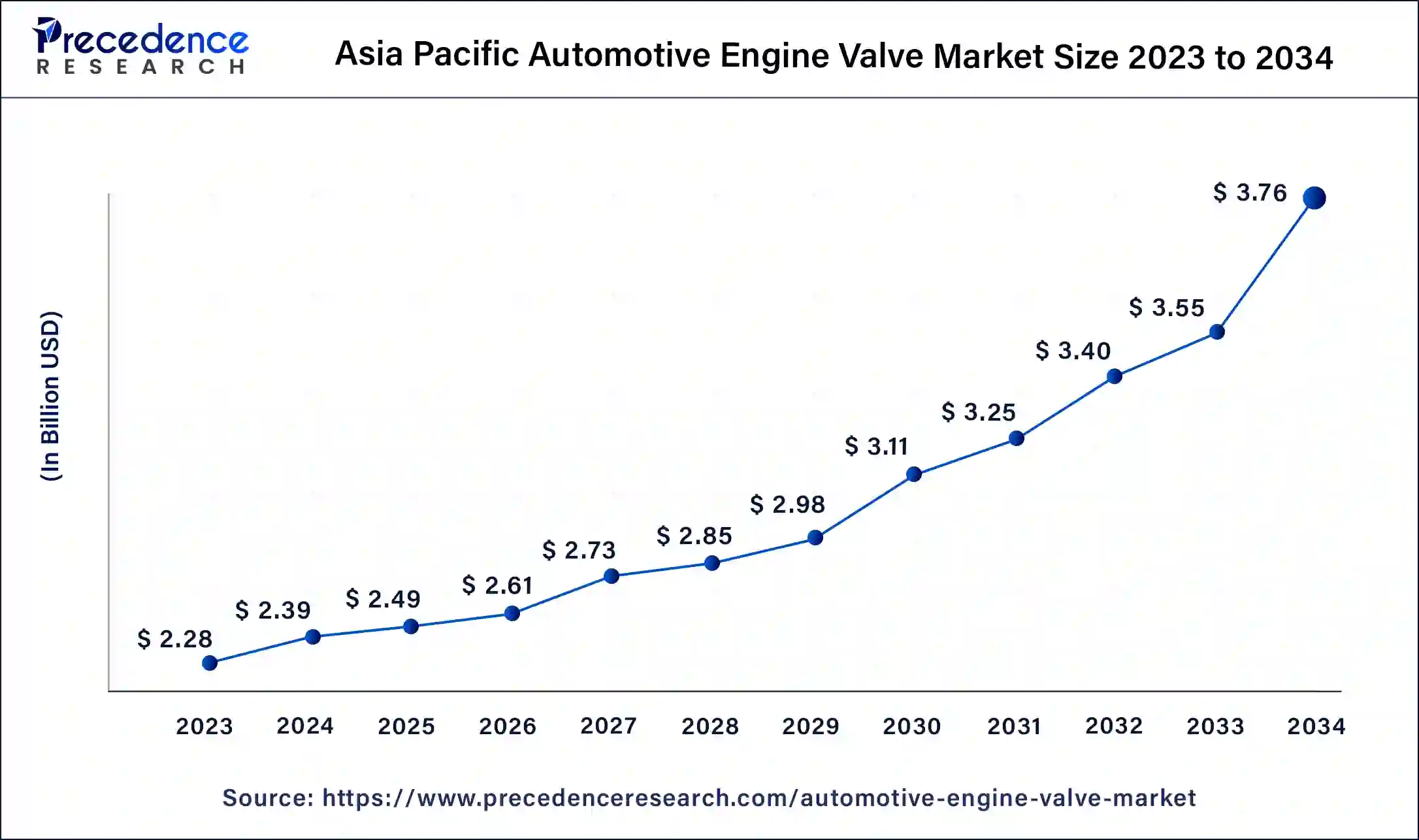

Asia Pacific Automotive Engine Valve Market Size and Growth 2025 to 2034

The Asia Pacific automotive engine valve market size was exhibited at USD 5.55 billion in 2024 and is projected to be worth around USD 3.79 billion by 2034, poised to grow at a CAGR of 4.64% from 2025 to 2034.

Asia Pacific dominated the automotive engine valve market in 2024. The growth of the market is attributed to the rising population, and the increasing demand for passenger vehicles and commercial vehicles is driving the demand for automotive engine valves. The rising advancement in automobile vehicles in regional countries like China, India, and Japan is driving the growth of the market. Additionally, the rising investment in research and development activities in the growth of the automotive industry is highly useful.

Currently, Asia Pacific is dominating the automotive engine valve market. Within the region, China holds the largest automotive market share with the increasing vehicle production. The rising demand for automotive vehicles is due to the large regional population. The advancement and enhancement are an addition to the market to uplifting development.

North America is estimated to grow at the fastest rate during the forecast period. The growth of the automotive engine valve market is attributed to the rising demand for the automotive industry due to the rising disposable income in the population and the rising living standards are driving the demand for the automobile industry. The higher presence of the leading automotive players is driving the demand for the automotive engine valve market. The rising technological advancements, such as autonomous vehicles and electric vehicles, are beneficial.

- In the U.S., the total registration of personal and commercial vehicles accounted for 278,870,463 in 2022. 91% of the residents had at least one car in 2022, and only 8.3% of the households did not have a vehicle.

- Commercial trucks are the most popular type of vehicle, accounted 170,239,357 commercial and private trucks registered in 2022.

- According to the National Automobile Dealers Association, the sales of hybrid electric vehicles, electric vehicles, and plug-in hybrid electric vehicles in 2023 accounted for 16.7% of all new vehicles.

Market Overview

The engine valves are used in the regulation of the movement of fuel and air in and out of the internal combustion engine. The engine valve plays one of the most important roles in the internal combustion engine due to its precise mechanism and intricate designs. There are different types of engine valves, including poppet valves, sleeve valves, rotary valves, and reed valves. The engine valves consist of two major types of valves: an intake valve and an exhaust valve.

The entry valve allows the entrance of the mixture of air-fuel, and the exhaust valve facilitates the expulsion of exhaust gases. Both the engine valves are made of different materials due to their optimization in the engine. The inlet valves are made from materials like tungsten or nickel steel, and the exhaust valves are made from cobalt-chromium and silicon-chromium alloys. The engine valves play an important role in optimizing power output, engine performance, and fuel efficiency.

Automotive Engine Valve Market Growth Factors

- The rising demand for the automobile sector in the commercial, industrial, and passenger vehicles due to the rising population and the increasing transportation activities are driving the growth of the automotive engine valve market.

- The rising population and the increasing disposable income in the population are driving the demand for the luxury lifestyle, and self-mobility solutions by the population are driving the demand for passenger vehicles that are anticipated to drive the growth of the market.

- The rising transportation and logistics in economically developing countries for efficient supply chain management and fulfilling the rising demand for consumer goods are driving the demand for commercial vehicles, driving the growth of the market.

- The increasing involvement of the leading market players in the technological advancements in vehicles, such as autonomous and electric vehicles, is driving the growth of the market.

- The rising government support and favorable policies in the advancement of the automobile sector and the ongoing research and development activities in the launch of new products are driving the growth of the automotive engine valve market.

Automotive Engine Valve Market Trends

- Volta Trucks, a Swedish startup, launched the Volta Zero, a specialized electric truck that is designed for urban deliveries. The design includes enhanced features like driver safety, comfort, and panoramic vision for clear visibility.

- ChargeX, a German Startup providing a modular charging solution that efficiently converts the parking location into a charging station. The name of the launch is Aqueduct, and it had four charging modules with monthly reports, 22kW, and a Typ2 charging cable.

- ApexAI, a US-based startup offering automotive companies the opportunity to install Apex.OS is a complex AI solution that works on automotive electronic control units (ECUs) and offers strong, secure, and reliable APIs to develop autonomous mobility solutions.

Technological Advancement

Technological advancements in the automotive engine valve market feature smart valves, camless engine technology, and VVT. The smart valves are an actuation system. Smart valves, such as solenoid-based valve systems and electronic ones, are in demand for their efficient performance. The camless engine technology uses electronically controlled actuators; this is low-cost and offers a simple design. Variable valve timing (VVT) and variable valve lift systems optimize valve operations and improve fuel performance. The material advancement, like sodium-filled hollow head valves, which is introduced by Eaton, is minimizing engine knock. It also enhances and improves combustion chamber cooling.

The lightweight and durable materials, such as ceramic, titanium, and advanced alloy-based materials, are in demand for their heat resistance and sufficient strength. These advancements and innovations are raising expectations of new development in the automotive engine valve market.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 8.64 Billion |

| Market Size in 2025 | USD 5.80 Billion |

| Market Size in 2024 | USD 5.55 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 4.53% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product Type, Vehicle Type, Material Type, Sales Channel, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

The rising demand for EV valves

The rising evaluation of electronic vehicles is transforming the era of the automotive industry. The rising concern about environmental pollution due to the rising carbon emission by vehicles is driving the adoption of electric vehicles globally. The increasing advancements in the EV valves for electric vehicles provide durability and can handle the temperature of fluid up to 400° F. The electric vehicles valve series provides customer-specific end connections, specially coated materials, and trim materials. The EV valves are used to maintain and control the flow of air, vacuum, water, and other lower-viscosity fluids.

- In the U.S., the combined sales of battery electric vehicles, plug-in electric vehicles, and hybrid vehicles will increase by 16.3% in total new light-duty vehicle (LDV) sales in 2023. The United States sales of the BEV, hybrids, and plug-in hybrids accounted for the highest LDV sales in the 2nd half of 2023 with 17.9%.

Restraint

Higher cost

The increased cost of raw material and end-products related to the automobiles and the high cost of manufacturing process in the automobile is restraining the growth of the automotive engine valve market.

Opportunity

Advancements in the automotive sector

The rising demand for the automobile sector and the investment in the evalution of the automotive sector such as electric vehicles and autonomous or self-driving cars are driving the demand for the market. Additionally, the rising intervention by the leading industry giants such as Tesla, Honda, Toyota, and others in the advancements in the contribution in the growth.

Product Type Insights

The bimetallic engine valves are projected to capture the largest share of the automotive engine valve market during the forecast period. The growth of the market is attributed to the rising demand for the bimetallic type of engine valves due to their high corrosion resistance and extreme temperature resistance. The material has a high tensile strength, which is an advantageous property for automotive applications. The metallic engine valves are made through friction welding. On the other hand, mono-metallic valves are also in demand for engine valves due to their greater siding properties and high heat resistance. The engine valves are made from one material only.

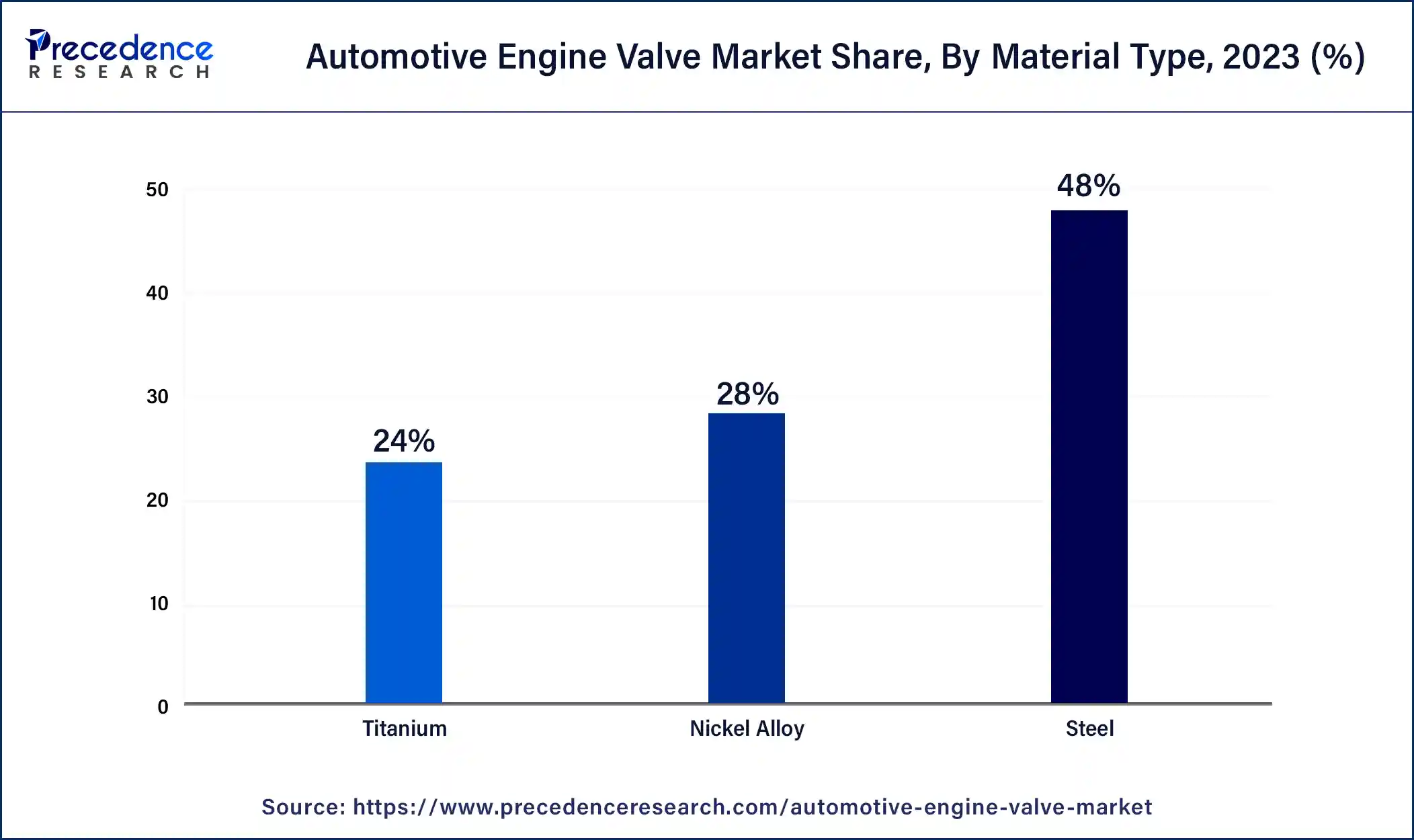

Material Type Insights

The titanium segment is expected to have the largest share of the automotive engine valve market during the forecast period. The rising demand for titanium material automotive engine valves is due to their higher tensile strength and heat and corrosion resistance properties. Titanium material is used in several automotive applications, primarily for internal combustion engine components like valve springs, valves, connecting rods, and retailers.

Titanium logically offers higher tensile strength, lower modules, lower density, and excellent oxidation and corrosive properties. Titanium has various beneficial properties, such as being more durable and longevity, lightweight in design, and corrosion resistant. Its lightweight properties make it easy to handle and install in automotive parts; as compared to stainless steel or other materials, titanium has higher strength and corrosion resistance.

Vehicle Type Insights

The compact passenger cars segment is expected to have the largest share of the automotive engine valve market during the forecast period. The rising population, the increasing economic stability in the countries, and the rising disposable income are collectively raising the living standards of the population, tending to the higher demand for passenger cars for self-owned mobility and luxury.

The rising demand for passenger cars and the continuous launch and innovations in passenger cars with more accurate features and luxury are driving the sales of passenger cars. Additionally, the rising number of major automobile market players are investing in the further development and launch of new passenger vehicles, which boosts the growth of the passenger cars segment.

Sales Channel Insights

The OEM segment is expected to hold the largest share of the automotive engine valve market during the forecast period. The OEM sales channel is the original manufacturer of the vehicle parts and it is designed by themselves only those it provide more accurate and original part of vehicle which reduces the time to quality check.

Automotive Engine Valve Market Companies

- Knorr-Bremse AG

- Mahle Group

- Hitachi Ltd.

- FUJI OOZX Inc.

- Federal-Mogul Holding Corp

- Eaton Corporation Plc

- Denso Corporation

- Continental AG

- Delphi Automotive AG

- FTE Automotive GmBH

Recent Developments

- In February 2024, the Rane group took a significant step towards simplifying its group structure and enhancing operational efficiencies. Rane Group announced the merger of Rane Brake Lining and Rane Engine Valve. It is a huge contribution to the automotive engine valve market. (Source - https://www.mobilityoutlook.com)

- In February 2025, Tata launched a petrol-powered Sierra, Harrier, and Safari. The Tata Harrier and Safari petrol SUVs will be offered with Tata's all-new 1.5L turbocharged, direct injection petrol engine. The new 1.5L TGDi petrol engine has benefited from variable valve timing, smoothing the engine system. (Source - https://www.carlelo.com)

- In November 2023, the Instrumentation Products Division, Europe (IPDE) of Parker Hannifin, a leading player in the control and motion technologies, announced the launch of HNV Series needle valves and Hi-Pro Series ball valves combining O-LOK O-Ring Face Seal (ORFS) fitting connections.

- In May 2023, Hero MotoCorp, the global leader in motorcycles and scooters manufacturer demonstrated the advancements in technology-driven mobility solutions with a clean environment by launching its most awaited XPulse 200 4 Valve adventure motorcycle with OBD-II and E20 standards, allowing a more eco-friendly and efficient ride.

- In July 2023, Hero MotoCorp has launched the new Xtreme 200S 4-Valve at INR 141,250 (ex-showroom Delhi). The launch is powered by a 200cc 4-valve oil-cooled engine. The bike offers 5% added torque and 6% more power than the old model.

Segment Covered in the Report

By Product Type

- Bimetallic Valves

- Hollow Valves

- Mono Metallic Valves

By Vehicle Type

- Compact Passenger Cars

- Mid-Passenger Cars

- Premium Passenger Cars

By Material Type

- Titanium

- Steel

- Nickel Alloy

By Sales Channel

- OEM

- Aftermarket

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting