What is the Masterbatch Market Size?

The global masterbatch market size was calculated at USD 7.11 billion in 2025 and is predicted to increase from USD 7.56 billion in 2026 to approximately USD 13.07 billion by 2035, expanding at a CAGR of 6.28% from 2026 to 2035. The replacement of metal with plastics in end-use industries such as consumer products, building, and construction, automotive and transportation, and packaging is expected to play a significant role in the growth of the global masterbatch market over the course of the forecast period.

Masterbatch Market Key Takeaways

- The global masterbatch market was valued at USD 7.11 billion in 2025.

- It is projected to reach USD 13.07 billion by 2035.

- The masterbatch market is expected to grow at a CAGR of 6.28% from 2026 to 2035.

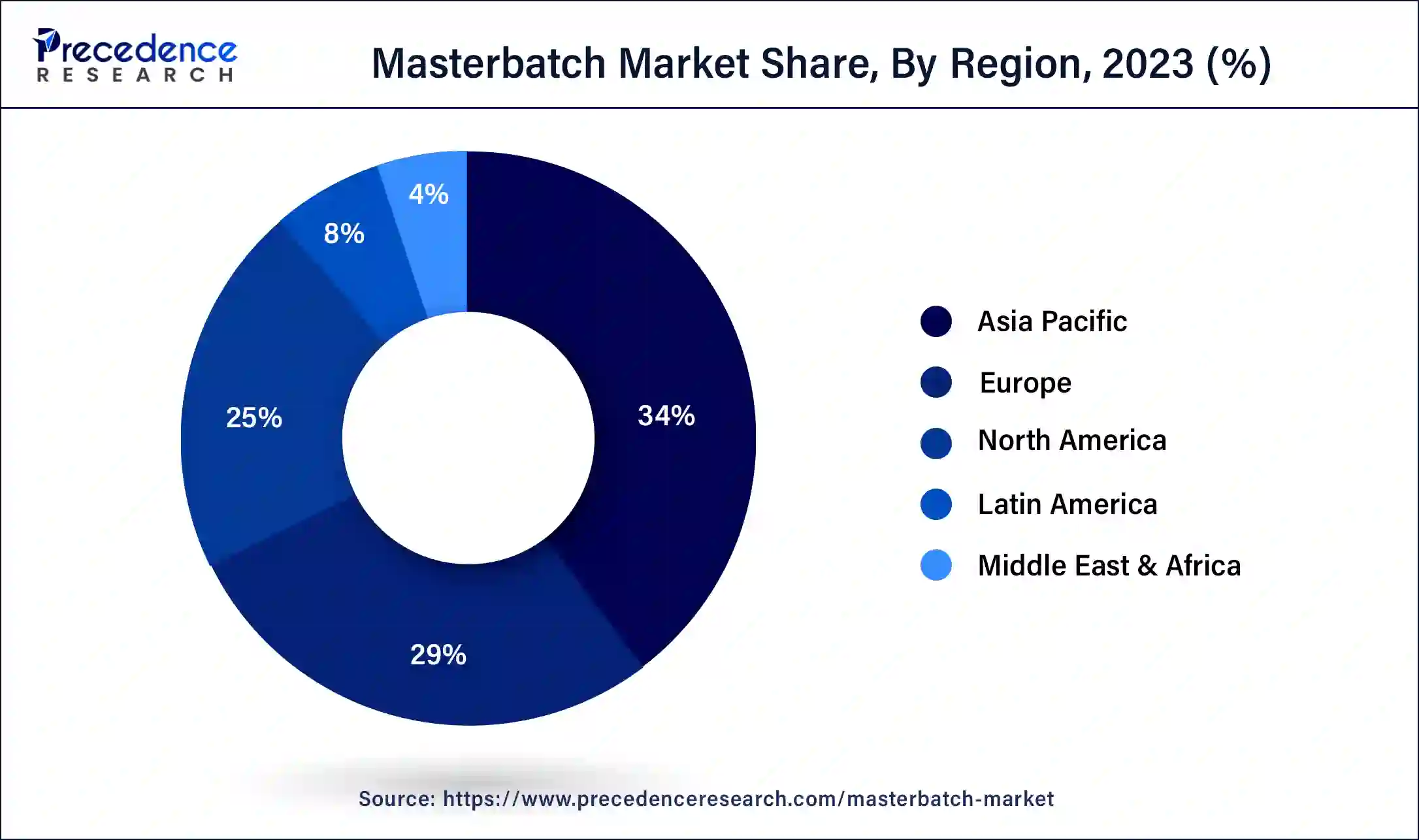

- Asia Pacific dominated the masterbatch market with the largest revenue share of 34% in 2025.

- Europe is expected to grow at a significant rate in the market during the forecast period.

- By carrier polymer, the polypropylene (PP) segment has contributed the biggest revenue share of 29% in 2025.

- By type, the black segment has generated more than 30% of revenue share in 2025.

- By type, the color segment is expected to grow at a significant rate during the forecast period.

- By end user, the packaging segment has held a major revenue share of 28% in 2025.

Market Overview

Masterbatch is a solid product that is typically made of rubber, plastic, or elastomer that contains additives or colors that have been carefully distributed at high concentrations within a carrier material. In polymer processing, masterbatches are frequently used to mix antimicrobials, color pigments, or additives into liquid polymer resin. A concentrated mixture of an additive enclosed in a carrier material, such as polyethylene (PE) or polypropylene (PP), is called a masterbatch. Usually, the carrier is a polymer resin in the form of chips or pellets, although liquid masterbatches are also offered for specific materials and purposes.

The final plastic product will inherit the color and qualities of the masterbatch from the carrier material, which is compatible with the primary plastic in which it will be blended during molding. A masterbatch is a concentrated combination made with a high-shear mixing extruder and heat treatment to distribute additives and colors into a polymer carrier. After cooling, the mixture is chopped with a pelletizer to shape it into granules.

Masterbatches dilution properties enable more precise dosing of pricey components. Since the solvent in the polymer won't evaporate, masterbatches solid crystals are solvent-free and typically have a longer shelf life. In general, masterbatch has between 40 and 65 percent additives, but in a few more instances, the range may change to 15 to 80 percent. Between machine runs liquid masterbatches provide extremely accurate dosing and rapid color changes.

The masterbatch is available in several types, such as black masterbatch, additive masterbatch, white masterbatch, color masterbatch, and special Effect Masterbatch, among others. The top five benefits of the masterbatch are as follows: easier incorporation of additives, better process stability and consistency in products, cleaner production, greater additive stability and shelf-life, and easier integration of antimicrobial technology.

Artificial Intelligence: The Next Growth Catalyst in Masterbatch

AI is profoundly impacting the masterbatch industry by enabling smarter, more efficient, and highly customized manufacturing processes. AI-driven analytics and machine learning algorithms optimize formulations, accelerating product development cycles and ensuring precise color matching and performance outcomes while reducing waste. In production, AI powers real-time quality control systems using computer vision and facilitates predictive maintenance, minimizing human error and costly equipment downtime.

Masterbatch Market Growth Factors

- Emerging masterbatch markets are expected to drive the growth of the industry over the forecast period.

- Increasing focus on cost reduction and production efficiency can drive the specialty masterbatch market growth further.

- Increasing adoption of advanced technology for the production of masterbatch is estimated to drive the growth of the global masterbatch market in the near future.

- Development of gas and oil exploration operations in North America and Asia-Pacific is anticipated to drive the growth of the market over the forecast period.

- Power plants are expected to contribute to the development of high-performance anti-corrosion coatings, which is expected to drive the growth of the masterbatch market during the forecast period.

- Increasing healthcare expenditure to develop compatible medical and analytical instruments is estimated to drive the growth of the market over the forecast period.

- Increasing regulatory support is estimated to drive the growth of the global masterbatch market over the forecast period.

Market Outlook

- Market Growth Overview: The masterbatch market is expected to grow significantly between 2025 and 2034, driven by the rising plastic consumption, the rising need in the packaging industry, and enhanced aesthetics and functionality.

- Sustainability Trends: Sustainability trends involve eco-friendly and bio-based masterbatches, focus on reduced environmental impact, and the circular economy.

- Major Investors: Major investors in the market include Avient Corporation, Ampacet Corporation, LyondellBasell Industries Holding B.V., Plastika Kritis S.A., and Plastiblends India Ltd.

- Startup Economy: Startup economy focuses on sustainable and bio-based formulations, technological integration, and specialized functional additives.

Masterbatch Market Scope

| Report Coverage | Details |

| Market Size by 2035 | USD 13.07 Billion |

| Market Size in 2025 | USD 7.11 Billion |

| Market Size in 2026 | USD 7.56 Billion |

| Market Growth Rate from 2026 to 2035 | CAGR of 6.28% |

| Largest Market | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Carrier Polymer, Type, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Advantages associated with the use of masterbatch

The key players operating in the market are influenced by the advantages associated with the use of masterbatch, and hence, the demand for the masterbatch has been found to increase, which is estimated to drive the growth of the global masterbatch market over the forecast period. The masterbatch has the strength to raise volume output as well, and it helps reduce the material cost as masterbatches utilize low energy to run the machine due to higher calcium carbonate-specific heat.

Moreover, masterbatch gets blended easily with plastics during the molding process. Hence, by focusing on masterbatch consistent, economical, and reliable offerings, the key market players are influenced by it and are raising the demand for the same.

- In June 2023, according to the data published by the International Council of Chemical Associations (ICCA), the trade association of the global chemical industry, revealed that masterbatches assist in enhancing the physical properties like making the plastics stiffer, tougher, and easily printable.

Restraint

Need for extra storage space and longer lead time

Masterbatches require more storage space and longer lead times than pure pigments. An additional disadvantage is that the additive and carrier must be exposed to heat, which can restrict the growth of the market in the near future.

- In December 2022, according to the data published by the National Center for Biotechnology Information, filling masterbatch consists of fillers, additives, and resin. The filling masterbatch is observed to be low quality, significantly on tenacity; it even increases the ratio of product weight as filling masterbatch accounts for 90% of fillers, which are composed of heavy calcium carbonate (CaCO3), kaolin calcium powder, talcum, and other inorganic fillers.

Opportunities

Increase demand for masterbatches in black polyester fibers

The polyester fibers are mostly utilized in the automotive and textile sectors. In the automotive industry, it is accommodated in applications such as interior, seat covers, roof lining, and cladding. Polyester fibers made from polyethylene terephthalate get their desired properties by adding functional pigments and additives, generally in the form of black masterbatches. Hence, the key players operating in the market are focused on the launch of the black masterbatch due to the rise in the demand for the black masterbatch, which is expected to create lucrative opportunities for the growth of the global masterbatch market in the near future.

- In May 2024, Cabot Corporation, a performance materials and chemicals company, revealed the introduction of the REPLASBLAK universal circular black masterbatches. The newly launched REPLASBLAK universal circular black masterbatches are supported by EVOLVE Sustainable Solutions, allowing Cabot to keep providing the high caliber, dependability, and performance that the plastics sector needs on a large scale for certified circular solutions.

Geographical expansion of market presence

The key players operating in the market are focused on extending their market presence by launching their company branch presence in another region, which is expected to create lucrative opportunities for the growth of the masterbatch market over the forecast period.

- In February 2024, Modern Dispersions, Inc., masterbatch manufacturer and thermoplastics compounder headquartered in Massachusetts U.S., revealed that the first phase of multifaceted industrial expansion at Modern Dispersions' new 168-acre location in Fitzgerald, Georgia, has been completed and put into service.

Carrier Polymer Insights

The polypropylene (PP) segment dominated the masterbatch market in 2024 on account of the launch of the new polypropylene polymer in the market. Novel products are built on polypropylene (PP), contain 30% glass fiber reinforcement, and are intumescent and flame retardant (FR). It can be utilized for electric vehicle (EV) battery pack components like enclosures, module separators, and top covers.

- In July 2023, Saudi Basic Industries Corporation, a chemical manufacturing company, announced the launch of two new carrier polymer materials, STAMAX 30YH611 resin and SABIC PP compound H1090 resin, for injection and compression molding.

Segment Insights

Type Insights

The black segment dominated the global masterbatch market in 2024. This significant market share can be attributed to the increasing demand for black masterbatch and its use in products for the automotive, transportation, building, construction, agriculture, and packaging industries, particularly in tires and PVC containers. Furthermore, the market is also expected to witness growth due to the rising need for agricultural products like shade cloth, drip irrigation tubing and tape, geomembranes, and greenhouse films.

The color segment is expected to grow at a significant rate in the masterbatch market during the forecast period. Increasing the launch of new products for the expansion of the product portfolio is estimated to drive the growth of the segment over the forecast period. Moreover, the key players operating in the market are focused on launching new technology for coloring the masterbatch, which is expected to drive the growth of the segment over the forecast period.

- In June 2024, Ampacet Corporation, a chemical plant, revealed the expansion of its ELTech portfolio by launching a range of high-performance color masterbatches based on a polybutylene terephthalate (PBT) carrier resin and significantly developed for optical fiber cable polybutylene terephthalate (PBT) jacketing. Masterbatches that combine color and useful additives are another product in the ELTech line.

- In May 2023, Tosaf Color Service, a company focused on providing color service for masterbatch processors, revealed the launch of the universally applicable masterbatch carrier system. Tosaf Color Service claims that their recently created, globally applicable masterbatch carrier system now meets with all standard food contact regulations.

End-use Insights

The packaging segment dominated the masterbatch market in 2024. Increasing the launch of new carrier polymers for packaging purposes is expected to foster the growth of the segment over the forecast period. Key players are adopting newer technologies, and rapid innovations further add to the segment's dominance.

- In June 2023, Ampacet Corporation, a chemical plant, revealed the introduction of the PET UVA, a U.S. Food and Drug Administration-approved masterbatch that protects packaging contents from hazardous ultraviolet radiance, prolonging product shelf life, reducing waste and keeping food fresher.

- In May 2024, LyondellBasell Industries Holdings B.V., a multinational chemical company, unveiled the launch of the ‘Polybatch Effects FROST' masterbatches. The ‘Polybatch Effects FROST' masterbatches are available in two different types and give polyethylene terephthalate (PET) packaging an appealing matte frost look.

Regional Insights

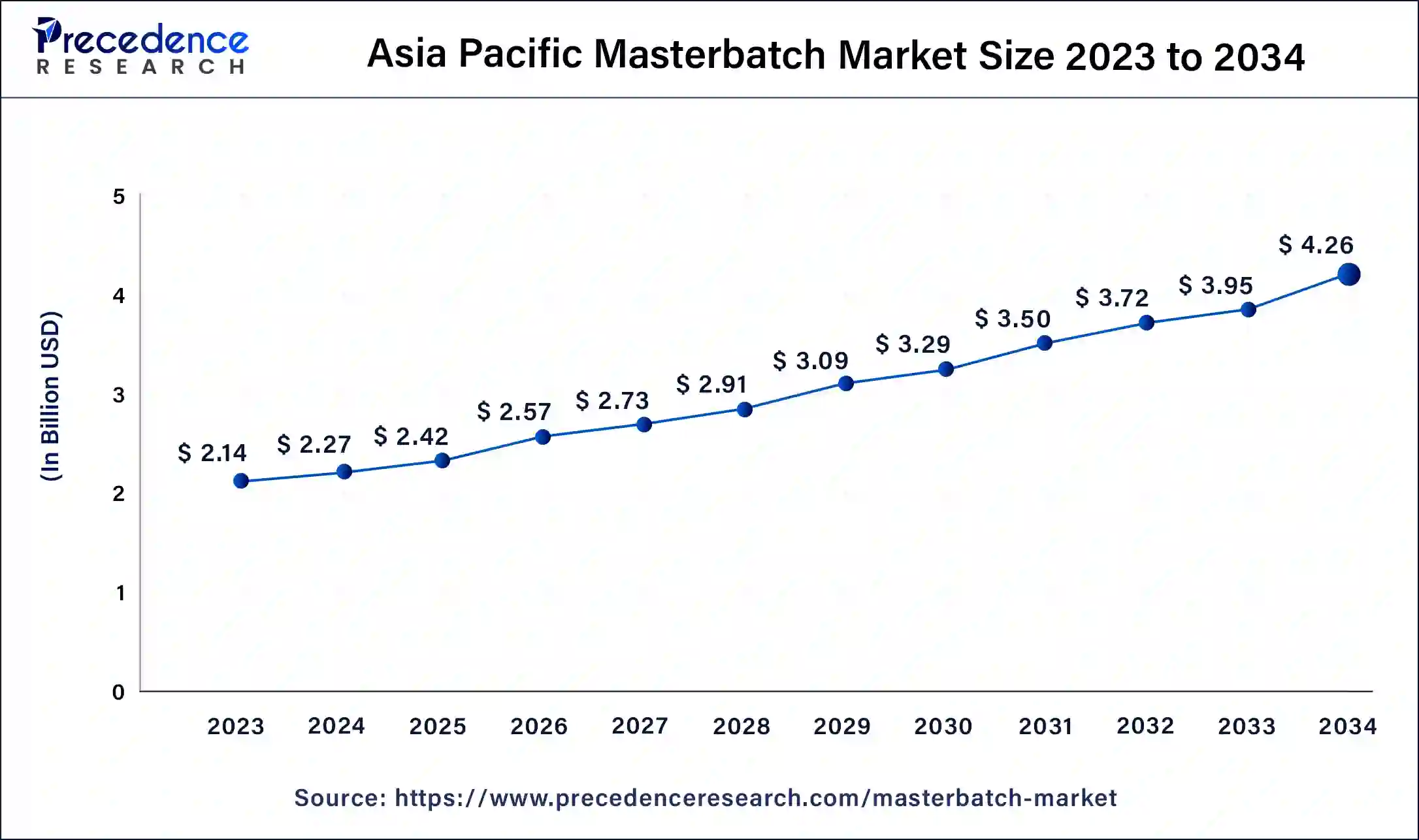

What is the Asia Pacific Masterbatch Market Size?

The Asia Pacific masterbatch market size was exhibited at USD 2.42 billion in 2025 and is projected to be worth around USD 4.52 billion by 2035, poised to grow at a CAGR of 6.45% from 2026 to 2035.

Asia Pacific dominated the masterbatch market in 2024. Significant growth opportunities exist in the region for industry participants from multiple countries. It is projected that a number of factors, including continuous innovation, affordable labor costs, an expanding population in Asia-Pacific, a rise in the use of recently developed technology, affordable and easily accessible land, and easily accessible raw resources, will propel considerable market expansion in the area.

China Masterbatch Market Trends

China's immense demand for masterbatches across the packaging, automotive, and construction sectors. The high-performance specialty additives and biodegradable solutions to meet increasingly stringent sustainability standards and e-commerce aesthetic requirements.

When it comes to automobile production, Asia Pacific is the leader, which has greatly increased the need for masterbatches in the automotive sector. The increasing innovation and design of electric vehicles in the region has raised the demand for the different types of masterbatch, which is estimated to drive the growth of the Asia Pacific masterbatch market in the near future.

- In June 2024, Hyundai Motor Company, a multinational automotive company headquartered in Korea, announced the launch of the electric vehicle, the Hyundai Inster EV. The Hyundai Inster EV, which has pixel-themed turn indicators embedded in a black bar and circular light-emitting diode (LED) daytime running lamps (DRLs), is modeled after the Casper.

Europe is expected to grow at a significant rate in the market during the forecast period due to the increasing launch of new carrier polymers. Furthermore, the key players operating in the region are adopting inorganic growth strategies like agreements in order to distribute their products worldwide and expand their geographic presence, which is expected to drive the growth of the masterbatch market over the forecast period.

- In May 2024, XENIA srl, based in Italy, Europe, announced the introduction of a new range of polyvinylidene fluoride (PVDF)-based compounds that are used for 3D printing pellet-fed applications. In applications where high performance and chemical resistance are required, this new class of polyvinylidene fluoride (PVDF)-based compounds offers the advantages of carbon fiber combined with the outstanding qualities of polyvinylidene fluoride, creating new avenues for production through additive manufacturing.

- In November 2023, TER Chemicals Distribution Group, a Chemical wholesaler based in Germany, signed an agreement with Momentive Performance Materials, a chemical company, to expand the scope of their high performance additives for polymer distribution. This agreement of polymer distribution will encompass all of Europe, with the exception of the UK and Iberia.

Germany Masterbatch Market Trends

Germany's automotive industry's shift toward lightweighting and high-performance aesthetics, alongside the medical sector's need for specialized bio-compatible additives, remains a core growth catalyst. Technological innovations in functional additives, such as flame retardants and UV resistance, are becoming essential for high-end industrial applications.

How did North America experience notable growth in the Masterbatch Market?

North America's packaging industries transition toward lightweighting and circular economy models. Demand is specifically high for specialized additives that provide UV protection, anti-fogging, and flame retardancy for durable infrastructure and customized consumer goods.

U.S. Masterbatch Market Trends

The U.S.'s demand for biodegradable options and recycled-content lines like Cabot's REPLASBLAK. Growth is propelled by "smart" additive masterbatches, including UV stabilizers and antimicrobial agents, that enhance product longevity and safety in the automotive and healthcare sectors.

Value Chain Analysis of the Masterbatch Market

- Raw Material Sourcing/Suppliers

This stage involves the procurement of essential components like pigments, additives, and carrier resins.

Key Players: BASF SE, Saudi Basic Industries Corporation, and LyondellBasell - Manufacturing/Compounding

In this stage, the raw materials are mixed, blended, and extruded together in a carrier matrix to create a concentrated, uniform pelletized mixture, known as masterbatch.

Key Players: Avient Corporation, Ampacet Corporation, Clariant AG, and Cabot Corporation. - Distribution and Sales

The finished masterbatch is then distributed through a wide network to plastic product manufacturers across various industries.

Key Players: Tosaf Group, ALBIS Distribution.

Masterbatch Market Companies

- A. Schulman, Inc. (now part of LyondellBasell):As a leading global supplier, this company provides an extensive portfolio of high-performance color and additive masterbatches used to enhance plastic performance in the automotive and packaging sectors.

- Ampacet Corporation: Ampacet is a major innovator in the market, specializing in custom color and functional masterbatches that provide UV protection, anti-static properties, and antimicrobial benefits.

- Alok Masterbatches: This company is a dominant player in the Indian and global markets, offering a vast range of specialty masterbatches for applications in agriculture, infrastructure, and consumer goods.

- Arihant Polyplast: Based in India, Arihant Polyplast focuses on the production of high-grade color and white masterbatches that cater to the textile, packaging, and household product industries.

- Americhem: Americhem excels in providing highly customized masterbatch solutions with a strong emphasis on the "Single Source Solution" for the synthetic fiber, automotive, and medical industries.

- Cabot Corporation: Cabot is a global leader in black masterbatches, leveraging its expertise in carbon black to provide superior opacity, UV protection, and mechanical reinforcement for plastics.

Other Major Key Players

- Clariant AG

- Global Colors Group

- Granula Masterbatch India

- Hubron International Ltd.

- Penn Color, Inc.

- Perfect Colourants & Plastics Pvt.

- Merit Polymers

- Masterpack Industries

- Mundhra Masterbatches

- Rang Mahal (Sachdeva Polycolor)

- Sankhla Polymers

- Sumiran Masterbatch

- Plastiblends India Ltd.

- PolyOne Corporation

- Sumiran Masterbatch Pvt Ltd

- Tosaf Group

- Universal Masterbatch LLP

Recent Developments

- In July 2025, Avient Corporation launched new oxygen scavenger additives designed to enhance the recyclability of PET packaging, working with up to 100% rPET and maintaining food contact compliance. (Source: https://www.avient.com )

- In April 2024, Black Swan Graphene Inc., a company that is engaged in the commercialization and production of patented graphene products for industrial sectors, revealed the introduction of the range of Graphene Enhanced Masterbatch (GEM) products.

- In March 2024, LyondellBasell Industries Holdings B.V., a multinational chemical company, announced that their company has included the KARO 5.0 laboratory stretching machine from Brückner Maschinenbau, the leading supplier of film-stretching machines into its portfolio. The company's capacity to create and test masterbatch solutions for a range of oriented film applications will be substantially improved by the addition of KARO 5.0 to the research and development resources provided at the LyondellBasell Technical Center in Ohio, U.S.

Segment Covered in the Report

By Carrier Polymer

- Biodegradable Plastics

- Polyethylene Terephthalate (PET)

- PUR

- PS

- Polyvinyl Chloride (PVC)

- Polyethylene (PE)

- High-density Polyethylene

- Low-density Polyethylene

- Polypropylene (PP)

- Other Carrier Polymers

By Type

- Biodegradable

- Filler

- Additive

- Color

- Black

- White

By End-use

- Building & Construction

- Consumer Goods

- Automotive & Transportation

- Agriculture

- Packaging

- Others

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Tags

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting