What is Metallocene Polyethylene Market Size?

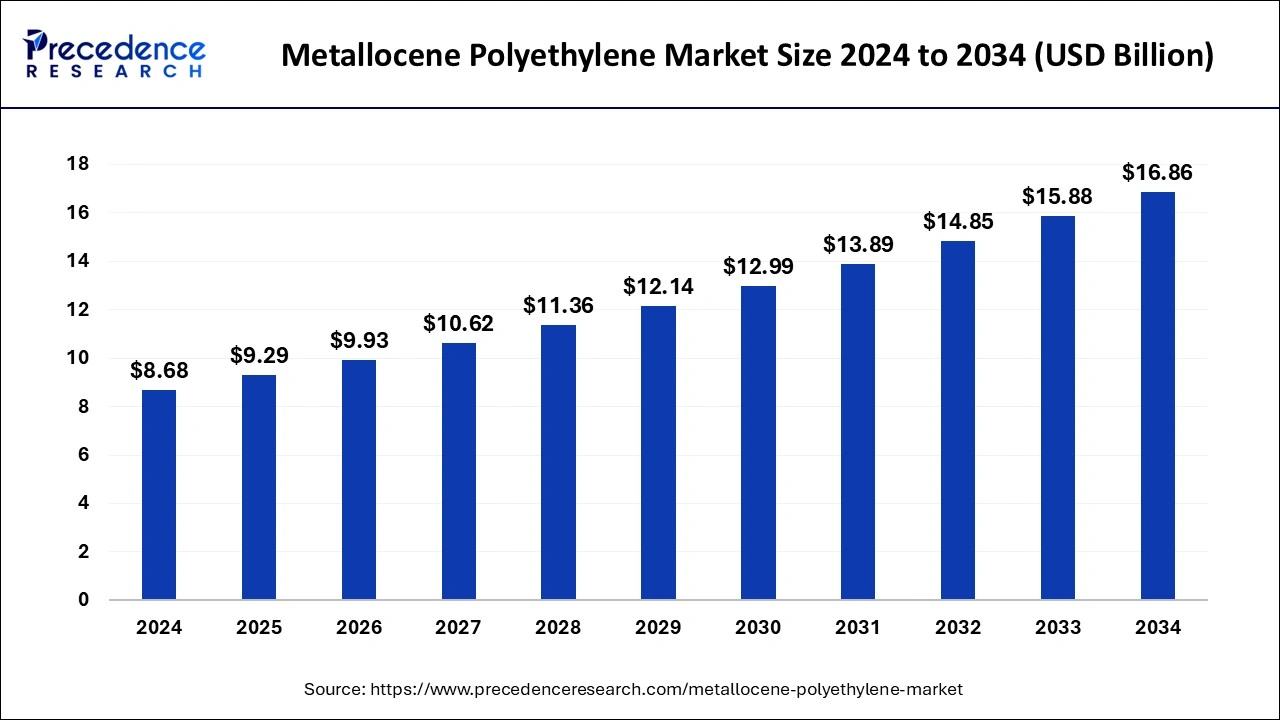

The global metallocene polyethylene market size is calculated at USD 9.29 billion in 2025 and is predicted to increase from USD 9.93 billion in 2026 to approximately USD 17.87 billion by 2035, expanding at a CAGR of 6.76% from 2026 to 2035. Metallocene polyethylene is used in industrial, building, construction, agriculture, and packaging applications.

Market Highlights

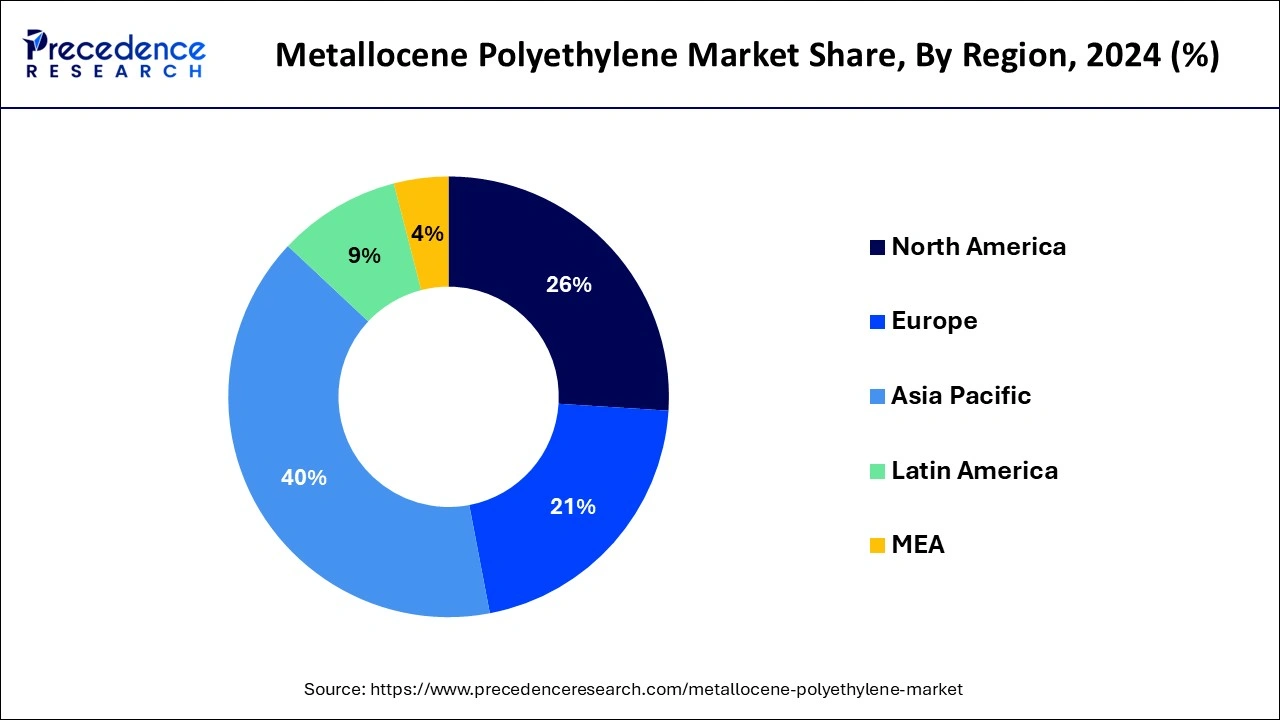

- Asia Pacific led market with the largest market share of 40% in 2025.

- North America is estimated to be the fastest-growing CAGR of 6.14% the forecast period of 2026 to 2035.

- By type, the mLLDPE segment dominated the market in 2025.

- By type, the mHDPE segment is the fastest growing during the forecast period.

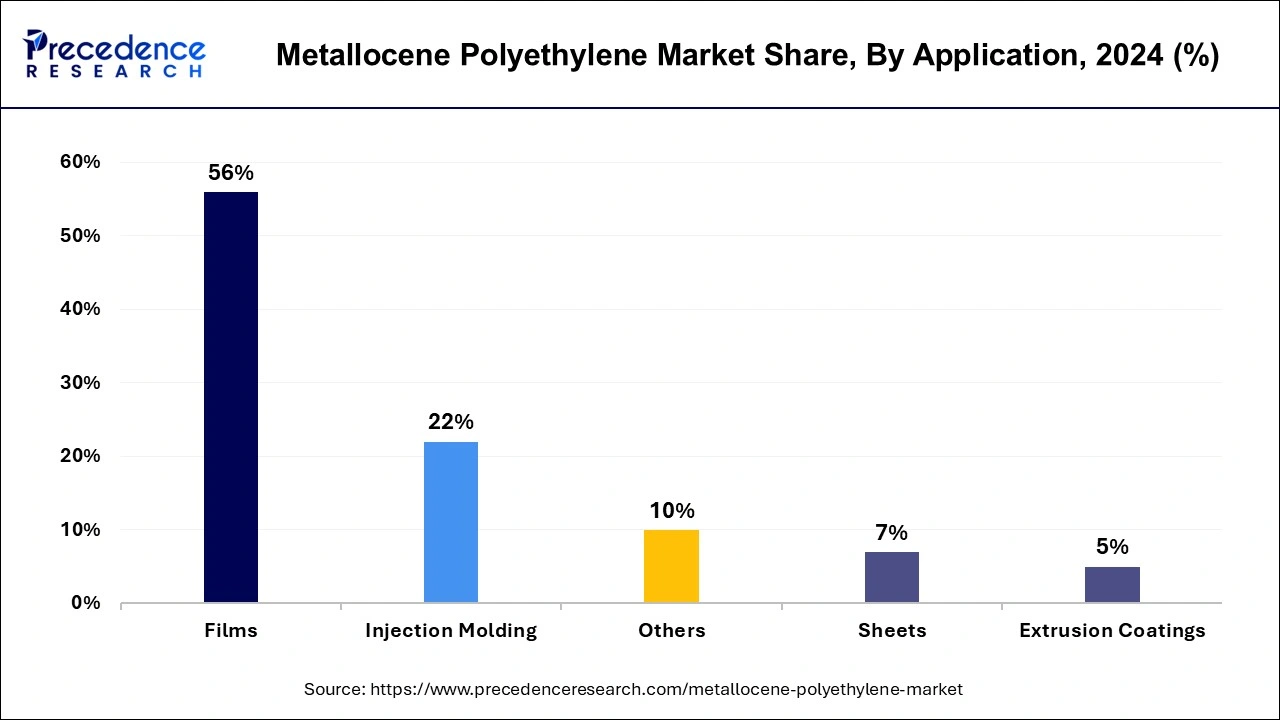

- By application type, the films segment has held the biggest market share of 56% in 2025.

- By application type, the sheets segment is the fastest growing during the forecast period.

- By catalyst type, the zirconocene segment dominated the market in 2025.

- By end-use industry type, the packaging segment dominated the market.

What is the Metallocene Polyethylene?

The metallocene polyethylene is prepared by utilizing metallocene catalysts during the polymerization process and normally includes copolymers such as hexene or ethene and has exceptionally high toughness, narrow molecular weight distribution, uniform comonomer content, and excellent optical properties. The metallocene polyethylene market deals with various industries like healthcare, agriculture, building and construction, automotive, food and beverages, and packaging for different applications.

Metallocene polyethylene applications such as medical products, polymer modification, hose or tubing, cable or wire, stretch or shrink films, rigid food packaging, flexible food packaging, consumer or industrial packaging, non-packaging films, and non-food packaging. In automotive products, it is used in greenhouse film, silage, bale wrap, tunnels, and mulching. These applications of various industries lead to the growth of the market.

How is AI contributing to the Metallocene Polyethylene Industry?

Artificial intelligence supports various processes in advanced manufacturing by utilizing data-driven modeling and real-time process control to enhance bimodal polyethylene production, which includes multiple functions such as catalyst discovery, polymer property prediction, reactor optimization, quality monitoring, demand forecasting, sustainability improvement, inverse design execution, energy consumption reduction, and defect prevention.

Metallocene Polyethylene MarketTrends

- Rising use of flexible packaging Metallocene polyethylene is increasingly used in food packaging, films, and e-commerce bags because of its superior strength, clarity, and flexibility.

- Focus on sustainability and recyclability Manufacturers prefer mPE as it supports thinner packaging films and improved recyclability, helping reduce plastic waste and meet green goals.

- Strong growth in emerging economies Asia-Pacific, especially China and India, is witnessing rapid adoption due to expanding packaging industries and growing consumer demand.

- Technological advancements in resin design Ongoing innovation in catalyst systems and new resin grades is enhancing product quality, enabling use in advanced packaging and agricultural applications.

Metallocene Polyethylene Market Growth Factors

- The metallocene polyethylene market has various growth factors, such as regulatory support, increasing demand, and technological advancements.

- Metallocene polyethylene is used in domestic electrical appliances, non-woven fabrics, cosmetics, and food packaging fabrics, which helps the growth of the market.

- The metallocene polyethylene advantages include easy processing with high resistance, optical properties, excellent sealing, and high resistance to impact, tearing, and perforation.

- Metallocene polypropylene is highly used for packaging purposes rigid food packaging, flexible packaging, industrial or consumer packaging, nonfood packaging, etc.

- The metallocene polyethylene used in automotive products includes greenhouse film, silage, bale wrap, tunnels, and mulching.

- In medical products, polymer modification, tubing or hose, cable or wire, and stretch or shrink films it is used. This contributes to the growth of the metallocene polyethylene market.

Market Outlook

- Industry Growth Overview: The metallocene polyethylene market is growing as businesses look for polyethylene that is thinner, clearer, and stronger for construction, packaging, and agriculture. North America is in the lead but Asia Pacific is in the lead but Asia Pacific is rapidly growing. Higher expenses and the requirement for specialized progress are obstacles.

- Sustainability Trends: Lighter, more durable films are made possible by the metallocene polyethylene market, which also helps to achieve eco-friendly packaging objectives. New grades make products more effective and sustainable by enhancing clarity, durability, and recyclability. Businesses are also experimenting with films for heavy-duty food and agricultural uses. While upholding performance standards, these advancements lessen their negative effects on the environment.

- Global Expansion: North America leads adoption thanks to established packaging and industrial sectors. Asia Pacific is the fastest-growing region due to rapid industrialization and rising packaging demand. Emerging markets are increasingly investing in the market for high-performance and sustainable applications. Global demand is also driven by brands looking to reduce material usage while improving product quality.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 9.29 Billion |

| Market Size in 2026 | USD 9.93 Billion |

| Market Size by 2035 | USD 17.87Billion |

| Growth Rate from 2026 to 2035 | CAGR of 6.76% |

| Largest Market | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Type, Application, Catalyst Type, and End-use Industry Type, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Expansion of applications

Metallocene polyethylene has increasing demand in numerous industries due to its various advantages, which include increased toughness, reduced haze, elimination of the non-targeted molecular weight species in resins, offering control of the MWD (molecular weight distribution), and it also provides excellent organoleptic, which contributes to the growth of the market.

The products made from metallocene polyethylene include the elimination of very low and very high molecular weight polymer components and structural uniformity. These are used in hygiene for disposals and diapers, in medical for operation covers and gowns, in filtration for air purification systems, in wet wipes, in households for disposable products, upholstery, mattress covers, and in geotextiles. These various applications of metallocene polyethylene in different industries help the growth of the metallocene polyethylene market.

Restraint

Environmental impacts

Metallocene polyethylene has the bad effects on the environment. The degradation of metallocene polyethylene can produce toxins that contaminate the waterways and soils, enter into the food chain, and are harmful to animals and plants. It is harmful to human health and environmental sustainability. Some limitations of metallocene polyethylene include poor temperature capability, flammability, difficulty in bonding, subject to stress cracking, poor weathering resistance, and high thermal expansion. Metallocene polyethylene has insufficient recycling efficiency, which has negative effects on the environment. Million tons of metallocene polyethylene impurities accumulate in the marine or terrestrial environments. These factors may restrict the growth of the metallocene polyethylene market.

Opportunities

Rising investments in research and development

Increasing investment in research and development for lowering production costs, increasing metallocene polyethylene properties, and expanding the applications that can help the growth of the market. Development of new technologies for the reduction of bad environmental effects. Improvement in the technologies for degradation of the metallocene polyethylene for environmental sustainability and human health. These factors help the growth of the metallocene polyethylene market.

Demand for specialized materials

The metallocene catalysts can allow the synthesis of polyolefin composite materials, atactic polymers, stereoblock polymers, syndiotactic, isoblock, and isotactic with a low content of extractables and superior properties. Metallocene polyethylene is used in specialized materials production due to its improved mechanical properties. The properties also include strength, processability, toughness, stiffness, and narrow molecular weight distribution. These help with the production of specialized materials and contribute to the growth of the market.

Segment Insights

Type Insights

The mLLDPE segment dominated the market in 2025. Metallocene linear low-density polyethylene (mLLDPE) is an efficient performance polymer that offers increased flexibility, processability, and mechanical properties than conventional LLDPE. It has improved mechanical properties like tear strength, puncture resistance, and higher tensile strength. The benefits include state-of-the-art optical properties, excellent sealing properties, very good tear resistance, very dart drop value, processability because of the next-generation mLLDPE technology, and highly demanding industrial films.

The applications of metallocene polyethylene include high-demanding industrial films, lamination films, multi-layer films for food and non-food applications, stretch hood or stretch films, and cast-blown films. When maintaining performance at thinner gauges, mLLDPE products provide cost reduction through remarkable down gauging. These contribute to the growth of the segment and help the growth of the metallocene polyethylene market.

The mHDPE segment is the fastest growing during the forecast period. Metallocene high-density polyethylene (mHDPE) exhibits environmental stress crack resistance, impact strength, and excellent stiffness properties. It also has some advantages, including pipe extrusion, injection molding, and blow molding. mHDPE advantages include stiff materials, resistance to most chemical solvents, dishwasher safe, UV-resistant, non-leaching, may withstand temperatures from -148�F to 176�F, and cost-effective. Other properties of metallocene polyethylene include UV resistance and many times; it is used in children's outdoor playground types of equipment.

It is an appropriate option for outdoor applications. It can produce opaque packaging products. It is used in blown mold containers and extruded packaging films. These factors contribute to the growth of the segment and help the growth of the metallocene polyethylene market.

Applications Type Insights

The films segment dominated the metallocene polyethylene market in 2025. In the medical packaging industry, metallocene polyethylene is used in film. The films have improved clarity and reduction of crystallinity and initial seal temperatures. It provides many advantages to the packaging industries. The properties of the film include clarity, toughness, strength, and uniform molecular structure. The film is used in food packaging to replace cellophane in tobacco and snack packaging because of its low cost and favorable properties.

The films are used in shrink-wrap applications as heat-shrinkable films. Metallocene polyethylene is a new generation of polyethylene that is utilized in many film applications, including industrial, building, construction, agriculture, and packaging. These factors help the growth of the segment and contribute to the growth of the market.

The sheets segment is the fastest growing during the forecast period. Metallocene polyethylene is used in the sheets due to their properties like thermoformability, elasticity, dead fold properties, printability, confirmability, drape, stress relaxation, heat sealability, mechanical properties, and processability which helps the growth of the metallocene polyethylene market.

Catalyst Type Insights

The zirconocene segment dominated the metallocene polyethylene market in 2025. The synthesis of the polypropylene is done with the help of three types of zirconocene catalysts. The zirconocene catalysts include advantages such as low cost, low toxicity, high catalytic activity, and strong coordination ability. These are used in the organic reactions. The zirconocene catalyst is 10 to 100 times more active than the Ziegler catalyst. The zirconocene catalysts are used in the polymerization of the ethylene. These factors help the growth of the segment and contribute to the growth of the market.

End-use Type Industry Insights

The packaging segment dominated the market in 2025. Metallocene polyethylene is used for food packaging such as candies, deli bags or wraps, cheese wrap, poultry, meat, frozen foods, baked goods, and fresh produce. Metallocene polyethylene is generally used in the world for packaging and various industrial applications. It is mostly used in the product packaging. Metallocene polyethylene is used in the production of containers, geomembranes, bottles, plastic films, and plastic bags. It has a very low density that may help the manufacturers save money while distributing large quantities of products. These factors help the segment grow.

Regional Insights

What is the Asia Pacific Metallocene Polyethylene Market Size?

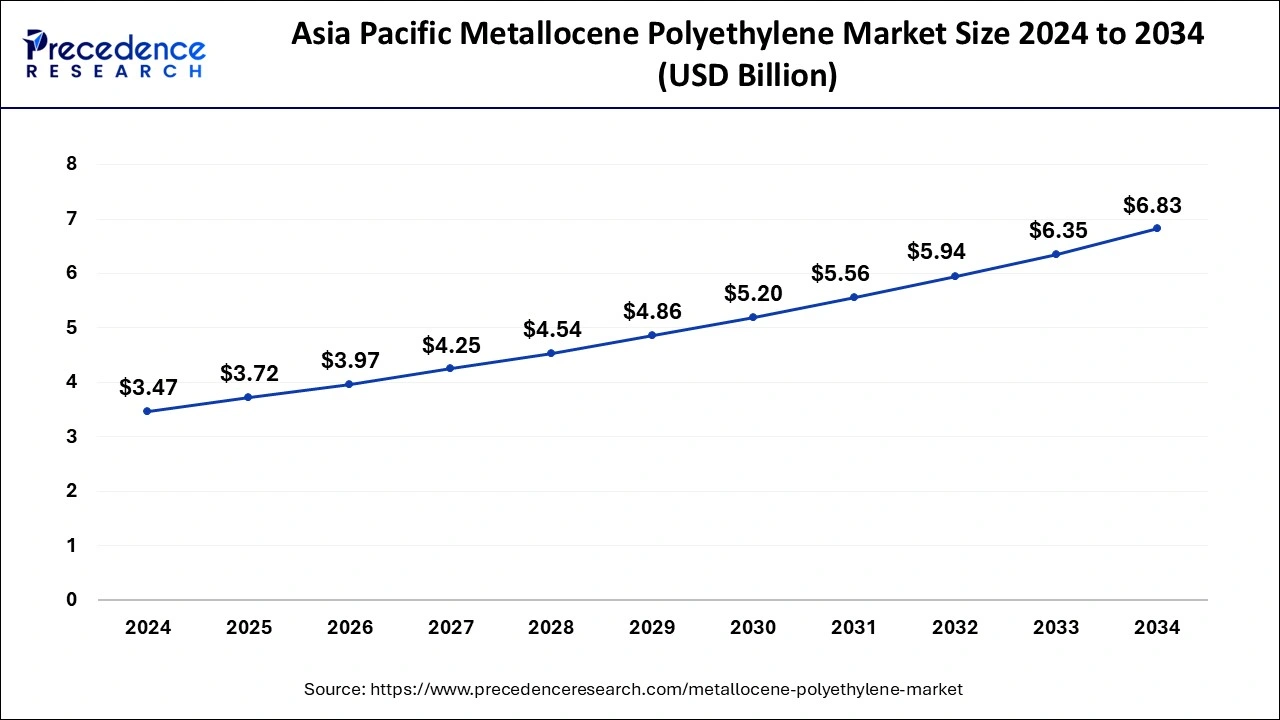

The Asia Pacific metallocene polyethylene market size is exhibited at USD 3.72 billion in 2025 and is projected to be worth around USD 7.26 billion by 2035, growing at a CAGR of 6.92% from 2026 to 2035.

Asia Pacific held the largest share of the market while contributing 40% of the market share in 2025. Increasing demand for disposable products, consumer products, and packaged products helps the growth of the market in this region. In infrastructure development, the materials that are needed are wrapped or packed with the help of metallocene polyethylene. China and India are the leading countries in the metallocene polyethylene market of the Asia Pacific region. China's leading polypropylene and polyethylene manufacturers company in July 2023 launched the NXBF Chemical Technology Group. It has easily achieved metallocene polyethylene mass production, uses metallocene polyethylene as a polymerization catalyst, and is different from the traditional catalysts. It has a better toughness degree, transparency, flexibility, and texture.

- In December 2022, Dushi Petrochemical qualified metallocene polyethylene products produced successfully using chromium powder as the domestic catalyst and seed bed and became the first enterprise in China to realize stable, serial, and large-scale production of metallocene polyethylene film materials. In 2015, Dushi Petrochemical began research and development on the production of metallocene polyethylene products to fill the domestic gap in the chemical industry.

- In May 2023, Sinopac officially began the first round of the domestic catalyst metallocene conversion. After eleven days, Sinopac produced more than 3000 tons of the metallocene polyethylene product mLL1018, and later, the metallocene products Mhd3702 and mLL2010 were converted successfully.

Currently, the annual growth rate in Western developed countries is 15% of the metallocene polyethylene products, and in developed countries, it is expected that half of the growth comes from the metallocene products of linear low-density polyethylene production. In January 2024, in India, quality control measures were established for the polyethylene regulations under the Bureau of Indian Standards (BIS) Act, 2016. It includes LDPE extrusion coating, LDPE film grades or pharma, LLDPE butene grades, LLDPE hexene or octene grades, metallocene grades, base resins of jacketing, power cable, and other applications.

North America is observed to grow at a CAGR of 6.14% during the forecast period. America's polyethylene division, Chevron Phillips Chemicals, produces metallocene polyethylenes, MDPE, LLDPE, LDPE, and HDPE. Packaging is in high demand due to its eco-friendly alternative to food packaging. The United States in the North American region is the largest market for the market. This is due to the versatile applications and unique properties among the many industries. Metallocene polyethylene is highly used for different purposes in different industries like healthcare, food and beverages, renovation, and building industries. These factors help the growth of the market in the North American region.

What Are the Driving Factors of The Metallocene Polyethylene Market in Europe?

Europe is expected to grow at a significant rate during the forecast period. Strict environmental regulation is used to expand Europe, in favor of recyclable, thinner, high-performance materials. Metallocene polyethylene can be adopted at a faster rate through sustainability policies in packaging and industrial films. Germany has been a force in terms of regional demand, where producers align their innovation, compliance, and efficiency targets in high-tech polymer manufacturing systems across regions.

Germany Metallocene Polyethylene Market Trends

Germany promotes growth by establishing stringent policies against plastic waste and promoting sustainability. The producers invest in the bio-based feedstock and effective production technologies. They still have a great demand for special industrial films and lightweight protection packages that involve high performance of metallocene polyethylene properties and uniform quality of the material.

Value Chain Analysis of the Metallocene Polyethylene Market

- Feedstock Procurement: The purchase of ethylene and metallocene catalysts is needed to produce stable, efficient, and consistent operations that metallocene polyethylene produces.

Key players: ExxonMobil, Reliance Industries, and SABIC - Chemical Synthesis and Processing: The process of changing the raw materials into final metallocene polyethylene by polymerizing them into the required molecular structures.

Key Players: Dow Chemical Company, ExxonMobil, SABIC, LyondellBasell - Quality Testing and Certification: The testing of the completed material to determine compliance of the material with quality standards, specifications, and regulatory requirements.

Key players: Agilent, Waters Corporation, SGS, Bureau of Indian Standards - Metallocene Polyethylene Packaging and Labelling: Preparation of finished polyethylene to be stored, transported, safely handled, and identified by the customer.

Key players: Amcor, Berry Global, Sealed Air

Metallocene Polyethylene Market Companies

- Borealis AG: Offers high-performance metallocene polyethylene solutions in flexible packaging and rigid packaging, both focused on environmental sustainability, consistency in performance, and material productivity.

- Braskem: The company manufactures metallocene polyethylene as part of its polyolefin offering, with a wide range of applications using scalable, reliable, and market-specific material solutions.

- Chevron Philips Chemical Company LLC: Offers metallocene polyethylene grades in support of films, packaging, and pipe works that demand durability, processing mastery, and predictable polymer conduct.

Other Major Key Players

- Dow Chemical Company

- Exxon Mobil Corporation

- INEOS Group Holdings S.A.

- LyondellBasell Industries N.V.

- LG Chem and UBE Corporation

- Mitsui & Co.

- Reliance Industries Limited

- SABIC

- SASOL

- Total Energies SE

- Westlake Chemical Corporation

Recent Developments

- In September 2024, Indian Oil Corporation Ltd. chose Univation's UNIPOL� PE Process Technology for a production line at Paradip, India. The facility aims for 650,000 tons per annum of polyethylene, producing both LLDPE and HDPE for the expanding Indian market. (Source: https://www.prnewswire.com )

- In February 2025, ExxonMobil initiated its 730,000 t/yr LLDPE No.1 unit in Huizhou, China, achieving on-spec production with purchased ethylene. Commercial operations will commence between late February and March, coinciding with the startup of its 1.6mn t/yr cracker, transitioning to mLLDPE thereafter. (Source: https://www.argusmedia.com )

- In September 2024,Indian Oil Corporation Ltd. selected Univation Technologies' UNIPOL and metallocene catalyst technology for a world‑scale PE production line in India (including mPE grades)(Source: https://www.prnewswire.com)

- In October 2024, TotalEnergies SE launched a new metallocene PE grade, �Advanced Supertough 12AST05� (VLLDPE), to extend its mPE range for film and packaging applications(Source: https://www.pressreleasefinder.com)

Segments Covered in the Report

By Type

- mLLDPE

- mHDPE

- Others

By Application

- Films

- Sheets

- Injection Molding

- Extrusion Coatings

- Others

By Catalyst Type

- Zerconocene

- Ferrocene

- Tetanocene

- Others

By End-use Industry Type

- Packaging

- Food and Beverages

- Automotive

- Building and Construction

- Agriculture

- Healthcare

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Get a Sample

Get a Sample

Table Of Content

Table Of Content