What is Pharmaceutical Spray Drying Market Size?

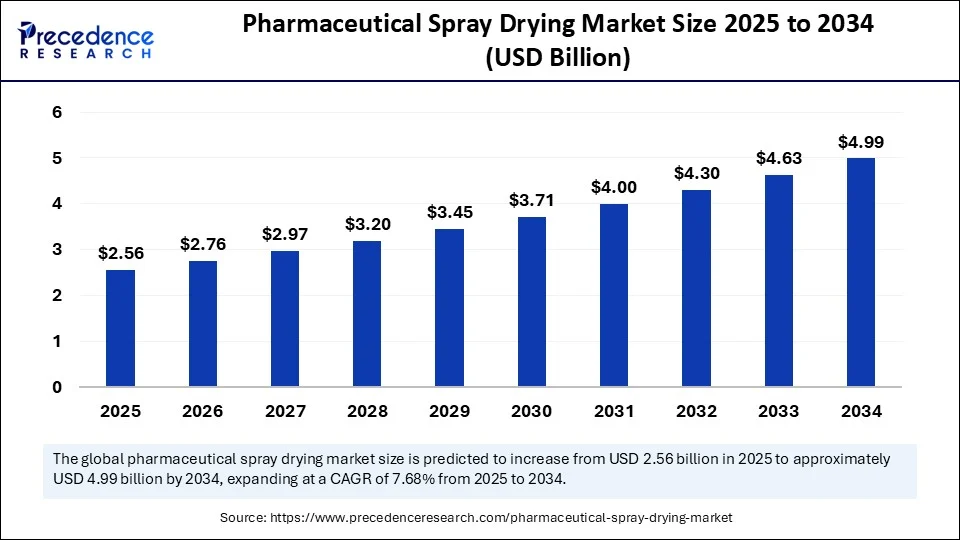

The global pharmaceutical spray drying market size accounted for USD 2.56 billion in 2025 and is predicted to increase from USD 2.76 billion in 2026 to approximately USD 4.99 billion by 2034, expanding at a CAGR of 7.68% from 2025 to 2034. Rising adoption of spray drying in biopharma companies, rising prevalence of poorly water-soluble drugs, demand for high-quality products, and technological advancements are driving the growth of the market.

Market Highlights

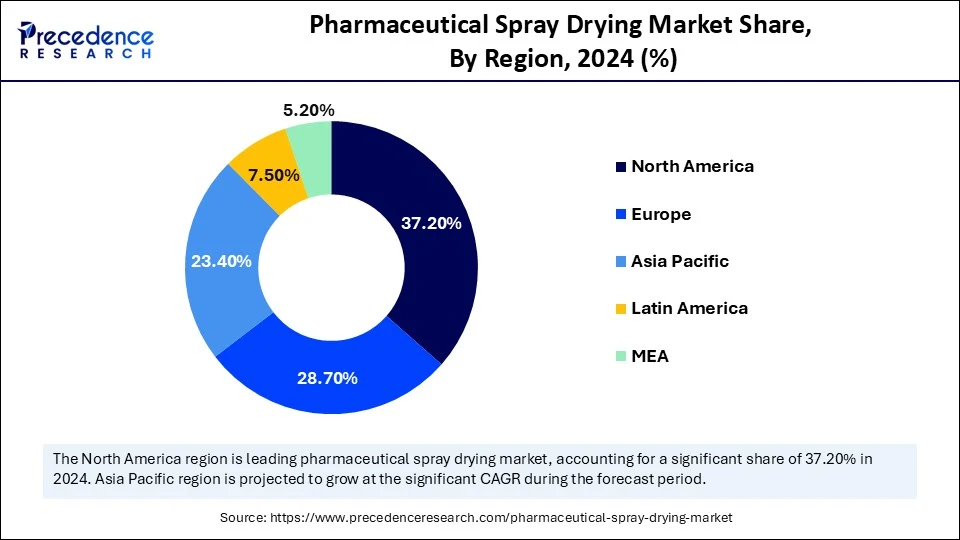

- North America dominated the pharmaceutical spray drying market with the largest market share of 37.20% in 2024.

- Asia Pacific is anticipated to grow with the highest CAGR of 10.20% during the forecast period.

- By product type, the spray-dried formulations segment held the biggest market share of 61.50% in 2024.

- By product type, the spray drying equipment segment is expected to grow at the fastest CAGR of 9.30% during the forecast period.

- By drug type, the small molecule drugs segment captured the highest market with the largest market share of 52.70% in 2024.

- By drug type, the biologics & monoclonal antibodies segment is projected to experience the highest growth CAGR between 2025 to 2034.

- By formulation type, the powder segment held the largest share of 46.20% in 2024.

- By formulation type, the nanoparticles segment is set to experience the fastest CAGR of 11.00% from 2025 to 2034.

- By application, the oral drug delivery segment contributed the maximum market share of 39.40% in 2024.

- By application, the pulmonary drug delivery segment is anticipated to grow with the highest CAGR of 10.60% during the studied years.

- By operation mode, the batch mode segment generated the major market share of 58.10% in 2024.

- By operation mode, the continuous mode segment is projected to expand rapidly, with a CAGR of 9.70% in the coming years.

- By scale of operation, the commercial/industrial production segment accounted for the significant market share of 54.80% in 2024.

- By scale of operation, the clinical/pilot scale segment is predicted to witness significant growth of 9.20% over the forecast period.

- By end-user, the pharmaceutical companies segment held the biggest market share of 43.60% in 2024.

- By end-user, the CDMOs segment will gain a significant share of 9.90% over the studied period.

- By technique/technology used, the two-fluid nozzle spray drying segment generated the major market share of 33.90% in 2024.

- By technique/technology used, the nano spray drying segment is expected to grow at the fastest CAGR of 11.40% during the forecast period.

Spray Drying: Transforming Drug Development with Precision and Power

Spray drying in the pharmaceutical industry is the process of converting a solution, suspension, or emulsion into a dried powder in a single step by passing an automated spray through a high-temperature gaseous medium. The spray dryer is a type of industrial machinery used to turn liquids into powders or granules. This whole thing is done in a single step. Spray drying an API with a polymer can create a stable, amorphous dispersion, which enhances the dissolution rate and thus, the bioavailability. It also helps to increase bioavailability to create nanoparticles isolated in larger composite particles, then recovering them through spray drying.

Increasing use of spray drying in biopharma companies to ensure consistent delivery and complex molecules, rising prevalence of poorly water-soluble drugs, growing chronic diseases, demand for high-quality products, and technological advancement are driving the growth of the global pharmaceutical spray drying market.

How is Artificial Intelligence (AI) Transforming the Global Pharmaceutical Spray Drying Market?

The benefits of artificial intelligence (AI) based spray drying in the pharmaceutical industry, including enhanced stability, bioavailability, and scalability, make it an important tool for pharmaceutical manufacturers. By including new technologies, manufacturers can improve their formulations and deliver innovative solutions to patients worldwide. AI transforms many pharmaceutical aspects. AI assistance to the pharmaceutical industries helps to enhance the life cycle of the product.

In the pharmaceutical industry, AI-based spray drying also includes the benefits of more productivity and quality. Drying through a dryer allows for speeding up the process, allowing greater flexibility and an increase in productivity. In a few hours, it is possible to dry various tons of product, a process that can take many days with the traditional methods.

What Are the Factors Fueling the Rapid Expansion of the Global Pharmaceutical Spray Drying Market?

- Technological advancements: Advancements in technology in spray drying for pharmaceuticals improve control over particle properties, stability, and bioavailability. Spray drying is a process for the production of dry pharmaceutical powders. Spray drying atomizes a liquid feed into small droplets in a hot drying gas, which flash-dries the droplets into solid particles. These particles are separated from the gas, and then they are sent to the next phase of the pharmaceutical manufacturing process.

- High use in biopharma companies: Spray drying is highly recognized as an efficient drying and formulation technique for pharmaceutical and biopharmaceutical processing. It offers significant economic and processing benefits as compared to lyophilization/freeze drying methods, even though optimization of process parameters may be a costly and time-consuming procedure.

Market Outlook

- Industry Growth Offerings- The industry is growing due to rising demand for poorly water-soluble drugs, increased biologics production, and advanced drug delivery systems. Innovations in high-performance, scalable spray dryers and process optimization further drive global market expansion.

- Global expansion- Global expansion of pharmaceutical spray drying is driven by increasing adoption in emerging markets, rising biopharmaceutical production, and growing demand for improved drug formulations. Investments in modern equipment and technology transfer support wider international market penetration.

- Startup ecosystem-The startup ecosystem for pharmaceutical spray drying is growing, focusing on innovative solutions like miniaturized spray dryers, AI-driven process optimization, and novel excipients. Emerging companies aim to enhance bioavailability, streamline formulations, and support scalable, cost-effective drug manufacturing.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 2.56 Billion |

| Market Size in 2026 | USD 2.76 Billion |

| Market Size by 2034 | USD 4.99 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 7.68% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product Type, Drug Type, Formulation Type, Application Type, Operation Mode, Scale of Operation, End-User, Technique/Technology Used, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Rising pharmaceutical production

Pharmaceutical manufacturing plays an important role in the ongoing fight against disease. Effective cleaning processes ensure the quality, efficacy, and safety of all products made. The benefits of medicines are helpful to use, like relieving pain, curing infections, or lowering blood pressure. The risks of drugs refer to the potential for something unexpected or unwanted to occur when they are used. The benefits of pharmaceutical companies play an important role in the healthcare sector, like job creation, export revenue, affordable medicines, and contribution to GDP.

Restraint

Strict regulatory standards

Strict regulatory standards' disadvantages include slowed competitiveness, negative effect on small businesses, and regulating activities within an economy or a region can be costly due to the processes involved, and imposing regulatory controls and checks can be time-consuming since plenty of controls may be needed. Some disadvantages of a regulated market are asymmetric information, regulatory recapture, and the second best. Non-compliance may lead to disruptions in operations, loss of clientele, financial penalties, and even regional lockouts.

Opportunity

Increasing investment in R&D

Research and development (R&D) can help our business or ideas become more attractive to investors and other companies looking to expand. R&D can lead to innovations in business. This may be in terms of new products and services, improved processes, and new ways to interact with customers. These advancements can lead to lower costs and greater profits. Increased investment benefits include tax benefits, better option than saving accounts, growth potential, market performance, combine passion with financial growth, diversify your portfolio, plan for retirement, provide regular income, and grow our wealth.

Segment Insights

Product Type Insights

The spray-dried formulations segment held the largest share of the market at around 61.50% in 2024. Spray-drying offers a slow method of drying by exposing substances to only a short burst of extreme temperature, then providing a cooling effect via the evaporation process. Spray drying is a method of forming a dry powder from a liquid or slurry by rapidly drying with a hot gas. This is the preferred method of drying various thermally sensitive materials like foods and pharmaceuticals, or materials that may need extremely consistent, fine particles size.

The spray drying equipment segment is expected to grow at the fastest rate of 9.30% in the market during the forecast period of 2025 to 2034. Spray drying equipment benefits include versatility, quality, being perfect for heat-sensitive materials, innovative concepts, extended shelf life, efficiency, uniform particle size, scalability, rapid drying, and consistency.

Drug Type Insights

The small molecule drugs segment peaked with the largest share of 52.70% in the global pharmaceutical spray drying market in 2024. Small molecule drugs offer many benefits, starting with their high oral availability which allows for convenient self-administration, most often in oral solid dose (OSD) form. Groundbreaking small molecule drugs like penicillin for treating bacterial infections, aspirin for pain relief and inflammation, and statins for managing cholesterol levels have transformed the healthcare landscape and improved patient outcomes worldwide.

The biologics & monoclonal antibodies segment is projected to experience the highest growth rate in the market between 2025 to 2034. Monoclonal antibodies are proteins made in laboratories that act like proteins called antibodies in our bodies. Monoclonal antibody therapy can also benefit the treatment of specific infectious diseases. Biologics can effectively control chronic inflammation and pain, preventing the need for corticosteroids.

Formulation Type Insights

The powder segment held the largest share of 46.20% in pharmaceutical spray drying market in 2024. Spray drying is a method of forming a dry powder from a liquid or slurry by rapidly drying with a hot gas. Spray drying, a widely used technique in pharmaceutical manufacturing, involves converting a liquid solution or slurry into a fine, dry powder by rapidly evaporating the solvent using hot gas. This process not only ensures better stability, solubility, and bioavailability of active pharmaceutical ingredients (APIs), but also enables precise particle size control, which is critical for pulmonary and controlled-release applications.

The nanoparticles segment is set to experience the fastest rate of 11.00% market growth from 2025 to 2034. Nanoparticles can be made by altering the method of fabrication. Nanoparticles have been proven to be useful as drug delivery vehicles. Many uses for nanoparticulate drug delivery systems exist, including radiation, AIDS therapy, cancer therapy, and gene therapy. Using nanotechnology, materials can effectively be made more reactive, more durable, lighter, stronger, more sieve-like, or better electrical conductors, among many other traits.

Application Type Insights

The oral drug delivery segment held the largest share of the market at around 39.40% in 2024. Oral drug delivery is the choicest route for drug administration due to its non-invasive nature. The oral routes present the benefit of avoiding pain and discomfort associated with injections and also reducing contamination. It is the most preferred route of drug delivery due to its benefits like non-invasiveness, patient compliance, and convenience of drug administration.

The pulmonary drug delivery segment is anticipated to grow with the highest CAGR of 10.60% in the market during the studied years. The pulmonary drug delivery system benefits include rapid, efficient, and well-targeted, with few systemic effects.

Operation Mode Insights

The batch mode segment registered its dominance over the global pharmaceutical spray drying market with a share of 58.10% in 2024. Batch mode processing benefits include faster business intelligence, lower costs, greater efficiency, offline features, better use of existing computer systems, and improved data quality.

The continuous mode segment is projected to expand rapidly in the market, with a share of 9.70% in the coming years. Continuous operation mode can reduce the time required to load, unload, and clean the reactor. It offers benefits like reduced operation interaction and material storage, and also increased process efficiency through a smaller number of utilities.

Scale of Operation Insights

The commercial/industrial production segment led the market with a share of 54.80%. Commercial/industrial scale production benefits include large-scale manufacturing or production processes, which involve the creation of goods or products on a massive scale.

The clinical/pilot scale segment is predicted to witness significant growth of 9.20% in the market over the forecast period. Pilot plants help pharmaceutical companies to reduce risks, improve efficiency, and accelerate drug development with practical insights. A pilot plant is a scaled-down version of an industrial production line.

End-user Insights

The pharmaceutical companies segment registered its dominance with a global pharmaceutical spray drying market share of 43.60% in 2024. Pharmaceutical companies boost the global economy and also driving medical progress by researching, developing, and bringing new medicines that enhance health and quality of life for patients around the world, the pharmaceutical industry is a key asset to the global economy.

The CDMOs segment will gain a significant share of 9.90% the market over the studied period of 2025 to 2034. The CDMOs benefits include cost savings, quality assurance, access to expertise, risk mitigation, regulatory compliance, focus on core competencies, cost efficiency, speed to market, and scalability.

Technique/technology Used Insights

The two-fluid nozzle spray drying segment enjoyed a prominent position in the market share of 33.90% during 2024. Two-fluid nozzle spray drying transforms spraying by turning liquid into finer particles with high-speed air, improving cleaning and chemical reaction efficiency on surfaces. These nozzles use two fluid streams, one for atomizing and the other for providing the necessary pressure.

The nano spray drying segment is expected to grow at the fastest rate of 11.40% in the market during the forecast period of 2025 to 2034. The benefits of nano spray drying allow the generation allows the generation of smaller particle sizes than conventional spray dryers, which enhances bioavailability and release of bioactive components and drugs.

Regional Insights

U.S. Pharmaceutical Spray Drying Market Size and Growth 2025 to 2034

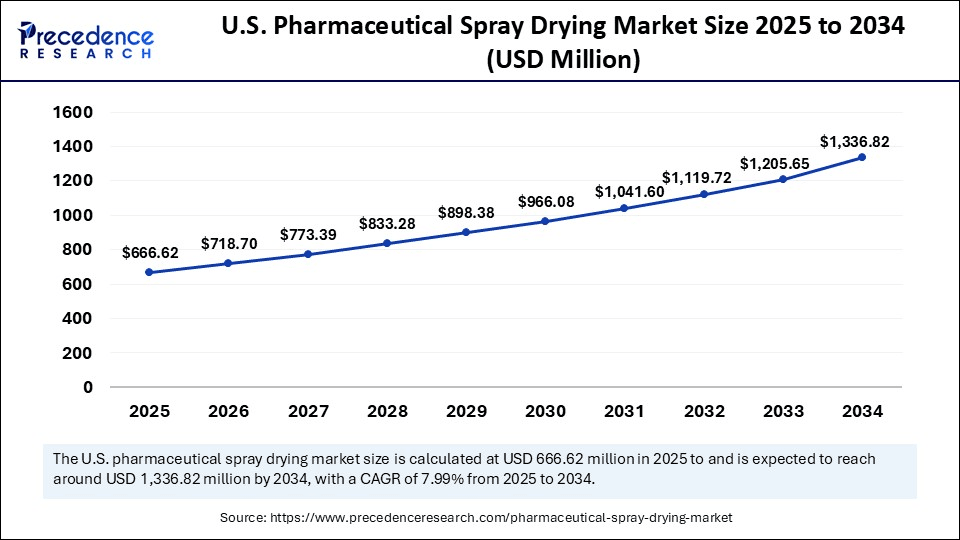

The U.S. pharmaceutical spray drying market size is exhibited at USD 666.62 million in 2025 and is projected to be worth around USD 1,336.82 million by 2034, growing at a CAGR of 7.99% from 2025 to 2034.

What is Powering the U.S. Boom in Pharmaceutical Spray Drying?

The U.S. market is growing due to the rising development of complex and poorly water-soluble drugs that require advanced formulation technologies to improve bioavailability. Increasing R&D investments, strong biopharma presence, and demand for stable, high-quality drug formulations are boosting adoption. Additionally, the shift toward continuous manufacturing and rapid technological advancements in spray-drying equipment further support market expansion.

How North America's Strong Hold on the Pharmaceutical Spray Drying Market?

North America held a significant share of 37.20% in the global pharmaceutical spray drying market and is forecast to have a share of 33.00% in 2034. North America is investing in research and development (R&D) of pharmaceutical research leads to the development of new drugs and biologics, technological advancement, and stringent regulations are driving the growth of the global pharmaceutical spray drying market.

Why are Manufacturers Flocking to Asia Pacific for Spray Drying Solutions?

Asia Pacific is anticipated to grow with the highest CAGR of 10.20% in the market during the forecast period of 2025-2034. Affordable solutions, manufacturers looking for high-performance and affordable dryers, and the rapid expansion of pharmaceutical manufacturing in countries like China and India are contributing to the growth of the global pharmaceutical spray drying market in the Asia Pacific region.

Why China is Rapidly Emerging as a Spray Drying Powerhouse?

China's market is growing due to the rapid expansion of its biopharmaceutical sector and rising production of complex, poorly soluble drugs that require advanced formulation methods. Increasing government support for pharma innovation, growth in contract manufacturing organizations (CMOs), and strong investment in modern drug-delivery technologies are accelerating adoption. Additionally, rising healthcare demand and continuous upgrades in manufacturing infrastructure further drive market growth.

What's Driving Europe's Expanding Pharmaceutical Spray Drying Market?

Europe's market is expanding due to the region's strong focus on advanced drug formulation technologies and the growing need to enhance the bioavailability of poorly soluble drugs. Rising investments in biopharmaceutical R&D, strict quality standards, and the presence of leading contract manufacturing organizations support wider adoption. Additionally, increased demand for stable, high-performance formulations and continuous processing technologies is further driving market growth across Europe.

Uncovering the Drivers of the UK's Rising Spray Drying Market

The UK market is increasing due to rising demand for advanced drug formulations, especially for poorly water-soluble APIs. Growth in biologics, inhalable therapies, and controlled-release drugs is also boosting adoption. Strong R&D capabilities, extensive clinical trial activity, and investments in novel manufacturing technologies support market expansion. Additionally, regulatory encouragement for high-quality, stable, and scalable drug production strengthens the market's long-term growth potential.

Value Chain Analysis

- R&D

Concentrates on optimizing spray drying processes for efficiency and consistency.

Focuses on formulation development to enhance drug stability, solubility, and bioavailability.

Aims for scalable solutions suitable for commercial production of advanced drug delivery systems.

Key players: GEA Group, Büchi Labortechnik, SP Scientific, Dedert Corporation, and Yamato Scientific - Clinical Trials and Regulatory Approvals

Focus on demonstrating drug safety and efficacy, with emphasis on the spray drying process as a critical manufacturing step.

Spray drying is used to enhance drug properties, including solubility and bioavailability.

Regulatory agencies like the FDA and EMA evaluate both the drug and its manufacturing process to ensure safety and quality.

Key players: GEA Group, SP Scientific, Büchi Labortechnik, Dedert Corporation - Formulation and Final Dosage Preparation

Involves choosing the API, solvents, and excipients to prepare a liquid feed with target properties.

The feed is atomized into fine droplets and rapidly dried to form a powder.

Produced powders are designed for enhanced solubility, taste masking, or controlled-release properties in the final dosage form.

Key players: GEA Group, Büchi Labortechnik, SP Scientific, Dedert Corporation

Key players in Pharmaceutical Spray Drying Market and Their Offerings

- Armfield Ltd: Provides laboratory-scale spray dryers and pilot equipment for R&D, formulation development, and process optimization in pharmaceuticals.

- GEA Group: Offers industrial and pilot-scale spray drying systems for APIs, biologics, and complex drug formulations, focusing on efficiency and scalability.

- Micro Powders, Inc.: Specializes in engineered powders and high-performance spray-dried excipients for enhanced solubility, flow, and bioavailability.

- Anhydrous, Inc.: Supplies spray-dried excipients, lactose derivatives, and carriers to improve drug stability, solubility, and formulation performance.

- SPX Flow Inc.: Provides advanced spray drying solutions and process equipment for pharmaceutical powders, emphasizing consistency, scalability, and high-quality production.

Recent Developments

- In July 2025, the spray drying platform at the Killorglin site for amorphous solid dispersions (ASD) and inhalation powders was launched by Aenova, a global contract development and manufacturing organization (CDMO). The new brand laboratory and pilot scale equipment are aimed at developing formulations for innovative drug candidates to overcome bioavailability hurdles, which are one of the greatest challenges in modern drug development.

(Source: https://www.aenova-group.com) - In April 2025, to launch a pharmaceutical lactose to the Life Sciences Market, LBB Specialty (LBBS), a leader in specialty chemicals and ingredient distribution in North America, collaborated with Kerry Group, a world-leading taste nutrition partner for the food, beverage, and pharmaceutical markets with innovative, sustainable specialty ingredients for the industry. (Source:https://www.lbbspecialties.com)

Segment Covered in the Report

By Product Type

- Spray Dried Formulations

- Amorphous Solid Dispersions

- Encapsulated APIs

- Inhalable Dry Powders

- Controlled Release Formulations

- Spray Drying Equipment

- Closed System Spray Dryers

- Open System Spray Dryers

- Bech-top/Laboratory Scale

- Pilot Scale

- Commercial Scale

By Drug Type

- Small Molecule Drugs

- Biologics

- Peptides

- Proteins

- Vaccines

- Monoclonal Antibodies

- Highly Potent APIs (HPAPIs)

By Formulation Type

- Powder

- Granules

- Microparticles

- Nanoparticles

By Application Type

- Pulmonary Drug Delivery

- Oral Drug Delivery

- Nasal Drug Delivery

- Parenteral Drug Delivery

- Topical Drug Delivery

By Operation Mode

- Batch Mode

- Continuous Mode

By Scale of Operation

- R&D/Laboratory Use

- Pilot Scale Production

- Commercial/Industrial Production

By End-User

- Pharmaceutical Companies

- Biopharmaceutical Companies

- Contract Development & Manufacturing Organizations (CDMOs)

- Academic & Research Institutes

By Technique/Technology Used

- Closed Loop Spray Drying

- Open Loop Spray Drying

- Nano Spray Drying

- Multi-Fluid Nozzle Spray Drying

- Two-Fluid Nozzle Spray Drying

- Rotary Automization

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle, East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting