What is the Powder-Bonding 3D Printing Construction Market Size?

The powder-bonding 3D printing construction market plays a vital role in addressing housing shortages and rapid infrastructure demand. Innovations in powder materials and bonding techniques improve strength and durability.The increasing rate of smart cities demand with growing population, government support for 3D printing over traditional construction methods due to its unprecedented benefits, and ongoing research and development for creating materials like geopolymer are some of the propelling factors of the market on a global scale.

Powder-Bonding 3D Printing Construction Market Key Takeaways

- North America held the largest powder-bonding 3D printing construction market with the largest market share of 36% in 2024.

- Asia Pacific is expected to witness the fastest CAGR during the foreseeable period of 2025-2034.

- By technology, the binder jetting segment held the biggest market share of 58% in 2024.

- By technology, the powder bed fusion (PBF) segment is expected to witness the fastest CAGR of 12.8% during the foreseeable period.

- By material type, the concrete segment captured the highest market share of 54% in 2024.

- By material type, the composite powders segment is expected to witness the fastest CAGR of approximately 13.2% during the foreseeable period.

- By construction type, the building construction segment captured the maximum market share of 61% in 2024.

- By construction type, the infrastructure segment is expected to witness the fastest CAGR of around 14.1% during the foreseeable period.

- By end user, the residential sector segment generated the major market share of 49% in 2024.

- By end user the industrial sector segment is expected to witness the fastest CAGR of 13.8% during the foreseeable period.

Market Overview

The powder-bonding 3D printing construction market involves the use of powder-based 3D printing technologies, such as binder jetting and sintering, to create structural components, buildings, and infrastructure. In this process, layers of powdered materials like concrete, sand, ceramics, or metal are selectively bonded using a liquid binder or thermal energy. Powder bonding offers high design flexibility, faster construction timelines, reduced material waste, and cost efficiency, making it increasingly adopted in residential, commercial, and industrial construction projects worldwide.

How is AI transforming the Powder-Bonding 3D Printing Construction Market?

The incorporation ofartificial intelligence into powder bonding 3D printing construction sector is a revolutionary step in terms of its design and planning, process control, and optimization, along with defect detection and quality control. These parameters are highly influential for the success rate of the market on a large scale, and AI is supporting in meeting the standards of all these aspects. By analyzing historical data with real-time information, behaviors of material under certain conditions can be predicted and which is crucial to know the outcomes leading towards highly reliable and cost-effective production.

AI-based automation offers fewer errors than human methods with a shortened period to complete the project, highlighting its potential for automation. Also, models like CNN can detect defects in individual printed layers to offer precision and allow immediate action to fix them, making it more effective 3D printing. AI can streamline workflows, minimize errors, and project deadlines while optimizing resources is further expanding the market's growth.

Powder-Bonding 3D Printing Construction Market Outlook

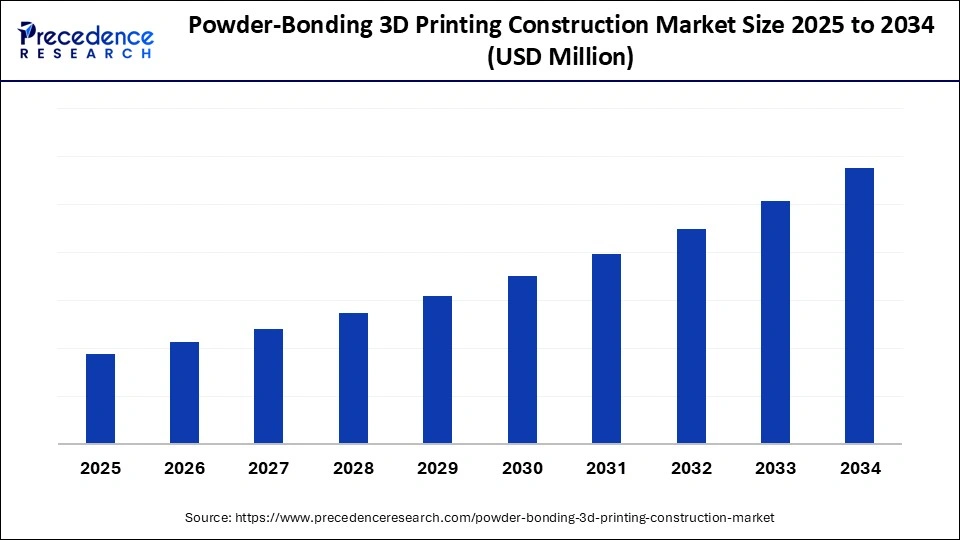

- Industry Growth Overview: The market is poised for substantial growth from 2025 to 2034, driven by the need for faster, cost-effective construction methods and solutions to labor shortages. The growing demand for faster, more sustainable construction methods and the ability to produce complex, customized building designs also support market growth. Moreover, advancements in powder-based materials, enhanced printing precision, and the increasing adoption of 3D printing technology by the construction industry for large-scale projects and infrastructure development support market growth.

- Automation and Digital Integration of the Building Process: This trend uses robotics for quicker printing, AI for quality assurance and design improvements, and BIM/digital twins for effective project management, enabling precise, complex, and fast construction.

- Global Expansion:The market is expanding globally due to the rising demand for faster, cost-effective, and sustainable construction methods, alongside technological advancements in 3D printing materials and processes. Emerging regions, particularly in Asia-Pacific, Latin America, and the Middle East, present significant opportunities as infrastructure development accelerates, and governments push for innovative, environmentally friendly construction solutions.

- Major Investors: Major investors, including venture capital and strategic partners, are increasing their investments due to the potential for efficiency improvements, design flexibility, and alignment with sustainable development goals. Key investors include firms like ICON, COBOD, and Sika AG.

- Startup Ecosystem: The startup ecosystem is maturing, focusing on innovations in specialized material development and robotic printing systems. Emerging firms are attracting funding by offering scalable, customized solutions to revolutionize traditional construction practices.

What are the Key Trends in the Powder-Bonding 3D Printing Construction Market?

- Material innovation with sustainability: A significant trend that propels the market further is the growing rate of innovation and sustainability in powder-bonding 3D printing construction processes. Much of the research is ongoing to develop 3D printing methods that can be possible with recycled materials and wastes, like geopolymers, and convert mixtures that can be built with up to 70% lower rates of embodied carbon dioxide. Manufacturers are finding better use of binder jetting for an eco-friendly approach.

- Functional gradient material: An advancement in multi-material jetting and binder chemistry offers the generation of functional gradient components with increased mechanical properties. It enables different parts with varying characteristics such as strength, thermal properties, and acoustic properties.

Market Scope

| Report Coverage | Details |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Technology, Material Type, Construction Type, End User, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Cost-friendly and time-saving method

A significant driving factor for the powder-bonding 3D printing construction market is cost cost-friendly and time-saving process of innovative construction by reducing extra labor costs with affordable housing. The technology provides an energy-efficient method, unlike conventional construction methods, which are highly responsible for CO2 emissions globally by the construction industry. Advances in materials like geopolymer with carbon-neutral properties are an additional benefit of 3D printing, boosting the market's growth globally. Automation in 3D printing has significantly lowered the need for labor and offers much faster project development with high precision, making it a cost-effective and time-saving technological process to build sustainable infrastructure without compromising on the aesthetics of the buildings.

Restraint

Requirements of post-processing

Despite having several benefits, the powder-bonding 3D printing construction market is witnessing some barriers that hinder market growth, which include high upfront costs for the whole setup, the mandate of post-processing, along limited certification for materials. Expenditure needed for powder bonding machines and infrastructure is highly expensive, and small firms cannot easily adapt to it. Based on the material type, components and small parts created by 3D printing with binders and jetting may need further complex post-processing to stabilize and make them sustainable for other applications, further adding to costs.

Opportunity

Innovation, freedom, and government support

A prominent opportunity held by the powder-bonding 3D printing construction market is innovation and various intricate, yet aesthetic design freedom offered by 3D printing, unlike the traditional way of constructing parts or infrastructure. Powder bonding technology can develop innovative and delicate but pliable parts, designs, and lightweight components with a durable structure that are highly difficult to create by any other method. The whole process provides high precision and reliability in the final product with enhanced building quality. Therefore, by acknowledging these benefits, many governments are highly investing in the development of powder-bonding 3D printing construction method by offering incentives and tax exemptions on it to build smart cities that will be eco-friendly and comply with environmental protection regulations.

Segment Insight

Technology Insights

What factors fuel binder jetting technology in the powder-bonding 3D printing construction market?

The binder jetting segment held the largest market share of nearly 58% in 2024. Segment growth is attributed to several factors, including its high speed, lower costs, and its potential to use various materials like metal, polymers, and ceramics, along with its inherent freedom without the need for a support structure, making it a highly demanding technology in the powder-bonding 3D printing construction market. Also, this process is much faster than other processes and can be applicable where large-scale production is mandatory within a specific period.

The powder bed fusion (PBF) segment is expected to witness the fastest CAGR of nearly 12.8% during the foreseeable period. This technology allows various material processing, including titanium, aluminum, cobalt chrome, and others, which are highly applicable in industrial usage. It allows intricate design creation with higher accuracy by using PBF methods like selective laser melting and electron beam melting, which further enables easy fabrication of complex parts that are difficult to create with the traditional way of manufacturing.

Material Insights

Why is concrete majorly used in the powder-bonding 3D printing construction market?

The concrete segment held the largest market share of nearly 54% in 2024. The concrete material can be easily modified as per changing demand in the market, and it is widely available in nature with relatively cheap prices, which are highly affordable for large construction projects. Concrete is pliable, and it ensures compatibility with the automation in the construction area. Also, concrete has inherent durability with strength, making it an ideal option for building integrity and infrastructure projects.

The composite powders segment is expected to witness the fastest CAGR of nearly 13.2% during the foreseeable period. Composite powders provide an excellent ratio of strength-to-weight and superior durability. Composite powders can incorporate various useful features like sensors and enable monitoring of structural health, with performance to improve safety and longevity.

Construction Type Insights

Why is building construction found to have extensive application in the powder-bonding 3D printing construction market?

The building construction segment held the largest market share of nearly 61% in 2024. The reason for segment dominance is significant cost reductions in labor and material expenses, which is an attractive option for builders and developers with 3D printing. 3D printing makes it possible to build highly intricate and complex architectural designs that are not possible with conventional manufacturing, and is a major driver for the segment's growth.

The infrastructure segment is expected to witness the fastest CAGR of nearly 14.1% during the foreseeable period. The global inclination towards smart cities requires advanced infrastructure, which is possible using 3D printing that can further integrate sensors, data analytics, along necessary connectivity features. 3D printing further helps to minimize labor requirements up to 80% and reduces the extra cost needed to build specific constructions, while reducing material waste as well is an additional benefit.

End User Insights

How does the residential sector perform in the powder-bonding 3D printing construction market?

The residential sector segment held the largest market share of nearly 49% in 2024. Rapid urbanization rate has generated high demand for affordable, Fastly developed, and technologically well-sound residential structures with sustainability. 3D printing offers a cost-friendly and efficient way to meet these requirements of the modern age, especially for emergency housing projects, which can be fulfilled by conventional methods to build residency. The residential sector is a major emitter of carbon waste, and 3D printing offers excellent solutions to minimize this, further fueling the segment's growth globally.

The industrial sector segment is expected to witness the fastest CAGR of nearly 13.8% during the foreseeable period of 2025-2034. The industrial applications majorly require exceptional precision with structural integrity, which can be provided by powder bonding 3D printing method without extensive need for manual labor, and easily building the necessary construction within a given timeframe is a major driver.

Regional Insights

Why does North America dominate the powder-bonding 3D printing construction market?

North America held the largest market share of nearly 36% in 2024. The government in North America offers financial backing to firms offering 3D printing construction, which accelerates space-based construction techniques and innovative ways. The growing demand for eco-friendly and affordable building methods with the use of composite and recycled waste material further strengthens the market's growth in the region. Significant research and development investments and projects related to it further fuel the application of powder bonding 3D printing as the best solution and alternative for conventional manufacturing methods. Moreover, initiatives such as the co-investment mechanism, demonstration build, and established printed home benchmark 2024-2025 facilitate fewer financial risks for contractors and help them to streamline their operations effectively.

U.S. Powder-Bonding 3D Printing Construction Market Trends

The U.S. leads the North American powder-bonding 3D printing construction market through its technological innovation, strong R&D, and substantial investment. U.S. efforts concentrate on creating advanced, sustainable building methods for various applications, supported by top tech companies and academic research, with the goal of enhancing the technology's efficiency and structural integrity.

What are the factors supporting the Asia Pacific powder-bonding 3D printing construction market?

Asia Pacific is expected to witness the fastest CAGR during the foreseeable period of 2025-2034. The region's growth can be attributed to factors such as growing demand by urban populations for affordable housing with technologically sound structures can be fulfill by powder bonding 3D printing construction method.

The governments in the leading nations, such as China, Japan, and India, are hugely investing in transforming their construction method and urban planning to build robust and sustainable constructions, and hence, investing in 3D printing technologies while aligning with their environmentally friendly construction goals and regulations. Further, the Asia Pacific is witnessing a significant rate of research and development regarding 3D printing methods, and finding innovative ways to apply it is accelerating the region's growth.

India Powder-Bonding 3D Printing Construction Market Trends

India is a rapidly growing market focused on practical, scalable adoption of this technology. Its main goal is to address large-scale affordable housing shortages and reduce construction time, aligning with national housing initiatives. Indian companies are actively completing pioneering construction projects, with efforts centered on mass deployment and building a skilled local workforce.

How is the Opportunistic Rise of Europe in the Powder-Bonding 3D Printing Construction Market?

Europe is emerging as a significant market, supported by strong R&D investments and a focus on sustainability. The region, including countries like Germany, the UK, and Italy, faced a slight demand dip during the pandemic but is now recovering, fueled by the need for eco-friendly practices and complex, customized designs. Strict regulations on building materials are driving the industry toward advanced, environmentally friendly options like geopolymers and specialized polymer or metal powders, building a robust regional ecosystem for advanced additive manufacturing solutions.

Germany Powder-Bonding 3D Printing Construction Market Trends

Germany is a key player and hub for advanced manufacturing in Europe. The country has historically been a major demand center for powder-bonding 3D printing, especially for prototyping and high-precision industrial use. Home to global additive manufacturing companies, Germany leads in technological advancements and R&D in materials like metal and polymer powders for various industries, including construction, to achieve efficient, accurate, and reliable building processes.

How Big is the Role of Latin America in the Powder-Bonding 3D Printing Construction Market?

Latin America plays a distinctive role in the global market, driven by demand for faster, affordable, and sustainable building solutions to address urbanization challenges. While the wider 3D printing construction market in the region is currently led by extrusion methods, the powder-bonding segment is expected to see significant growth due to its ability to create highly durable and complex designs with minimal waste. The market benefits from rising government initiatives and investments in advanced manufacturing technologies, with Brazil becoming a key regional player.

Brazil Powder-Bonding 3D Printing Construction Market Trends

Brazil is a key contributor to the market. The market in Brazil is driven by the need for affordable housing and the adoption of modern construction methods. The use of powder bonding in Brazil is accelerating, offering advantages such as high customization and reduced material waste, although the extrusion method currently holds the largest market share.

How Big is the Opportunity for the Market in the Middle East and Africa?

The Middle East and Africa (MEA) region presents significant opportunities in the powder-bonding 3D printing construction market, fueled by ambitious urban development initiatives and smart city projects. Countries like the UAE and Saudi Arabia are at the forefront of adoption, striving to transform their construction industries through innovation, efficiency, and sustainability. The region focuses on crafting intricate architectural details and large-scale structures efficiently, although extrusion techniques are currently more widespread.

Saudi Arabia Powder-Bonding 3D Printing Construction Market Trends

Saudi Arabia is a major contributor to the market in the MEA. The market in Saudi Arabia is growing rapidly, with leading real estate companies like Dar Al Arkan partnering with technology providers like COBOD to build the world's tallest and largest on-site 3D-printed buildings using locally sourced materials. Technology is valued for its ability to increase construction speed, reduce labor, and enhance energy efficiency, making it central to the Kingdom's modern infrastructure development.

Value Chain Analysis

Raw material sourcing

In this initial stage, raw materials have been collected and processed for additive manufacturing, which supports the designing and development of desired products or construction.

- Key players- Epuls3D, Wipro 3D, Vexma Technologies, and Incredible AM.

Component fabrication and machining

This process involves the fabrication of powder bonding, which is a specialty of 3D printing manufacturers and advanced service bureaus.

- Key players- Voxel Jet, COBOD International, Simpliforge Creations, and XtreeE.

Testing and certification

This stage involves testing and credibility of constructed products to ensure their reliability and sustainability.

- Key players- TUV Rheinland, Bureau of Indian Standards, in-house testing by Voxeljet, and COBOD.

Top Five Companies in the Powder-Bonding 3D Printing Construction Market and Their Offerings

- Sika AG: Proprietary material solutions (binders/mortars), print-head tech licensing, material science expertise.

- CONCR3DE: Large-scale binder jetting printers (Elephant series), recycled stone powders, production services.

- XtreeE: Digital platform and Printing-as-a-Service network for complex architectural components.

- Mighty Buildings: Factory-based production of prefabricated homes using proprietary UV-cured composite material (LSM).

- Contour Crafting Corp.: Development of large-scale automated construction systems, exploring powder-bed techniques in R&D.

Other Key Players

- COBOD International

- ICON Technology, Inc.

- Apis Cor

- Winsun Construction Engineering

- CyBe Construction

- PERI Group

- WASP Srl

- LafargeHolcim

- BetAbram

- Branch Technology

- SQ4D

Recent Developments

- In April 2025, a researcher's team from FAMU-FSU College of Engineering found a way to improve defect detection in powder-based 3D printing methods by leveraging the capabilities of AI. The project is focused on binder jetting, a 3D printing technique that uses a liquid binder to stick powdered materials together. (Source: https://news.fsu.edu)

- In April 2025, India's first 3D printed villa was introduced in Pune, Maharashtra state, capturing the attention of online social media users across the globe by offering a sneak-peek video inside the huge 2000-square-foot house, built using 3D technology.(Source: https://www.hindustantimes.com)

Segments Covered in the Report

By Technology

- Binder Jetting

- Selective Laser Sintering (SLS)

- Electron Beam Melting (EBM)

- Powder Bed Fusion (PBF)

- Others (Hybrid and Emerging Techniques)

By Material Type

- Concrete

- Sandstone

- Ceramics

- Metals

- Composite Powders

- Others

By Construction Type

- Building Construction (Residential, Commercial)

- Infrastructure (Bridges, Roads, Public Utilities)

- Industrial Facilities

- Others

By End User

- Residential Sector

- Commercial Sector

- Industrial Sector

- Public Infrastructure

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting