What is the Hydraulic Intensifiers Market Size?

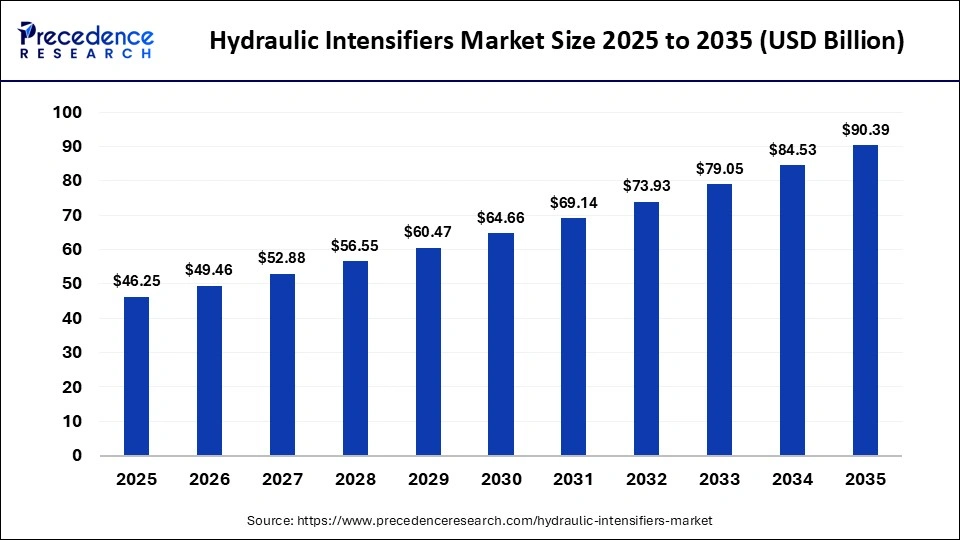

The global hydraulic intensifiers market size accounted for USD 46.25 billion in 2025 and is predicted to increase from USD 49.46 billion in 2026 to approximately USD 90.39 billion by 2035, expanding at a CAGR of 6.93% from 2026 to 2035. The market is rapidly growing as industries increasingly demand high-pressure fluid systems for efficient, precise, and compact hydraulic operations across manufacturing, construction, and energy sectors.

Market Highlights

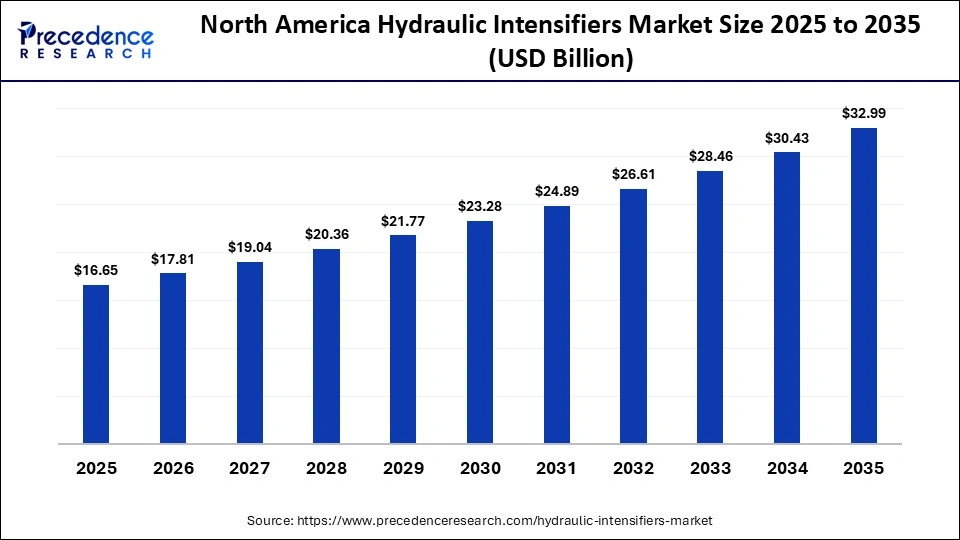

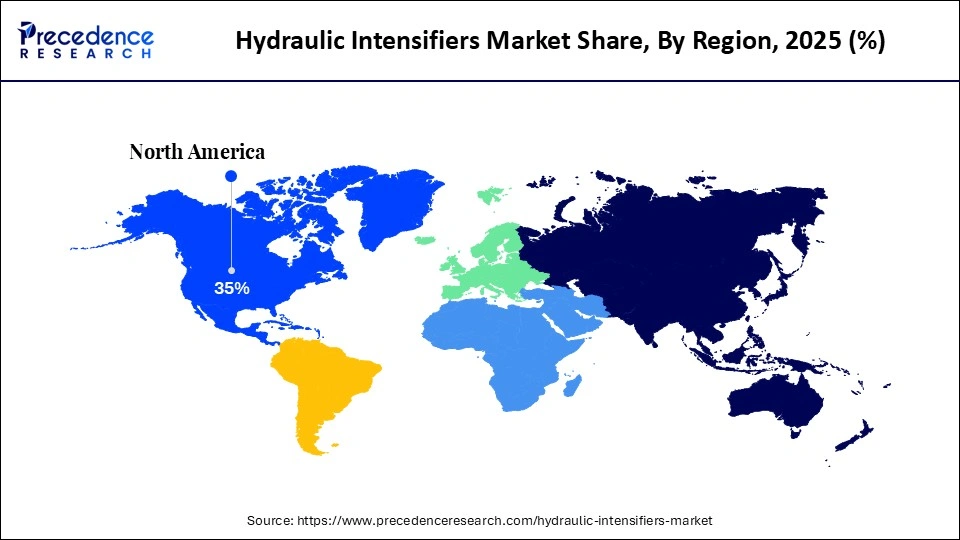

- North America held the largest market share of 35% in 2025.

- Asia Pacific is expected to grow at the fastest CAGR of 7.2% during the foreseeable period.

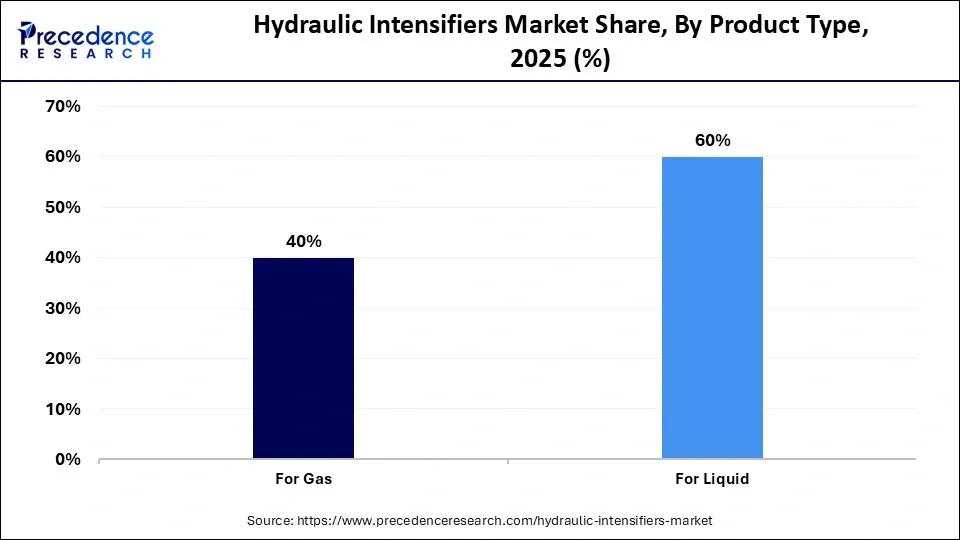

- By type, the for liquid segment held the largest market share of 60% in 2025.

- By type, the for gas segment is expected to grow at the fastest CAGR of 5.9% during the forecast period.

- By end user, the construction industry segment held the largest market share of 28% in 2025.

- By end user, the machine manufacturing segment is expected to grow at the fastest CAGR during the foreseeable period.

- By pressure range, the 2000-10000 psi segment dominated the market with around 45% share in 2025.

- By pressure range, the above 10000 psi segment is expecetd to grow at a CAGR of 6.0% in the coming years.

Market Overview

Hydraulic intensifiers are devices that boost fluid pressure by converting low‑pressure hydraulic energy into high‑pressure output using differential piston areas. They are essential in industrial systems requiring localized high pressure for testing, forming, clamping, and other precision tasks across sectors such as manufacturing, petrochemical, construction, and energy. Hydraulic intensifiers improve efficiency, enable compact system designs, enhance performance, and support automation in applications where central high‑pressure pumps are impractical. The market is currently driven by a strong focus on industrial automation and increasing infrastructure development projects that demand smarter, precision hydraulic tools.

Hydraulic Intensifiers Market Trends

- Manufacturers are turning from reactive to predictive maintenance models by embedding advanced sensors and IoT connectivity into intensifier units. This enables real-time telemetry and data analytics, allowing operators to optimize performance parameters and data analytics, allowing operators to optimize performance parameters and drastically mitigate the risk of unscheduled downtime.

- The growing demand for smaller, more efficient hydraulic intensifiers that can be directly integrated into machinery without occupying significant space, particularly for robotics and mobile equipment.

- The industry is focusing on developing eco-friendly and low-energy consumption intensifiers to comply with stringent environmental regulations and reduce operating costs.

- Increasing adoption of robotics, automated pick-and-place systems, and assembly lines in manufacturing is driving the demand for precise and high-performance hydraulic intensifiers.

- Large-scale infrastructure developments, particularly in the Asia-Pacific region, are boosting the demand for heavy-duty machinery that utilizes high-pressure hydraulics.

How is AI Influencing the Hydraulic Intensifiers Market?

The integration ofartificial intelligence is transforming the market by enabling predictive maintenance through real-time monitoring of pressure, flow, and temperature, which minimizes unplanned downtime and extends equipment lifespan. AI-powered analytics optimize system performance dynamically, improving energy efficiency and operational precision. Additionally, generative AI supports the design of compact, high-density intensifiers that deliver superior force-to-mass ratios, allowing manufacturers to achieve high-intensity output within smaller, more efficient footprints.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 46.25 Billion |

| Market Size in 2026 | USD 49.46 Billion |

| Market Size by 2035 | USD 90.39 Billion |

| Market Growth Rate from 2026 to 2035 | CAGR of 6.93% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Product, End Users, Pressure Range, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segment Insights

Product Type Insights

Why Did the For Liquid Segment Lead the Hydraulic Intensifiers Market?

The for liquid segment led the market while holding about 60% share in 2025. This is because of its widespread use in applications that require high-pressure fluid for processes such as industrial manufacturing, chemical production, and hydraulic testing. Liquids are nearly incompressible, making them superior for transmitting pressure efficiently. Rising integration of IoT, sensors, and automations has improved the precision and safety of liquid-based hydraulic systems, and rising investment in infrastructure, particularly in emerging regions fuel the demand for heavy machinery relying on this system.

The for gas segment is expected to grow at a 5.9% CAGR during the projection period. This is because of the increasing demand for high-pressure gas applications across industries such as energy, oil & gas, and testing equipment. Gas-based intensifiers offer advantages like lighter weight, compact design, and precise pressure control for pneumatic systems, making them suitable for specialized operations where liquid systems are less practical. Additionally, the shift toward clean, efficient, and environmentally friendly solutions is driving the adoption of gas intensifiers in emerging applications like hydrogen fueling, compressed air systems, and laboratory testing setups.

End User Insights

Why Did the Construction Segment Dominate the Hydraulic Intensifiers Market?

The construction segment dominated the market with a major share of 28% in 2025, as hydraulic intensifiers are a critical component for modernizing construction fleets. By delivering high-force operational efficiency within compact, space-saving designs, these devices allow machinery to tackle heavy-duty lifting and drilling without the cost of complete system overhauls. The shift toward IoT-integrated "smart" hydraulics further ensures real-time performance tracking and superior reliability in harsh environments. Ongoing advancements in these systems have improved site safety and productivity, making them indispensable for high-intensity urban developments.

The machine manufacturing segment is expected to grow at the fastest rate over the forecast period due to the rising demand for high-pressure systems in metal forming, forging, and stamping equipment, where precise and reliable force is critical. Hydraulic intensifiers help manufacturers achieve faster cycle times, improved product quality, and reduced energy consumption, making them essential for modern automated production lines. Additionally, the increasing adoption of advanced manufacturing technologies and Industry 4.0 solutions is driving the need for integrated, high-performance hydraulic systems in machine manufacturing.

The petrochemical segment is expected to grow at a notable rate during the foreseeable period, driven by the need for high-pressure systems in synthetic production and subsea drilling, enabling operations without expensive full-system overhauls. Their compact, retrofittable design allows easy integration into existing plants to boost localized pressures, while use in remotely operated vehicles and blowout preventers improves safety and efficiency in deep-water exploration.

Pressure Range Insights

What Made 2000-10000 psi the Leading Segment in the Market?

The 2000-10000 segment led the market with a 45% share in 2025 due to its versatility and ability to handle a wide range of industrial applications, including manufacturing, oil and gas, and automotive industries. This pressure range offers optimal performance for both high-intensity and precision applications, enabling efficient operation while maintaining cost-effectiveness and reliability. Additionally, it caters to the growing demand for hydraulic systems that require moderate to high pressures for tasks like material processing, testing, and heavy machinery operation.

The above 10000 psi segment is expected to grow at the fastest CAGR of 6.0% during the forecast period due to its increasing demand in high-performance industries such as aerospace, oil and gas exploration, and deep-sea drilling. These applications require extreme pressure levels for tasks such as hydraulic fracturing, subsea operations, and advanced testing systems, where higher intensities are crucial for ensuring optimal efficiency, safety, and reliability. The growing trend toward deep-water exploration, high-precision machining, and demanding energy production processes is driving the need for hydraulic intensifiers that can consistently handle pressures above 10,000 psi.

Regional Insights

How Big is the North America Hydraulic Intensifiers Market Size?

The North America hydraulic intensifiers market size is estimated at USD 16.65 billion in 2025 and is projected to reach approximately USD 32.99 billion by 2035, with a 7.08% CAGR from 2026 to 2035.

What Made North America the Dominant Region in the Hydraulic Intensifiers Market?

North America registered dominance in the market by holding the largest market share of 35% in 2025. This is mainly due to the shale gas boom and large-scale federal infrastructure investments, which demand high-pressure reliability for both unconventional drilling and urban upgrades. The regional push for industrial automation and eco-friendly manufacturing ensures that hydraulic systems are becoming smarter and more energy-efficient to meet modern regulatory standards.

There is a robust aftermarket and maintenance network that provides a stable foundation for growth, allowing aging fleets to be retrofitted with innovative, high-durability components. Ultimately, the synergy between technological leadership and resource expansion secures North America's position as a dominant force in the global market.

What is the Size of the U.S. Hydraulic Intensifiers Market?

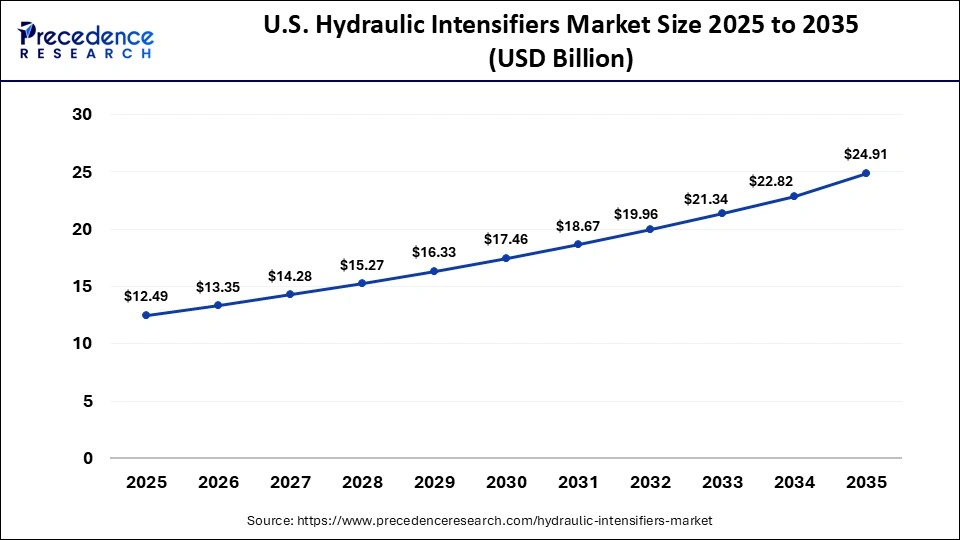

The U.S. hydraulic intensifiers market size is calculated at USD 12.49 billion in 2025 and is expected to reach nearly USD 24.91 billion in 2035, accelerating at a strong CAGR of 7.15% between 2026 and 2035.

U.S. Hydraulic Intensifiers Market Analysis

The market in the U.S. is growing due to a shift toward industrial automation and smart infrastructure, as factories integrate AI-driven robotics and IoT for real-time diagnostics. These compact intensifiers have become essential for achieving high-precision force in space-constrained environments. The region continues to lead this expansion, fueled by massive construction projects and a transition toward energy-efficient, sustainable machinery that complies with stricter environmental regulations.

Why is Asia Pacific Rapidly Expanding in the Hydraulic Intensifiers Market?

Asia Pacific is expected to grow at the fastest CAGR of 7.2% during the foreseeable period due to massive urbanization projects, which demand heavy-duty machinery for high-rise construction and deep-tunneling. The region's pivot toward Industry 4.0 has also accelerated the adoption of smart intensifiers that feature IoT sensors for real-time performance tracking and predictive maintenance in automotive and electronics manufacturing. Ultimately, strategic M&A activity and a focus on energy-efficient, low-noise designs are helping manufacturers overcome high maintenance costs while securing dominance in both the construction and emerging offshore energy sectors.

China Hydraulic Intensifiers Market Analysis

In China, the market is expanding due to a surge in industrial automation, manufacturing, and robotic applications, which drives the need for advanced hydraulic systems. There is a strong focus on developing more compact, energy-efficient, and lightweight intensifiers suitable for high-performance applications in the automotive and aerospace sectors, which further drive the market.

Why is Europe Experiencing Notable Growth in the Hydraulic Intensifiers Market?

Europe's rigorous transition toward Industry 4.0 and the EU green deal mandate systems that are both digitally connected and highly energy efficient. The integration of IoT-enabled smart intensifiers has revolutionized manufacturing and mining through predictive maintenance, while the region's expanding renewable energy sector, particularly hydropower, relies on these components for high-precision operational control. With ongoing industrial modernization across the continent, compact and low-waste hydraulic solutions are no longer optional but essential for meeting stringent environmental and workplace safety standards.

Germany Hydraulic Intensifiers Market Analysis

Germany's hydraulic intensifier market is evolving with the adoption of IoT-enabled smart hydraulic systems in the automotive and manufacturing sectors, enabling real-time predictive maintenance. The growing preference for compact, liquid-driven intensifiers is further boosting the market. Additionally, increased use of mobile hydraulic solutions in infrastructure and construction projects is driving the need for high-pressure, space-efficient components that deliver reliable performance.

How is the Opportunistic Rise of Latin America in the Hydraulic Intensifiers Market?

Latin America is expected to grow at a significant rate in the market, driven by the rising demand for high-pressure intensifiers for extracting minerals like copper and lithium. Furthermore, more regional manufacturers are now adopting Industry 4.0 and IoT-enabled systems to improve precision and meet new ESG-driven safety mandates. Ultimately, the surge in nearshoring and large-scale infrastructure upgrades is positioning Latin America as a high-potential hub for durable, energy-efficient hydraulic technology.

Brazil Hydraulic Intensifiers Market Analysis

Brazil's market is being driven by the country's large-scale infrastructure and mining activities, where high-capacity machinery demands robust, high-pressure solutions for deep-earth extraction and urban development. The manufacturing sector is rapidly adopting industrial automation, using energy-efficient intensifiers to modernize aging equipment and cut operational costs in agribusiness and oil & gas industries. Additionally, sustainability and reliability goals are fueling a replacement cycle, with companies shifting from traditional systems to compact, durable components that comply with global environmental standards.

What Drives the Middle East & Africa Hydraulic Intensifiers Market?

The Middle East & Africa hydraulic intensifiers market is being fueled by the booming extraction of battery minerals, which requires durable, high-pressure hydraulic systems for heavy-duty excavators and drilling equipment. Additionally, the region's rapid adoption of Industry 4.0 has led 62% of manufacturers to integrate AI-driven smart intensifiers for real-time predictive maintenance and improved energy efficiency. Combined with MEA's focus on economic diversification and sustainable energy, these trends are positioning the region as a key growth corridor for advanced, high-precision hydraulic technologies.

Saudi Arabia Hydraulic Intensifiers Market Trends

There is increasing demand for ultra-reliable, high-pressure hydraulic systems to support large-scale construction and mining operations. This is driving the adoption of liquid-based intensifiers, which deliver the necessary force for heavy industrial manufacturing and specialized oil and gas extraction. By incorporating IoT-enabled sensors and smart monitoring, regional operators are cutting downtime and meeting the high-efficiency standards required for modern smart city infrastructure.

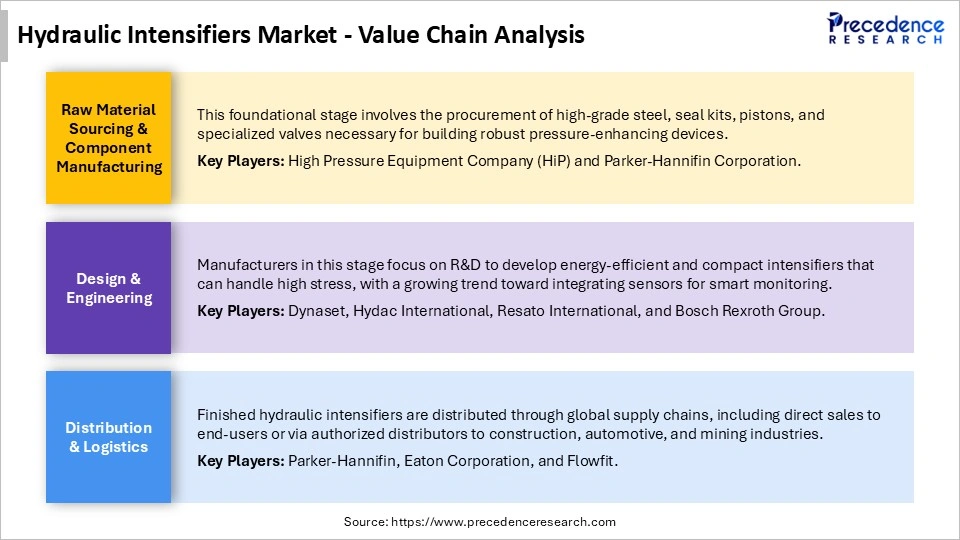

Hydraulic Intensifiers MarketValue Chain Analysis

Who are the Major Players in the Global Hydraulic Intensifiers Market?

The major players in the hydraulic intensifiers market include Parker Hannifin Corporation, Bosch Rexroth AG, Enerpac Tool Group, Haskel (Ingersoll Rand), Maximator GmbH, HYDAC International, jbj Techniques Limited, ROEMHELD, High Pressure Equipment Company, Herbert Hänchen GmbH, Air System Products, LLC, Jergens Inc, Scanwill Fluid Power ApS, Power Team SA, and WDS Components.

Recent Development

- In March 2025, Scanwill Fluid Power launched the MP-2100-CT intensifier with an NG6 connection and up to 3,200 bar pressure, responding to customer demand for smaller high-pressure power packs. The company is also expanding collaboration with sister company WTB Control to create a shared engineering department and strategic procurement function for growth, while focusing on customer visits, such as one in Spain, to enhance system understanding and integration.

Segments Covered in the Report

By Product

- For Gas

- For Liquid

By End Users

- Construction

- Petrochemical

- Power & Energy

- Auto Industry

- Machine Manufacturing

- Others

By Pressure Range

- Below 2000 psi

- 2000-10000 psi

- Above 10000 psi

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting