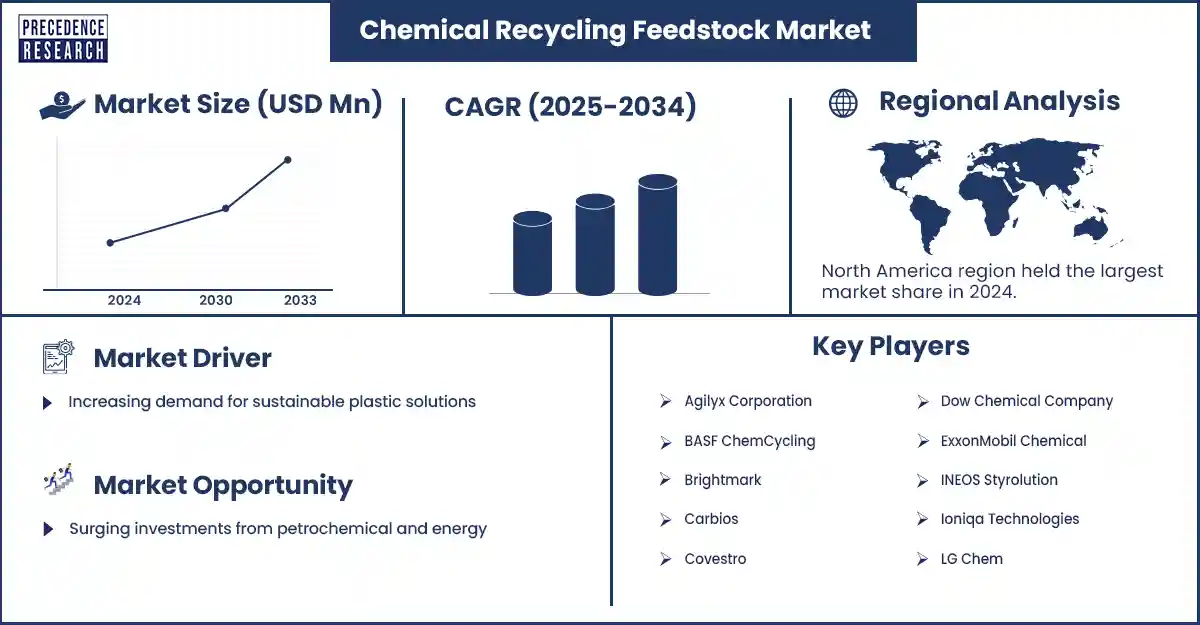

Chemical Recycling Feedstock Market Revenue and Forecast by 2033

Chemical Recycling Feedstock Market Revenue and Trends 2025 to 2033

The global chemical recycling feedstock market is growing with innovations, rising demand, and sustainable solutions in global recycling processes. The chemical recycling feedstock market is driven by increasing plastic waste management initiatives, circular economy adoption, and rising demand for sustainable raw materials.

Overview of the Chemical Recycling Feedstock

Chemical recycling feedstock is an emerging sector experiencing significant growth as a result of increased plastic waste generation, sustainability priorities, and new recycling technologies. Chemical recycling feedstock encapsulates a process that transforms plastic waste into similar feedstock including pyrolysis oil, syngas, and monomers, which can be repurposed into new plastics and chemicals. There are new (and emerging) regulations in place across multiple industries fuelling the introduction of circular economy initiatives and a need for low carbon resources in packaging, automotive, and various manufacturing sectors. The market is developing as an important tool to provide solutions around circular economy practices and move society away from reliance on virgin fossil resource.

Segmental Analysis

- By Feedstock Type –In the feedstock type segment, polyethylene (PE) predominates, owing to high availability from packaging waste and successful conversion into hydrocarbons.

- By Recycling Technology –In the recycling technology type segment, pyrolysis predominates, due to the encouraging efficiency of converting mixed plastic waste back into reusable oil, and overall efficiencies regarding thought leadership and new recycling technology, and it's overall place in a circular economy pathway.

- By Application- In the application segment, packaging continues to be dominant segment for its tremendous use in consumer goods (solutions for food, beverages, and variety of other scenarios), which provides a source of high amounts of recyclable materials.

- By Scale of Operation –For scale of operation, large-scale prevailing, as related to high volume operational and processing efficiency. Industrial player in these markets and technology provide great rationale for investment in recycling and overall advancement in technologies related to recycling systems/infrastructures.

Regional Analysis

North America is the leading region in chemical (feedstock) recycling and has a dense cluster of polymers and petrochemical players, complimentary corporate commitments to recycled content, and policy incentives that lower commercial risk for advanced-recycling projects. The existence of large pilot commercial plants, developed collection/sorting infrastructure, and proximity to technology developers all shorten commercialization timeframes and improve feedstock quality, enabling North America to capture high-value offtake and investments in 2024–25.

Asia Pacific, rapidly emerging as the fastest-growing region, continues to expand in response to strong plastics consumption, growing industrial capacity, and public/private funding. Government and company investments are being made for new crackers, storage, and logistics to secure cheaper feedstocks and advance circularity, while upstart regional players jump in with scale-up projects and partnerships—all leading to APAC surpassing and announcing projects and capacity additions. Current manufacturing growth and policy momentum drive this growth.

Chemical Recycling Feedstock Market Coverage

| Report Attribute | Key Statistics |

| Quantitative Units | Revenue in USD million/billion, Volume in units |

| Largest Market | North America |

| Base Year | 2024 |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa |

Chemical Recycling Feedstock Market Key Players

- Agilyx Corporation

- Brightmark

- Loop Industries

- Plastic Energy

- Renewlogy

- Carbios

- Ioniqa Technologies

- BASF ChemCycling

- Dow Chemical Company

- ExxonMobil Chemical

- LyondellBasell Industries

- Shell Chemicals

- TotalEnergies

- Versalis (Eni)

- SABIC

- Covestro

- INEOS Styrolution

- Mitsubishi Chemical Corporation

- LG Chem

- Reliance Industries

Recent Developments

- In March 2025, OMV has successfully launched its ReOil® plant to transform end-of-life plastics into circular feedstocks which reduce CO2 emissions by up to 34% compared to plastic waste incineration. (Source: https://www.omv.com)

Get this report to explore global market size, share, CAGR, and trends, featuring detailed segmental analysis and an insightful competitive landscape overview @ https://www.precedenceresearch.com/sample/6966

You can place an order or ask any questions, please feel free to contact us at sales@precedenceresearch.com |+1 804 441 9344