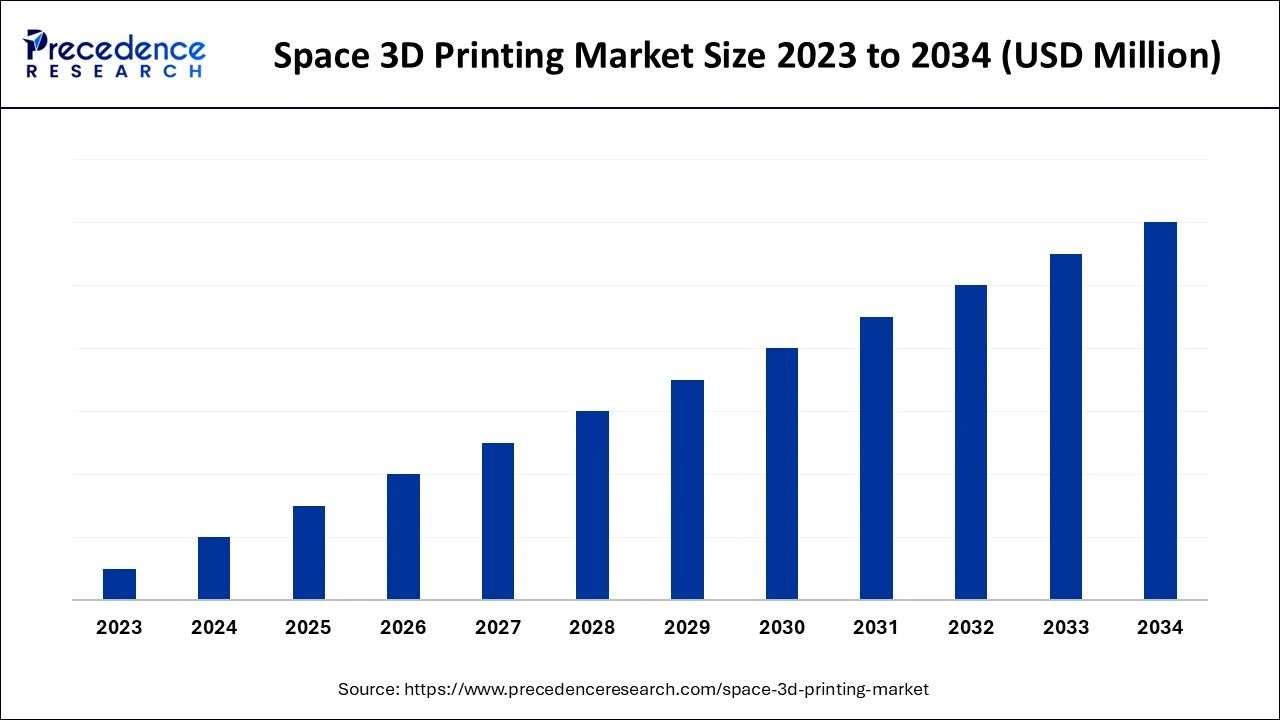

Space 3D Printing Market Size and Forecast 2025 to 2034

The global space 3D printing market is projected to grow significantly from 2025 to 2034, driven by advancements in housing, infrastructure, tools, and spare parts. The rising advancements in building housing, infrastructure, tools, and spare parts, when needed for space exploration, potentially increase the demand for the space 3D printing market.

Space 3D Printing Market Key Takeaways

- North America dominated the space 3D printing market in 2024.

- Asia Pacific is expected to witness the fastest growth in the market during the forecast period.

- By offering, the hardware segment contributed the largest market share in 2024.

- By offering, the software segment is predicted to witness significant growth in the market over the forecast period.

- By technology, the stereolithography (SLA) segment led the global market in 2024.

- By technology, the selective laser sintering (SLS) segment will witness significant growth during the forecast period.

- By application, the satellite segment accounted for the biggest share of the market in 2024.

- By end user, the government agency segment dominated the market in 2024.

- By end user, the research institutes segment expected significant growth during the predicted period.

How is AI Changing the Space 3D Printing Market?

The integration of artificial intelligence in the space 3D printing market enables engineers to rapidly design and print the required parts and equipment on Earth and in space. With the help of AI-driven technology, large-scale structures such as space stations, solar power arrays, and spacecraft components can be manufactured directly in space. The integration can dramatically reduce the cost and complexity of launching heavy and bulky material from Earth. Moreover, AI can optimize resource use and ensure materials' efficiency in the manufacturing process.

- In October 2024, Freeform, a former SpaceX engineer, took metal 3D printing into the AI era. The founder of this start-up aims to combine supercomputing with real-time process control to rewrite the rules of manufacturing in aerospace, defense, and many more. The freeform has received USD 14 million in funds from NVIDIA, NVentures, and AE Ventures.

Market Overview

Space 3D printing is an advanced technology for producing spare parts, tools, and even new spacecraft components in orbit. This ability provides significant potential to improve long-duration space missions. This process, also known as additive manufacturing, allows space engineers to design and print product prototypes in a short period compared to traditional fabrication methods. NASA has achieved considerable expenditures in space 3D printing. They have tested the 3D printer of the International Space Station (ISS) and formulated a plan to employ 3D printing in constructing habitats on Mars.

- In January 2024, Airbus developed their first metal 3D printer for space for the European Space Agency, which will soon be tested aboard the Columbus module of the International Space Station (ISS).

Space 3D Printing Market Growth Factors

- Long-duration space mission: The ability to manufacture essential tools or parts when required provides a useful asset for long-term trips to destinations such as the moon or Mars. These factors increase the adoption of space 3D printing.

- Rapid prototyping: With the help of a 3D printer, a designer and inventor can quickly transform digital designs into functional models. This eliminates the traditional method, which includes mol-making, casting, or CNC machining.

- Customization: 3D printing allows creators to cater to individual preferences, and the consumer has the ability to create as required which also makes mass customization feasible.

- Reduce tooling cost: 3D printing eliminates the need for expensive molds and tooling. This cost-effective approach standardizes production and encourages creators with small businesses.

- Geographical independence: 3D printing breaks the geographical boundaries. The availability of a printer and suitable material is only required to manufacture anything, anywhere.

Market Scope

| Report Coverage | Details |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Application, Offering, Technology, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East, & Africa |

Market Dynamics

Driver

Efficient space exploration

The creation of rapid prototypes is essential in the fast-paced world of space exploration for testing and iterating designs quickly. 3D printing allows engineers to create prototypes on-site, significantly reducing the time and costs associated with traditional manufacturing methods. Additionally, numerous other factors driving the space 3D printing market provide an easy, load-free, and innovative opportunity to explore the space. The lightweight and limitless design flexibility make 3D printing demanding; this technology allows the manufacturing of components directly in space, which reduces the need for transporting heavy payloads from Earth.

Restraint

High Initial Cost

The primary challenge for the space 3D printing market is the high initial investment required for high-quality 3D printers and materials. However, the technology is becoming more affordable with time, but professional-grade 3D printers can still be prohibitively expensive for small and medium-scale enterprises (SMEs). To mitigate this issue, space companies can partner with contract manufacturers, which will provide access to businesses with advanced 3D printing technology with the need for significant upfront investment.

Opportunity

Cutting-edge Innovations

As technologies are advancing, the application of the space 3D printing market is increasing. The advancement in 3D printing technology supports the utilization of on-the-spot resources, which is an essential part of future space exploration. The advanced materials used for prototype creation exist and are still being developed by using locally available materials to build 3D infrastructures.

Space 3D printing technology is capable of reducing the expense of transporting construction material from Earth to space. For instance, carbon nanotubes are used to create even stronger and more lightweight structures. Furthermore, space research is expected to be carried out using material obtained from asteroids or the lunar surface.

- In August 2024, the NASA Marshall Space Flight Center collaborated with Jacobs Space Exploration Group, has awarded 3DCERAM Sinto, Inc. a contract for a C1000 FLEXMATIC ceramic 3D printer and will add 3DCERAM as an official partner working with NASA. This printer will create prototypes of small and large parts and components which will be tested in space and other harsh environments.

Offering Insights

The hardware segment contributed the largest space 3D printing market share in 2024. The evolution of this segment is observed due to fast, more reliable production capabilities. The materials used for 3D printing are metal, polymer, and ceramic. Widely used materials are metal and polymers. Metals are cheaper than the Powder Bed Fusion (PBF) system, and polymers are ideal for technologies such as selective laser sintering, multi-jet fusion, and stereolithography.

The software segment is predicted to witness significant growth in the space 3D printing market over the forecast period. The expansion of this segment is due to the utilization of the software segment to prepare and convert 3D models for 3D printing. One of the commonly used software is Autodesk Fusion. It is widely used in healthcare for tailored prosthetics, in automotive and aerospace for prototypes and lightweight structures, and in architecture for building models and components. The software enhances the process by streamlining designs, collaborating, and fabricating workflow.

Technology Insights

The stereolithography (SLA) segment led the global space 3D printing market in 2024. The stereolithography process uses ultraviolet light to cure liquid resin into solid objects. The application of SLA is observed in international space stations and commercial airlines. The primary role of SLA in space exploration is fabricating lightweight parts with intricate geometric shapes and assisting in prototyping, testing, and design validation.

- In January 2024, Sahajanand Technologies Private Limited, unveiled its latest 3D printing product – the SLS 3D printer, at IMTEX 2024 exhibition in Bengaluru. The product includes Fused Deposition Modelling (FDM) and Stereolithography (SLA) which will be an addition to the industrial field.

The selective laser sintering (SLS) segment will witness significant growth in the space 3D printing market during the forecast period. The growth of this segment is due to its trustworthy property to engineers and manufacturers across different industries and its ability to produce strong and functional parts. Recent advancements in machinery, material, and software have made SLS printing accessible to a wide range of businesses, encouraging companies to use these tools.

Application Insights

The satellite segment accounted for the biggest share of the space 3D printing market in 2024. The dominance of this segment is due to the manufacturing of lightweight and optimized structural parts. The key elements of the satellite structure are structural panels and supports, which are printed using fiber-reinforced composite material such as carbon or glass, which provides high strength while reducing weight. The complex internal structures are also created using 3D printing, which optimizes panel rigidity and lightness.

End-use Insights

The government agency segment dominated the space 3D printing market in 2024. NASA and the European Space Agency (ESA) are both renowned government agencies that are utilizing 3D printing in space. NASA has been exploring 3D printing on the International Space Station since 2014, collaborating with other space agencies, universities, and private companies. Various government and private organizations are heavily investing in the development of space applications.

The research institutes segment expected significant growth in the space 3D printing market during the predicted period. The growth of this segment is observed due to the development of new research institutes to promote understanding to engineers. This segment is also growing due to collaboration and partnership with other institutes and companies to raise funds and create a discovery.

Regional Insights

North America dominated the space 3D printing market in 2024. The U.S. is the global leader in 3D printing in space with its cutting-edge innovations and substantial investment in technology. From this region, the United States is particularly leading the market. The expansion is observed due to government initiatives such as NASA and other government agencies investing in 3D printing in space to advance space exploration and zero-G technology.

Asia Pacific is expected to witness the fastest growth in the space 3D printing market during the forecast period. The growth in this region is due to the increasing adoption of aerospace and space industries. The market is heavily driven by countries such as China, India, and Japan where the adoption of aerospace 3D printers is observed in large quantity.

Space 3D Printing Market Companies

- Relativity Space

- Blue Origin

- SpaceX

- ASTA SPACE

- Northrop Grumman

- 3D Systems

- Virgin Orbit

- Rocket Lab

- ABL Space Systems

- Axiom Space

- United Launch Alliance

- Orbex

Latest Announcements by Industry Leaders

- In September 2024, Elon Musk, CEO of SpaceX, said, “It is not widely understood that SpaceX has the most advanced 3D metal printing technology in the world.”

- Gwenael Aridon, lead engineer at Airbus Space Assembly, says, “The metal 3D printer will open new manufacturing opportunities in orbit, including the ability to produce load-bearing structural parts that will be more resilient than the plastic equivalent. Astronauts can directly fabricate tools such as spanners or mounting interfaces that can connect multiple parts. The flexibility and rapid availability of 3D printing in space will greatly improve astronaut autonomy.”

Recent Developments

- In June 2024, Agnikul Cosmos, an India-based private aerospace manufacturing company, launched the nation's first 3D-printed rocket engine. This initiative reduces the time and cost associated with building rockets and boosts the country's spacefaring capabilities.

- In October 2024, Rocket Lab, a publicly traded aerospace manufacturer, commenced using a 90-tom 3D printer to build the largest carbon composite rocket structures in history. The company's goal is to combine carbon composite technology, additive manufacturing, and autonomous robotics to design and build large-scale aerospace components to support Neutron's launch cadence and Electron and Carbon composite structures.

Segments Covered in the Report

By Application

- Satellite

- Spacecraft and Launch Vehicles

- Rovers

- Space Stations

By Offering

- Hardware

- Software

- Services

By Technology

- Stereolithography (SLA)

- Continuous Liquid Interface Production (CLIP)

- Fusion Deposition Modeling (FDM)

- Direct Metal Sintering (DMLS)

- Selective Laser Sintering (SLS)

- Others

By End-use

- Government Agency

- Research Institutes

- Commercial

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting