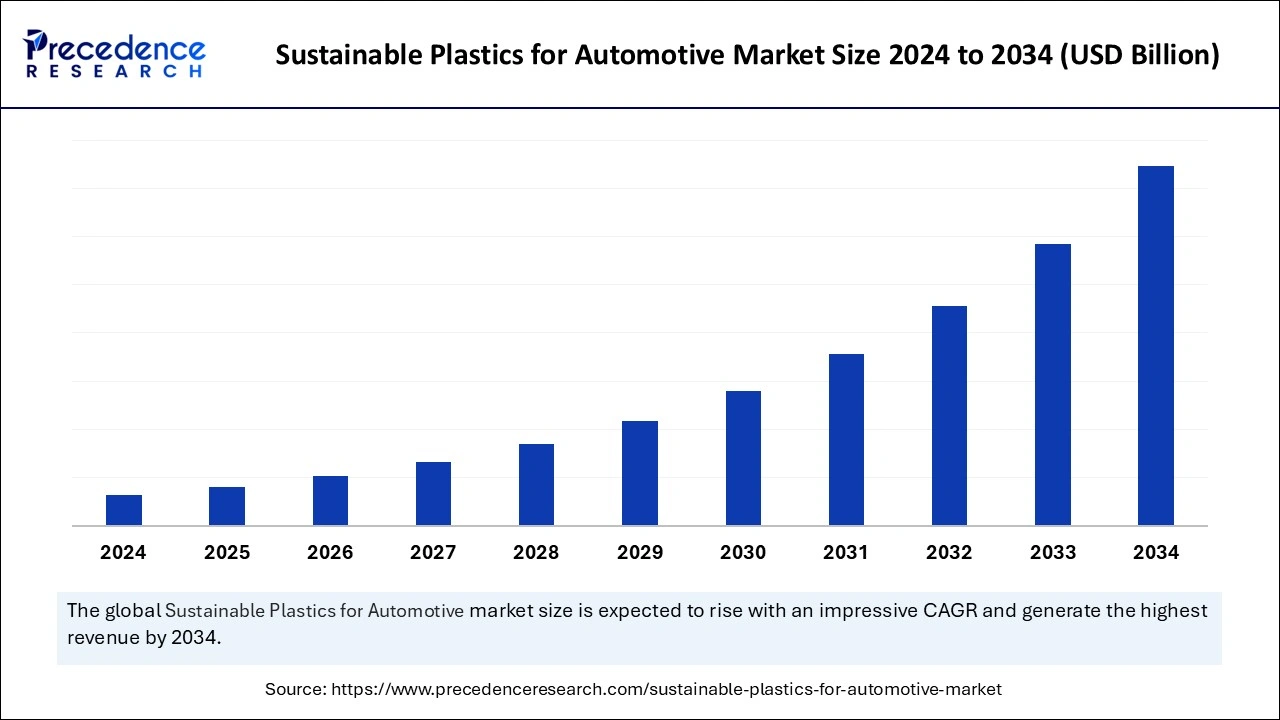

Sustainable Plastics for Automotive Market Size and Forecast 2025 to 2034

The global sustainable plastics for automotive market is experiencing strong growth, driven by eco-friendly innovations, increasing demands, and industry-wide sustainability efforts. The increasing adoption of sustainable solutions for reducing carbon footprints in the environment by the automotive industry accelerates the growth of the market.

Sustainable Plastics for Automotive Market Key Takeaways

- North America dominated the global sustainable plastics for automotive market in 2024.

- Asia Pacific expects significant growth in sustainable plastics for the automotive market during the forecast period.

How Can Artificial Intelligence (AI) Impact the Sustainable Plastics in Automotive Market?

Integrating Artificial Intelligence into automotive operations and manufacturing processes has contributed to further accelerating sustainable plastics for automotive market growth. AI can also be used to mitigate sustainable goals in the automotive industry. AI can provide enhanced visibility to the customer about the carbon impact of their product. AI enhances the interior features of vehicles. The evaluation of electrification and autonomous cars further strengthens the integration of AI into the automotive industry.

- In November 2024, Martur Fompack International (MFI), a leading manufacturer of seating and interior systems for some of the world's largest automakers, launched an AI-driven system designed to allow customers to visualize the material that they want to add to the interior of the vehicle and provide the quantification of carbon footprint reductions which are done by choosing the right material that company pulled from the plastic waste by the world's oceans.

Market Overview

Sustainable or recycled plastics are widely used in different industrial applications. In the automotive industry, there are a number of plastics utilized during the manufacturing processes. The four major polymers, polyurethane, polypropylene, PVC, and polyamides are highly used in automobile manufacturing. The rising inclination towards environmental safety and sustainability in the automobile industry for reducing waste drives the demand for recycled plastics. The use of recycled plastic also helps minimize the demand for new raw materials for auto parts making, which also helps in mitigating the challenge of expanding carbon footprint on the environment.

Sustainable Plastics for Automotive Market Growth Factors

- Increasing awareness regarding recycling material: The rising trend towards recycling material when it touches the end of its lifecycle. The recycling of plastic material benefits the environment by reducing carbon footprints and preventing excess global warming.

- Electrification of vehicles:The transformation of the automotive industry with the rise in the electrification of vehicles accelerates the adaptation of sustainable plastic for the manufacturing of lightweight and fuel-efficient vehicles.

- Government intervention: The government's rising intervention in the pollution-free environment is implementing strategies and policies for the recycling of products to reduce global warming.

Market Scope

| Report Coverage | Details |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Increasing demand for the automotive industry

The increasing demand for the automotive industry worldwide, especially in economically developing countries, is due to the rising per capita of the people and the increasing expenditure on lifestyle maintenance. There is an increasing inclination towards plastic material in automotive manufacturing to enhance speed, efficiency, fuel efficiency, and others. Vehicle bumpers, interior panels, cable insulation, and engine covers are some of the important parts of the vehicle or automobile that can be made using plastic materials.

Plastic material provides lightweight capabilities, corrosion resistance, and increased tensile strength that helps automobile manufacturers achieve less carbon emission and fuel efficiency. The rising investment in automobile technologies and material adaptation to achieve enhanced efficiency and sustainability in vehicles contributes to the growth of sustainable plastics for automotive market.

Restraint

Lowered availability of professionals

The shortage of skilled professionals to operate advanced machinery used in the manufacturing of plastic car parts is one of the major challenges faced by automobile manufacturers. Additionally, the lowered availability of the material and cost of operation are collectively restraining the growth of sustainable plastics for the automotive market.

Opportunity

Growing awareness regarding sustainability

The rising concern about the rising global warming in the automotive consumer as well as in the manufacturers due to the increasing carbon emission by gasoline or petroleum vehicles boosts the advancements in the sustainable plastics for automotive market. The increasing use of sustainable plastics rather than metal in the manufacturing of automobiles helps in addressing different challenges such as material costs, environmental pollution, and resource conservation.

The rising focus on sustainability and more energy-efficient materials for automobile manufacturing, with the increasing inclination towards electric and lightweight vehicles, drives the growth opportunity towards sustainable plastics for the automotive market. There are a number of leading automobile players who are using recycled plastic material in the manufacturing of different auto parts, including:

- Ford, the leading automobile manufacturer in the United States, uses recycled plastics to make passenger seat cushions, and about 23000 tons of recycled plastic are used to make exterior parts of vehicles.

- The TSOP special recycled plastics developed by the Toyota Motor Corporation are used in the manufacturing of different automobile parts.

- Jaguar/ Hyundai uses super strong plastic material, which is made by the waste transformation in pyrolysis oil using a thermochemical process. Plastic is used in the development of the Jaguar I-Pace electric vehicle.

- The leading automobile player, Volvo, made a commitment that 25% of the plastics will be made from recycled materials by 2025. The player incorporates recycled fibers and plastics made from fishing nets and ropes used to make the interior of the Volvo SUV XC60.

Regional Insights

North America dominated the global sustainable plastics for automotive market in 2024. The growth of the market is attributed to the rising demand for the automotive industry and the rising evaluation of electric vehicles in the regional countries, driving the demand for lightweight raw materials for the manufacturing of vehicles to reduce fuel consumption, speed vehicles, and efficiency, and enhance features drive the adoption of the plastic material in the automotive industry.

The rising presence of the leading automobile players and their manufacturing units in the United States contributes to the expansion of the market. The increasing adoption of electric and autonomous vehicles by the U.S. population is driving the demand for lightweight vehicles. Also, there is increasing awareness among the consumers and manufacturers of the automotive industry for waste management, reducing carbon emissions, adaptation of recycled material usage, and sustainability in automotive operations.

- The sales of lightweight vehicles in the United States were 11.5 million units in 2022, and as per the report on Autos Drive America, 4.9 million vehicles were produced by international automakers in the United States in 2023.

- The United States exported 1.6 million new light vehicles and 160,000 heavy and medium trucks, with USD 93.7 billion of automotive part exports in 2023.

Asia Pacific expects significant growth in sustainable plastics for the automotive market during the forecast period. The growth of the market is attributed to the rising government initiatives in the development of sustainability, and the increasing awareness in the industries regarding sustainable infrastructure development drives the adoption of sustainable plastics in different industries.

The expanding automotive industry in regional countries like India, China, and Japan, as well as further investment by the leading automotive manufacturers in expanding automobile manufacturing units, the growing population and the economic development in India and China, with the rising per capita income in the population, drive the demand for the automotive sector in the countries.

- The total production volume of passenger vehicles in India, including three-wheelers, two-wheelers, and quadricycles, was 27,73,039 units in September 2024. The annual production volume of automobiles in FY23 was 25.9 million vehicles. The automobile export from India stood at 47,61,487 in FY23.

- The automotive exports in China set a record high of 4.91 million vehicles in 2023. the automotive sales in China will be 30.09 million units in 2023.

- The Japanese automotive industry is one of the most important parts of the country's economy. Japan's automotive sales in the retail sector reached 18.36 trillion Japanese yen in 2023.

Sustainable Plastics for Automotive Market Companies

- Arkema SA

- BASF SE

- Borealis AG

- DuPont

- DSM Engineering

- Evonik Industries AG

- ExxonMobil Corporation

- LANXESS

- LG Chem

- LyondellBasell

Latest Announcement by Industry Leaders

- In June 2024, BASF is set to introduce its further achievements in the plastic journey at the Recycling and Sustainability Conference Europe (PRSE) 2024. The BASF provides mechanical recycling solutions for cleaning, sorting, processing, and the quality of recyclates.

Recent Development

- In April 2024, FORVIA automotive supplier's sustainable materials subsidiary MATERI'ACT launched the concept cars with integrating instrument and door panels manufactured with Ocean Bound Plastics (OBP). The doors and instruments are made of plastic material collected from oyster shells and Plastic Odyssey on beaches.

- In June 2024, Aimplas, the Spanish Plastics Technology Centre, started a new project named Surftop in collaboration with Prisma Soporte Industrial for research on the use of plastic material in automotive applications.

- In June 2024, Prism Worldwide introduced the IRX car mats, crafted from its Ancora C-1082 TPE; it is an advanced material with 50% recycled content found from end-of-life tires.

- In July 2024, LyondellBasell, the leading player in the chemical industry, launched its new Schulamid ET100 product line, a polyamide-based compound product made for automotive interior parts such as door window frames.

Segments Covered in the Report

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting