What is the Automotive Adhesives Market Size?

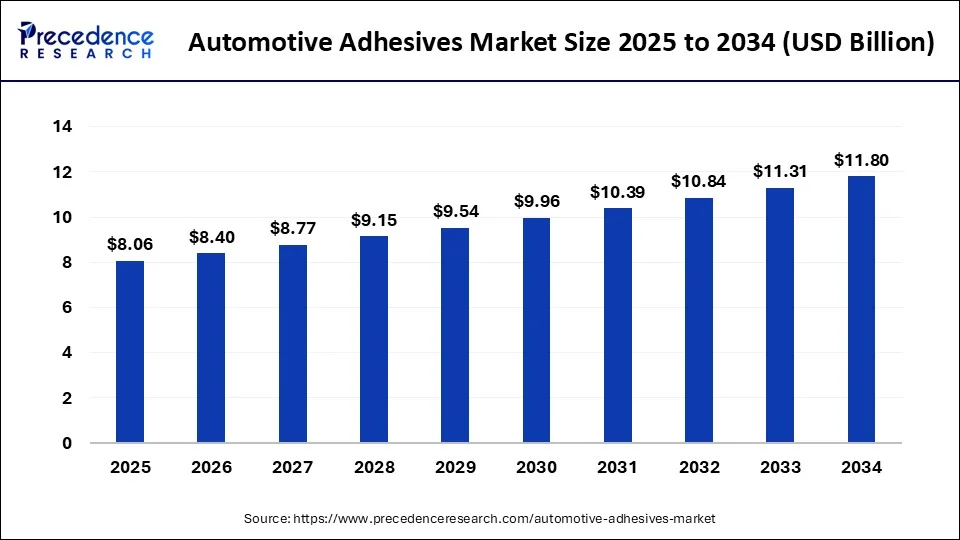

The global automotive adhesives market size is calculated at USD 8.06 billion in 2025 and is predicted to increase from USD 8.40 billion in 2026 to approximately USD 11.80 billion by 2034, expanding at a CAGR of 4.33% from 2025 to 2034. The need for automotive adhesives is being driven by the increase in vehicle production worldwide, especially in emerging nations.

Automotive Adhesives Market Key Takeaways

- The global automotive adhesives market was valued at USD 7.72 billion in 2024.

- It is projected to reach USD 11.80 billion by 2034.

- The automotive adhesives market is expected to grow at a CAGR of 4.33% from 2025 to 2034.

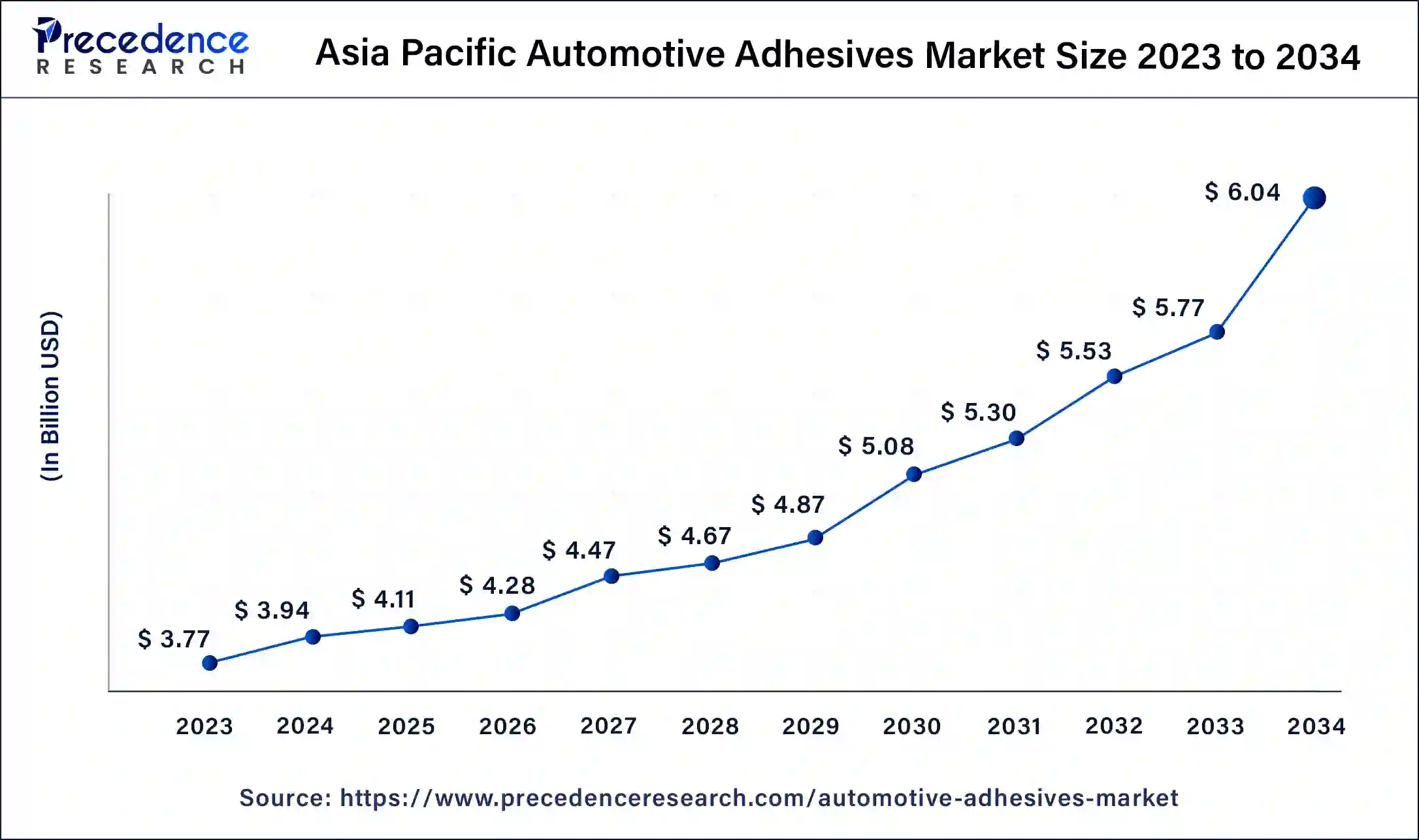

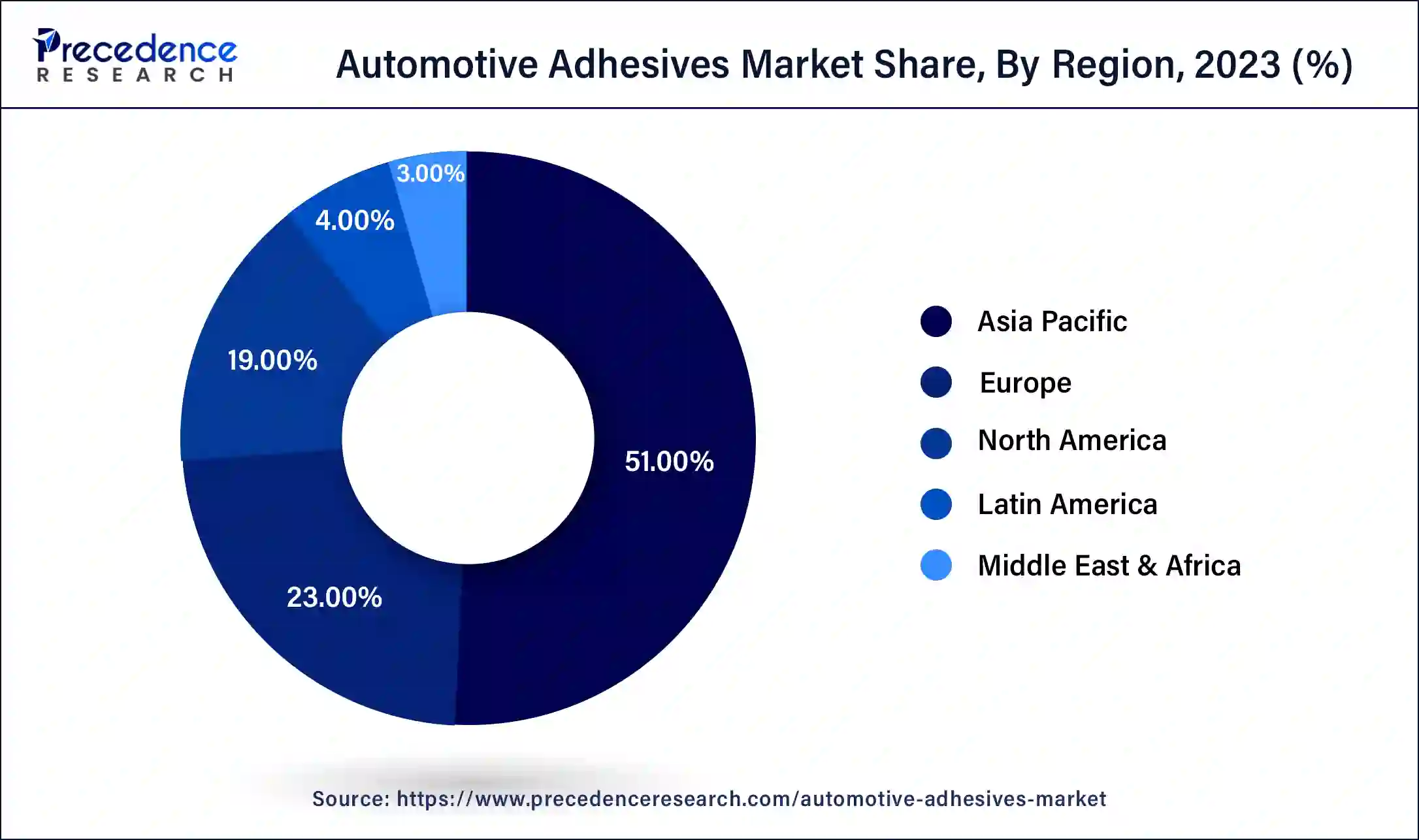

- Asia Pacific dominated the automotive adhesives market in 2024 and accounted for 51% revenue share.

- North America is expected to witness notable growth in the market over the forecast period.

- By technology, the reactive segment held the largest share of 63% in 2024.

- By technology, the water-based segment is expected to grow at the fastest rate in the market during the forecast period.

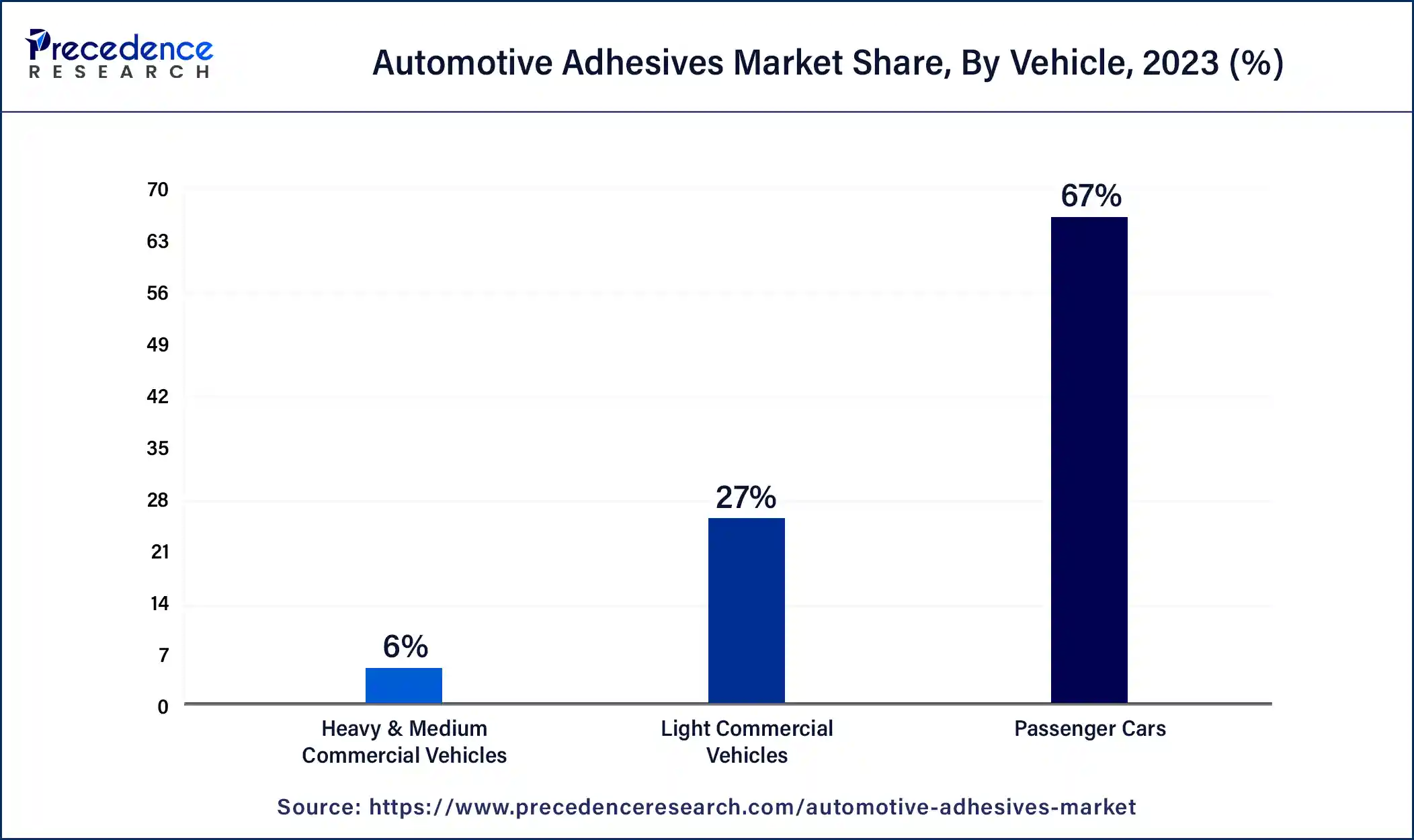

- By vehicle, the passenger cars segment led the global market with 67% revenue share in 2024.

- By vehicle, a commercial vehicle segment is expected to witness rapid growth in the market over the forecast period.

- By function, in 2024, the bonding segment led the market.

- By function, the NHV segment is expected to grow at the fastest rate in the market during the forecast period.

- By application, the body in the white segment dominated the market in 2024 with a revenue share of 34%.

- By application, the exterior segment is expected to witness rapid growth in the market over the forecast period.

What are the Significant Advantages of the Automotive Adhesives?

Driven by the need for lightweight materials, better vehicle performance, and higher safety regulations, the automotive adhesives market is a significant sector of the automotive industry. Because of the strict environmental rules pushing for lightweight materials, the industry is likely to rise rapidly. There are several kinds of adhesives used in automobiles, including tapes, sealants, and structural adhesives (epoxy, acrylic, and polyurethane). When joining disparate materials, such as metals, composites, and plastics, structural adhesives are especially useful because they reduce vehicle weight and enhance crash safety.

The development of adhesive technologies, rising car production, and the trend toward electric vehicles (EVs) have all contributed to the steady growth of the automotive adhesives market. These adhesives are utilized in a number of automotive applications, including glass bonding, under-the-hood components, exterior trimmings, body in white (BIW), interior assembly, and so on. Particularly for BIW applications, structural adhesives' great strength and longevity are advantageous.

The main goals of adhesive formulation innovations are to improve cure periods, binding strength, and substrate compatibility. Adhesives with enhanced corrosion resistance and resilience to extreme temperatures are likewise becoming more and more popular. One significant trend influencing the automotive adhesives market is the growing use of lightweight materials (such as aluminum and composites) to increase fuel economy and lower emissions. Furthermore, the increasing need for specialty adhesives that can satisfy the particular needs of EV assembly is being influenced by the expanding popularity of electric vehicles.

Market Trends

- In July 2025, the opening of an Initial Public Offering (IPO) was announced by Sellowrap Industries Limited, which is a Mumbai-headquartered manufacturing company, leading OEMs across automotive, non-automotive, and white goods on 25th July 2025. 29th July 2025 will be the closing date for the issue, where the listing will be proposed on 1st August 2025 on the NSE EMERGE platform. A fresh issue of 36,48,000 Equity Shares is included in the IPO of the company. Being recognized as the trusted manufacturer of both adhesive and non-adhesive processed components, Sellowrap Industries has been evolving for over four decades.

- In July 2025, as per the hedge funds, the Dover Corporation is being recognized as one of the best manufacturing stocks to buy. A new Side-by-Side/SBS Dispensing Cartridges of Techcon were launched by Dover Corp in June. To target different industries such as automotive, industrial, electronics, and medical device, these cartridges will provide precise metering of 2-component adhesives as well as sealants.

Automotive Adhesives Market Growth Factors

- The demand for automotive adhesives is increased by rising vehicle production and sales worldwide, particularly in emerging economies. These adhesives play a crucial role in the assembly of different car parts.

- The automotive adhesives market expansion is fueled by ongoing developments in adhesive technologies, such as the creation of high-performance adhesives with improved bonding, durability, and resistance to environmental variables.

- The automobile industry's drive for lighter vehicles to improve fuel economy and cut emissions has resulted in a rise in the use of adhesives since they offer strong bonding without significantly increasing weight.

- Adhesives are used instead of traditional mechanical fasteners because they can reduce vehicle weight and increase fuel efficiency, which is required by stricter environmental standards.

- The automotive adhesives market is expanding rapidly as a result of the rising popularity of electric vehicles, which call for specific adhesives for battery assembly and other parts.

- Specialized adhesives are required because of consumer desire for more comfortable and safe features in cars, such as advanced driver-assistance systems (ADAS) and noise-dampening technology.

- The growth of automotive aftermarket businesses and original equipment manufacturers (OEMs) satisfies the ongoing need for automotive adhesives for both new car manufacturing and maintenance/repair.

- The demand for automotive adhesives is driven by rising vehicle ownership and production in emerging nations due to rapid economic growth and urbanization.

- The automotive adhesives market is growing as a result of strategic alliances and collaborations between major industry participants to provide cutting-edge adhesive solutions and increase their market share.

Automotive Adhesives Market Outlook:

- Global Expansion: The market is propelled by a rise in demand for lighter multi-material bodies, the requirement for high-performance solutions for EV battery sealing, and the push for faster-curing technologies.

- Major Investor: In late 2024, Sika AG, a Swiss specialty chemicals company, inaugurated a new adhesives and sealants plant in Pune, India.

- Startup Ecosystem: Gecko Materials, a startup, has evolved a bio-inspired, highly reusable dry adhesive described as "the next industrial Velcro".

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 11.80 Billion |

| Market Size in 2025 | USD 8.06 Billion |

| Market Size in 2026 | USD 8.40 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 4.33% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Technology, Vehicle, Function, Application, Sales Channel, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa |

Market Dynamics

Driver

Increasing adoption of advanced materials

Because innovative materials are being used more often, the automotive adhesives market is undergoing a major transition. The desire for increased productivity, sustainability, and efficiency in the car industry is what is causing this change. Automakers are always looking for ways to lighten vehicles in order to increase fuel economy and lower emissions. In order to accomplish these objectives, lightweight materials like carbon fiber, aluminum, and composites must be used, which is made possible by advanced adhesives.

Advanced adhesives offer superior bonding strength, longevity, and resistance to environmental conditions. These characteristics are essential to guaranteeing the safety and structural integrity of contemporary automobiles. Innovative manufacturing techniques like multi-material bonding and modular assembly are made possible by the use of sophisticated adhesives. These procedures improve overall vehicle quality, expedite production, and lower expenses.

Restraint

High costs of advanced adhesives

More expensive, specialized raw ingredients are frequently needed in the manufacturing of sophisticated adhesives. These materials have been developed to deliver exceptional performance, including chemical resistance, high strength, and resistance to extreme temperatures. More expensive, complex manufacturing procedures might be needed to produce advanced adhesives. These procedures guarantee that the adhesives fulfill the strict requirements needed for automotive applications, including performance under pressure and durability. Costs are increased by complying with safety regulations and standards. In order for advanced adhesives to comply with environmental and safety laws, lengthy testing and certification procedures may be necessary. Because economies of scale aren't fully achieved, high-performance adhesives are sometimes produced in lower quantities than more typical adhesives, which raises the cost per unit.

Opportunity

Automotive electronics and interior

Due to the growing need for strong, lightweight cars, the automotive adhesives market is expanding significantly. Automotive adhesives are essential for improving the functionality and design of car interiors and electronics. Electronic components are mounted on circuit boards using adhesives to guarantee their functionality and longevity. The attachment of sensors and cameras which are necessary foradvanced driver assistance systems (ADAS) and autonomous driving technologies requires adhesives. Adhesives offer endurance and clarity when attaching touchscreens and display panels together. Adhesives give inside moldings and trim a smooth, long-lasting bond, improving the vehicle's aesthetic appeal. When compared to conventional mechanical fasteners, adhesives can reduce the weight of vehicles, which improves performance and fuel efficiency.

Technology Insights

The reactive segment held the largest share of the automotive adhesives market in 2024. Adhesives that cure through chemical reactions are included in the reactive category of the market. These adhesives are utilized in a variety of automobile applications and usually offer strong, long-lasting bonding. Used to preserve the longevity and visual quality of dashboards, panels, and other interior parts by bonding them together. Used in bonding components that require strong adhesion and weather resistance, such as spoilers, bumpers, and other exterior trim. High-strength adhesives are replacing mechanical fasteners in vehicles due to growing demand for lighter vehicles that increase fuel efficiency and lower pollution. Reactive adhesives are essential for battery assembly and thermal control, two areas where the EV market is expected to grow.

The water-based segment is expected to grow at the fastest rate in the automotive adhesives market during the forecast period. Water-based adhesives, which emit less emissions and are more environmentally friendly, are becoming increasingly popular due to strict limits on volatile organic compounds (VOCs). Adhesives based on water are thought to be more environmentally friendly than those based on solvents. They lessen the impact that adhesive application and disposal have on the environment. The handling and application of these adhesives are generally safer, lowering the health risks for workers in the car manufacturing industry. Technological developments have improved the efficacy of water-based adhesives, enabling a greater range of automotive uses, such as soundproofing, bonding, and sealing. Compared to solvent-based adhesives, water-based adhesives are typically less expensive to use since they are simpler to clean up after and require fewer protective gear.

Vehicle Insights

The passenger cars segment led the global automotive adhesives market in 2024. One major area of focus is the passenger automobile segment. The use of adhesives in passenger cars improves the functionality, safety, and appearance of the car. Various sections of passenger cars, such as body panels, windshields, trim, and interior components, are joined together using adhesives. They contribute to lighter vehicles, increased fuel economy, and enhanced NVH (noise, vibration, and harshness) management. Regional differences exist in the need for automotive adhesives in the passenger car market. Expanding car sales and an expanding automotive production base are important considerations in Asia Pacific. Specialized adhesives are becoming more and more popular in North America and Europe due to strict safety regulations and advances in automotive technology.

A commercial vehicle segment is expected to witness rapid growth in the automotive adhesives market over the forecast period. The need for effective and long-lasting adhesives in a variety of commercial vehicle applications is driving the expansion of the commercial vehicle segment in the automotive adhesives market. Panels, frames, and other structural elements are bonded together with adhesives to increase the vehicle's strength and decrease its weight. The attachment of dashboards, moldings, and emblems, as well as interior trims, depends heavily on adhesives. The application of adhesive technologies in commercial vehicles is growing thanks to advancements like high-performance epoxy and polyurethane adhesives. The use of cutting-edge adhesives that improve vehicle performance is being fueled by growing requirements pertaining to fuel economy and vehicle security.

Function Insights

The bonding segment led the automotive adhesives market in 2024. These adhesives offer high strength and durability when attaching structural components. They are utilized in applications like body-in-white components, chassis, and structural reinforcements where load-bearing capacity is required. Adhesives are used to attach body panels and components, like roofs, fenders, and doors. These adhesives improve the vehicle's aerodynamics and appearance while assisting in the achievement of a seamless and smooth finish. Adhesives are used to bind car glass to the body of the vehicle. These are essential for installing and repairing windshields since they guarantee adequate sealing and safety features. Adhesives are used to attach dashboards, trim, and upholstery to interior components. These adhesives offer a superior polish and guarantee that interior components are firmly attached.

The NHV segment is expected to grow at the fastest rate in the automotive adhesives market during the forecast period. The NVH (noise, vibration, and harshness) segments of the automotive adhesives market are devoted to adhesives that are used to reduce noise, vibration, and harshness in order to enhance vehicle performance and comfort. Damping vibrations and obstructing sound transmission to reduce cabin noise. Reducing vibrations' negative effects on car parts in order to improve driving comfort and lifetime. Improving the strength and stiffness of several car components to reduce rattling and enhance ride quality overall. Products including polyurethane, epoxy, and silicone-based adhesives are frequently used in NHV adhesives; these adhesives are selected for their flexibility, damping capacity, and longevity. Lowering vibration and noise in places like floor panels, dashboards, and doors.

Application Insights

The body in the white segment dominated the automotive adhesives market in 2024. The term ‘body in white' in the automotive adhesives market describes adhesives that are used to assemble the car's body structure prior to painting. These adhesives offer strength and endurance when they are used to join structural components. They are essential for attaching components like the doors, side panels, and roof. Used to ensure a better fit and stop leaks between various automotive body elements by sealing joints and gaps. These are specialist adhesives with great strength and longevity that are used to join metal panels. Used to provide safety and structural integrity by adhering windshields and glass to the vehicle body. These adhesives contribute to a quieter ride by lessening noise and vibrations within the car.

The exterior segment is expected to witness rapid growth in the automotive adhesives market over the forecast period. The exterior divisions of the market usually comprise goods and applications intended for sealing and bonding vehicle exteriors. For car exteriors to be long-lasting, weather-resistant, and structurally sound, these sections are essential. Adhesives are used to join different body components, including fenders, doors, and hoods. Adhesives for side, rear, and windshield installation and sealing. Adhesives are used to join moldings, trim pieces, and bumpers to the body of the car. Headlights, taillights, and other exterior lighting components are secured with adhesives. Adhesives for attaching roof rails and sunroofs to one another. High-performance requirements for these adhesives must be met, including resistance to UV rays, harsh temperatures, and a variety of environmental factors.

Regional Insights

Asia Pacific Automotive Adhesives Market Size and Growth 2025 to 2034

The Asia Pacific automotive adhesives market size is exhibited at USD 4.11 billion in 2025 and is projected to be worth around USD 6.04 billion by 2034, poised to grow at a CAGR of 4.36% from 2025 to 2034.

How did the Asia Pacific Dominate the Automotive Adhesives Market in 2024?

Asia Pacific dominated the automotive adhesives market in 2024. The manufacturing of automobiles is booming throughout the area, especially in China, Japan, South Korea, and India. The need for automotive adhesives is rising in these nations due to rising car ownership rates. New adhesive technologies are making it possible to create adhesives that are stronger, lighter, and more long-lasting. This is essential for the production of modern cars, which prioritizes the use of lightweight materials to increase fuel economy and lower emissions. The region's governments are enforcing strict laws pertaining to fuel economy and car emissions. Automotive adhesives facilitate the use of lightweight materials and improve vehicle performance, which are critical components in meeting these standards.

Ongoing Automotive Technological Advances are Fueling North America

North America is expected to witness notable growth in the automotive adhesives market over the forecast period. The development of automotive technology, expanding vehicle production, and the growing desire for lightweight and fuel-efficient automobiles are the main drivers of the North American automotive adhesives market. Adhesives are being used more frequently than traditional attachment techniques like welding and riveting as a result of the drive for lighter automobiles that will increase fuel economy and lower emissions. In order to create lighter cars, adhesives are needed to join disparate components like metals and composites. The market is being driven by advancements in adhesive technologies, such as the creation of high-performance adhesives with improved bonding strength, endurance, and resistance to harsh environments.

Enhancement in the R&D Area Supporting Europe

Europe is expected to grow significantly in the automotive adhesives market during the forecast period. The growing adoption of electric vehicles in Europe is increasing the demand for automotive adhesives. At the same time, to accelerate their development, various investments as well as research and development are increasing. This promotes market growth.

UK

The demand for automotive adhesives is increasing in the UK for various purposes such as thermal management, battery assembly, etc. This, in turn, is increasing their production. Furthermore, due to stringent regulations, eco-friendly adhesives are also being developed.

Germany

The increasing use of electric vehicles in Germany is increasing the use of automotive adhesives. Moreover, the growing research and development are leading to new innovations that are supported by various investments.

Emphasis on Sustainability: South Korean Market Analysis

Nowadays, South Korea's leaders are fostering the development of more eco-friendly and high-performance approaches for electric vehicles (EVs), specifically water-based and bio-based adhesives, fast-curing polyurethanes, and structural adhesives for bonding dissimilar materials, such as aluminium and composites.

A Surge in Advanced Materials: U.S. Market Analysis

The U.S. market has been increasingly putting efforts into evolving advanced materials for automotive solutions, such as in September 2025, Huntsman Advanced Materials unveiled a new variety of Araldite epoxy adhesives that don't have intentionally added BPA. Alongside, Henkel has expanded its manufacturing facility in Brandon, South Dakota, in September 2025, to deliver high-performance materials for the electronics and EV industries.

Adoption in Lightweighting & Interiors is Boosting Latin America

The automotive adhesives market in Latin America is experiencing a notable growth, due to its rising steps towards the use of the bonding of lightweight materials, like plastics and carbon fiber. Additionally, mainly companies are implementing adhesives in automotive interiors to escalate aesthetics by allowing sleeker designs and protecting from environmental factors like UV radiation and moisture.

Brazil's Market Expansion

Brazil's automotive adhesives market is expanding rapidly, driven by increasing vehicle production and the demand for lightweight materials and electric vehicles. Strict safety regulations and the adoption of advanced materials are boosting the demand for high-performance adhesives, crucial for modern car manufacturing.

Diversified Technologies are Impacting the MEA

The MEA market is leveraging extensive technological variations in adhesives, including hot melt adhesives, as they can bond various materials in use, such as seats, interiors, and carpets. UV curing is employed to lower assembly times, and viscoelastic adhesives are increasingly utilised in the reduction of noise, vibration, and harshness (NVH) in vehicles.

Growth in GCC Countries

The GCC automotive adhesives market is witnessing substantial growth, fueled by government initiatives to diversify economies and rapid infrastructure development, encouraging automotive production. Significant investments in the automotive sector, including new assembly plants, are propelling the use of advanced bonding solutions across the region's automotive industry.

Automotive Adhesives Market: Value Chain Analysis

- Raw Material Sourcing

This mainly consists acquisition of base chemicals like acrylics, polyurethanes, epoxies, and rubber-based polymers.

Key Players: BASF SE, Evonik Industries AG, Huntsman Corporation, etc. - Distribution to Dealers and OEMs

They can be distributed via distinct supply chains, which usually encompass a mix of direct sales from significant manufacturers to OEMs and a network of specialized distributors for the aftermarket.

Key Players: 3M, Sika, Bostik, etc. - Aftermarket Services and Spare Parts

The market focuses on repair, maintenance, and replacement of bonded or sealed components, whereas spare parts are incorporated into the adhesives themselves, along with related application tools and repair kits.

Key Players: Pidilite, Loctite, Permabond, etc.

Key Players Offerings:

- Henkel & Co. KGaA- A vital leader offers diverse structural and non-structural bonding solutions for vehicle assembly, lightweighting, and crash resistance.

- Bostik S.A.- They mainly facilitate products for bonding interior electronic devices, sealing and glazing windshields, bonding trim and badges, and general automotive assembly.

- 3M Company- A major player leverages primers and activators to expand adhesion and adhesion promoters for several surfaces and materials.

- The DOW Chemical Company- It has introduced BETASEAL, BETAMATE, BETAFORCE, and DOWSIL.

- Sika AG- They usually offer solutions for exterior bonding, interior applications, acoustic systems, and specific technologies, including PowerCure systems.

Automotive Adhesives Market Companies

- Henkel & Co. KGaA

- Bostik S.A.

- 3M Company

- The DOW Chemical Company

- Sika AG

- H.B. Fuller

- PPG Industries

- Jowat AG

Recent Developments

- In February 2024, the company Pidilite Industries Limited, which produces sealants, adhesives, building supplies, and car care items, launched a new online advertisement for Motomax Insta Shine, a simple-to-use and reasonably priced DIY car polish.

- In February 2024, KRAIBURG TPE introduced a new line of thermoplastic elastomer (TPE) products with a minimum of 73% recycled content. Numerous technological applications are catered to by the new Recycling Content TPE for Automotive series.

Segment Covered in the Report

By Technology

- Water-based

- Solvent-based

- Hot melt

- Reactive & Others

By Vehicle

- Passenger Cars

- Light Commercial Vehicles

- Heavy & Medium Commercial Vehicles

By Function

- Bonding

- NVH

- Sealing/Protection

By Application

- Exterior

- Interior

- Powertrain

- Electronics

- Body In White

- Others

By Sales Channel

- OEMs

- Aftermarket

By Geography

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting