Epoxy Composites Market Size and Forecast 2025 to 2034

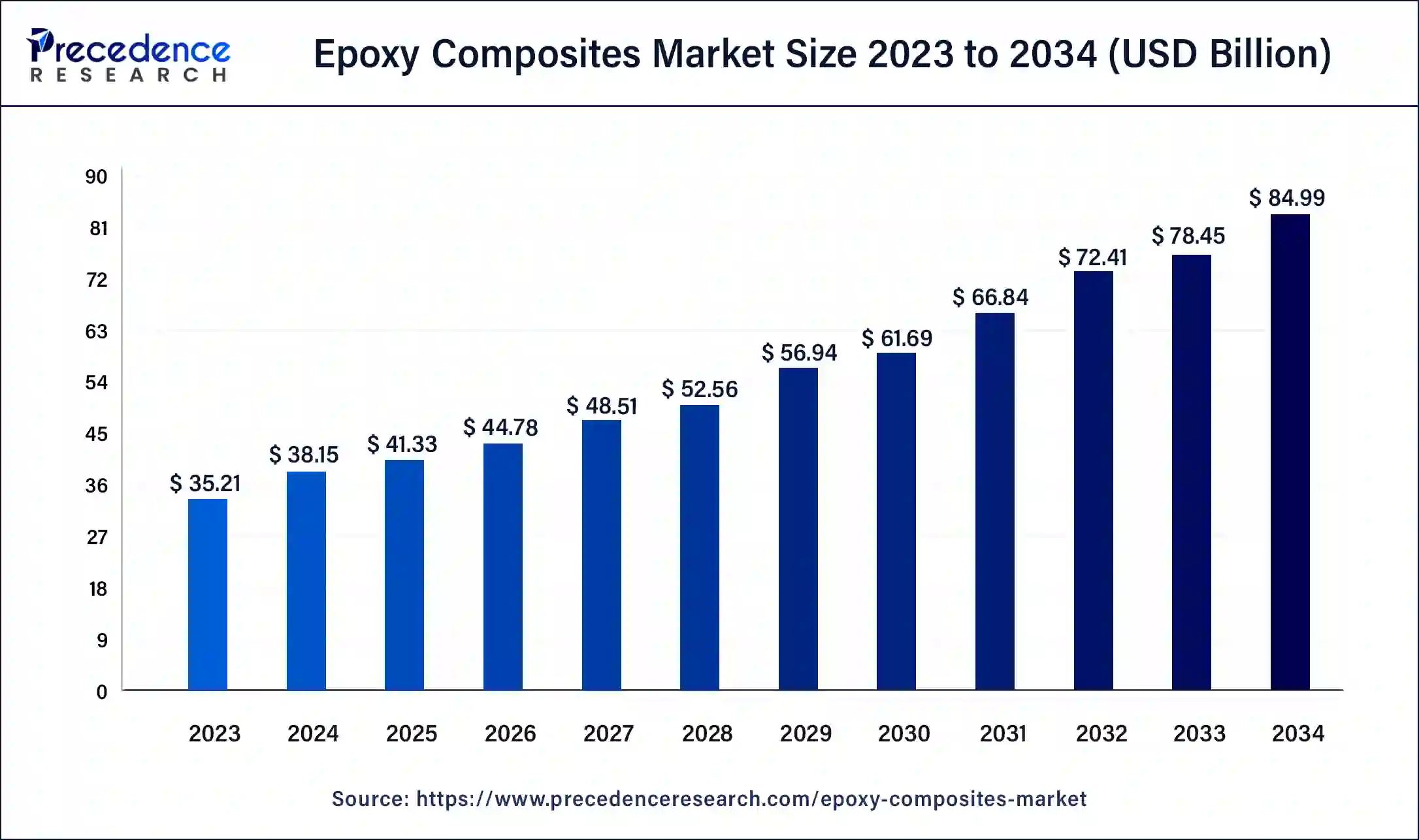

The global epoxy composites market size was USD 38.15 billion in 2024, calculated at USD 41.33 billion in 2025 and is expected to reach around USD 84.99 billion by 2034, expanding at a CAGR of 8.34% from 2024 to 2034. Epoxy composites are ideal for a variety of applications in the automotive and aerospace industries due to their exceptional mechanical qualities and high strength-to-weight ratios.

Epoxy Composites Market Key Takeaways

- The global epoxy composites market was valued at USD 38.15 billion in 2024

- It is projected to reach USD 84.99 billion by 2034.

- The market is expected to grow at a CAGR of 8.34% from 2025 to 2034.

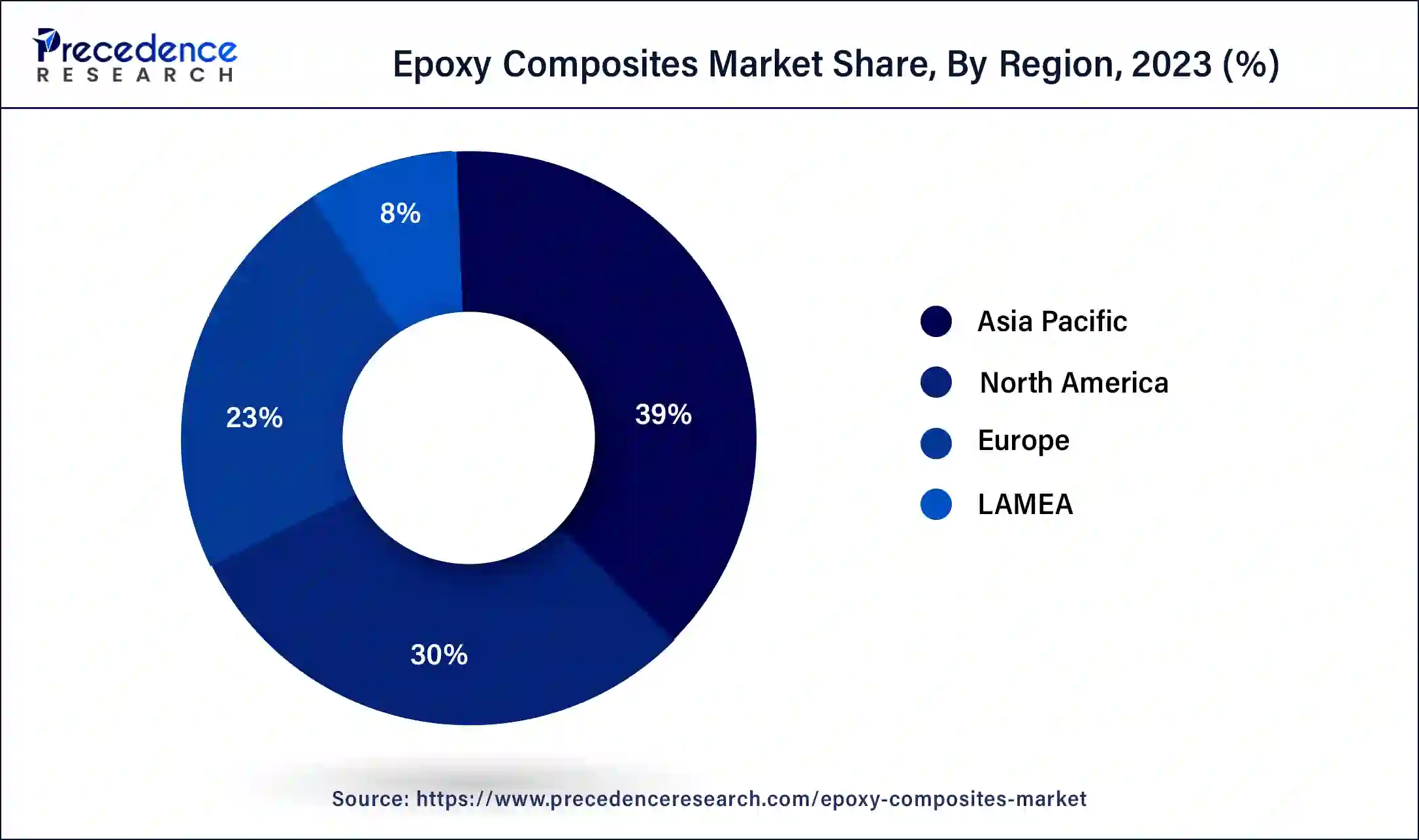

- Asia Pacific dominated the epoxy composites market with the largest revenue share of 39% in 2024.

- North America is expected to host the fastest-growing market during the forecast period.

- By fiber type, the glass fiber segment has held a major revenue share of 63% of revenue share in 2024.

- By fiber type, the carbon fiber segment is expected to grow at a fastest CAGR of 8.53% during the forecast period.

- By end use, the automotive & transportation segment has generated more than 28% of revenue share in 2024.

- By end use, the aerospace segment is expected to grow at the fastest rate in the market during the forecast period.

Asia Pacific Epoxy Composites Market Size and Growth 2025 to 2034

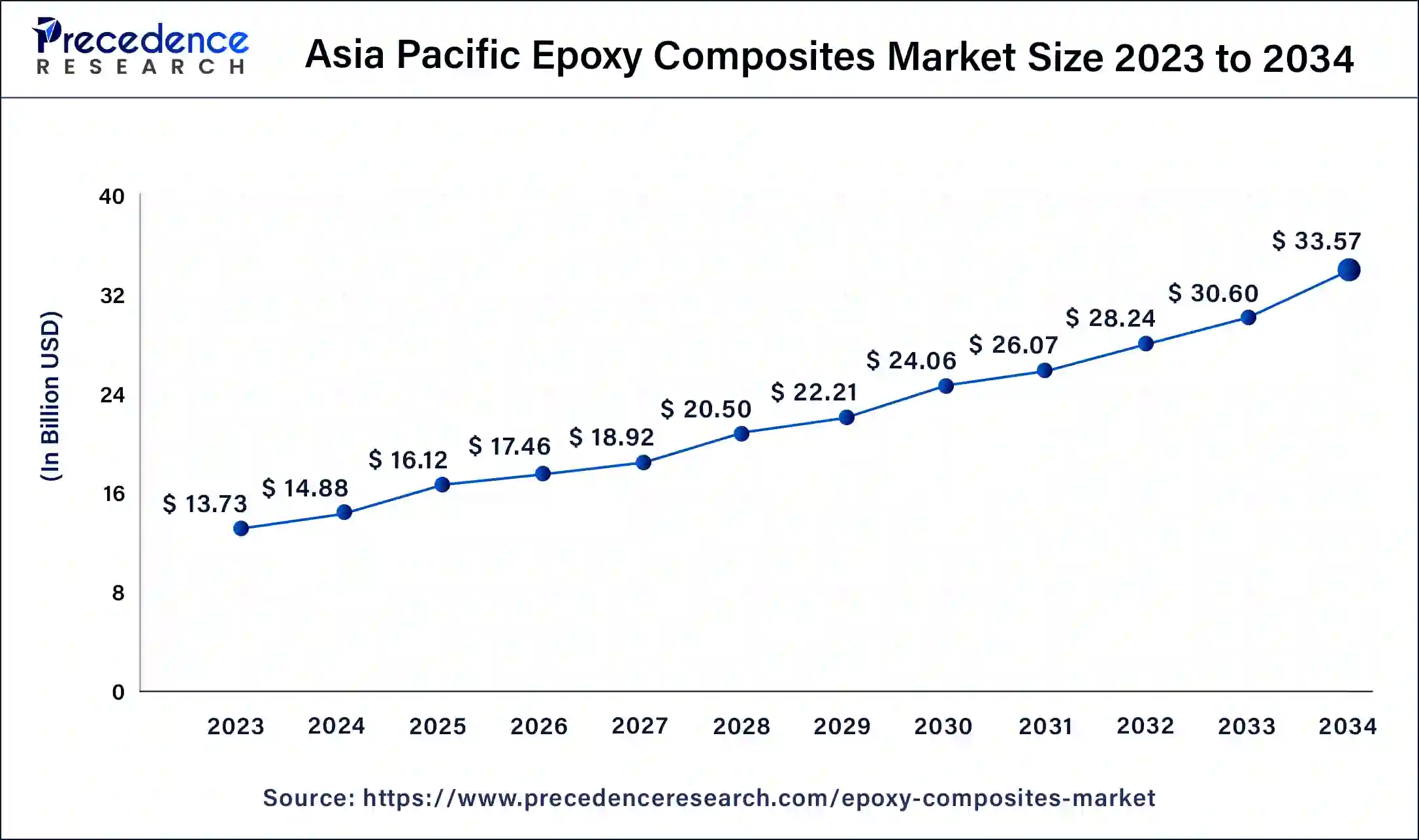

The Asia Pacific epoxy composites market size was exhibited at USD 16.12 billion in 2025 and is projected to be worth around USD 33.57 billion by 2034, poised to grow at a CAGR of 8.48% from 2025 to 2034.

Asia Pacific held the largest share of the epoxy composites market in 2024. The need for strong, lightweight materials like epoxy composites in a variety of industrial applications has increased due to the rapid industrialization of nations like China, India, and Japan. The market for epoxy composites is being driven by rising investments in infrastructure projects, including transportation and construction, because of its high strength-to-weight ratio and resilience to corrosion.

The epoxy composites market is being used by the Asia Pacific car sector to create lightweight components that lower emissions and increase fuel efficiency. Epoxy composites profit from the growing electronics manufacturing sector in the region and are frequently employed in electrical insulation applications and electronic components. The increasing use of renewable energy projects, such as solar panels and wind turbine blades, is driving up demand for epoxy composites because of their high mechanical strength and resilience to weathering.

North America is expected to host the fastest-growing epoxy composites market during the forecast period. The epoxy composites market is expanding in North America as a result of rising use in a number of sectors, including wind energy, construction, automotive, and aerospace. The durability, corrosion resistance, high strength-to-weight ratio, and lightweight characteristics of epoxy composites are some of the factors propelling this rise. Epoxy composites are widely used in the aerospace industry, particularly to reduce weight and increase fuel efficiency in airplane components.

Epoxy composites are utilized in automotive applications to create lightweight structural parts that improve vehicle efficiency and performance. Epoxy composites are also widely used in infrastructure projects because of their exceptional strength and resistance to environmental variables in the construction industry. All of these elements work together to support the growth of the epoxy composites market in North America.

Market Overview

The industry that produces, distributes, and uses composite products that use epoxy resins as their main matrix material is known as the epoxy composites market. Epoxy composites are engineered materials that are made of lightweight, robust, and long-lasting structures by combining epoxy resins with reinforcing fibers like carbon, glass, or aramid fibers. Because epoxy composites are resistant to chemicals and corrosion, they are employed in pipelines, maritime vessels, and offshore constructions in the infrastructure. Rising industrialization and infrastructure development in emerging economies are fueling demand for epoxy composites in a number of industries. Because of their superior mechanical qualities, resilience to corrosion, and adaptability in production processes, these composites are widely used in a variety of industries, including electronics, aircraft, automotive, construction, and maritime.

Since the epoxy composites market products are lightweight and have a high strength-to-weight ratio, they are frequently employed in aerospace and defense applications. Epoxy composites are being used more often in automobile manufacture to lighten vehicles, increase their fuel economy, and improve their durability. Because of their great mechanical strength, resistance to corrosion, and capacity to endure challenging climatic conditions, epoxy composites find application in the construction industry. Because epoxy composites are lightweight and have great fatigue resistance, they are widely utilized in wind turbine blades, which are becoming more and more common as wind energy projects expand globally. Because of their electrical qualities and flame-retardant nature, epoxy composites are used in electrical insulation, circuit boards, and electronic components.

Key Factors Influencing Future Market Trends

- Demand for lightweight materials: Industries such as aerospace, automotive, and wind power continuously aim at increasing their efficiency and decreasing emission rates. The need for lightweight material is on the rise. Emphasis on cutting fuel consumption and carbon emissions is enforcing lightweight composites in sustainability, which fuels epoxy.

- Sustainability and eco-friendly innovations: Rising environmental issues and increasing regulatory policies regarding epoxies are shifting the market towards green epoxy composites. Bio-based resins, recycled fiber reinforcement, and low-emission production processes should be a necessity.

- Expanding end-use applications: The accelerating demand for the automotive, construction, marine, and sporting goods industries plays a significant role in the growth of the epoxy composites market. Due to the increasing demand for materials that are stronger, lighter, and more durable for application in industries calling for the replacement of metal and plastics by epoxy composites are progressively emerging as valuable commodities.

- Advancements in smart composites: These materials can be embedded with sensors, are self-healing, or have adaptive properties; therefore, they are suitable for application in high-performance industries such as aerospace, the automobile industry, and civil construction.

Epoxy Composites Market Growth Factors

- Epoxy composites are highly valued for their longevity and high strength-to-weight ratio, which makes them indispensable for use in military and aviation applications.

- Because they are lightweight and resistant to adverse weather, epoxy composites are widely employed in wind turbine blades, which is fueling the epoxy composites market expansion.

- The epoxy composites market products and services are being utilized more frequently in automobile components with the goal of lowering vehicle weight to improve performance and fuel economy.

- Epoxy composites are used in infrastructure projects, including buildings and bridges, because of their strength, resistance to corrosion, and adaptability in design.

- Epoxy composites are finding more applications thanks to innovations in resin compositions, curing procedures, and composite manufacturing techniques.

- Epoxy composites are preferred because they can improve performance without sacrificing durability in a variety of products, including sporting goods and leisure gear.

- Because epoxy composites are resistant to corrosion, water, and chemicals, they are employed in the construction of boats and other marine structures.

Technological Advancement

The incorporation of nanocomposites such as carbon nanotubes and graphene with the epoxy matrix of composites is further improving these benefits, making the composites conductive, flame retardant, and capable of performing structural health monitoring. The advancement in the smart composites, which can self-heal, detect damages, as well adapt to their surroundings, broadened the functional application of epoxy composites in aerospace, automotive, construction industries, among others.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 84.99 Billion |

| Market Size in 2025 | USD 41.33 Billion |

| Market Size in 2024 | USD 38.15 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 8.34% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Fiber Type, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Growing demand for renewable energy

Since epoxy composites are lightweight, very durable, and resistant to corrosion, they are widely utilized in wind turbine blades. The need for cutting-edge composite materials like epoxy composites is rising along with the wind energy industry. Photovoltaic (PV) panels are made using epoxy resins, specifically for encasing solar cells. They increase the longevity and effectiveness of solar panels by offering superior adhesion and protection against environmental elements. Epoxy composites are utilized for supports, frames, and structural elements, among other infrastructure components, in renewable energy projects. The spread of renewable energy installations worldwide is supported by this application.

Restraint

Limited recycling options

One major difficulty in the epoxy composites sector is the scarcity of recycling possibilities. When compared to other materials like metals or some thermoplastics, epoxy composites might be more challenging to recycle because of their intricate structure and the curing process that goes into them. The curing process epoxy resins go through to form a cross-linked structure in composites. This structure is irreversible after it has cured, making it difficult to break down and recycle the material effectively in typical circumstances. Fibers (such as carbon or glass) are usually placed in an epoxy resin matrix to form epoxy composites. The process of separating these components for recycling is difficult and frequently not profitable. Because of the possible effects on the environment, traditional disposal techniques like landfilling and incineration could not be in line with sustainability objectives.

Opportunity

Construction and infrastructure

Epoxy composites are used to strengthen and repair buildings, bridges, and other infrastructure, increasing the structural integrity and longevity of the structures. They are used in construction parts where strong, lightweight materials are needed, such as beams, columns, and panels. Because they are low maintenance and resistant to abrasion, epoxy composites are widely used in flooring systems and protective coatings.

Epoxy composites are utilized in infrastructure projects to make pipelines, tanks, and other industrial equipment because of their resistance to corrosion and long-term durability. Epoxy composites are essential to the production of wind turbine blades in the context of renewable energy because of their low weight and resistance to adverse environmental conditions.

Fiber Type Insights

The glass fiber segment held the largest share of the epoxy composites market in 2023. As reinforcement materials, glass fibers are essential in the epoxy composites market. They are frequently employed to improve the impact resistance, stiffness, and strength of epoxy composites. Glass fiber-reinforced epoxy composites find extensive application in a multitude of industries, such as electronics, automotive, aerospace, and construction. They are especially well-suited for applications where their corrosion resistance, lightweight design, and cost are favorable characteristics. Furthermore, glass fibers can be customized to satisfy certain performance needs in various market applications by using alternative weaving patterns and fiber orientations. Glass fiber composites are also used in the sports equipment, automobile, aerospace, and marine industries, which further enhances the market's expansion and adaptability.

The carbon fiber segment is expected to grow at the fastest rate in the epoxy composites market during the forecast period. Because of their excellent stiffness-to-weight ratio and high tensile strength, carbon fibers are a great choice for applications requiring lightweight materials with excellent structural integrity. Epoxy composites reinforced with carbon fibers are appropriate for demanding applications in sports equipment, automobiles, and aerospace because of their exceptional fatigue resistance and endurance.

Carbon fibers can be customized with various weaves, orientations, and surface treatments to produce desired mechanical, thermal, and electrical properties, depending on the particular application. They are widely employed in a variety of industries, including wind turbine blades for renewable energy, sports and recreation, aerospace, automotive, construction, and sports and leisure (for reinforcement and high-performance equipment). Because carbon fibers don't corrode, epoxy composites last longer and are more reliable in challenging conditions.

End-use Insights

The automotive & transportation segment held the largest share of the epoxy composites market in 2024. The need for strong, lightweight materials is drawing a lot of attention to the automotive and transportation industries. Epoxy composites can improve overall vehicle performance and fuel efficiency since they are lighter than conventional materials like metals. These composites are ideal for structural applications in automobiles because they have high strength-to-weight ratios and superior fatigue and impact resistance.

Epoxy composites may be molded into intricate designs, enabling designers to create pieces that are visually beautiful and aerodynamic. As more automakers use these materials to meet emissions, efficiency, and performance regulations, the automotive and transportation segment of the epoxy composites market is expected to develop.

The aerospace segment is expected to grow at the fastest rate in the epoxy composites market during the forecast period. Because epoxy composites are lightweight, have a high strength-to-weight ratio, and are resistant to corrosion and fatigue, they are essential to the aerospace industry. These materials are widely utilized in the construction of fuselages, wings, empennage, and interior parts of aircraft. Epoxy composites aid in the overall weight reduction of aircraft, which is essential for performance and fuel efficiency.

The aerospace industry's market for epoxy composites is expanding as producers look for cutting-edge materials to satisfy strict legal specifications and improve aircraft performance. Aerospace engineering performance criteria and structural integrity are preserved by epoxy composites, which also contribute to total weight reduction. Their application greatly enhances aircraft performance overall and fuel efficiency.

Epoxy Composites Market Companies

- Axiom Materials

- Barr day

- Hexcel Corporation

- Mitsubishi Chemical Corporation

- Park Aerospace Corp

- Sanders Composites

- SGL Carbon

Recent Developments

- In July 2024, Solvay launched the epoxy-based CYCOM EP2190 system, which offers exceptional durability in thick and thin structures together with good in-plane performance in hot/wet and cold/dry situations. The material, which is the company's new flagship product for aerospace primary structures, competes with existing solutions for wing and fuselage applications in the majority of aviation market segments, from defense and rotorcraft to urban air mobility (UAM) and private and commercial aerospace segments (sub and supersonic).

- In June 2024, With the introduction of its new NE7 low-temperature curing prepreg system, Notus Composites (UAE), the distinguished manufacturer of epoxy prepreg materials, is pleased to announce the newest addition to its high-performance epoxy portfolio. With the completely new Notus NE7 formulation, producers of composites can cure components at as low as 70ËšC, saving energy and opening up more affordable tooling possibilities.

Segment Covered in the Report

By Fiber Type

- Glass Fiber

- Carbon Fiber

- Other Fiber

By End-use

- Automotive & Transportation

- Aerospace & Defense

- Wind Energy

- Electrical & Electronics

- Sporting & Consumer Goods

- Other End-Use (Oil & Gas, Marine, Construction)

By Region

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting