Medical Fluoropolymers Market Size and Forecast 2025 to 2034

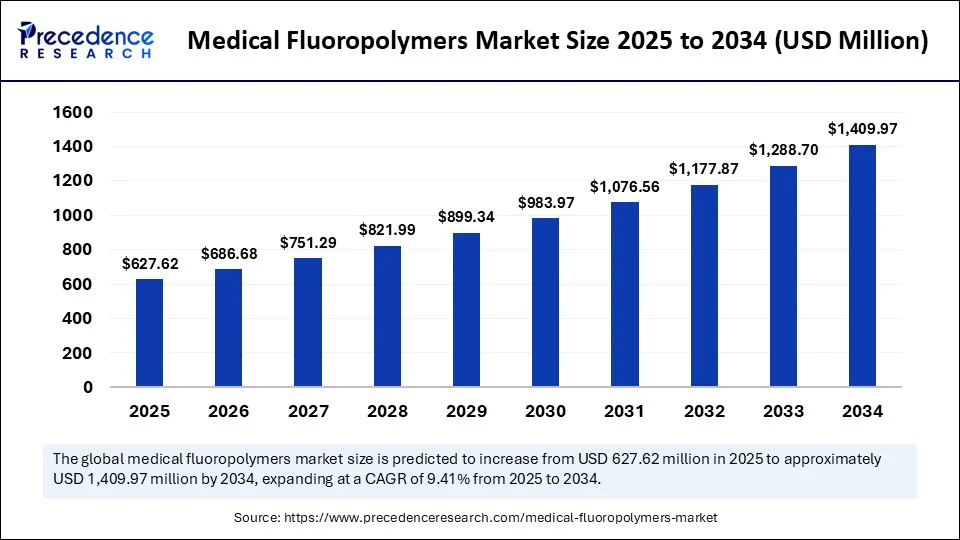

The global medical fluoropolymers market size accounted for USD 573.64 million in 2024 and is predicted to increase from USD 627.62 million in 2025 to approximately USD 1,409.97 million by 2034, expanding at a CAGR of 9.41% from 2025 to 2034. The market is driven by the rising demand for minimally invasive surgeries, biocompatible materials, and high-performance medical devices.

Medical Fluoropolymers MarketKey Takeaways

- In terms of revenue, the global medical fluoropolymers market was valued at USD 573.64 million in 2024.

- It is projected to reach USD 1,409.97 million by 2034.

- The market is expected to grow at a CAGR of 9.41% from 2025 to 2034.

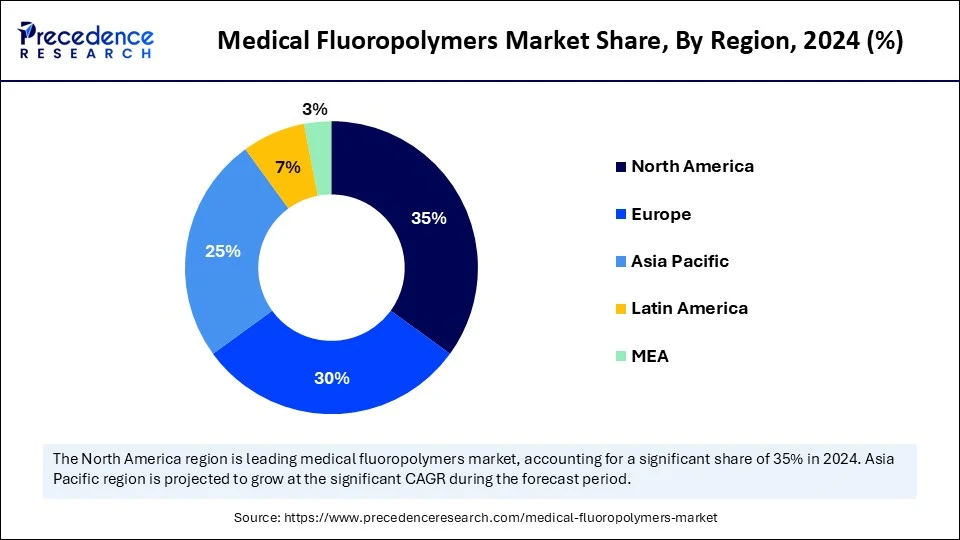

- North America dominated the global market with the largest share of around 35% in 2024.

- Asia Pacific is anticipated to witness the fastest growth from 2025 to 2034.

- The European market is expected to gain a substantial share.

- By type, the Polytetrafluoroethylene (PTFE) segment led the market in 2024.

- By type, the Polyvinylidene Fluoride (PVDF) segment is anticipated to show considerable growth in the market over the forecast period.

- By form, the rod and tubes segment held the largest market share of 40% in 2024.

- By form, the coatings segment is anticipated to show considerable growth in the market over the forecast period.

- By application, the medical tubing and catheters segment contributed the highest market share of 12.5% in 2024.

- By application, the pharmaceutical packaging segment is anticipated to show considerable growth in the market over the forecast period.

- By end-use industry, the cardiovascular segment accounted for the biggest market share of 35% in 2024.

- By end-use industry, the pharmaceuticals & biotechnology segment is anticipated to show considerable growth in the market over the forecast period.

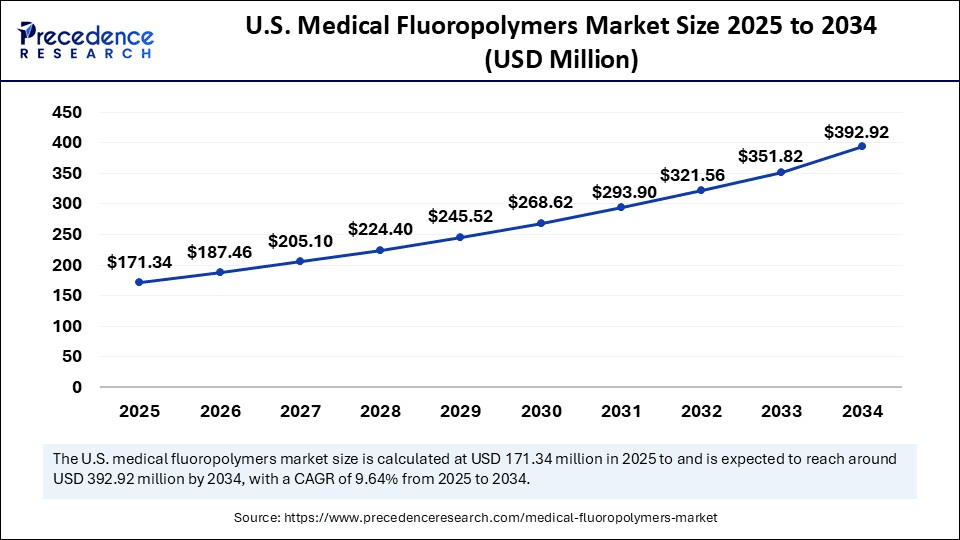

U.S. Medical Fluoropolymers Market Size and Growth 2025 to 2034

The U.S. medical fluoropolymers market size was exhibited at USD 156.60 million in 2024 and is projected to be worth around USD 392.92 million by 2034, growing at a CAGR of 9.64% from 2025 to 2034.

Why did North America dominate the global market with the largest market share of 35% in 2024?

North America led the global market with the highest medical fluoropolymers market share of 35% in 2024, driven by a large consumption of the advanced materials used in drug delivery devices, medical tubing, catheters, surgical instruments, and medical bags. The high standards of the healthcare infrastructure in the region and the large outlays on healthcare are one of the main stimulants of market growth. The outstanding biocompatibility of medical fluoropolymers, together with chemical and sterilization compatibility, renders them essential in medical processes of high performance. Also, fluoropolymer formulas and processing technologies continue to be developed, which makes them more efficient to produce and expands their application in the healthcare sector.

Medical fluoropolymers in the U.S. have a growing market, attributed to the developed healthcare system in the country, the well-developed R&D environment, as well as relatively strict regulations. The high standards of the U.S. Food and Drug Administration stimulate the utilization of such high-quality fluoropolymers as PTFE, FEP, and PFA. Durability and biocompatibility of products are in growing demand due to demographic factors, including an aging population that will ramp up their healthcare requirements shortly. Moreover, the growth of investment in minimally invasive technology promotes innovation in the fluoropolymer-based parts.

In August 2025, the FDA stated that fluoropolymers were safe and critical in medical devices with zero health-based risks and low toxicity owing to their high size of their molecular mass. The agency also found no necessity to place limitations on the use and medical devices and diagnostic manufacturers who relied on these materials were relieved.(Source:https://www.akingump.com)

Why is Asia Pacific Undergoing the Fastest Growth in the Medical Fluoropolymers Market?

Asia Pacific is estimated to grow at the fastest CAGR during the forecast period, thrilled by the increasing demand for enhanced medical tubing, catheters, membranes, venous cannulas, and other essential substances. The fast-growing healthcare infrastructure and healthcare spending that is evident in great economies like China and India are stimulating the use of high-performance healthcare materials. The demand for fluoropolymer-based products has been experiencing a phenomenal growth in the Asia Pacific region, with increasing numbers of hospitals concentrating on the incorporation of the best possible medical devices to fulfill the emerging standards of patient care.

The fluoropolymers medical market in China is one of the fastest-growing markets that utilizes extensive healthcare reforms, large investments in medical infrastructure, and increased requirements for advanced medical technology. The demand of the nation towards self-sustenance in manufacturing high-value medical equipment is increasing the demand for high-performance materials such as fluoropolymers, especially in surgical equipment, catheters, tubing, diagnostic equipment, and implanted products. Specifically, the characteristics of fluoropolymers, such as being biocompatible, chemically inert, and conversing well with sterilization, lead to the absolute necessity of fluoropolymers to satisfy the increasing needs of the Chinese market that requires reliable, safe, and superior performing medical solutions.

What Are the Key Trends Driving the European Medical Fluoropolymers Market?

The European medical fluoropolymers market is expected to account for a substantial market share in 2024. Due to the active promotion by governments in Europe, the proposed focus on the future trends of the modernization of the medical infrastructure stimulates upgrading to high-performance materials, including fluoropolymers, presented in the new version of next-generation medical devices. Market growth is stimulated by the regulatory framework provided by the European Union and financial support to encourage innovation in healthcare and the digital transformation of the market. Europe also has the advantage of a long-established presence of medical device producers, a growing health tech startup community, and strategic mergers and acquisitions that help in increasing R&D capacity.

U.K., aided by substantial government investment, centers of excellence, and industry-academia partnerships, is playing a leading role in the development of medical devices, especially in the field of minimally invasive surgery, diagnostics, and implants. As the population ages and greater attention is given to patient safety as well as infection control, the demand in the U.K. is likely to grow towards fluoropolymer-enabled devices, solidifying its position as a contributor to the European market

Market Overview

The medical fluoropolymers market refers to the global market for specialized fluoropolymer materials designed for medical applications. These fluoropolymers are high-performance, fluorine-containing polymers known for their exceptional chemical resistance, biocompatibility, thermal stability, low friction, and non-reactivity. These properties make them ideal for a variety of critical medical uses, including implantable devices, medical tubing, catheters, syringes, and other surgical instruments.

Medical fluoropolymers enhance device performance by improving durability, flexibility, and patient safety. They find significant application in cardiovascular, orthopedics, diagnostics, and pharmaceutical packaging, driven by the rising demand for minimally invasive surgeries, advanced medical devices, and biocompatible materials. The medical fluoropolymers market is driven by the increasing minimally invasive procedures, biocompatible and chemically unresponsive material requirements, and enhancement in the production of medical devices.

What Factors Are Fueling the Rapid Expansion of the Medical Fluoropolymers Market?

- Expanded Growth in Minimally Invasive Procedures: Minimally invasive procedures need materials of good flexibility, durability, as well as biocompatibility. All these are met through the application of medical fluoropolymers that enable safer and more efficient surgeries.

- Advanced Material Properties: Fluoropolymers are of medical grade with excellent chemical resistance, thermal stability, and biocompatibility, a quality that makes them applicable in healthcare products. They are offering the extended performance of implants and diagnostic systems.

- Patient Safety Emphasis on Regulation: The global healthcare regulations require an increase in the use of tested, safe, and reliable materials used in medical devices. This is a regulatory trend where safer, more effective medical products are getting their way into the market, which is greatly adding to the expansion of the market.

How is AI Revolutionizing Material Development in the Medical Fluoropolymers Market?

Artificial intelligence is introduced to the medical fluoropolymers market to improve material innovation, production automation, and production quality testing. Predictive modeling of fluoropolymers based on an AI program enables researchers to test and simulate new fluoropolymer formulations to be more breathable, flexible, and chemically resistant. Automation, by the use of AI in manufacturing, ensures perfection in extrusion, molding, and coating in producing high-performance parts of catheters, surgical devices, and implants. The existence of microscopic flaws in fluoropolymer products can be detected through the assistance of an AI-based inspection system, and their solutions facilitate this industry to achieve the stringent healthcare standards.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 1,409.97 Million |

| Market Size in 2025 | USD 627.62 Million |

| Market Size in 2024 | USD 573.64 Million |

| Market Growth Rate from 2025 to 2034 | CAGR of 9.41% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Form, End-Use Industry, Application, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Rising Patients' Preference for Minimally Invasive Surgeries

The medical fluoropolymers market is driven by the rising trends in the utilization of minimally invasive procedures. Such surgeries that involve smaller incisions and physical damage are favored, as they have reduced healing duration, formation of scar formation, and risk of infections. Fluoropolymers are a significant contributor to fluoropolymers because they facilitate these techniques in stamping extraordinary versatility, chemical resistance, and biocompatibility of medical equipment tools like catheters, endoscopic, and surgical instruments.

With the improvement of medical technology, devices are turning small, sensitive, and can easily pass through complex anatomical paths, all of which require the specific characteristics of fluoropolymers. The increasing global interest in patient comfort, quick rehabilitation, and affordable treatments is the driving force behind the demand for the materials. Also, inventions in fluoropolymers formulations will make it possible to build the next-gen devices with increased durability, less friction, and more safety.

Restraint

Environmental and Disposal Concerns

There are emerging environmental and disposal challenges, which can be a major disinhibitor of the global medical fluoropolymers market. The materials are so durable and their breakdown is extremely slow in rate, thus posing obstacles to waste management and long-term effects on the environment. The frequent use enhances the chance of fluoropolymers leaking hazardous substances into the waterways and the soils, which may be hazardous to the ecology and the health of humans.

The number of used medical fluoropolymer products is also increasing as their use in the healthcare industry continues to expand, fueling concerns about environmental impacts. The rising regulatory concern over non-biodegradable and even toxic waste is mounting pressure on manufacturers to seek green alternatives, as well as environmentally sound ways of disposing of their waste.

Opportunity

Medical Devices and Drug Delivery Systems Innovation

Fluoropolymers can be used in delicate medical applications since the high chemical inertness, biocompatibility, and fluid resistance of fluoropolymers make them ideally suited to such applications where material stability and reliability are required. More radical uses of drug delivery are controllable release formulations and implantable pumps, in which fluoropolymers are used to permit the management and replicable release of drugs to offer an improved beneficial outcome and patient adherence.

New technologies involve micro-scale delivery channels, implant coating, and fluoropolymer-based capsules that serve to preserve active pharmaceutical ingredients until they are released to desired places in the body. They are low-friction and highly durable, which tends to support next-generation surgical instruments, catheters, and diagnostic tools with greater functionality and longevity.

Type Insights

How did the PTFE segment achieve a leading 45% share in the market in 2024?

The Polytetrafluoroethylene (PTFE) segment led the medical fluoropolymers market, with the expanded PTFE (ePTFE) holding a 45% share in 2024. Polytetrafluoroethylene refers to a synthetic fluoropolymer that is popularly known to have extraordinary chemical resistance, low friction, and non-reactivity, thus essential in the most important medical applications. PTFE finds significant application in health facilities in the production of catheters, surgical meshes, gaskets, pump interiors, washers, and seals. PTFE can readily be compounded with filler materials like carbon graphite, glass bead, and molybdenum disulfide to improve certain performance characteristics, e.g., wear resistance, as well as strength. The microporous structure of ePTFE is found in advanced medical equipment manufacturing: its process provides excellent flexibility and permeability properties sensitive to vascular grafts and implanted devices.

The Polyvinylidene Fluoride (PVDF) segment is expected to grow at a significant CAGR over the forecast period. In health care, PVDF coatings also offer abrasion, weathering, and chemical resistance, and are high dielectric strength as well as flame retardant, and are therefore used in critical equipment. PVDF is a biocompatible material that is stable during sterilization processes, making PVDF a desirable material in the fabrication of tubing, filters, wearable medical devices, and parts of advanced drug delivery systems. Also, PVDF can be produced in flexible, lightweight forms and therefore can be adapted to make portable and patient-centered products. The flexibility of the material to various fabrication processes also increases its market potential, making PVDF one of the strongest growth drivers in the next generation in the biomedical field.

Form Insights

How did the rod & tubes segment dominate the medical fluoropolymers market in 2024?

The rod & tubes segment led the market while holding a 40% share in 2024 as fluoropolymer tubes and rods are used extensively in the manufacture of precision medical components, which comprise the catheter shafts, endoscope instrument channels, the diagnostics instrument housing, and any other associated applications that are manufactured within the healthcare sector. These are applicable in an environment that needs sterilization and toughness since they are chemically resistant, have high thermal stability, and are biocompatible. They have low friction, and since the devices are smooth during operation, they also ensure less wear and the safety of patients. Tubes and rods are used for medical purposes also find use in the laboratory setting in generating semiconductor parts in the health electronics and high-purity fluid-handling applications.

The coatings segment is expected to grow at a significant CAGR over the forecast period, prompted by the growing use of fluoropolymer coatings in the medical and industrial sectors. In the medical field, fluoropolymer coatings are used to decrease friction on surgical instruments, catheters, and guidewires, increasing precision and patient comfort levels. Continued research in the fluoropolymer coatings formulations, e.g., antimicrobial and anti-thrombogenic fluoropolymer coatings, is increasingly finding application in advanced medical devices, and their durability over the years is a guarantee of success in multiple industries in the upcoming years.

Application Insights

Medical tubing & catheters dominates the market

The medical tubing & catheters segment held a 50% share in the market in 2024. Anesthesiology, respiratory therapeutics, peristaltic pumps, biopsies, cardiac diagnostics, and bio-processing fluids that involve transfer all rely on medical tubing. Tubing based upon fluoropolymers (such as PTFE, FEP, and PVDF) is especially sought out because of their outstanding resistance to chemicals, excellent biocompatibility, flexibility, and resistance to elevated temperatures and sterilization. The increasing rates of chronic diseases like cardiovascular disorders, kidney disease, and respiratory conditions drive the growth of the segment further because these diseases demand constant usage of medical tubing. Other technologies and the growth of home healthcare services are also increasing safety and performance, including the expansion of anti-thrombogenic, antimicrobial, and other coatings on catheters.

The pharmaceutical packaging segment is expected to grow substantially in the medical fluoropolymers market, due to growing concerns about high-performance, safe, and durable packaging materials. Medical fluoropolymers provide unique chemical resistance, heat stability, and barrier capabilities that are a perfect choice to prevent moisture, oxygen, and contamination of sensitive pharmaceutical products. Growing cases of chronic diseases, the rising pharmaceutical industry, and the increased awareness of drug safety are the driving forces behind the deployment. They are non-reactive and biocompatible, making them have product integrity, particularly on injectable drugs, biologics, and high-potency medicines. Market prospects are also gaining increased heights due to the increase in investments into innovative, sustainable, and tamper-proof pharmaceutical packaging.

End-User Insights

Which drivers led the cardiovascular segment led the market in 2024?

The cardiovascular segment held a 35% share in the market in 2024 as fluoropolymers such as PTFE, ePTFE, and PVDF are widely used in applications related to cardiovascular due to a high level of biocompatibility, chemical inactivity, and the capacity to be repeatedly used without being them by the sterilization process. The description of the low-friction surface of fluoropolymers is used in angioplasty and other interventional routes in cardiology that use guidewires and catheters to give superior guidance of the blood vessels and cause minimal disturbance. As the device miniaturisation and coating technology take place, fluoropolymers will be used in progressively more cardiovascular procedures.

The pharmaceuticals & biotechnology segment is expected to grow substantially in the medical fluoropolymers market, backed by a rising R&D investment, future drugs pipeline expansion, and a growing tandem of biologics and complex therapies uptake. Fluoropolymers are also involved in making the pharmaceutical grade tubing, sealant, gaskets, and equipment lining. They are chemically resistant, have low extractable material, and are inert, therefore protecting sensitive drug formulations in the manufacturing, storage, and transport activities. Targeted drug delivery device applications of fluoropolymers with implantable pump devices, transdermal patches, and inhalers..

Medical Fluoropolymers Market Companies

- Chemours Company

- AGC Inc.

- Daikin Industries, Ltd.

- Solvay S.A.

- 3M Company

- Saint-Gobain Performance Plastics

- Arkema Group

- Kuraray Co., Ltd.

- Solvay Specialty Polymers

- Zhejiang Juhua Co., Ltd.

- Daikin Fluorochemicals

- Zhejiang Wynca Chemical Industry Group

- Asahi Glass Co., Ltd.

- Dongyue Group

- Zhejiang Jiuzhou Pharmaceutical Packaging Materials

- Gujarat Fluorochemicals Limited

- Dongyue Group Limited

- Sinochem International Corporation

- Guangzhou Dongfeng Fluoroplastic Co., Ltd.

- Daikin Chemicals (Thailand) Ltd.

Recent Development

- In 2023, Chemours introduced a new generation of extremely pure PTFE resins suitable for use in implantable medical devices. According to Market Reports World, this new line was made available to more than 28 original equipment manufacturers (OEMs) in Europe and the United States.(Source: https://www.chemours.com)

- In August 2023, the Kureha Group revealed that it was expanding the production volume of polyvinylidene fluoride (PVDF) at its Iwaki Plant in Fukushima, Japan. The growth has been strategized to incorporate the increased global demand for PVDF, which is being utilized as an adhesive raw material in lithium-ion batteries (LiB) and a processing polymer used in multiple areas of industry.(Source:https://www.kureha.co.jp)

Medical Fluoropolymers Market Companies

By Type

- Polytetrafluoroethylene (PTFE)

- Expanded PTFE (ePTFE)

- Virgin PTFE

- Fluorinated Ethylene Propylene (FEP)

- Perfluoroalkoxy Alkane (PFA)

- Polyvinylidene Fluoride (PVDF)

- Ethylene Tetrafluoroethylene (ETFE)

- Others

- Fluorinated Polyimides

- Fluoroelastomers

By Form

- Films & Sheets

- Rod & Tubes

- Powders & Granules

- Coatings

- Others

- Fibers

- Dispersions

By Application

- Medical Tubing & Catheters

- Cardiovascular Catheters

- Neurological Catheters

- Urological Catheters

- Others (Drainage Tubing, Respiratory Tubing)

- Surgical Instruments & Devices

- Implants (Vascular Grafts, Orthopedic Implants)

- Surgical Tools & Accessories (Needles, Scalpels, Guidewires)

- Pharmaceutical Packaging

- Syringes & Vials

- Seals & Gaskets

- Diagnostic Equipment

- Others

- Medical Membranes & Filters

- Bioprocessing Components

By End-Use Industry

- Cardiovascular

- Orthopedics

- Neurology

- Urology

- Pharmaceuticals & Biotechnology

- Others

- General Surgery

- Diagnostic Centers

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting