What is the Cellulose-Reinforced Hydrogels Market Size?

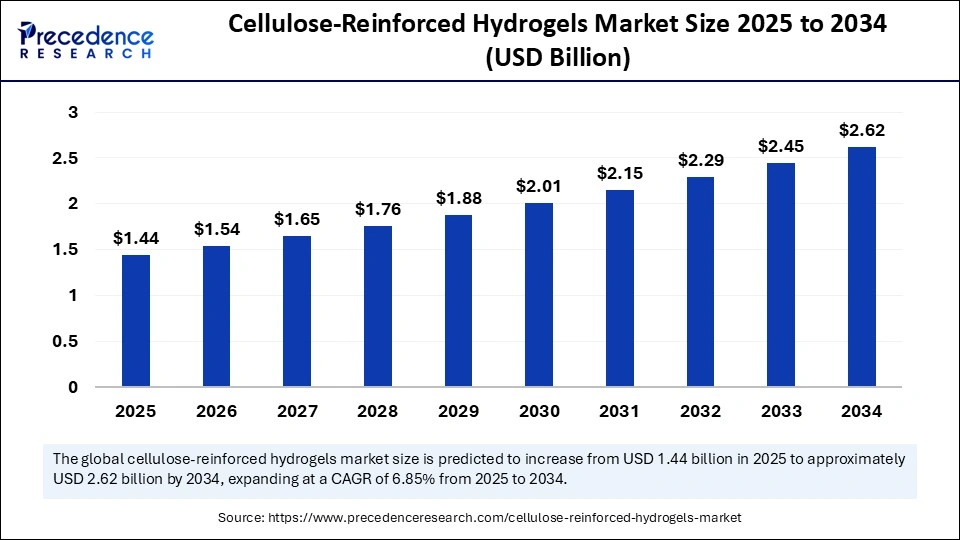

The global cellulose-reinforced hydrogels market size accounted for USD 1.44 billion in 2025 and is predicted to increase from USD 1.54 billion in 2026 to approximately USD 2.62 billion by 2034, expanding at a CAGR of 6.85% from 2025 to 2034. The market is driven by the growing demand for sustainable biomaterials, advancements in tissue engineering, and increasing applications in drug delivery and wound healing.

Market Highlights

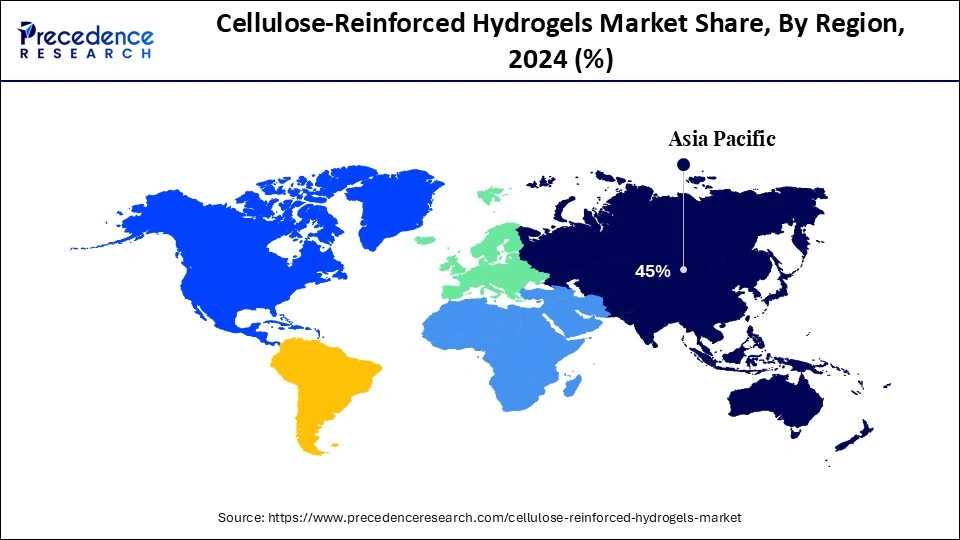

- Asia Pacific dominated the global market with 45% of market share in 2024.

- The North America region is growing at a notable CAGR between 2025 and 2034.

- By cellulose type, the bacterial cellulose nanofibers segment has captured a 38.4% revenue share in 2024.

- By cellulose type, the nanocellulose segment is growing at a strong CAGR of 8.1% from 2025 to 2034.

- By polymer matrix/hydrogel base, the natural polymer hydrogels segment held the dominant share in 2024.

- By polymer matrix/hydrogel base, the hybrid/composite hydrogels segment is expanding at a notable CAGR between 2025 and 2034.

- By application, the wound care & dressings segment contributed the biggest market share in 2024..

- By application, the tissue engineering & scaffolds segment is expected to show considerable CAGR from 2025 to 2034.

- By end-user / sector, the healthcare & biomedical segment held the major market share in 2024.

- By end-user / sector, the agriculture & horticulture segment is poised to grow at a solid CAGR between 2025 and 2034.

Strengthening Sustainable Innovation: How Cellulose-Reinforced Hydrogels Are Revolutionizing the Biomaterials Value

The cellulose-reinforced hydrogels market is becoming an essential part of the global biomaterials market, offering sustainability, biocompatibility, and high functionality. These are polymeric networks reinforced with cellulose nanofibers, nanocrystals, or bacterial cellulose to enhance mechanical strength, elasticity, and water-holding capacity. They are used in wound dressings, drug delivery systems, and tissue engineering scaffolds due to their exceptional structural integrity and bioactivity.

The market for cellulose-reinforced hydrogels is growing due to rising demand for biocompatible, eco-friendly materials across healthcare, agriculture, and industry. The adoption of hydrogels in the medical field is being fuelled by the growth in chronic wounds, regenerative medical research, and controlled drug-delivery solutions. Additional advances in the properties of nanocellulose products, such as performance and scalability, are being achieved through technological advances in processing, including enzymatic hydrolysis and incorporation of 3D bioprinting considerations.

Applying AI and Data Analytics to Unlock Materials Efficiency

The cellulose-reinforced hydrogels market is steadily evolving with Artificial Intelligence, which will help to boost the research process, streamline the formulation procedures, and facilitate the prediction of the performance. The modeling and machine learning algorithms based on AI are being applied to simulate interactions of cellulose nanostructures with polymer matrices to enable researchers to design hydrogels with specific mechanical strength, porosity, and water retention capabilities. In biomedical, AI is used in the customization of hydrogels to be used in tissue engineering, wound healing, and in the delivery of drugs by examining the biological compatibility, diffusion pattern, and patient specifications. Besides, AI-fueled image recognition and digital twins have assisted in monitoring the hydrogel degradation and reaction in real-time applications.

Cellulose-Reinforced Hydrogels Market Outlook

The cellulose-reinforced hydrogels market is experiencing a healthy industry with the need to have sustainable and high-performance biomaterials. They are growing in the industry and commercial acceptance worldwide due to improved applications in healthcare, agriculture, and personal care, as well as advances in nanocellulose production technology.

North America, Europe, and the Asia-Pacific market are booming and supported by the growth in biomedical research, green manufacturing initiatives, and applications in high-end wound care and tissue engineering. Newly developing economies are investing in the infrastructure of bio-based materials to make them more sustainable.

Biotechnology companies, material science companies, and the sustainable innovations venture capital companies are the main investors. BASF, Nippon Paper Industries, and Axcelon Biopolymers are corporations driving R&D investments in cellulose hydrogel production and commercialization.

There is a promising future for a vibrant startup ecosystem, with creative companies emerging to develop customized cellulose-reinforced hydrogels for deployment in the biomedical, cosmetic, and agricultural industries. Startups are using nanocellulose technologies, green chemistry, and AI-based materials design to create high-performance, ecologically friendly solutions to an extremely broad array of industrial requirements.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 1.44 Billion |

| Market Size in 2026 | USD 1.54 Billion |

| Market Size by 2034 | USD 2.62 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 6.85% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2025 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Cellulose Type, Polymer Matrix / Hydrogel Base, Application, End-User / Sector, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Cellulose-Reinforced Hydrogels Market Segment Insights

Cellulose Type Insights

Bacterial Cellulose Nanofibers: The bacterial cellulose nanofibers segment held a 38.4% share in the cellulose-reinforced hydrogels market in 2024, due to its excellent purity, strength, and biocompatibility. It is produced via the fermentation process of microbes and has stronger structural and water retention properties than the cellulose found in plants. The sustainability of the segment and its biodegradability conform to the trends of eco-friendly materials. It is also used in biosensors, soft robotics, and drug delivery, and its expanding applications in advanced biomedical and materials science are driving greater demand and innovation globally.

Nanocellulose: The nanocellulose segment captured an 8.1% share of the market in 2024 and is expected to grow significantly. It improves the strength, elasticity, and responsiveness of hydrogel to expand its application to biomedicine, cosmetics, and environmental engineering. Nanocellulose is associated with the controlled release of drugs, bio-packaging, and personal care products. The innovations in the extraction and surface modification are enhancing the economies of scale and cost-efficiency, as well as broadening the industrial applications.

Modified Cellulose Derivatives: The carboxymethyl cellulose and hydroxypropyl cellulose are the derivatives of the modified cellulose derivatives segment that are necessary in enhancing the functionality of the gel. The derivatives improve the viscosity, stability, and water retention, and also offer tunable mechanical and responsive properties in a broad spectrum of applications. The applications of these materials in pharmaceuticals are controlled drug delivery, cosmetics, moisturization, and agricultural soil conditioning. They can be chemically modified to produce pH-or temperature-sensitive hydrogels, and thus have expanded application possibilities.

Polymer Matrix / Hydrogel Base Insights

Natural Polymer Hydrogels: Natural polymer hydrogels contributed the most revenue in 2024 and are expected to dominate throughout the projected period. They are highly biocompatible, biodegradable, and environmentally safe, and therefore are used within the biomedical, pharmaceutical, and personal care products. The core of this segment consists of materials like alginate, chitosan, and gelatin, which are good in terms of water retention, flexibility, as well as cell adhesion. These natural polymers can be incorporated effectively with cellulose nanomaterials and improve the hydrogel strength, as well as the biological performance.

Hybrid / Composite Hydrogels: The segment of cellulose-reinforced hydrogels that the hybrid / composite hydrogels is likely to increase considerably in the market. Higher degrees of durability, elasticity, and responsiveness can be added by using synthetic polymers reinforced with cellulose or natural polymers with cellulose nanofiber blends. They are highly flexible in nature to control the properties of swelling, degradation, and drug release finely. Enhanced studies in material hybridization and the development of nanocellulose integration will advance the market share of this segment.

Synthetic Polymer Hydrogels: The synthetic polymer hydrogels segment, with materials like polyacrylamide and polyethylene glycol, has a stable market presence based on the predictability and chemical stability. These hydrogels are high-mechanical performance, cross-linking control, and Standard swelling characteristics, which are useful in industrial, biomedical, and agricultural research. Combination with cellulose-based reinforcers is enhancing sustainability and toxicity reduction, so synthetic hydrogels are not becoming inapplicable in high-performance applications needing accuracy and longevity in the structure.

Application Insights

Wound Care & Dressing: The wound care & dressings segment led the cellulose-reinforced hydrogels market and accounted for the largest revenue share in 2024, owing to rising cases of chronic wounds, burns, and diabetic wounds. Hydrogels reinforced with cellulose give it good moisture retention, oxygen permeability, and antibacterial properties, which make it form the most perfect healing environment. They are non-toxic and have high biocompatibility, which limits the irritation with little effect, and their mechanical stability increases their durability during the application.

Tissue Engineering & Scaffolds: The tissue engineering & scaffolds segment is expected to grow at a significant CAGR over the forecast period. Cellulose-reinforced hydrogels are 3D porous, mechanically strong, thereby facilitating cell development, nutrient transport, and tissue regeneration. The ability to tailor their biodegradation rate and elasticity makes them useful in the synthesis of skin, cartilage, and bone tissues. Further expansion in their use in customized tissue-engineered constructs and implantable medical devices is likely to be met with the increased number of research collaborations and investment in biomaterials development.

Drug Delivery Systems: Another growth opportunity is the drug delivery systems, which are the leading business through the controlled-release and biocompatibility characteristics of cellulose-reinforced hydrogels. They are particularly useful because of the high water content and the ability to control the size of their pores and enabling the efficient encapsulation and release of the therapeutic agent in the drug. The addition of cellulose nanofibers increases structural integrity and physiological response to physiological conditions like pH or temperature.

End User / Sector Insights

Healthcare & Biomedical: The healthcare & biomedical sector contributed the most revenue in 2024 and is expected to dominate throughout the projected period. They are the most suitable to use in the medical field due to their superior biocompatibility, non-toxic, and high moisture retention characteristics. The nanocellulose is incorporated to increase the mechanical strength, increase the biofunctionality, and enable safer and more effective therapeutic solutions. The increasing investment in the areas of regenerative medicine, personalized healthcare, and sustainable biomaterials is an additional stepping stone in strengthening the dominance of the segment in the global market.

Agriculture & Horticulture: The agriculture and horticulture segment is projected to increase significantly over the forecast period due to increasing demand for water-saving and environmentally friendly agricultural materials. Hydrogels fortified with cellulose improve the capacity of the soil to retain moisture, transport nutrients, and germinate seeds, which increases yield in crops and decreases the frequency of irrigation. Also, the development of hydrogel formulation to control fertilizer release and limit drought is expanding their use in large-scale farming and in horticulture, especially in water-deficient areas.

Consumer Goods / Personal Care: The consumer goods and personal care segment is on the rise because of the growing consumer preference for natural, skin-friendly friendliness and biodegradable ingredients. Hydrogel solutions that have been reinforced using cellulose are being used in moisturizers, face masks, and hygiene products because of their high content of hydration, softness, as well as bio-safety. As the industry trends towards clean-label, sustainable personal care items, the suppliers are moving away from the use of petroleum-based polymers in favor of cellulose-based hydrogel.

Cellulose-Reinforced Hydrogels MarketRegion Insights

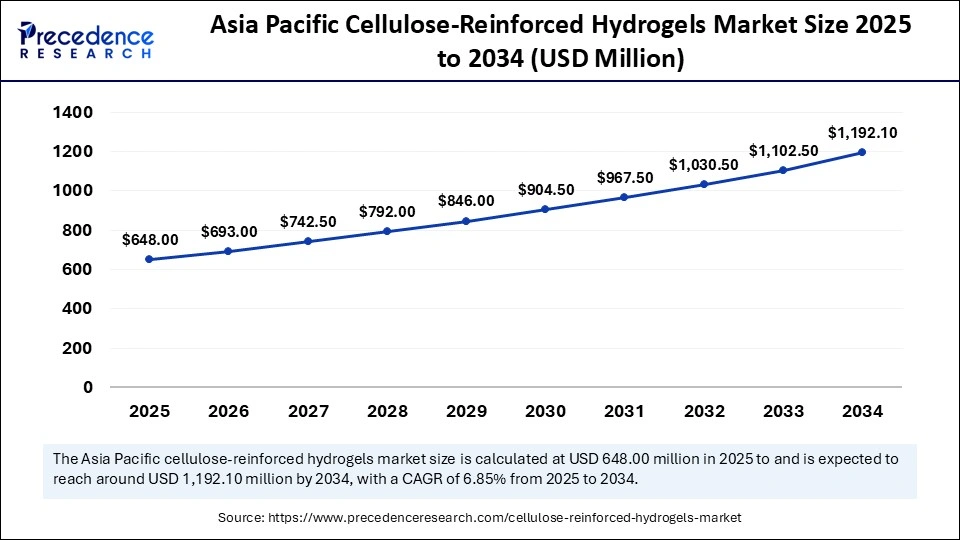

The Asia Pacific cellulose-reinforced hydrogels market size is expected to be worth USD 1,192.10 million by 2034, increasing from USD 648.00 million by 2025, growing at a CAGR of 6.97% from 2025 to 2034.

Why Did Asia Pacific Lead the Global Cellulose-Reinforced Hydrogels Market in 2024?

Asia Pacific held the dominating share of the cellulose-reinforced hydrogels market in 2024, due to the growing biomedical, pharmaceutical, as well as agricultural sectors in China, Japan, South Korea, and India. The high availability of cellulose in the region, coupled with the fast development of technology in the field of nanocellulose, has enhanced its dominance in sustainable biomaterials. Government programs promoting the use of bio-based materials, low-cost production, and availability of raw materials are promoting the production of hydrogel on a large scale. There is also an increasing demand for healthcare investment, wound care products, tissue engineering products, and environmental consciousness that is stimulating the adoption across the region. The academic institutions and biotechnology companies are also engaging in strategic partnerships to hasten research and commercialization efforts, making the Asia Pacific the global center of innovation and production of cellulose-reinforced hydrogel.

India Cellulose-Reinforced Hydrogels Market Trends

India is the most rapidly developing market in the Asia Pacific, which is estimated to achieve a CAGR of approximately 8.5% in the forecast period. The increasing number of healthcare facilities within the country, the growing attention to regenerative medicine, and the growing application of bio-based materials to wound care and pharmaceutical use are the drivers of growth. The domestic production and R&D investment of cellulose nanotechnology are also looking good because of government assistance in sustainable material research and the Make in India program. Cellulose-reinforced hydrogel is currently being utilized in agriculture to conserve water and rehabilitate soils to deal with drought and sustainability issues.

North America is estimated to grow at the fastest CAGR during the forecast period, due to the robust developments in biomedical engineering and nanotechnology, and sustainable material science. The high healthcare system in the region and the growing use of bio-based wound care, drug delivery, and tissue engineering products are creating a demand for cellulose-reinforced hydrogels. The next generation of cellulose composites is currently being worked on by research universities and biotechnology companies, and is more biocompatible and functional. Market growth is also promoted by the favorable policies of the government that stimulate the usage of environmentally friendly and biodegradable substances. Some new developments, such as collaborations between hydrogel manufacturers and pharmaceutical agencies that are improving commercialization, and the growing interest of consumers and industries in supporting green materials, are also present.

U.S. Cellulose-Reinforced Hydrogels Market Trends

The U.S cellulose-reinforced hydrogels market is witnessing a robust development because of the growing interest in the research of regenerative medicine, advanced wound management, and nanocellulose-based materials. The innovation in biotechnology and the cooperation between academia and industry are the leading positions of the country that are stimulating the product development and commercialization. Market growth is supported by high demand for sustainable and biocompatible materials used in medical devices and pharmaceuticals. Moreover, there is increased utilization of the cellulose-reinforced hydrogels in personal care and the environment, like water purification and packaging, in the U.S.

The European cellulose-reinforced hydrogels market is witnessing sustainable growth. Increased demand for cellulose-based reinforced hydrogels is being driven by the sustainable innovation and strict policies of the region that encourage the use of biodegradable materials in health care, cosmetics, and agriculture. Germany, Sweden, and Finland are some of the key nations that are putting significant investments in the development of nanocellulose and the production of bio-based polymers. Subsidies facilitating the process of green materials and biomanufacturing are still supportive of commercialization, making Europe a leading facility for the development of sustainable cellulose-reinforced hydrogel and manufacturing.

UK Cellulose-Reinforced Hydrogels Market Trends

The UK cellulose-reinforced hydrogels market is continuously rising, with vibrant research in the biomedical engineering, regenerative medical science, as well as sustainable material science. Wound care, drug delivery, and tissue regeneration Cellulosic Hydrogels Cellulosic hydrogels are being used as an advanced wound care, drug delivery, and tissue regeneration material by universities and biotech startups. The trend of plastic waste reduction and substitution of synthetic polymers with bio-based solutions is the trend that is adopted by the country, as the demand of the consumers is directed towards more environmentally friendly solutions. Commercialization and industrial application are also being pursued through government funding and alliances with innovators in the healthcare industry.

Quick Picks by Regional Insights: Cellulose-Reinforced Hydrogels Market

| Company | Country | Product/Technology |

Uses/Purpose |

| Axcelon Biopolymers Corp. | Canada | Nanocellulose-Reinforced Hydrogel Matrix | Used for wound dressings and tissue regeneration; enhances mechanical strength and moisture retention in biomedical applications. |

| Cellucomp Ltd. | U.K | Curran Nanocellulose Hydrogel | Utilized in cosmetic formulations and coatings; provides high viscosity and strength with sustainable cellulose reinforcement. |

| University of Uppsala / FiberLean Technologies | Sweden | CNF-Reinforced Hydrogel Composites | Research and industrial collaboration for sustainable medical and packaging hydrogels using cellulose nanofibers. |

| Nippon Paper Industries Co., Ltd. | Japan | Cellenpi Nanofiber Hydrogel | Applied in cosmetics, biomedical scaffolds, and flexible electronic substrates; focuses on high-purity cellulose nanofibers. |

| American Process Inc. | U.S. | BioPlus Nanocellulose Hydrogel | Bio-based reinforcement agent improving the elasticity and stability of polymer hydrogels for medical and industrial use. |

| BASF SE | Germany | Cellulose-Reinforced Polymer Hydrogel Systems | Integrated into personal care and medical applications, offers biodegradable alternatives to synthetic gels. |

| Suzano S.A. | Brazil | Microfibrillated Cellulose Hydrogel (MFC) | Developed for packaging and agricultural moisture control, promotes sustainable cellulose utilization in emerging markets. |

Recent Developments

- In October 2024, UPM Biomedicals introduced FibGel, a permanent medical implant injectable nanocellulose hydrogel. Comprised of birch wood cellulose and water as a whole, it is one of the biggest innovations of sustainable and biocompatible implants.(Source: https://www.upm.com)

- In July 2024, Cosmos Health manufactured the weight-management hydrogel CCX0722, having completed the pilot production of the product, which was made of natural ingredients. The product exhibited an impressive swelling ratio, indicating its possible efficacy in the areas of controlling the appetite and maintaining health in the metabolism.(Source: https://ng.investing.com)

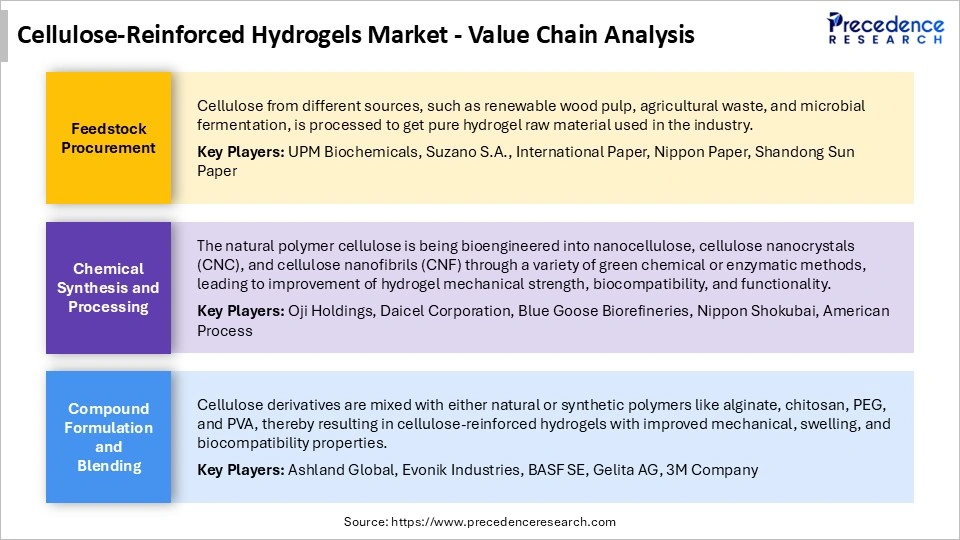

Cellulose-Reinforced Hydrogels Market Value Chain

Cellulose-Reinforced Hydrogels Market Companies

- Headquarters: Montreal, Quebec, Canada

- Year Founded: 2011

- Ownership Type: Joint Venture (Domtar Corporation and FPInnovations)

History and Background

CelluForce was founded in 2011 as a joint venture between Domtar Corporation and FPInnovations to commercialize nanocrystalline cellulose (CNC) — a breakthrough biomaterial derived from wood fibers. The company was one of the earliest and most significant industrial ventures dedicated to scaling up the production and application of cellulose nanocrystals (CNCs), positioning itself as a pioneer in advanced biomaterials innovation.

In the Cellulose-Reinforced Hydrogels Market, CelluForce plays a leading role as a global supplier of high-quality nanocellulose materials that significantly enhance the mechanical, rheological, and structural properties of hydrogel systems. Its CelluForce NCC® (nanocrystalline cellulose) is used in biomedical, cosmetic, and industrial hydrogel formulations, providing superior reinforcement, viscosity control, and biodegradability.

Key Milestones / Timeline

- 2011: Established as a joint venture between Domtar and FPInnovations

- 2012: Opened the worlds first commercial-scale nanocrystalline cellulose (CNC) plant in Windsor, Quebec

- 2016: Expanded production capacity and refined CNC purification processes

- 2020: Launched new grades of CelluForce NCC® tailored for high-performance hydrogels

- 2024: Strengthened R&D collaborations for CNC applications in biomedicine and soft materials engineering

Business Overview

CelluForce operates as a global producer of cellulose nanocrystals (CNCs), focusing on sustainable, bio-based materials that replace synthetic additives in polymer composites, coatings, and hydrogels. In the Cellulose-Reinforced Hydrogels Market, CelluForces CNCs serve as reinforcing agents that enhance the strength, stability, and elasticity of hydrogel networks. Its materials are used in wound dressings, drug delivery matrices, cosmetics, and industrial gels.

Business Segments / Divisions

- Nanocrystalline Cellulose Production

- Advanced Materials R&D

- Application Development for Biomedicine and Industrial Hydrogels

Geographic Presence

Headquartered in Montreal, with a large-scale production facility in Windsor, Quebec, CelluForce serves customers in North America, Europe, and Asia-Pacific.

Key Offerings

- CelluForce NCC® (nanocrystalline cellulose)

- High-purity CNC grades for biomedical and cosmetic hydrogels

- Technical collaboration and formulation support for hydrogel optimization

- Customized CNC dispersions for rheological modification in gels

Financial Overview

CelluForce operates as a privately held joint venture with annual revenues estimated at $25–40 million USD, supported by industrial contracts, government partnerships, and R&D funding for advanced biomaterials.

Key Developments and Strategic Initiatives

- April 2022: Announced strategic expansion of CNC capacity for life sciences and industrial applications

- August 2023: Introduced new formulation-grade CNC for bio-hydrogels used in wound healing

- May 2024: Collaborated with biomedical researchers for nanocellulose-based hydrogel scaffolds

- January 2025: Began pilot-scale production of CNC-stabilized hydrogel composites for cosmetic formulations

Partnerships & Collaborations

Collaborations with universities and research institutions for biomedical and hydrogel R&D

Partnerships with cosmetics and personal care brands for CNC integration into skincare hydrogels

Joint projects with industrial firms developing bio-based hydrogel composites

Product Launches / Innovations

- CelluForce NCC® Hydrogel Grade (2023)

- Nano-reinforced hydrogel additive for biomedical applications (2024)

- CNC dispersion designed for high-transparency cosmetic gels (2025)

Technological Capabilities / R&D Focus

Core technologies: Nanocellulose extraction, surface modification, and aqueous dispersion technologies

Research Infrastructure: R&D and pilot-scale production center in Windsor, Quebec

Innovation focus: Bio-based nanoreinforcement for hydrogels, sustainable materials for life sciences, and high-strength polymer composites

Competitive Positioning

- Strengths: First-mover advantage in CNC production, proprietary manufacturing technology, and proven industrial scalability

- Differentiators: High-purity nanocellulose and strong research integration in hydrogel development

SWOT Analysis

- Strengths: Sustainable production process, established supply chain, deep R&D expertise

- Weaknesses: Limited global production capacity relative to demand

- Opportunities: Growing biomedical and cosmetic hydrogel applications

- Threats: Competition from emerging nanocellulose suppliers and price-sensitive industrial markets

Recent News and Updates

- March 2024: CelluForce announced expansion of partnerships with life sciences companies for biohydrogel development

- July 2024: Launched new CNC-based reinforcing additives for wound care and medical gel products

- January 2025: Received government funding to scale sustainable nanomaterial production for hydrogel applications

- Headquarters: Sarpsborg, Norway

- Year Founded: 1889

- Ownership Type: Publicly Traded (Oslo Stock Exchange: BRG)

History and Background

Borregaard AS was established in 1889 as a pulp and paper company and has since evolved into a leading global producer of advanced biochemicals and sustainable biomaterials derived from wood. The company has transitioned from traditional cellulose production to high-value biopolymers, lignin-based chemicals, and microfibrillated cellulose, positioning itself as a global leader in green chemistry and bio-based innovation.

In the Cellulose-Reinforced Hydrogels Market, Borregaard develops and supplies microfibrillated cellulose (MFC) and specialty biopolymers that act as rheology modifiers, stabilizers, and structural reinforcements for hydrogel formulations. Its Exilva® MFC product line is designed to enhance the viscosity, mechanical strength, and durability of hydrogels in pharmaceutical, cosmetic, and industrial applications.

Key Milestones / Timeline

- 1889: Founded in Sarpsborg, Norway as a pulp manufacturer

- 2012: Launched Exilva, Borregaards flagship microfibrillated cellulose (MFC) product line

- 2017: Expanded commercial production capacity for MFC and lignin derivatives

- 2021: Enhanced R&D for cellulose-based materials in biomedicine and soft matter applications

- 2024: Introduced next-generation Exilva formulations optimized for hydrogel reinforcement

Business Overview

Borregaard operates as a bio-based chemical company, producing specialty cellulose derivatives, lignin-based polymers, and MFC for diverse applications. Within the Cellulose-Reinforced Hydrogels Market, Borregaards MFC serves as a bio-reinforcement agent that improves hydrogel consistency, elasticity, and water retention. Its bio-based solutions are applied across personal care, wound healing, controlled-release systems, and industrial thickening applications.

Business Segments / Divisions

- Performance Chemicals (Lignin and Cellulose Derivatives)

- Specialty Cellulose and Microfibrillated Cellulose

- Fine Chemicals and Biopolymers

Geographic Presence

Borregaard has operations in over 20 countries with production facilities in Norway, the United States, Germany, and Brazil.

Key Offerings

- Exilva® microfibrillated cellulose (MFC) for hydrogel reinforcement

- Bio-based polymers and rheology modifiers for hydrogel stability

- Sustainable cellulose derivatives for industrial and cosmetic formulations

- Customized hydrogel blends for wound care and personal care markets

Financial Overview

Borregaard reports annual revenues of approximately $700–750 million USD, with growing contributions from specialty cellulose and bio-based polymer divisions. Its investments in microfibrillated cellulose (MFC) technologies continue to support expansion in the biohydrogel and green materials sectors.

Key Developments and Strategic Initiatives

- April 2022: Increased Exilva® MFC production capacity at its Sarpsborg facility

- October 2023: Partnered with cosmetic formulators to expand hydrogel-based skincare products

- May 2024: Launched advanced Exilva® formulations for biomedical and industrial hydrogel applications

- January 2025: Began pilot-scale trials on hybrid cellulose-lignin hydrogels for medical and packaging applications

Partnerships & Collaborations

- Collaborations with academic institutions for biomaterial and hydrogel research

- Partnerships with pharmaceutical and personal care companies for MFC-based product integration

- Strategic alliances with industrial manufacturers for sustainable hydrogel reinforcement solutions

Product Launches / Innovations

- Exilva® MFC Hydrogel Series (2023)

- Next-generation bio-stabilizers for cellulose-reinforced hydrogels (2024)

- Hybrid cellulose-lignin hydrogel formulations (2025)

Technological Capabilities / R&D Focus

- Core technologies: Microfibrillated cellulose production, biopolymer synthesis, and rheology engineering

- Research Infrastructure: Innovation center and pilot plant in Sarpsborg, Norway

- Innovation focus: Advanced bio-based reinforcement for hydrogels, high-performance rheology control, and biodegradable material design

Competitive Positioning

- Strengths: Extensive bio-based materials expertise, scalable MFC technology, strong global distribution network

- Differentiators: Proven industrial track record in cellulose chemistry and sustainable hydrogel applications

SWOT Analysis

- Strengths: Technological leadership in cellulose biopolymers, sustainability credentials, global reach

- Weaknesses: High production costs compared to synthetic alternatives

- Opportunities: Growing demand for green and biodegradable hydrogel components

- Threats: Competition from lower-cost MFC producers and synthetic polymer suppliers

Recent News and Updates

- March 2024: Borregaard expanded R&D focus on Exilva® MFC applications in hydrogel medical materials

- September 2024: Partnered with European cosmetics brand for cellulose-based skincare hydrogels

- January 2025: Announced hybrid biopolymer program for next-generation cellulose-reinforced hydrogel technologies

Other Companies in the Market

- Stora Enso Oyj: The company is involved in the biomaterials division, whereby it is developing renewable cellulose nanofiber technologies to be used in the production of hydrogel for use in healthcare and packaging.

- JRS Rettenmaier & Sohne GmbH + Co KG: Provides a large selection of functional cellulose fibers and microcrystalline cellulose to enhance the texture, stability, and performance of the hydrogel.

- Fibril AB: Specializes in the development of innovative nanocellulose-based formulations in high-strength biocompatible hydrogels in medical, cosmetic, and industrial final applications.

- Stora Enso Oyj (Finland): Through its Biomaterials division, Stora Enso is advancing renewable cellulose nanofiber (CNF) technologies for hydrogel production in medical, wound-care, and sustainable packaging applications. The company R&D focus lies in replacing petroleum-based polymers with bio-based hydrogel materials.

- JRS Rettenmaier & Söhne GmbH + Co KG (Germany): JRS Rettenmaier provides functional cellulose fibers, microcrystalline cellulose, and derivatives that enhance the texture, stability, and fluid-holding capacity of hydrogels. Its products are used across pharmaceutical, food, and cosmetic hydrogel formulations.

- Fibril AB (Sweden): Fibril AB specializes in nanocellulose-based hydrogel systems designed for biomedical, cosmetic, and industrial applications. The company focuses on high-strength, biocompatible, and biodegradable formulations, enabling innovation in tissue engineering and wound-care materials.

- NanoCell Farms (U.S.): NanoCell Farms produces customized cellulose nanomaterials optimized for hydrogel reinforcement, with a focus on high surface-area nanocellulose for enhanced mechanical strength and water retention in advanced biomaterials.

- ASHA Cellulose (I) Pvt. Ltd. (India): ASHA Cellulose manufactures cellulose ethers and microcrystalline cellulose used in hydrogel production for pharmaceutical, cosmetic, and industrial purposes. Its emphasis on cost-effective biopolymer solutions supports emerging-market applications.

- Ankit Pulps & Boards Pvt. Ltd. (India): Ankit Pulps & Boards produces high-purity cellulose derivatives including MCC and CMC grades that act as structural and rheological modifiers in cellulose-reinforced hydrogels, widely used in personal care and controlled-release formulations.

- Cellulose Lab Inc. (Canada): Cellulose Lab provides nanocellulose dispersions and powders tailored for biomedical and industrial hydrogel formulations. Its R&D efforts focus on surface-functionalized nanocellulose to improve hydrogel flexibility and bioactivity.

- Innventia AB (now RISE Research Institutes of Sweden): RISE develops nanocellulose-enhanced hydrogels for biomedical and packaging applications, leveraging expertise in fiber technology and material science. Its collaborative research programs accelerate the commercialization of bio-based hydrogel technologies.

- Weiming Pharmaceutical Co., Ltd. (China): Weiming produces pharmaceutical-grade cellulose derivatives used in drug-delivery hydrogels. The company advanced hydrogel excipients support controlled release and stability in topical and oral formulations.

- Mingtai Chemical Co., Ltd. (Taiwan): Mingtai Chemical supplies cellulose-based excipients and hydrogel ingredients, including MCC and HPMC, for medical, food, and cosmetic uses. The companys GMP-certified production ensures consistency for hydrogel reinforcement applications.

- Huzhou City Linghu Xinwang Chemical Co., Ltd. (China): The company manufactures carboxymethyl cellulose (CMC) and hydroxyethyl cellulose (HEC) for use as thickening, binding, and film-forming agents in hydrogel systems across multiple end-use industries.

- Izumi Bio-Material Co., Ltd. (Japan): Izumi develops biodegradable cellulose-based materials utilized in cosmetic and biomedical hydrogels. The company emphasizes environmental sustainability and high biocompatibility, aligning with Asias green materials innovation trends.

- Sappi Europe (Nanocellulose Division, Belgium): Sappi Europe produces Cellulose NanoFibrils (CNF) and microfibrillated cellulose (MFC) for hydrogel reinforcement in cosmetic, medical, and packaging sectors. Its focus on circular bio-economy principles and renewable raw materials strengthens its position in sustainable polymer replacements.

Cellulose-Reinforced Hydrogels MarketSegments Covered in the Report

By Cellulose Type

- Bacterial Cellulose Nanofibers

- Nanocellulose (cellulose nanofibers, nanocrystals)

- Modified Cellulose Derivatives (carboxymethyl cellulose, hydroxypropyl cellulose)

- Microcrystalline / Amorphous Cellulose

By Polymer Matrix / Hydrogel Base

- Synthetic Polymer Hydrogels

- Polyacrylamide

- Polyethylene Glycol

- Natural Polymer Hydrogels

- Alginate

- Chitosan

- Gelatin

- Hybrid / Composite Hydrogels

- Synthetic + Cellulose reinforcement

- Natural polymer + cellulose nanofiber blends

By Application

- Wound Care & Dressings

- Tissue Engineering & Scaffolds

- Drug Delivery Systems

- Agriculture & Soil Moisture Management

- Personal Care & Cosmetics

- Others

By End-User / Sector

- Healthcare & Biomedical

- Agriculture & Horticulture

- Consumer Goods / Personal Care

- Packaging & Functional Materials

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting