Piezoelectric Smart Material Market Size and Forecast 2025 to 2034

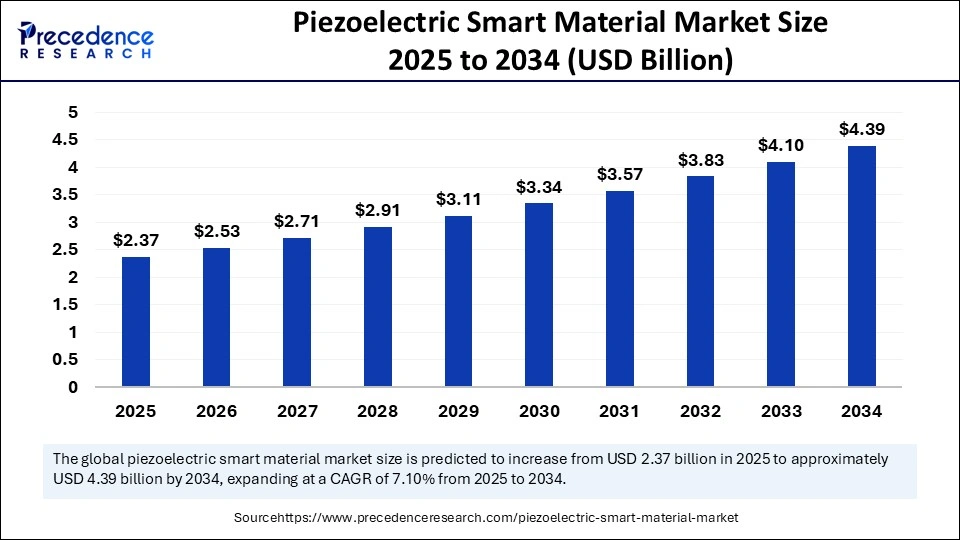

The global piezoelectric smart material market size was estimated at USD 2.21 billion in 2024 and is predicted to increase from USD 2.37 billion in 2025 to approximately USD 4.39 billion by 2034, expanding at a CAGR of 7.10% from 2025 to 2034. The growth of the market is driven by the increasing demand from the military and aerospace sectors. Sectors such as commercial airlines, defense, and space exploration constantly seek reliable, strong, and modern materials suitable for highly specialized applications. This need has significantly contributed to the rising demand for piezoelectric smart materials within the aerospace and defense sectors.

Piezoelectric Smart Material Market Key Takeaways

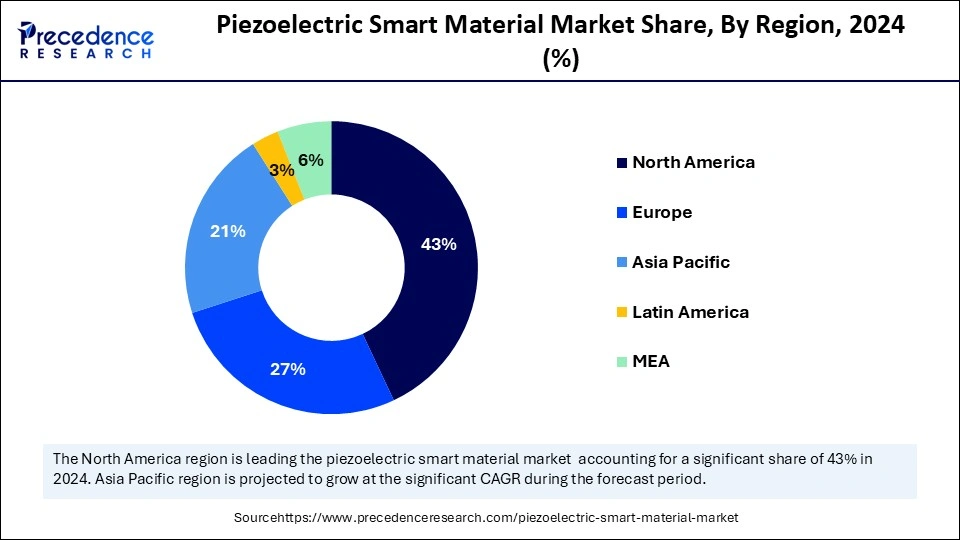

- North America dominated the piezoelectric smart material market with the largest share of 43% in 2024.

- Asia Pacific is estimated to grow at the fastest CAGR in the market between 2025 and 2034.

- Europe is considered to be a notably growing market in the upcoming period.

- By material type, the ceramic segment dominated the market in 2024.

- By material type, the polymer segment will grow at a notable CAGR from 2025 to 2034.

- By end use industry, the aerospace segment dominated the market with the largest share in 2024.

- By form factor, the flexible segment accounted for the largest market share in 2024.

- By form factor, the rigid segment will grow rapidly from 2025 to 2034.

- By application, the sensors segment dominated the market, accounting for the largest share in 2024.

- By application, the actuators segment will expand at a significant CAGR during the forecast period.

- By end use, the aerospace segment dominated the market in 2024.

- By end use industry, the automotive segment is the fastest growing segment with a significant CAGR during the forecast period.

Artificial Intelligence (AI) in Piezoelectric Smart Material Development

The incorporation of Artificial Intelligence within the piezoelectric smart material market is transforming multiple sectors by improving performance, predictive analytics, automation, and energy efficiency. Technologies powered by AI are enhancing the capabilities of piezoelectric materials through real-time monitoring, adaptive control, and smart features, broadening their use in automotive, aerospace, healthcare, and consumer electronics. A key application of AI in piezoelectric smart materials is seen in self-learning and adaptive sensor systems.

AI-enhanced algorithms boost sensor accuracy and responsiveness by persistently analyzing data trends from piezoelectric sensors. This proves particularly beneficial for health monitoring, industrial automation, and robotics, where real-time adaptive sensing is crucial for accurate control and predictive upkeep. AI-driven piezoelectric sensors can automatically adapt to environmental changes, increasing sensitivity and efficiency in detecting variations in pressure, vibration, and strain. In energy harvesting applications, AI improves the effectiveness of piezoelectric-based energy generation systems by optimizing power output according to real-time usage information.

U.S. Piezoelectric Smart Material Market Size and Growth 2025 to 2034

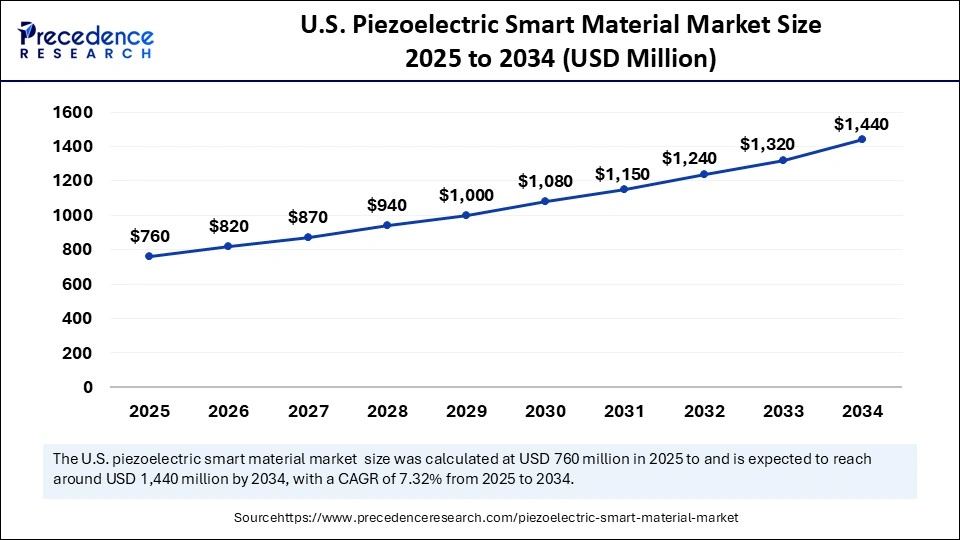

The U.S. piezoelectric smart material market size was exhibited at USD 760 million in 2024 and is projected to be worth around USD 1,440 million by 2034, growing at a CAGR of 7.32% from 2025 to 2034.

North America Market Trends

North America dominated the piezoelectric smart material market with the largest share due to advancements in technology, robust industrial frameworks, and significant use of smart materials in aerospace, healthcare, and automotive sectors. The region hosts numerous prominent manufacturers, research facilities, and key market stakeholders that are continuously investing in cutting-edge piezoelectric technologies.

The increasing focus on smart sensors, IoT-connected devices, and energy-efficient systems has heightened the demand for piezoelectric smart materials across different industries. The aerospace and defense sector in North America significantly drives the need for piezoelectric materials, utilizing them for vibration control, structural health monitoring, and sophisticated actuator systems in aircraft and satellites.

United States

The United States takes the lead in the North American piezoelectric smart material market due to its strong presence in the aerospace, healthcare, and consumer electronics sectors. Prominent aerospace companies like Boeing and Lockheed Martin utilize piezoelectric-based actuators and sensors extensively for applications in aircraft and satellites. Additionally, the U.S. serves as a center for medical innovation, with leading healthcare firms incorporating piezoelectric sensors into advanced diagnostic imaging systems, ultrasound instruments, and biomedical wearables.

Canada

Canada is experiencing steady growth in its market, bolstered by a burgeoning aerospace industry, increased investment in clean energy solutions, and heightened demand for automation in industrial settings. The Canadian Space Agency and prominent research organizations are actively exploring piezoelectric applications in satellite systems, robotic arms, and the structural monitoring of aircraft. Furthermore, Canada's commitment to sustainable transportation initiatives and smart city development is driving the demand for piezoelectric materials in applications related to energy harvesting and vibration monitoring.

Asia Pacific Market Trends

Asia Pacific is estimated to grow at the fastest CAGR in the piezoelectric smart material market, fueled by rapid industrial development, rising consumer electronics demand, and advancements in automotive and energy-harvesting technologies. The region's increasing focus on robotics, automation, and AI-driven smart materials has resulted in widespread implementation of piezoelectric sensors, actuators, and energy-harvesting solutions across industries like automotive, healthcare, and telecommunications. Supported by governmental initiatives in smart manufacturing and internet of things IoT adoption, Asia Pacific nations are making substantial investments in AI-integrated piezoelectric applications.

China

China plays a pivotal role in the Asia Pacific piezoelectric smart material market, propelled by its leading electronics manufacturing industry, swift developments in automotive technologies, and substantial investments in AI-driven industrial sectors. The Chinese government's Made in China 2025 initiative aims to bolster high-tech sectors, including robotics, AI, and smart materials, thereby increasing the demand for piezoelectric-based automation systems, flexible sensors, and self-powered devices.

Japan

Japan holds a prominent position in the global market for piezoelectric smart materials, featuring top companies that specialize in precision electronics, robotics, and healthcare applications. The nation is leading the way in AI-driven robotics, intelligent automation, and energy-efficient technologies, which are fostering opportunities for piezoelectric sensors and actuators in industrial automation, AI-enhanced diagnostic tools, and medical wearable devices.

Europe Market Trends

Europe is considered to be a significantly growing area in the piezoelectric smart material market, bolstered by considerable investments in aerospace, automotive advancements, and sustainable energy solutions. The European Union's commitment to reducing carbon emissions, improving energy efficiency, and fostering smart infrastructure has propelled the use of piezoelectric energy harvesting technologies, vibration monitoring systems, and AI-integrated industrial automation. The aerospace and defense sector in Europe plays a crucial role in driving demand for piezoelectric sensors and actuators, as they are essential for active noise control, flight stabilization, and satellite communications.

Germany

Germany serves as a key player in the piezoelectric smart material market across Europe, propelled by its robust automotive sector, leadership in industrial automation, and emphasis on AI-driven robotics. Major German automotive manufacturers like Volkswagen, BMW, and Mercedes-Benz are adopting piezoelectric-based motion control, intelligent sensors, and adaptive touch displays in their upcoming vehicle models.

France

France is experiencing an increased adoption of piezoelectric smart materials, especially in the aerospace, medical technology, and renewable energy sectors. The French aerospace sector, spearheaded by Airbus and Safran, utilizes piezoelectric actuators for enhanced aircraft control, noise reduction, and structural health monitoring. Furthermore, France's investments in sustainable energy initiatives, like wind turbine technology and smart grid solutions, are driving the demand for piezoelectric energy harvesting systems.

Market Overview

Piezoelectric smart materials are specialized construction materials utilized in sensors for evaluating fluid density, impact force, and composition. When subjected to external environmental stimuli such as temperature, moisture, stress, pH, or magnetic fields, these materials alter their properties. Consequently, they are incorporated into sensors, transducers, actuators, and various electronic devices. Piezoelectric smart materials can be categorized based on their type, including ceramics, composites, and polymers.

In the aerospace sector, the piezoelectric smart material market plays a crucial role in directing and maintaining airflow over an aircraft's wings during take-off and landing. These materials are known to address typical challenges faced by aircraft, such as engine vibrations, elevated cabin noise levels, ice accumulation on wings, turbulence-induced flow separation, and control surfaces in cold conditions. Many airlines globally have expanded their fleets by acquiring new aircraft and delaying the retirement of older models to meet passenger demand in this market environment.

Piezoelectric Smart Material Market Growth Factors

- Growing demand for advanced sensors and actuators: The rising usage of piezoelectric sensors and actuators across automotive, aerospace, and industrial automation sectors is propelling market expansion. These materials facilitate high-precision movement, vibration control, and structural health monitoring, rendering them vital in robotics, medical apparatus, and adaptive suspension systems.

- Growth of energy harvesting applications: Piezoelectric materials are becoming increasingly popular in energy harvesting systems, where they convert mechanical vibrations into electrical energy suitable for wearables, IoT devices, and smart infrastructure. As industries prioritize sustainable and self-sufficient technologies, the demand for efficient piezoelectric energy solutions is growing.

- Increased utilization in medical and healthcare technologies: The healthcare sector is experiencing a surge in the use of piezoelectric materials for ultrasound imaging, wearable biosensors, and smart prosthetics. Their capacity to deliver precise motion control, improved imaging resolution, and real-time patient monitoring is driving their use in advanced medical devices.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD4.39 Billion |

| Market Size in 2025 | USD 2.37 Billion |

| Market Size in 2024 | USD 2.21 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 7.10% |

| Dominated Region | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material Type, Form Factor, Application, End Use Industry and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Drivers

Increased demand for smart sensors and actuators in industrial automation and consumer electronics

A key factor propelling the piezoelectric smart material market is the growing need for high-precision sensors and actuators in industrial automation, robotics, and consumer electronics. Piezoelectric materials provide rapid response times, high sensitivity, and energy efficiency, making them well-suited for motion control systems, touch-sensitive devices, and vibration monitoring solutions. In the realm of industrial automation, piezoelectric sensors and actuators are utilized in smart manufacturing, adaptive machinery, and robotics to improve precision and efficiency. These materials are vital in structural health monitoring systems, allowing for real-time vibration detection and failure forecasting in infrastructure, aircraft, and bridges.

Restraint

High expense of advanced piezoelectric materials and manufacturing difficulties

A significant constraint hindering the growth of the piezoelectric smart material market is the elevated cost associated with advanced piezoelectric materials and the intricate manufacturing processes required for their production. Materials such as piezoelectric ceramics, including lead zirconate titanate, and advanced polymer-based piezoelectric substances demand precise fabrication techniques and specialized processing approaches, which elevate production costs and limit scalability. The expense of incorporating piezoelectric materials into complex electronic systems poses a challenge for manufacturers, especially in price-sensitive industries like wearable electronics and IoT devices.

Opportunity

Growth of Energy Harvesting Applications for Sustainable Power Solutions

A notable opportunity in the piezoelectric smart material market is the growth of energy harvesting applications, where piezoelectric materials convert mechanical vibrations into electrical energy. As the focus on sustainable power generation and self-sufficient electronics increases, piezoelectric energy harvesting is gaining popularity across various sectors, including wearables, infrastructure, and IoT devices. In the realm of wearable technology, piezoelectric energy harvesters are being incorporated into smartwatches, fitness trackers, and biomedical monitoring devices, allowing these devices to generate energy from body movements and mechanical strain. This development facilitates the creation of battery-free, self-sustaining electronic devices, reducing dependency on external power supplies and enhancing the longevity of the devices.

Material Type Insights

The ceramic segment dominated the piezoelectric smart material market with the largest share, owing to its excellent piezoelectric properties, durability, and stability under extreme conditions. Ceramic-based piezoelectric materials, such as lead zirconate titanate, find extensive use in sensors, actuators, medical ultrasound transducers, and industrial process monitoring. Their high piezoelectric coefficient, mechanical strength, and thermal resilience make them the preferred option for demanding applications, including automotive fuel injection systems, sonar devices, and non-destructive testing equipment.

The polymer segment will grow at a notable CAGR from 2025 to 2034, owing to its flexibility, lightweight characteristics, and capacity to adapt to complex surfaces. Piezoelectric materials based on polymers, like polyvinylidene fluoride, are becoming increasingly favored in wearable electronics, soft robotics, and flexible energy harvesting devices. In contrast to rigid ceramics, polymer piezoelectric materials can be integrated into fabrics, curved surfaces, and stretchable sensors, which makes them suitable for advanced biomedical devices, electronic skin, and foldable displays.

Form Factor Insights

The flexible segment dominated the market in 2024, due to its extensive application in wearable devices, biomedical fields, and bendable electronics. Flexible piezoelectric materials, such as films made from PVDF, are frequently employed in health monitoring patches, smart textiles, and pressure-sensitive touch interfaces. Their capability to adapt to curved surfaces and stretch without losing performance makes them ideal for future electronics, soft robotics, and biologically integrated sensors.

The rigid segment will grow rapidly from 2025 to 2034, driven by its excellent durability, mechanical strength, and stability in industrial settings. Rigid piezoelectric materials, including ceramic-based components, are commonly utilized in high-performance actuators, ultrasonic transducers, and non-destructive testing instruments. Their resilience under extreme temperatures, high-pressure conditions, and long-duration operational stress renders them suitable for heavy machinery, aerospace roles, and automotive powertrains.

Application Insights

The sensors segment dominated the market with the largest market share due to its widespread application in industrial automation, medical diagnostics, aerospace, and consumer electronics. Piezoelectric sensors are commonly utilized to detect pressure, force, acceleration, and vibrations, making them essential for structural health monitoring, touch-sensitive controls, and energy harvesting systems. The rising use of smart sensors in industrial IoT, automotive safety systems, and wearable health devices has significantly increased demand.

The actuators segment is the will expand at a significant CAGR during the forecast period, driven by innovations in robotics, aerospace control systems, and precision motion devices. Piezoelectric actuators transform electrical signals into mechanical motion, facilitating micro-positioning, haptic feedback, and active noise cancellation across numerous industries. In aerospace and defense sectors, these actuators are utilized for adaptive wing structures, vibration dampening, and fuel injection control, enhancing performance and fuel efficiency.

End Use Industry Insights

The aerospace segment dominated the market with the largest share, largely due to the essential function of piezoelectric materials in vibration control, structural health monitoring, and precise actuation within aircraft. These materials are widely utilized in active damping systems, engine health monitoring, ultrasonic inspections of aircraft structures, and morphing wing designs. In the realms of space exploration and satellite technology, piezoelectric actuators and sensors contribute to optimizing fuel efficiency, minimizing noise, and facilitating real-time assessments of structural integrity.

The automotive segment is the fastest growing segment with a significant CAGR during the forecast period due to the growing implementation of piezoelectric materials in electric vehicles, advanced driver-assistance systems, and intelligent interiors. These materials are crucial for applications such as knock sensors, fuel injection systems, tire pressure monitoring, and vibration-damping solutions that boost vehicle performance, fuel efficiency, and overall safety. As car manufacturers make investments in autonomous driving technologies, haptic touchscreens, and self-sufficient sensors, the incorporation of piezoelectric-driven motion control, energy harvesting, and noise reduction technologies is propelling swift market expansion.

Piezoelectric Smart Material Market Companies

- PI Ceramic

- Piezotech

- CeramTec

- Thales Group

- Texas Instruments

- Toshiba

- Honeywell

- Kyocera

- Noliac

- Meggitt

- CEDRAT Technologies

- Kistler

- APC International

- Sensata Technologies

- Mide Technology

Leader's Announcements

- In April 2023, a research team at KAIST, led by Professor Keon Jae Lee from the Department of Materials Science and Engineering, in collaboration with the College of Medicine at the Catholic University of Korea, successfully developed a highly sensitive wearable blood pressure sensor utilizing piezoelectric technology.

Recent Developments

- In January 2023, Kistler Group introduced a piezoelectric sensor solution specifically designed for angled structures, such as aircraft wings. The new cylindrical accelerometer 8775A meets various aerospace requirements, including high sensitivity, low noise levels, and lightweight characteristics.

- In June 2024, CeramTec GmbH unveiled the ceramic substrate Sinalit. This development enables greater diversity in solutions and enhances sustainability. The attributes of silicon nitride enhance performance across numerous applications and support a successful transition toward electromobility and new energy sources.

Segments Covered in the Report

By Material Type

- Ceramic

- Polymer

- Composite

- Single Crystal

By Form Factor

- Flexible

- Rigid

- Thin Film

- Bulk

By Application

- Sensors

- Actuators

- Energy Harvesting

- Medical Devices

- Others

By End Use Industry

- Aerospace

- Automotive

- Consumer Electronics

- Healthcare

- Industrial

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Get a Sample

Get a Sample

Table Of Content

Table Of Content