What is Traction Inverter Market Size?

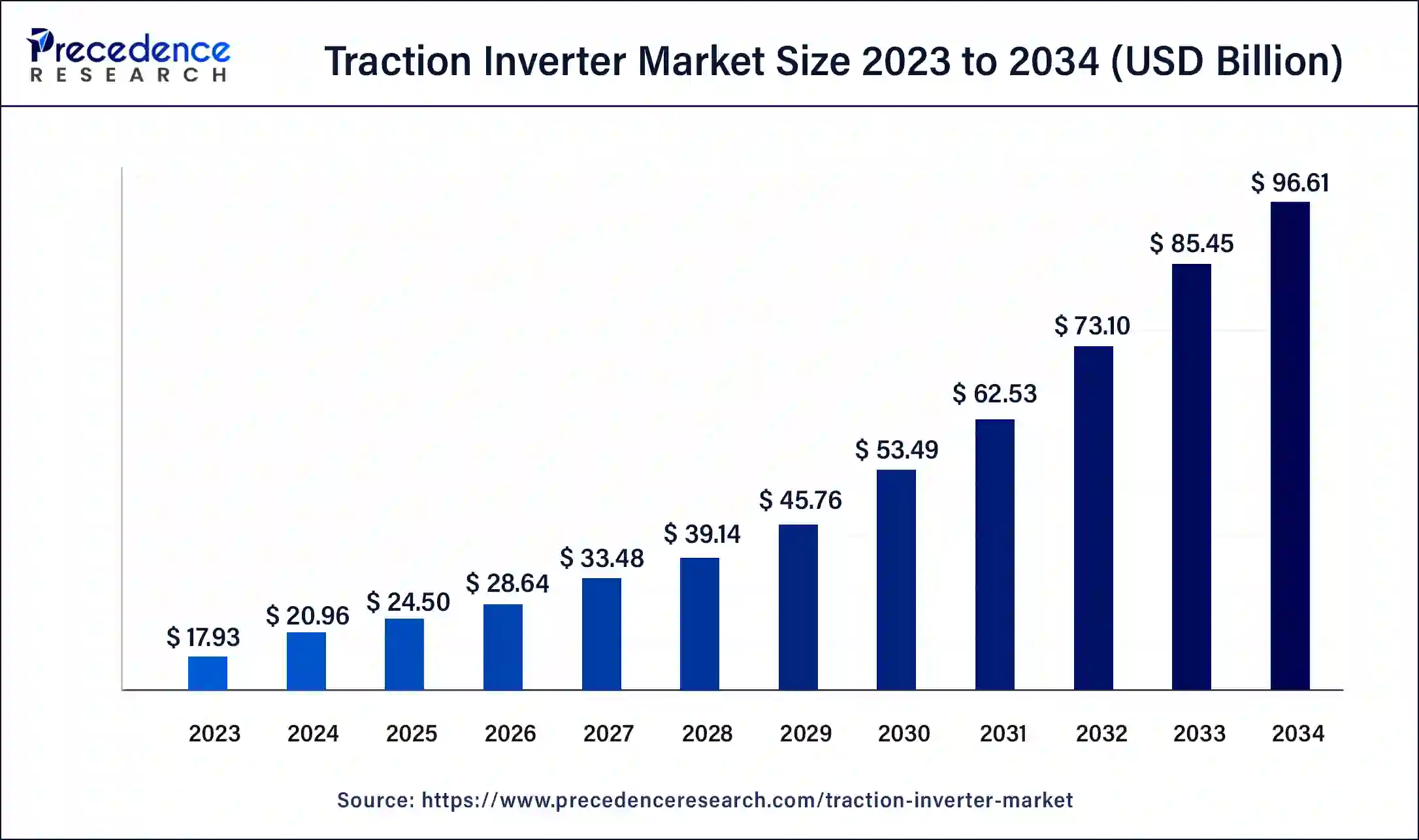

The global traction inverter market size accounted for USD 24.50 billion in 2025 and is predicted to reach around USD 96.61 billion by 2034, growing at a CAGR of 16.51% from 2025 to 2034.

Market Highlights

- North America contributed more than 44% of revenue share in 2024.

- Asia-Pacific is estimated to expand the fastest CAGR between 2024 and 2034.

- By propulsion, the BEV segment has held the largest market share of 44% in 2024.

- By propulsion, the PHEV segment is anticipated to grow at a remarkable CAGR of 17.2% between 2024 and 2034.

- By voltage, the 200 to 900V segment generated over 38% of revenue share in 2024.

- By voltage, the 900V and above segment is expected to expand at the fastest CAGR over the projected period.

- By technology, the MOSFET segment generated over 46% of revenue share in 2024.

- By technology, the IGBT segment is expected to expand at the fastest CAGR over the projected period.

- By vehicle, the commercial Vehicles segment generated over 42% of revenue share in 2024.

- By vehicle, the passenger cars segment is expected to expand at the fastest CAGR over the projected period.

Artificial Intelligence: The Next Growth Catalyst in Traction Inverter

Artificial Intelligenceis significantly impacting the traction inverter market by transforming inverters into intelligent, adaptive components critical for electric vehicle (EV) performance and efficiency. AI and machine learning algorithms are used in the design, control, and maintenance of inverters, helping to optimize energy flow from the battery to the motor and enabling features like Vehicle-to-Grid (V2G) technology. This technology allows automakers to develop customized inverter solutions for specific vehicle models and driving conditions, enhancing overall energy efficiency and range. AI-powered systems also provide predictive diagnostics and real-time performance optimization, enabling predictive maintenance that reduces operational downtime and extends component lifespan.

Strategic Overview of the Global Traction Inverter Industry

A traction inverter is a crucial component in electric and hybrid vehicles, responsible for turning the battery's direct current (DC) into the alternating current (AC) needed to power the electric motor. This conversion is essential for driving the vehicle. The traction inverter plays a vital role in managing power flow, controlling motor speed, and optimizing energy use.

Modern traction inverters feature sophisticated power electronics and control systems, ensuring precise control over AC output for seamless acceleration and deceleration. These inverters are also equipped with safety mechanisms, such as overcurrent and overvoltage protection, to safeguard the vehicle's electrical system. As the electric mobility landscape expands, the efficiency and dependability of traction inverters become increasingly significant, contributing to overall vehicle performance and advancing sustainable transportation by reducing reliance on traditional internal combustion engines.

Traction Inverter Market Growth Factors

- Rising Electric Vehicle Popularity: The traction inverter market is growing due to the increasing use of electric vehicles worldwide, as more people opt for eco-friendly transportation options.

- Tightened Emission Standards: Government regulations pushing for lower vehicle emissions are compelling carmakers to switch to electric propulsion, boosting the demand for traction inverters.

- Advancements in Technology: Ongoing progress in power electronics and semiconductors is improving the efficiency of traction inverters, making them more powerful and sought after.

- Widespread Charging Infrastructure: The expansion of electric vehicle charging networks globally is positively impacting the adoption of electric cars and, consequently, the demand for traction inverters.

- Investments in Research and Development: Increased funding in research and development by key industry players is fostering innovation, leading to more efficient and cost-effective traction inverter solutions.

- Government Support and Incentives: Governments around the world are providing financial incentives to promote electric vehicle adoption, creating a favorable environment for the traction inverter market.

- Growing Consumer Awareness: Rising consumer awareness of the environmental impact of traditional vehicles is driving interest in electric cars, contributing to the growth of the traction inverter market.

- Cost Reduction Efforts: Ongoing initiatives to lower the overall cost of electric vehicles, including traction inverters, are making electric mobility more accessible and supporting market growth.

- Enhanced Vehicle Performance: Traction inverters play a crucial role in improving the overall performance of electric vehicles, attracting consumers looking for superior driving experiences.

- Extended Electric Vehicle Range: Continuous improvements in traction inverter efficiency are extending the driving range of electric vehicles, addressing a key concern for potential buyers.

- Entry of New Market Players: New players entering the traction inverter market are spurring competition, encouraging innovation, and expanding the market landscape.

- Investment in E-Mobility Startups: Increased investment in startups focused on electric mobility is driving technological advancements and innovative traction inverter solutions.

- Global Expansion of EV Manufacturers: The expansion of electric vehicle manufacturers into new markets is increasing the demand for traction inverters due to higher production and sales.

- Smart Grid Integration: Integrating traction inverters with smart grid technologies is improving energy management in electric vehicles, contributing to market growth.

- Consumer Preference for Green Tech: Changing consumer preferences towards environmentally friendly technologies are boosting the adoption of electric vehicles and, subsequently, traction inverters.

- Advances in Battery Tech: Progress in battery technologies, such as higher energy density and faster charging, is positively impacting the efficiency and performance of traction inverters.

- Electrification of Commercial Vehicles: The focus on electrifying commercial vehicle fleets, driven by environmental concerns and regulatory support, is a significant growth factor for the traction inverter market.

- BorgWarner's annual revenue for 2022 was $15.801B, a 6.49% increase from 2021. Borg Warner's annual revenue for 2021 was $14.838B, a 45.97% increase from 2020.

Market Outlook

- Market Growth Overview: The Traction Inverter market is expected to grow significantly between 2025 and 2034, driven by the rapid adoption of electric vehicles (EVs) and advancements in power electronics like Silicon Carbide (SiC). The integration of inverters into compact e-axle systems, the move to higher voltage architectures, and the use of AI for improved performance and efficiency.

- Sustainability Trends: Sustainability trends involve the development of compact, lightweight designs that require fewer materials and the integration of Vehicle-to-Grid capabilities to support grid stabilization.

- Major Investors: Major investors in the market include Vanguard Group, Inc., BlackRock, Inc., Capital Research Global Investors, and State Street Corporation.

- Startup Economy: The startup economy in the market is an integrated powertrain solution, niche application and mobility segments, and advanced control and AI integration.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 24.50 Billion |

| Market Size in 2026 | USD 28.64 Billion |

| Market Size by 2034 | USD 96.61 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 16.51% |

| Largest Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Propulsion, Voltage, Technology, Vehicle, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Expansion of charging infrastructure and advancements in power electronics

The expansion of electric vehicle (EV) charging infrastructure and advancements in power electronics are two pivotal factors driving the surging demand for the traction inverter market. The widespread deployment of charging stations globally addresses a critical barrier to EV adoption, alleviating concerns about range anxiety and bolstering consumer confidence. As charging infrastructure becomes more accessible and efficient, the demand for electric vehicles rises, consequently increasing the need for high-performance traction inverters.

Simultaneously, advancements in power electronics play a crucial role in enhancing the efficiency and capabilities of traction inverters. Ongoing technological developments lead to more compact, lightweight, and energy-efficient inverters, contributing to improved overall EV performance. The synergy between an expanding charging infrastructure and sophisticated power electronics creates a mutually reinforcing cycle, fostering a robust market demand for traction inverters as the automotive industry embraces the shift towards electrification and sustainable transportation.

Restraints

Range limitations

Range limitations in electric vehicles (EVs) pose a notable restraint on the growth of the traction inverter market. The driving range of an electric vehicle is intrinsically linked to the energy capacity and efficiency of the traction inverter. Consumers often perceive limited range as a significant drawback, contributing to hesitancy in adopting electric vehicles. While traction inverters play a critical role in optimizing energy use, challenges in battery technology and energy density directly impact the vehicle's range.

Concerns about the availability of charging infrastructure further exacerbate range anxiety. Potential EV buyers are deterred by the fear of being stranded due to insufficient charging stations, creating a psychological barrier to widespread adoption. Overcoming these range limitations requires advancements in both traction inverter efficiency and battery technology, as well as the continued expansion of charging infrastructure to address consumer concerns and promote confidence in electric vehicle ownership.

Opportunities

Integration of smart grid technologies

The integration of smart grid technologies presents a significant opportunity for the traction inverter market. Smart grid integration enhances the capabilities of traction inverters by enabling more sophisticated energy management in electric vehicles (EVs). Traction inverters, when synchronized with smart grids, can actively respond to real-time energy demands and fluctuations, optimizing the use of power during charging and discharging cycles. This not only contributes to grid stability but also improves the overall efficiency of EVs.

Moreover, the interaction between traction inverters and smart grids facilitates vehicle-to-grid (V2G) connectivity. This two-way communication allows EVs to not only draw power from the grid but also feed excess energy back, acting as mobile energy storage units. The evolving landscape of smart grid technologies creates a mutually beneficial relationship, offering opportunities for enhanced energy efficiency, reduced operational costs, and increased grid reliability in the traction inverter market.

Segment Insights

Propulsion Insights

The BEV segment had the highest market share of 44% in 2023. Electric Vehicles Battery (EVB) operate solely on electric power, relying on rechargeable batteries for propulsion. In the traction inverter market, the BEV segment is witnessing significant growth as automakers increasingly prioritize electric mobility. Trends include a demand for high-efficiency traction inverters to enhance the performance of BEVs, improve range, and reduce charging times. Innovations focus on compact, lightweight designs and integration with advanced battery management systems, reflecting a commitment to advancing BEV technology and addressing the evolving needs of electric vehicle consumers.

The PHEV segment is anticipated to expand at a significant CAGR of 17.2% during the projected period. In the realm of traction inverters, the Plug-in Hybrid Electric Vehicle (PHEV) category refers to cars that can operate on both electricity and traditional fuel. Traction inverters in PHEVs manage the transfer of power between the electric motor and the internal combustion engine. The latest trends indicate a rising need for smaller, more efficient traction inverters to meet the growing demand for PHEVs, highlighting the significance of seamlessly navigating between electric and hybrid modes for optimal dual-powertrain performance.

Voltage Insights

The 200 to 900V segment has held a 38% revenue share in 2023. The 200 to 900V segment in the traction inverter market specifically refers to the voltage range of traction inverters utilized in electric vehicles. This category covers a wide range of applications, spanning from everyday cars to commercial and high-performance vehicles. A notable trend within this voltage range is the industry's movement towards higher voltages, driven by the goal to enhance power efficiency and overall performance in electric vehicles. This shift underscores the automotive sector's commitment to developing more potent and technologically advanced traction inverters for improved driving range and capabilities in electric vehicles.

The 900V and above segment is anticipated to expand fastest over the projected period. The 900V and above segment in the traction inverter market refers to high-voltage systems primarily utilized in electric vehicles. This segment is witnessing significant growth due to the increasing demand for electric mobility and the pursuit of higher power efficiency. Trends indicate a shift towards higher voltage systems to meet the demands of next-generation electric vehicles, enabling faster charging, improved performance, and increased overall efficiency. The 900V and above segment reflects the industry's trajectory towards advanced power electronics to address the evolving needs of electric vehicle technology.

Technology Insights

According to the technology, the MOSFET segment has held 46% revenue share in 2023. In the Traction Inverter market, the Metal-Oxide-Semiconductor Field-Effect Transistor (MOSFET) segment refers to the use of MOSFET technology in the construction of power inverters. MOSFETs offer advantages such as high switching speeds, low on-resistance, and efficient power handling, making them ideal for traction inverters in electric vehicles.

A trend in this segment involves continuous improvements in MOSFET technology to enhance power density, increase energy efficiency, and meet the evolving demands of the electric mobility sector, contributing to the overall advancement of traction inverter capabilities.

The IGBT segment is anticipated to expand fastest over the projected period. Insulated Gate Bipolar Transistor (IGBT) is a semiconductor device crucial in the traction inverter market. It serves as a switch, controlling the flow of electrical power in the conversion of direct current to alternating current for electric vehicles. In recent trends, IGBT modules are witnessing advancements such as higher voltage ratings and improved thermal performance, enhancing the efficiency of traction inverters. This technology evolution aligns with the increasing demand for high-performance electric vehicles and contributes to the overall growth and competitiveness of the traction inverter market.

Vehicle Insights

According to the vehicle, the commercial vehicles has held 42% revenue share in 2023. The commercial vehicles segment in the traction inverter market refers to electric powertrains used in buses, trucks, and other industrial vehicles. A notable trend in this segment is the increasing electrification of commercial fleets to reduce carbon emissions and operational costs. Traction inverters for commercial vehicles are evolving to meet the unique demands of heavy-duty applications, emphasizing durability, efficiency, and integration with smart fleet management systems. As governments worldwide introduce stringent emission regulations, the demand for traction inverters in the commercial vehicle sector is expected to witness continued growth.

The passenger cars segment is anticipated to expand fastest over the projected period. The passenger cars segment in the traction inverter market refers to the application of traction inverters in electric and hybrid passenger vehicles. This includes sedans, hatchbacks, and SUVs that rely on traction inverters to convert and regulate power from the vehicle's battery to drive the electric motor. Trends in this segment include a growing demand for compact and lightweight inverters, increased focus on energy efficiency, and advancements in power electronics to support the expanding market share of electric passenger cars worldwide.

Regional Insights

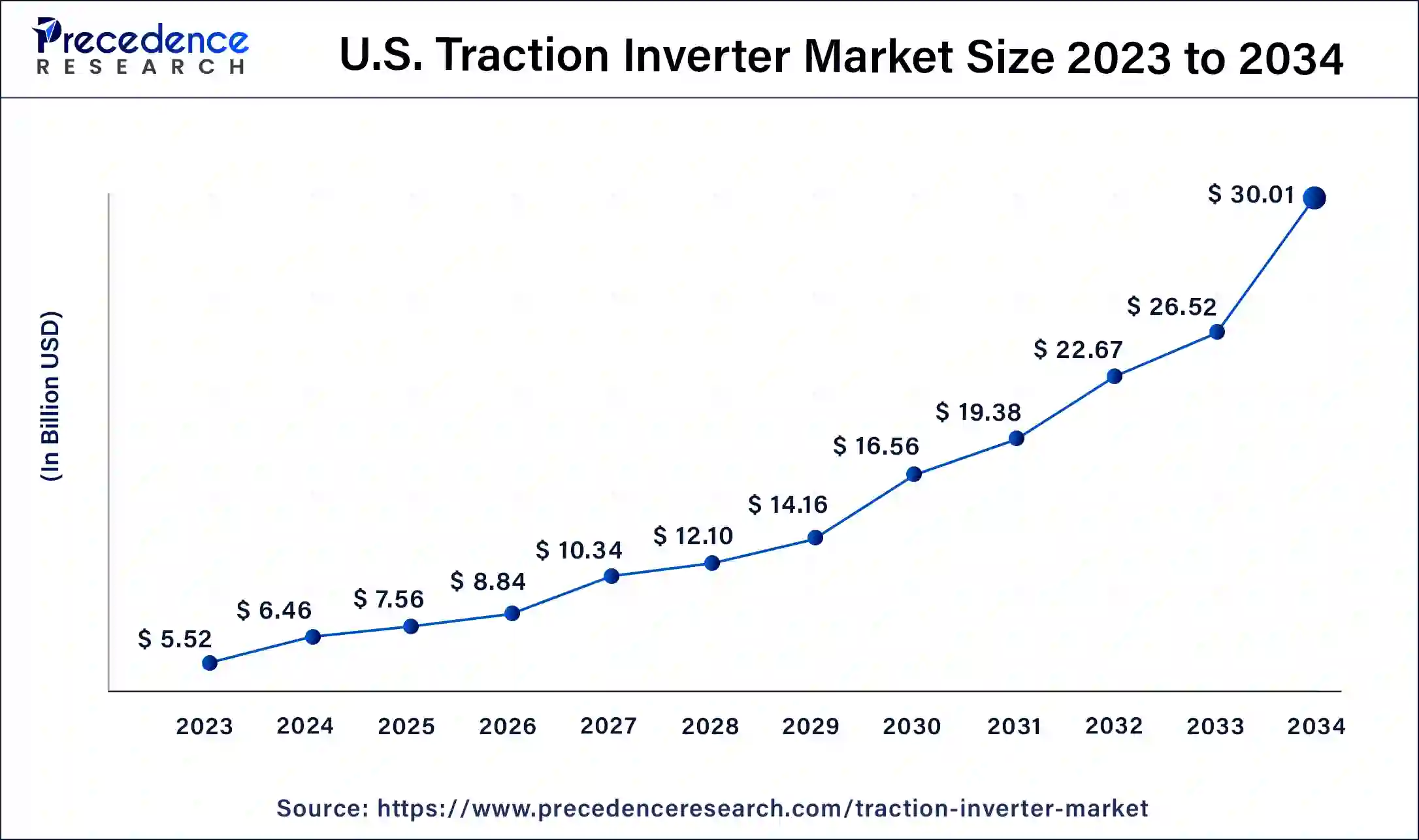

U.S. Traction Inverter Market Size and Growth 2025 to 2034

The U.S. traction inverter market size is valued at USD 7.56 billion in 2025 and is expected to be worth around USD 30.01 billion by 2034 rising at a CAGR of 16.60% from 2025 to 2034.

North America has held the largest revenue share of 44% in 2023. North America holds a major share in the traction inverter market due to a robust adoption of electric vehicles (EVs) and supportive government initiatives promoting clean mobility. The region witnesses significant investments in EV infrastructure, including charging networks, fostering increased demand for traction inverters. Moreover, a proactive approach from automakers in introducing electric models and a well-established automotive industry contribute to North America's prominent position in the traction inverter market, reflecting a strong commitment to sustainable transportation and technological innovation.

Asia-Pacific is estimated to observe the fastest expansion. Asia-Pacific dominates the traction inverter market due to the region's leadership in electric vehicle (EV) adoption. Governments in countries like China, Japan, and South Korea are actively promoting EVs, driving the demand for traction inverters. Favorable policies, extensive charging infrastructure development, and strong collaborations between automotive manufacturers and technology companies contribute to the region's market share. Additionally, the presence of key traction inverter manufacturers in Asia-Pacific further solidifies its significant position in the global market.

Traction Inverter Market Value Chain Analysis

- Component Sourcing and Semiconductor Manufacturing: This foundational stage involves sourcing essential materials and manufacturing the power semiconductors that are the core of a traction inverter.

Key Players: Infineon Technologies AG, STMicroelectronics N.V., and ROHM Co., Ltd. - Inverter Manufacturing and Assembly: In this key stage, the power semiconductors, along with capacitors, microcontrollers, cooling systems, and specialized software, are integrated into the final traction inverter unit.

Key Players: Robert Bosch GmbH, Continental AG, Denso Corporation, and ZF Friedrichshafen AG. - Integrated Drive System Manufacturing (Optional): Some manufacturers, particularly for EVs, integrate the inverter with the electric motor and transmission into a compact, single-unit system.

Key Players: GKN Automotive and BorgWarner Inc. - Distribution, Sales, and Post-Sales Service:This final stage includes the distribution of the final EVs to dealerships and end-users, along with crucial post-sales support and software updates.

Key Players: Tesla.

Key Players in Traction Inverter Market and their Offerings

- Siemens AG:Siemens contributes to the traction inverter market with advanced power electronic systems for a wide range of electric transport, from commercial vehicles to rail applications.

- Infineon Technologies AG:Infineon is a dominant supplier of power semiconductors, including the essential silicon (Si) IGBTs and advanced Silicon Carbide (SiC) modules that are the core of modern traction inverters.

- Continental AG:Continental develops and manufactures integrated eMobility solutions, including high-performance traction inverters that are seamlessly integrated with electric motors and power electronics.

- Robert Bosch GmbH:Bosch is a leading global supplier of automotive technology and a key player in the traction inverter market, focusing on integrated motor control units and advanced power electronics. Their R&D efforts focus on developing highly efficient, scalable inverter platforms that meet the demanding performance and cost requirements of global automakers.

- Delphi Technologies (now part of BorgWarner Inc.) :Delphi Technologies (now a BorgWarner brand) contributes with a range of advanced power electronics, including silicon and Silicon Carbide-based inverters designed for optimal efficiency and thermal management.

- Hitachi Automotive Systems (now part of Hitachi Astemo)

Hitachi Automotive Systems, now integrated into Hitachi Astemo, provides a range of eMobility products, including compact and lightweight traction inverters. - Mitsubishi Electric Corporation:Mitsubishi Electric is a major supplier of power modules and inverters for electric and hybrid vehicles, leveraging its expertise in power semiconductors to deliver highly reliable and efficient solutions.

- Toshiba Corporation:Toshiba supplies advanced semiconductor solutions and power modules for the automotive industry, which are crucial components of high-efficiency traction inverters. The company's technology enables improved power density and performance, supporting the development of next-generation electric vehicles.

- Fuji Electric Co., Ltd.:Fuji Electric specializes in power semiconductors and inverters, providing key components that enable efficient motor control in electric and hybrid vehicles. The company focuses on robust and reliable modules designed to operate in the demanding high-temperature environments of automotive applications.

- ABB Ltd:ABB contributes to the broader electric mobility market with power conversion solutions, including advanced inverters for electric vehicles and charging infrastructure. Their expertise in industrial power electronics translates into highly reliable and efficient solutions for a variety of electric transport applications.

- Dana Incorporated:Dana Incorporated is a key supplier of power transmission and e-Propulsion solutions, including integrated motor and inverter systems (e-Axles) for light and commercial electric vehicles.

- Lear Corporation:Lear Corporation is a global supplier of automotive seating and electrical architecture, contributing through the development of power electronics and sophisticated electrical distribution systems that manage the flow of power to components like traction inverters.

- Texas Instruments Incorporated:Texas Instruments (TI) provides crucial analogue and embedded processing semiconductor solutions used within traction inverters for control, sensing, and power management.

- STMicroelectronics:STMicroelectronics is a leading supplier of automotive semiconductors, including power modules and microcontrollers that are core components of traction inverters. The company heavily invests in Silicon Carbide (SiC) technology, providing the high-efficiency components needed for fast-charging and long-range EVs.

- ON Semiconductor (now onsemi):onsemi is a major supplier of power semiconductors for the automotive market, with a strong focus on high-efficiency Silicon Carbide (SiC) solutions for traction inverters. The company contributes by providing components that enhance the performance, reliability, and range of electric vehicles.

Recent Developments

- In July 2022, Curtiss-Wright expanded its industrial division, introducing a new lineup of products within the traction inverter sector. This expansion notably includes traction inverters designed for both hybrid and pure-electric on-highway and off-highway commercial vehicles. The focus on efficiency and innovation underscores Curtiss-Wright's commitment to advancing electric mobility solutions. By diversifying its product portfolio in the traction inverter market, Curtiss-Wright aims to cater to the growing demand for advanced electric propulsion systems in the commercial vehicle sector, aligning with the global trend toward sustainable and eco-friendly transportation.

- In June 2022, STMicroelectronics (ST) and Semikron joined forces to create a Silicon Carbide (SiC)-powered semiconductor, specifically designed for electric vehicle traction drives. This collaborative effort signifies a strategic move to propel advancements in automotive traction inverter technologies. Silicon Carbide, known for its superior performance in power electronics, is expected to enhance the efficiency and capabilities of traction inverters in electric vehicles. By leveraging the expertise of both STMicroelectronics and Semikron, this collaboration aims to contribute to the evolution of cutting-edge solutions, supporting the automotive industry's shift towards more efficient and sustainable electric propulsion systems.

Segments Covered in the Report

By Propulsion

- BEV

- HEV

- PHEV

- Others

By Voltage

- Up to 200V

- 200 to 900V

- 900V and above

By Technology

- IGBT

- MOSFET

- Others

By Vehicle

- Passenger Cars

- Commercial Vehicles

- Others

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting