What is the Automotive Quality Inspection AI System Market Size?

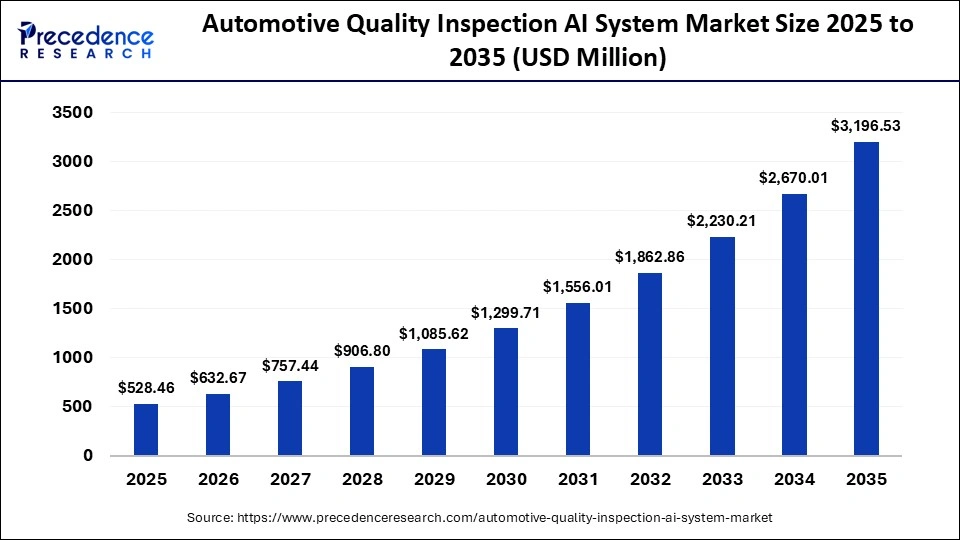

The global automotive quality inspection AI system market size accounted for USD 528.46 million in 2025 and is predicted to increase from USD 632.67 million in 2026 to approximately USD 3,196.53 million by 2035, expanding at a CAGR of 19.72% from 2026 to 2035. The market for automotive quality inspection AI systems is witnessing unprecedented growth, driven by the growing demand for automation to reduce human error and operational costs.

Market Highlights

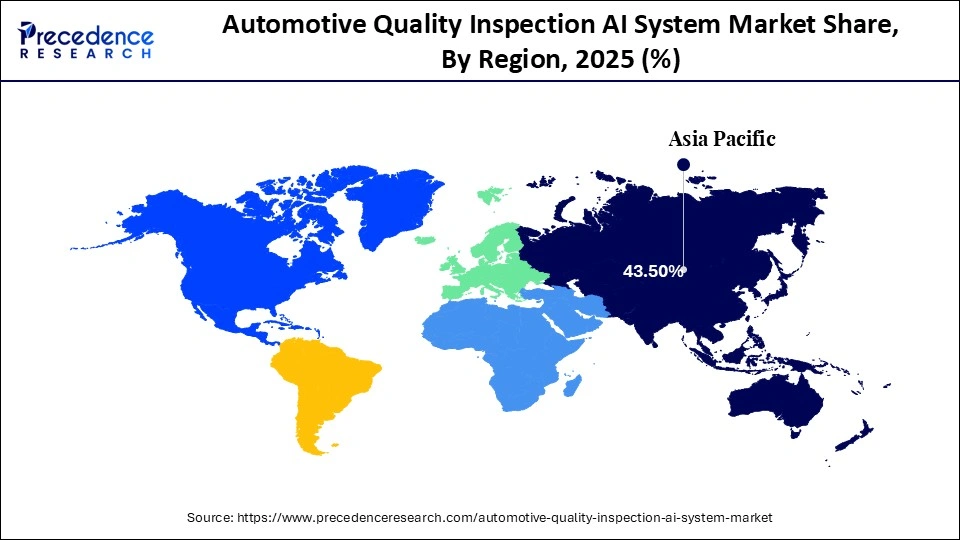

- Asia-Pacific dominated the market, holding the largest market share of 43.5% in 2025, with the fastest CAGR of 18.5% between 2025 and 2035.

- By component, the software segment held the largest market share of 55.8% in 2025.

- By component, the services segment is expected to grow at a remarkable CAGR of 16.5% between 2025 and 2035.

- By technology, the computer vision segment contributed the biggest market share of 38.5% in 2025.

- By technology, the deep learning segment is expanding at a significant CAGR of 16.7% between 2025 and 2035.

- By inspection type, the surface & defect inspection segment contributed the biggest market share of 43.8% in 2025.

- By inspection type, the functional inspection segment is poised to grow at a remarkable CAGR of 17.0% between 2025 and 2035.

- By application, the body-in-white inspection segment captured the biggest market share of 40.4% in 2025.

- By application, the final assembly inspection segment is set to grow at a notable CAGR of 16.9% between 2025 and 2035.

Automotive Quality Inspection AI System Market Overview

The automotive quality inspection AI system market comprises AI-enabled hardware and software solutions designed to inspect, measure, and validate automotive components and complete vehicles throughout the manufacturing process. These systems are deployed across various production stages to ensure that parts and assemblies meet strict quality, safety, and regulatory requirements before moving downstream.

AI-powered inspection platforms leverage computer vision, machine learning, deep learning, and advanced analytics to identify surface defects, dimensional deviations, assembly misalignments, and compliance issues in real time. By processing high-resolution images and sensor data at production-line speeds, these systems detect inconsistencies that are difficult to identify through manual inspection, even at high volumes.

Adoption of AI-based quality inspection systems enhances manufacturing efficiency by reducing rework, minimizing scrap rates, and lowering the risk of costly recalls. Consistent, automated inspection improves quality uniformity across production batches and supports traceability and audit readiness, which are critical for modern automotive manufacturing.

Automotive Quality Inspection AI System Market Outlook

- Industry Growth Overview: Between 2026 and 2035, the industry is expected to experience accelerated growth. The growth of the automotive quality inspection AI system industry is driven by stringent regulatory requirements and safety standards, the growing demand for zero-defect manufacturing, the increasing need for sophisticated inspection of electric and autonomous vehicles (EVs/AVs), and rapid technological innovation in computer vision, deep learning algorithms, and sensor technologies.

- Global Expansion: Several leading players in the automotive quality inspection AI system market, such as Siemens, Cognex, Nvidia, Landing AI, SICK AG, ISRA Vision, and Teledyne Technologies are expanding their global presence through strategic partnerships, infrastructure investments, mergers & acquisitions (M&A), and the launch of new product portfolios. For instance, Audi, BMW, and Mercedes-Benz are among the companies expanding their use of artificial intelligence to improve vehicle production efficiency, streamline quality control, and modernize factory operations.

- Major Investors: Several strategic investors and companies are actively engaged in the automotive quality inspection AI system sector, including major automakers, technology giants, and specialized AI startups, thereby accelerating market growth during the forecast period. Major automotive players are increasingly investing in AI companies to integrate technology directly into their manufacturing processes and after-sales services.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 528.46 Million |

| Market Size in 2026 | USD 632.67 Million |

| Market Size by 2035 | USD 3,196.53 Million |

| Market Growth Rate from 2026 to 2035 | CAGR of 19.72% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Component, Technology, Inspection Type, Application, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segmental Insights

Component Insights

What Causes the Component Segment to Dominate the Automotive Quality Inspection AI System Industry?

Software: The segment accounted for the majority of the market share at 55.8% in 2025, owing to its ability to offer flexibility, adaptability, continuous improvement through updates, and core processing capability for advanced AI functions. Software-driven platforms automate inspections on fast-moving production lines and execute quality checks within seconds that would otherwise require significantly more time through manual processes. Continuous model training and algorithm refinement further improve defect detection accuracy over time, enabling manufacturers to adapt inspection parameters as designs, materials, and production conditions evolve.

Services: This segment is expected to grow at a remarkable CAGR of 16.5% between 2025 and 2034, reflecting its critical role within the automotive quality inspection AI system industry. Growth is driven by increasing system complexity and the rising need for specialized expertise in deployment, customization, maintenance, and performance optimization. Service providers support manufacturers with model training, system calibration, data labeling, and ongoing performance tuning to ensure inspection accuracy under varying production conditions.

Technology Insights

Which Segment Dominated in Terms of Technology in the Automotive Quality Inspection AI System Industry?

Computer Vision: This segment is dominating the automotive quality inspection AI system industry by holding a majority share of 38.5%. Computer vision technology is enabling automation with high accuracy and the advancement of quality inspection in modern automotive manufacturing. Computer vision systems offer superior accuracy and consistency compared to manual inspection methods, which leads to enhancing operational efficiency, lowering manufacturing costs, and reducing downtime.

Deep Learning: The segment is the fastest-growing in the automotive quality inspection AI system market with an expected CAGR of 16.7%, with growth set to be primarily driven by its ability to handle complex inspection tasks and improve the accuracy of defect detection. Deep learning models, particularly Convolutional Neural Networks (CNNs), significantly enhance defect detection rates that manual inspection or conventional cameras might miss.

Inspection Type Insights

What Caused the Surface & Defect Inspection Segment to Dominate the Automotive Quality Inspection AI System Market in 2025?

Surface & Defect Inspection: The segment is dominating the automotive quality inspection AI system market with a 43.8% share in 2025, driven by the increasing focus on high-precision detection of surface anomalies such as dents, scratches, and paint defects using AI-driven computer vision. High-resolution imaging and deep learning models enable consistent inspection across complex body geometries and reflective surfaces. This capability is especially critical in body-in-white and final paint inspection stages, where cosmetic quality directly impacts brand perception and recall risk.

Functional Inspection: This segment is expected to expand at a remarkable growth rate of 17.0% between 2025 and 2034, owing to the rising demand for zero-defect manufacturing, the rise of electric vehicles (EVs) and autonomous systems, and stringent global safety and emissions regulations. Several automakers are increasingly adopting AI-driven functional inspections to detect internal or mechanical defects at early manufacturing stages to meet high safety and reliability standards before final assembly.

Application Insights

What Has Led the Body-in-White Inspection Segment to Dominate the Automotive Quality Inspection AI System Sector During 2025?

Body-in-White Inspection: The segment dominated the automotive quality inspection AI system sector during 2025 with a 40.4% share, as this segment has crucial applications in the automotive quality inspection AI systems, supplemented by the rising push for zero-defect production standards and the integration of AI-enabled cameras to identify defects early in the assembly process.

Final Assembly Inspection: This segment is set to grow at a significant CAGR of 16.9% during the forecasted period in the market for automotive quality inspection AI systems. AI-powered final assembly inspection systems assist in identifying potential issues or any defects to ensure high product quality before shipment. Automakers are implementing these systems to gain a competitive advantage by improving detection accuracy and significantly reducing rework incidents.

Regional Insights

What is the Asia Pacific Automotive Quality Inspection AI System Market Size?

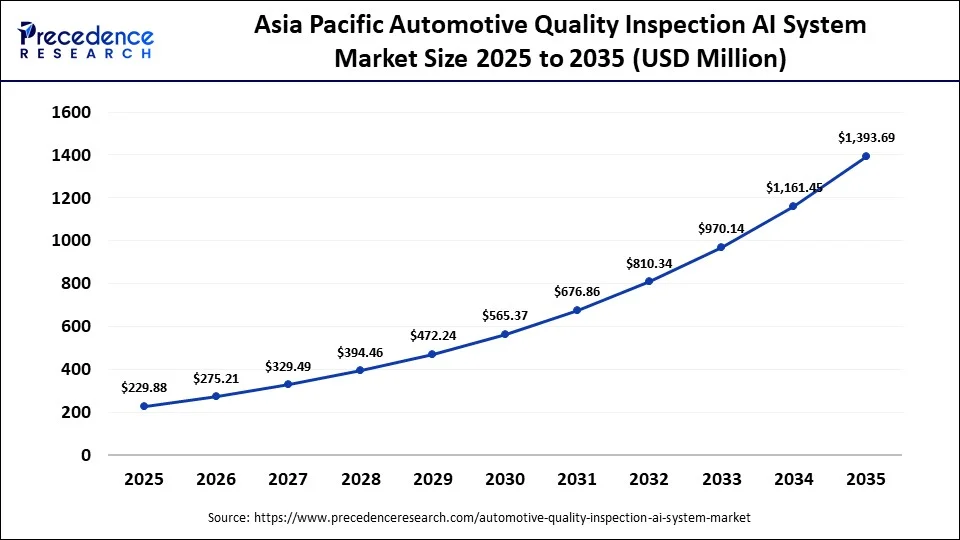

The Asia Pacific automotive quality inspection AI system market size is expected to be worth USD 1,393.69 million by 2035, increasing from USD 229.88 million by 2025, growing at a CAGR of 19.75% from 2026 to 2035.

What Led the Asia-Pacific Region to Dominate the Automotive Quality Inspection AI System Market During 2025?

Asia-Pacific dominated the automotive quality inspection AI system market, holding the majority revenue share of 43.5% in 2025. The region is home to major automotive production hubs, notably in China, Japan, South Korea, and India, creating robust demand for automated, AI-powered inspection systems that deliver high precision and consistency at scale. Several OEMs across the region are increasingly adopting AI-based inspection to reduce human error, standardize quality outcomes, and support high-throughput manufacturing environments. The region is also witnessing rapid growth in electric vehicle production alongside tightening safety and quality regulations, which is accelerating the need for faster, more accurate AI-enabled inspection and control systems. Strong investment in smart manufacturing and Industry 4.0 initiatives further reinforces Asia-Pacific's leadership position in the automotive quality inspection AI system market.

Asia Pacific is not only the dominant region but is also expected to witness the fastest growth, with a CAGR of 18.5% during the forecast period from 2026 to 2035. This accelerated growth is driven by continued expansion of automotive manufacturing capacity, particularly for EVs and next-generation vehicles that require more complex quality validation. Increasing adoption of fully automated production lines is raising reliance on AI-based inspection to manage inspection workloads that are impractical for manual methods. In addition, rising labor costs and shortages of skilled inspectors in several countries are pushing manufacturers toward scalable AI-driven quality systems. Ongoing government support for domestic semiconductor, AI, and advanced manufacturing ecosystems further supports long-term growth across the region.

China Automotive Quality Inspection AI System Market Trends

China is transforming the automotive quality inspection AI system market, driven by its vast and well-established automotive manufacturing base, strong government backing for advanced technologies, and accelerating shift toward smart manufacturing. The country's automotive sector operates at very high production volumes, making manual inspection increasingly impractical and reinforcing the need for AI-driven systems that can deliver consistent, real-time quality validation at scale.

Government-led initiatives promoting intelligent manufacturing, industrial automation, and artificial intelligence adoption are playing a central role in this transformation. National and provincial programs focused on smart factories and advanced industrial digitalization encourage automakers and suppliers to integrate AI-based inspection technologies across body-in-white, powertrain, battery, and final assembly lines. These policies align closely with the industry's growing emphasis on zero-defect manufacturing and export-quality compliance.

Why Is North America Set to Show Notable Growth in the Automotive Quality Inspection AI System Market in the Coming Years?

North America is emerging as the fastest-growing region in the automotive quality inspection AI system market, supported by a highly developed digital infrastructure and strong readiness for advanced manufacturing technologies. The region operates under some of the most stringent automotive safety, quality, and regulatory standards globally, which compels OEMs and Tier-1 suppliers to adopt highly accurate and auditable inspection systems across production lines.

Growth is strongly linked to the rapid expansion of electric, connected, and autonomous vehicle development in the United States and Canada. These vehicle architectures introduce complex components such as battery systems, sensors, cameras, and software-driven modules that require advanced, AI-enabled inspection for defect detection, validation, and compliance assurance. As a result, manufacturers are increasingly deploying AI-powered quality inspection systems to support zero-defect manufacturing goals and reduce recall risk.

Favorable government support for advanced manufacturing, artificial intelligence, and domestic semiconductor ecosystems is further reinforcing adoption. Public and private investment in smart factory initiatives, automation, and digital manufacturing platforms is accelerating the integration of AI-based inspection into production workflows.

U.S. Automotive Quality Inspection AI System Market Trends

The United States is set to experience significant growth in the automotive quality inspection AI system market, driven by a strong national push toward smart factories and advanced industrial automation. Automotive manufacturers across the country are increasingly deploying AI-enabled computer vision systems to support defect detection, quality assurance, and process optimization across high-throughput production lines. Growth is further supported by widespread adoption of Industry 4.0 practices, where AI-based inspection systems are integrated with manufacturing execution systems and robotics to deliver real-time quality feedback.

The development of these capabilities helps reduce production costs, minimize rework, and improve overall productivity by identifying defects early in the manufacturing process rather than at final inspection stages. The rapid uptake of AI-powered quality inspection platforms also enables faster detection, classification, and correction of production anomalies, which is critical as vehicles become more complex due to electrification, advanced electronics, and software-defined features.

In July 2025, UVeye, the global leader in AI-powered vehicle inspection technology, announced the launch of UV360, a powerful new platform helping car dealerships turn every fresh trade-in into showroom-ready images, even before they hit reconditioning. UV360 utilizes the company's trusted AI-powered drive-thru scanners, where these MRIs for vehicles are already used by hundreds of dealerships across the U.S. for automotive inspections, and transforms them into a comprehensive solution.

How Is the European Region Responsible for Growth in the Automotive Quality Inspection AI System Market?

Europe accounts for a notable share of the automotive quality inspection AI system market, supported by strong regulatory enforcement, advanced manufacturing practices, and early adoption of AI-driven quality assurance. Countries such as Germany, France, and the United Kingdom are leading adopters of AI-based inspection systems within automotive production, particularly across premium vehicle manufacturing, powertrain assembly, and final vehicle inspection processes.

Market growth is largely driven by large-scale government-backed initiatives promoting digital manufacturing, automation, and artificial intelligence adoption across industrial sectors. Rising technological innovation, combined with increasing production of electric and autonomous vehicles, is intensifying the need for high-precision inspection systems capable of validating batteries, power electronics, sensors, and software-integrated components. Expansion of EV charging infrastructure across Europe further reinforces the need for consistent quality assurance across vehicles designed for high-voltage and connected environments.

Strict regulatory and safety requirements are a defining factor for Europe. Standards enforced across the European Union are generally more stringent than those in North America and Asia Pacific, particularly in areas related to vehicle safety, emissions, and functional reliability. This regulatory environment compels automakers and suppliers to deploy advanced AI inspection systems that provide traceable, auditable, and repeatable quality validation.

Germany Automotive Quality Inspection AI System Sector Trends

Germany is seeing notable growth in Europe for the automotive quality inspection AI system sector, driven primarily by the increasing expansion of Industry 4.0, stringent quality needs, rising demand for deep learning, 3D vision, and sensor technologies, support for government frameworks, and increasing demand for automation and efficiency in automotive manufacturing. In addition, the rise of electric vehicles (EVs) is anticipated to create substantial demand for advanced AI inspection to meet complex safety and quality standards.

What Are the Significant Factors Driving the Growth of the Market for Automotive Quality Inspection in the Middle East & Africa Region?

The automotive quality inspection AI system market is expected to grow at a notable rate in the Middle East & Africa region, supported by increasing adoption of AI-driven inspection technologies across automotive manufacturing and assembly operations. Manufacturers in the region are progressively integrating computer vision and machine learning-based inspection systems into production lines to achieve defect-free output, improve consistency, and reduce dependence on manual quality checks.

Growth is further reinforced by tightening quality and safety standards as regional automotive production aligns more closely with international export and compliance requirements. As vehicles incorporate more electronics, software-driven components, and electrified systems, the need for high-precision, automated inspection tools capable of real-time defect detection is increasing across body, powertrain, and final assembly stages.

Rapid technological advancement and strong government backing for artificial intelligence adoption are also accelerating market momentum. National digital transformation and industrial modernization programs are encouraging manufacturers to invest in smart factory technologies, including AI-based quality inspection systems. Together, rising automation, regulatory alignment, and policy-led AI adoption are expected to drive sustained growth of the automotive quality inspection AI system market across the Middle East & Africa in the coming years.

South African Automotive Quality Inspection AI System Market Trends

South Africa is experiencing remarkable growth in this particular sector, with expansion driven by the rising adoption of Industry 4.0, increased demand for efficiency & accuracy in the automotive industry, a surge in electric vehicle growth, and the rising original equipment manufacturer focus on automated defect detection systems to reduce manual errors in fleets and standardize the inspections of second-hand vehicles. Additionally, the integration with IoT and machine vision that are transforming automotive production is expected to drive the expansion of the automotive quality inspection AI system market during the forecast period.

Key Players in the Automotive Quality Inspection AI System Market

- Siemens

- Keyence

- Cognex

- Omron Corporation

- Basler

- Rockwell Automation

- FANUC

- ZEISS Group

- Hexagon AB

- Nvidia

- Landing AI

- Intel Corporation

- SICK AG

- ISRA Vision

- Teledyne Technologies

Recent Developments

- In June 2025, FANUC America Corporation and Kitov AI, Inc., announced a strategic partnership to transform manufacturing automation with intelligent, AI-enhanced solutions. This collaboration unites FANUC America's robotic systems and automation expertise with Kitov AI's advanced machine vision and deep learning technologies. The partnership aims to deliver integrated solutions that optimize quality control, increase production efficiency, and address the evolving needs of industries such as automotive, electronics, aerospace, and medical device manufacturing.(Source: https://www.qualitymag.com)

- In June 2025, NVIDIA launched Cosmos Predict-2, an advanced world foundation model (WFM) for generating high-quality synthetic data to boost autonomous vehicle (AV) training. The model improves future world state prediction with better context understanding and fewer hallucinations.(Source: https://blogs.nvidia.com)

Segment Covered in the Report

By Component

- Software

- Hardware (Cameras, Sensors, Processors)

- Services

By Technology

- Computer Vision

- Machine Learning

- Deep Learning

- 3D Vision

- Edge AI

By Inspection Type

- Surface & Defect Inspection

- Dimensional Measurement

- Assembly Verification

- Functional Inspection

By Application

- Body-in-White Inspection

- Paint & Coating Inspection

- Powertrain Inspection

- Interior & Exterior Inspection

- Final Assembly Inspection

By Region

- North America

- Latin America

- Europe

- Asia-pacific

- Middle and East Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting