What is the Japan 3D Printing Market Size?

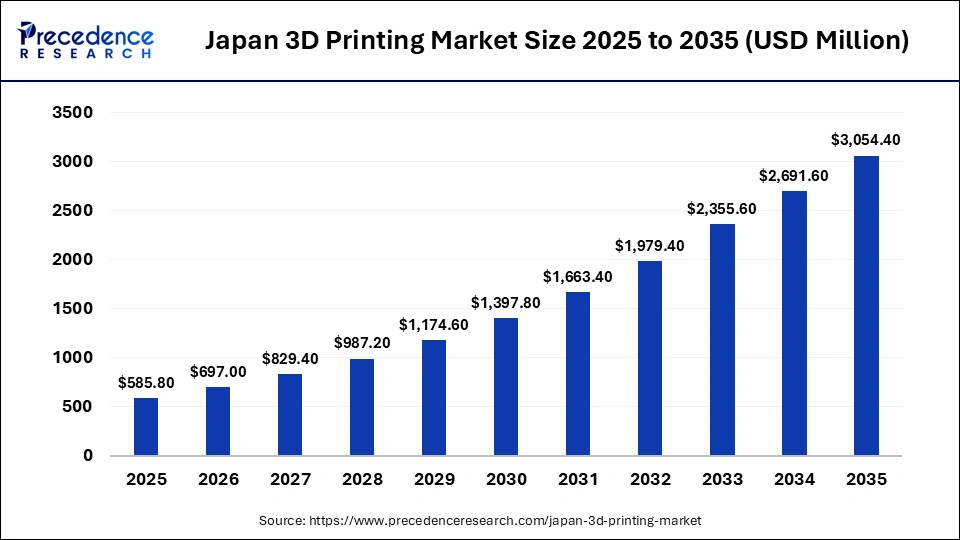

The Japan 3D printing market size was calculated at USD 585.80 million in 2025 and is predicted to increase from USD 697.00 million in 2026 to approximately USD 3,054.40 million by 2035, expanding at a CAGR of 17.96% from 2026 to 2035. The Japan 3D Printing Market is observing rapid growth due to the region's strong hold in precision engineering, rapid prototyping, advanced manufacturing, and advanced production systems. The 3D printing market's dominance due to factors such as industrial-grade hardware, precision, and integration into existing digital manufacturing workflows also helps to fuel the growth of the market. The market also observes growth due to its huge dominance over domains such as aerospace, automotive, healthcare, and construction industries. The market also observes growth due to its prominence in precision engineering, robotics, and material science, creating an ideal ecosystem for the market.

Market Highlights

- By technology, the fused deposition modeling (FDM) segment led the market in 2025.

- By technology, the selective laser sintering (SLS) segment is observed to grow at the fastest CAGR.

- By printing type, the desktop 3D printers segment led the market in 2025.

- By printing type, the industrial 3D printers segment is expected to grow at the fastest CAGR in the foreseeable period.

- By material type, the metal segment led the market in 2025.

- By material type, the polymer segment is observed to grow in the forecast period.

- By end user, the automotive segment led the Japan 3D printing industry in 2025.

- By end user, the healthcare segment is observed to be the fastest-growing segment in the foreseen period.

What is the Japan 3D Printing Market?

The market is observing a rapid growth due to the region's strong hold in precision engineering, helpful for domains such as aerospace and defense, automotive, and the healthcare industry. The regions' significant investment in materials, metal printing, and ceramics to propel sustainable manufacturing also helps to fuel the growth of the market. Higher precision and quality, rapid industrial approach, smoother supply chain, sustainability, and innovation are also some of the major factors helpful for the growth of the market.

The market is also observing growth due to companies deploying 3D printer tooling, jigs, fixtures, and demand for spare parts requiring high reliability. The healthcare industry requires additive manufacturing in orthodontics, dental implants, and patient-specific surgical guides, which also helps to fuel the growth of the market.

Role of Technology in the Growth of Japan 3D Printing Market

Technological advancements are helping to propel the market's growth easily. Advanced manufacturing, material science, and robotics, focusing on digital transformation, sustainability, and supply chain resilience, also help to propel the growth of the market. The major role of technology to enhance the domains such as automotive, aerospace, and healthcare, also aids the market's growth. Precision engineering is Japan's core strength, helpful to enhance robotics and material science for seamless integration with additive manufacturing, which holds a major position in driving the growth of the market.

Use of technologically advanced materials like biocompatible resins, composites, and ceramics for high-performance applications is another major factor propelling the growth of the market. Higher adoption of technologies such as AI, digital twins, and predictive analytics for process optimization and regulatory compliance also helps to fuel the growth of the market.

Japan 3D Printing Market Trends

- Advanced manufacturing needs in the region's automotive, healthcare, and aerospace sectors are one of the major factors fueling the growth of the market.

- Higher demand for AI for optimization and smoothing the whole supply chain is another major factor propelling the growth of the market.

- Innovation in metal printing, specialized ceramics, and material development also helps to fuel the growth of the market.

- Higher demand for advanced forms of materials, such as photopolymers, advanced ceramics, and other high-performance materials, also helps to fuel the growth of the market.

- Managing issues of supply chain and labor shortage smoothly is another helpful factor driving the growth of the market.

Market Scope

| Report Coverage | Details |

| Market Size in 2025 | USD 585.80 Million |

| Market Size in 2026 | USD 697.00 Million |

| Market Size by 2035 | USD 3,054.40 Million |

| Market Growth Rate from 2026 to 2035 | CAGR of 17.96% |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Technology, Printing Type, Material Type, and End User |

Segmental Insights

Technology Insights

Which Component of Technology Dominated the Market in 2025?

The fused deposition modeling (FDM) segment led the market in 2025. The segment led the market because of its affordability, ease of use, and compatibility with engineering thermoplastics. Domains such as SMEs, universities, and consumer-focused industries use FDM systems, further fueling the growth of the market. It is a cost-effective option for prototyping and functional testing, leading to its higher demand in the market. FDM printers are also used by the engineering sectors of Japan for creating jigs, fixtures, and internal prototypes. Material innovation helps to balance the FDM's mechanical performance to expand its industrial use, further propelling the growth of the market.

The selective laser sintering (SLS) segment is observed to be the fastest-growing segment in the foreseen period, with the highest CAGR. The segment observes major growth as it focuses on producing durable polymer parts without any support structures. The market also observes growth due to high demand for SLS due to its geometric flexibility and suitability for functional prototypes, housings, and short-run end-use components. Usage of SLS in the automotive industry for lightweight components is helpful to meet emission regulations and support EV development, also propelling the growth of the market.

Printing Type Insights

Which Segment of the Printing Category led the Japanese 3D Printing Market in 2025?

The desktop 3D printers segment led the market in 2025. Such printers are highly used in SMEs, design firms, and universities, which is helpful for the growth of the market. Such printers also support early-stage design validation, teaching programs, and knowledgeable development cycles. Hardware and AI integration acts as the key revenue of the segment, along with boosting efficiency, which is helpful for the growth of the market. Individuals and hobbyists have a major contribution to the growth of the market due to higher usage of such forms of printers for consumer-level purposes.

The industrial 3D printers segment is observed to be the fastest-growing segment with the highest CAGR in the forecast period. Such printers have superior precision, temperature control, and process repeatability, which are essential during the manufacturing process, and are helpful for the growth of the market in the foreseeable period. Domains such as aerospace, automotive, and healthcare have the highest contribution in the growth of the market due to the higher demand for industrial 3D printers for their tooling, production, and mission-critical components.

Material Type Insights

Why the Metal Segment Dominated the Japan 3D Printing Market in 2025?

The metal segment led the market in 2025, mainly because it leads Japan's additive manufacturing investment. Industries such as aerospace and automotive have a higher demand for metals such as aluminum, titanium, Inconel, and tool steels. Higher demand for high-performing parts that are helpful to provide efficient quality, along with maintaining sustainability, also helps to propel the growth of the market. Technological advancements to build volume, accuracy, speed, and material options also help to fuel the growth of the market.

The polymer segment is observed to be the fastest-growing segment with the highest CAGR in the forecast period. The segment is observing higher demand in domains such as electronics for the demand of high-performance plastics, automotive, and healthcare, with photopolymers and nylon being key materials. The segment also helps to fuel the market's growth in the foreseen period due to its shift towards sustainable materials, along with strong innovation and tech adoption. Higher demand for lightweight, durable, and customized parts in domains such as aerospace, automotive, and medical sectors further fuels the growth of the market. Government initiatives to boost adoption also elevate the market's growth.

End User Insights

Why did the Automotive Segment Lead the Market in 2025?

The automotive segment led the Japan 3D printing market in 2025. Higher demand for rapid prototyping, customization, and supply chain resilience are also some of the major factors propelling the growth of the market. AI and ML integration for the manufacturing of smart, sustainable, and high-performance automobile parts also helps to fuel the growth of the market. Usage of hybrid machines in Japan's big automotive companies, combining additive and subtractive processes, also helps to elevate the growth of the market.

The healthcare segment is observed to be the fastest-growing segment in the foreseen period with the highest CAGR. The growing aging population and higher demand for customized medications are two of the major factors propelling the growth of the market. Hence, it leads to higher demand for customized implants, prosthetics, surgical guides, and anatomical models. Government initiatives, coupled with collaborations between tech firms and healthcare providers, also help to propel the market's growth in the foreseeable period. Manufacturing of personalized crowns, bridges, and aligners, for enhanced customer satisfaction, is also a major segment driver. Customization is also useful for orthopedic implants and prosthetics.

Japan 3D Printing Market Competitive Landscape

The 3D printing market in Japan displays a huge and tough competition between global leaders and local innovators. The domains such as aerospace, automotive, and healthcare have a leading role in giving rise to this competition due to key dynamics involving material advancements, AI integration for maintaining quality, and government support for smart manufacturing. Higher demand for customization in domains like healthcare, especially in the dental and surgery segments, intensifies the competition in Japan.

Technological Advancements using AI and ML to elevate the product quality, along with smoothing the manufacturing procedure and supply chain management, also help to propel the growth of the market. Japan's precision engineering, competitive positioning, emphasizing accuracy, process control, and certification readiness, also helps to elevate the market's growth in the region. Major corporations of the region invest in metal additive manufacturing to expand the capacity for titanium, aluminum, and tool-steel components.

Top Companies and Their Contributions in the Market

| Company | Key Offerings | Key Contributions/Specialization |

| Mitsubishi Heavy | Metal DED 3D Printers (LAMDA) | High-speed large-scale metal parts, aerospace & energy components |

| Ricoh Company | SLS/MJF Printers, Bio-3D Printers | High-precision industrial, medical, & full-color inkjet printing solutions |

| Toshiba Machine | Laser Metal Deposition (LMD) printers | High-speed metal fabrication for large industrial structures & auto tooling |

| Canon Inc. | High-res DLP 3D Printers, Materials | Specialized resin systems for dentistry, healthcare & manufacturing |

| Mimaki Engineering | Full-color UV-cured 3D printers | High-fidelity 3D modeling, signage, & industrial design prototyping |

| Roland DG | Desktop 3D Milling & Additive | Rapid prototyping and 3D modeling for dental and education markets |

| NTT Data Eng | 3D Simulation & Additive Mfg | Software solutions, simulation tools, & industrial 3D printing consulting |

| JSR Corporation | Photopolymer Resins | High-performance materials for DLP/SLA, focusing on thermal resistance |

| Asahi Kasei | Engineered Plastics & Filaments | Specialized, high-strength thermoplastic materials for industrial 3D printing |

| Yamazaki Mazak | Hybrid Multi-Tasking Machines | 5-axis CNC machining combined with additive metal manufacturing capabilities |

Who are the Major Players in the Japan 3D Printing Market?

The major players in the Japan 3D printing market include Mitsubishi Heavy Industries, Ricoh Company, Toshiba Machine, Canon Inc., Mimaki Engineering, Roland DG, NTT Data Engineering Systems, JSR Corporation, Asahi Kasei, and Yamazaki Mazak.

Recent Developments

- In December 2025, Justin Bieber's new brand, Skylrk, opened a successful pop-up store in Tokyo. The Harajuku pop-up launched the brand's first-ever 3D printed sneaker named the ‘Earth Bender'. (Source: https://www.tokyoweekender.com)

- In January 2026, Hatsushima Station, in Japan's Arida town, got a replacement in just six hours. The workers replaced the weathered wooden structure with a 3D printed station, making it the world's first as well! The West Japan Railway Company, a major railway operator, was responsible for this feat and unveiled it. (Source: https://www.business-standard.com)

Segments Covered in the Report

By Technology

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

- Direct Metal Laser Sintering (DMLS)/ Selective Laser Melting (SLM)

- Polyjet

- Multi Jet Fusion

- Digital Light Processing (DLP)

- Binder Jetting

- Electron Beam Melting (EBM)

- Continuous Liquid Interface Production (CLIP)/ Continuous Digital Light Projection (CDLP)

- Selective Deposition Lamination (SDL)

- Laminated Object Manufacturing (LOM)

By Printing Type

- Desktop 3D Printer

- Industrial 3D Printer

By Material Type

- Metal

- Polymer

- Ceramics

By End User

- Automotive

- Aerospace and Defense

- Healthcare

- Architecture and Construction

- Consumer Products

- Education

- Others (Food, Fashion, and Others)

Get a Sample

Get a Sample

Table Of Content

Table Of Content