Barrier Films Market Size and Forecast 2025 to 2034

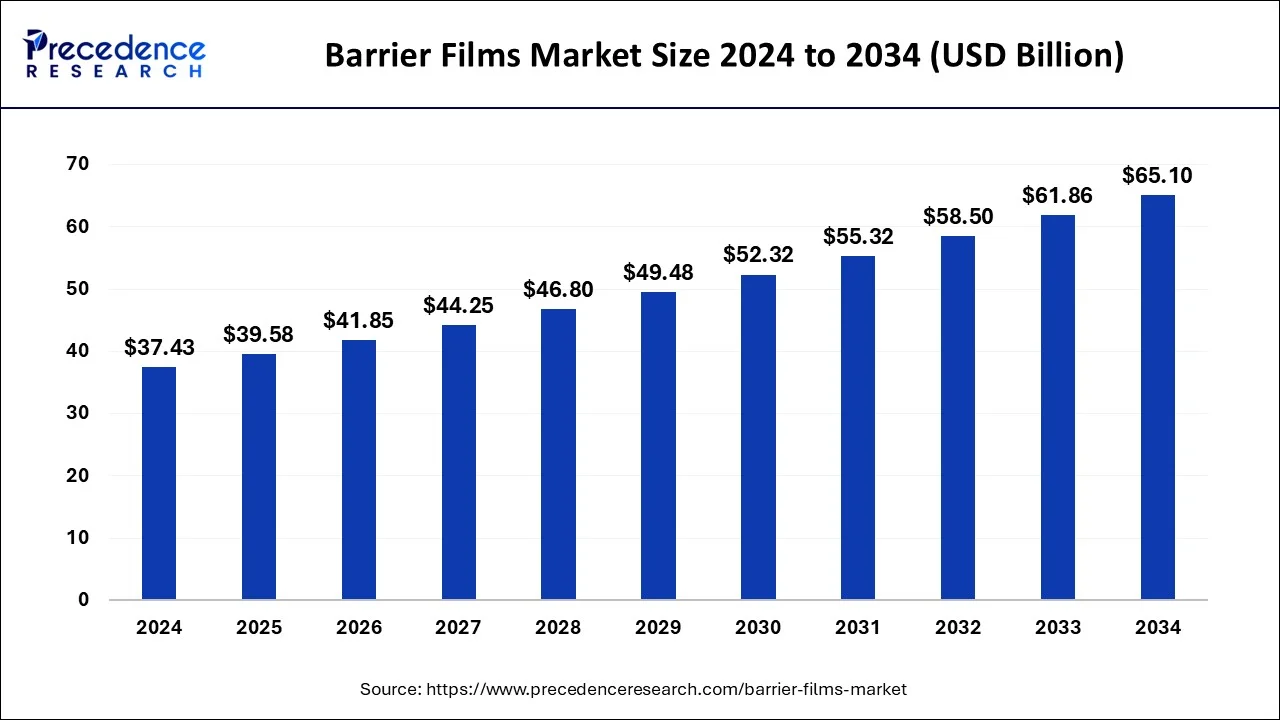

The global barrier films market size was estimated at USD 37.43 billion in 2024 and is predicted to increase from USD 39.58 billion in 2025 to approximately USD 65.10 billion by 2034, expanding at a CAGR of 5.69% from 2025 to 2034. Consumers, who are increasingly concerned about food safety, want packaging solutions that guarantee the integrity and freshness of food items. These factors drive the growth of the barrier films market.

Barrier Films MarketKey Takeaway

- The global barrier films market was valued at USD 37.43 billion in 2024.

- It is projected to reach USD 65.10 billion by 2034.

- The barrier films market is expected to grow at a CAGR of 5.69% from 2025 to 2034.

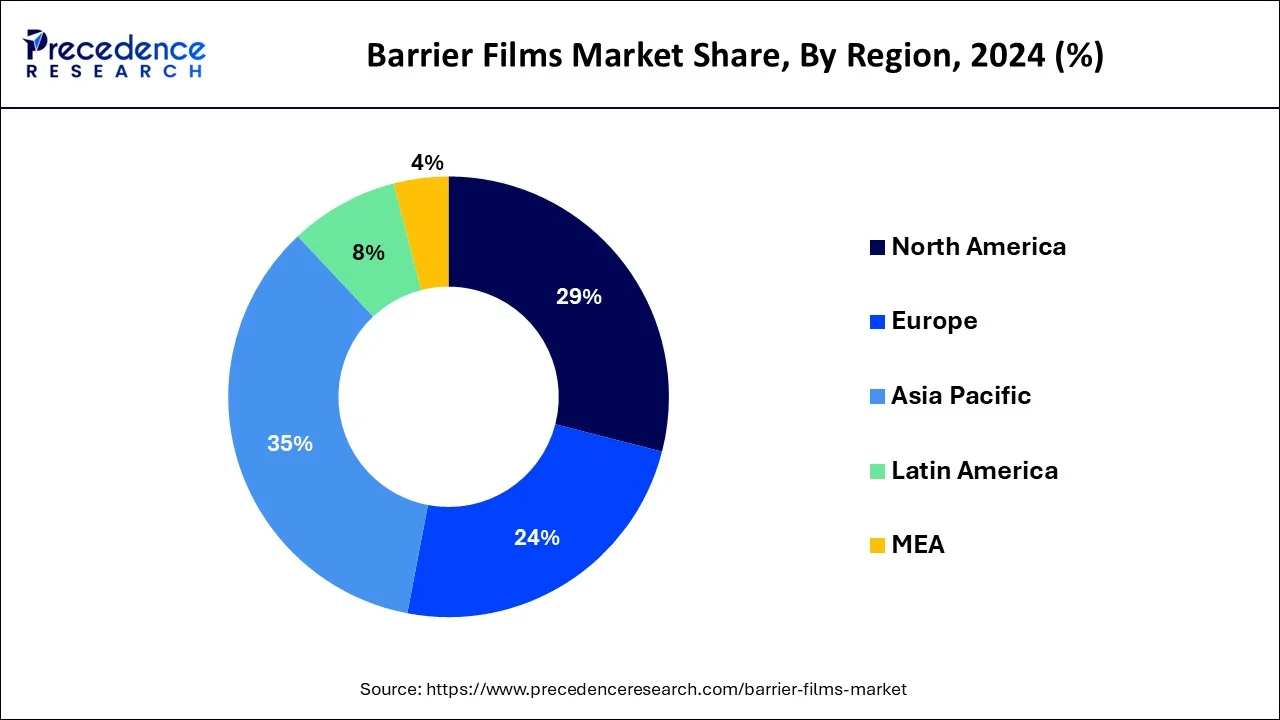

- Asia Pacific held the largest share of the barrier films market 35% in 2024.

- By region, North America is expected to show notable growth during the forecast period.

- By material, the organic coating segment held the largest share of the market.

- By packaging type, the pouches segment had the largest market share in 2024.

- By end use, the agriculture segment held the largest share of the market.

Asia PacificBarrier Films Market Size and Growth 2025 to 2034

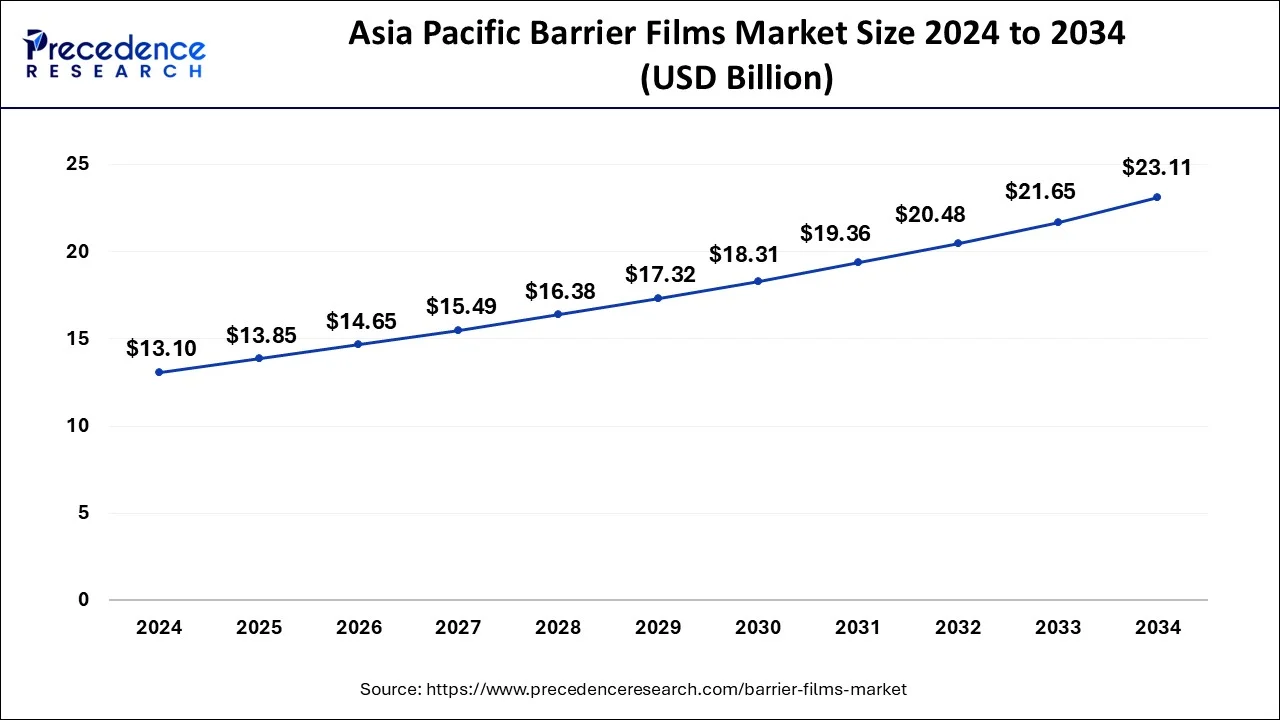

The Asia Pacific barrier films market size was estimated at USD 13.10 billion in 2024 and is predicted to hit around USD 23.11 billion by 2034 at a CAGR of 5.84% from 2025 to 2034.

Asia Pacific held the largest share in the barrier films market in 2024. The region's market is steadily expanding, mostly due to rising demand from a variety of sectors, including agriculture, electronics, food packaging, and pharmaceuticals. In order to prolong the shelf life of items, barrier films are specialized packaging materials made to shield contents from outside elements like moisture, oxygen, light, and gases.

Due to changes in dietary preferences, increased disposable incomes, and population growth, the food and beverage business has experienced tremendous growth in Asia Pacific. The need for barrier films in this industry is fueled by the necessity of shielding medications, medical equipment, and other healthcare supplies from moisture, oxygen, and other environmental variables.

Currently, Asia Pacific is dominating the barrier films market. Within the region, China has the largest market share. The vast growth and demand for the food and beverages market are eventually supporting the packaging market. The increasing demand for barrier films in several sectors is promoting the market. The use of barrier films in applications leads to the expansion of the business.

North America is also expected to hold the largest share during the forecast period. The market in North America has been steadily expanding due to a number of causes, including the growing popularity of packaged foods, increased awareness of food safety and hygiene, and technological developments in barrier film materials. Barrier films have become more and more popular in North America, especially in the United States and Canada, where packaged and convenient meals are becoming more and more popular.

The increasing demand from consumers for products with longer shelf lives, better freshness, and more safety is pushing manufacturers to use more sophisticated packaging techniques. As manufacturers concentrate on product innovation, sustainability, and satisfying changing consumer needs for safer and more convenient packaging solutions, the barrier films market in North America is anticipated to continue expanding.

Market Overview

The demand for packaged and convenient foods has increased due to changing lifestyles and rising urbanization. By shielding these goods from moisture, oxygen, and other outside influences, barrier films help to prolong their shelf life while preserving their freshness and quality. As consumers' concerns about the safety and quality of the food they eat grow, packaging solutions that maintain product integrity and hygiene are becoming more and more important. Significant developments in materials science and production technology have benefited the barrier films business, creating high-performance films with improved barrier qualities.

The barrier films market has applications in the food packaging industry and the pharmaceutical, electronics, and agricultural sectors. It is anticipated that as these industries expand, there will be a greater need for specialty barrier films made to fit particular specifications. Flexible packaging solutions are becoming increasingly popular since they are lightweight, affordable, and have a smaller environmental impact than conventional rigid packaging formats. The market for barrier films is extremely competitive, with numerous small and medium-sized businesses and international organizations fighting for market share. Businesses are spending money on R&D to create new goods and obtain a competitive advantage in functionality, affordability, and sustainability.

Barrier Films MarketGrowth Factors

- Barrier films are mostly used in packaging goods. Due to the growing global population and shifting lifestyles, there is an increased need for packaged goods in a number of industries, including food and beverage, pharmaceutical, electronics, and consumer goods. Strong barrier films are required to shield goods from air, moisture, and other outside influences.

- There is a great demand for barrier films in the market for improved protection with less material consumption or the use of recyclable or biodegradable materials. Producing eco-friendly barrier films is a new venture for manufacturers hoping to meet the needs of this expanding market.

- In the barrier films market, the popularity of flexible packaging—which includes bags, wraps, and pouches—keeps growing because of its affordability, space-saving design, and lightweight. Barrier films are essential for flexible packaging because they offer defense against UV rays, gasses, and moisture.

- Barrier films are used in a wide range of end-use sectors, including electronics, cosmetics, pharmaceuticals, food and beverage packaging, and agriculture. A variety of industries are adopting improved barrier films because they provide better protection, a longer shelf life, and higher-quality products.

- To guarantee product safety and quality, regulations pertaining to packaging materials are getting stricter, especially in the food and pharmaceutical industries that utilize products of the barrier films market.

- In the barrier films market, the demand for packaged goods is being driven by increased disposable incomes, rapid urbanization, and shifting consumer preferences in emerging economies. In order to minimize food waste and guarantee product efficacy, there is an increasing focus on product shelf-life extensions in sectors including food and pharmaceuticals.

Market Scope

| Report Coverage | Details |

| Growth Rate from 2025 to 2034 | CAGR of 5.69% |

| Market Size in 2025 | USD 39.58 Billion |

| Market Size by 2034 | USD 65.10 Billion |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | By Material, By Packaging Type, and By End-use |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Driver

Growing emphasis on flexible packaging

Flexible packaging options are becoming more and more popular in the barrier films market because of their capacity to offer strong barriers against environmental elements like light, moisture, and oxygen that can deteriorate product quality. This is especially crucial for goods that must be kept fresh and have a long shelf life, such as food, medications, and personal hygiene products. Compared to rigid options, flexible packaging typically utilizes less material, which reduces waste production.

The development of biodegradable and recyclable materials is also accelerating the use of flexible packaging solutions. Convenient and portable packaging alternatives that suit busy lifestyles are in high demand from consumers. Reusable bags and stand-up pouches are two examples of flexible packaging that satisfies these requirements and improves user experience.

Restraint

Limited recyclability

Environmental concerns cause significant hindrances in the barrier films market. Barrier films are frequently made up of several layers of various materials, each selected for its unique strength, barrier qualities, or other attributes. Polymers, including polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), and others, together with other materials like aluminum foil or ethylene vinyl alcohol (EVOH), may be present in these layers. Barrier films may get polluted while being used by food or chemical residues from the products they shield.

The recycling process may become more challenging if there is contamination since it may be more difficult to properly clean or separate the materials. The many components found in these films frequently make it difficult for current recycling techniques to successfully separate and recover, resulting in recovered materials of lower quality or even making them unrecyclable.

Opportunity

Smart packaging

In the barrier films market, smart packaging refers to the use of cutting-edge technologies in packaging materials to improve their usefulness, economy, and aesthetic appeal. More and more, barrier films with greater mechanical strength, improved barrier performance, and increased flexibility are being created using nanotechnology. Packaging can include NFC tags and QR codes to give customers access to details about the product, such as where it came from, what's in it, when it expires, and how to use it. Augmented reality (AR) and gamification are two examples of interactive packaging aspects that are used to engage customers and improve their entire product experience. For instance, you might be able to access promotions or interactive information by scanning the QR code on the box.

Technological Advancements

Technological advancements in the barrier films market feature smart barrier films, flexible electronics, plasma treatments, and coextrusion. The smart barrier films are a combination of active materials and sensors in barrier films that help in monitoring the temperature and analyzing environmental conditions. It's also used in IoT devices for data collection, applicable to applications such as industrial and healthcare monitoring. Multi-layer coextrusion process merges different polymer layers to invent films of efficient properties for applications. Nano-coatings and plasma treatments accelerate performance quality.

Flexible electronics integrates foldable electronic devices, which encourages the development of convenient barrier films. The bending and folding capability of the device without disrupting actual barrier properties enhances the barrier films market. This technology enhances the innovative factors, leading to the development of the market globally.

Material Insights

The organic coating segment held the largest share of the barrier films market in 2024. In the packaging industry, the use of organic coatings in barrier films is a major trend, especially in industries where maintaining freshness, prolonging shelf life, and shielding items from moisture, oxygen, and light are essential. Barrier films are given organic coatings to increase their barrier qualities and add features like heat sealing, printability, and better aesthetics.

The increasing demand from consumers for environmentally friendly packaging solutions is met by organic coatings, which are frequently made from renewable resources or biodegradable materials. Because of this, brands aiming to accomplish sustainability objectives and lessen their environmental impact find them appealing.

By adding another barrier against smells, moisture, oxygen, and other impurities, organic coatings can strengthen the barrier qualities of films. By doing this, packaged goods' shelf life is increased, and their quality and freshness are sustained throughout time. Because organic coatings are versatile in both formulation and application, manufacturers can customize barrier films to meet unique packaging needs. They can be designed to offer variable degrees of barrier protection, substrate compatibility, and desired features, including UV resistance, anti-fogging, and antibacterial qualities because organic coatings can improve the visual appeal of packaging because they offer a glossy, smooth surface and make it possible to print graphics, branding elements, and product information in high quality.

Packaging Insights

The pouches segment had the largest share of the barrier films market in 2024. In the barrier film industry, pouch packaging has grown and been used much more recently. Barrier films are perfect for keeping freshness and prolonging the shelf life of different items since they are specifically designed to shield contents from external influences, including moisture, oxygen, light, and scents. The food and beverage, pharmaceutical, cosmetic, and home goods industries are among those with a growing need for pouch packaging that uses barrier films. Pouches provide the portable, lightweight, and handy packaging options that consumers are increasingly choosing. By prolonging the shelf life of products, pouch packaging with barrier films lowers food waste and improves product quality.

Pouch packaging can be customized to satisfy the unique needs of various goods. Barrier films are available in a range of thicknesses and compositions, so producers can select the best one for their product depending on how sensitive it is to outside influences. Pouch packaging has many advantages for ease of use, including lightweight construction, reseal ability and simple opening. Because of these characteristics, pouches are especially well-liked for single-serve and on-the-go products. Pouch packaging gives producers plenty of room for branding and product details, enabling them to interact with customers more successfully and set their items apart on the shelf. The visual appeal of pouches is further enhanced by custom printing and design options, which can help to increase customer interaction and brand identification.

End-use Insights

The agriculture segment held the largest share of the barrier films market in 2024and is expected to sustain the position throughout the forecast period. The necessity for efficient packaging solutions to preserve and protect agricultural goods is the main driver of the agriculture segment's growth in the barrier films market. Barrier coatings are essential to agriculture because they prolong the shelf life of perishable items and shield them from environmental elements such as moisture, air, light, and microbial contamination. In agriculture, barrier films are widely used to package fresh goods like grains, fruits, and vegetables. When produce is being stored, transported, and distributed, these films aid in preserving its quality and freshness. The shelf life of agricultural products can be prolonged by using barrier films to create a barrier against moisture and oxygen.

By shielding agricultural products from outside elements like dust, UV rays, and pollutants, barrier films maintain the nutritional content and integrity of the items. In MAP systems, where the environment inside the packaging is altered to slow down the ripening process and prevent microbial growth, barrier films are frequently utilized. Fruits and vegetables can retain their freshness for longer thanks to this technique. In agriculture, there is a growing need for sustainable packaging options due to growing environmental consciousness. Recyclable, biodegradable, and renewable resource-based barrier films are becoming more and more common.

Barrier Films Market Companies

- Berry Global Inc.

- Amcor Plc

- Sealed Air

- Toppan Printing Co.

- Cosmo Films Ltd.

- Jindal Poly Films Ltd.

Recent Developments

- In May 2025, Vishakha Polyfab, one of India's leading manufacturers of high-performance barrier films, made a significant impact at IFFA 2025 with its innovative and sustainable packaging technologies. (Source - https://www.foodtechbiz.com)

- In May 2025, Pregis expanded its EVOH barrier film capacity to meet demand for recyclable packaging. The expansion strategy consists of all polyethylene mono-material films, all set to replace less recyclable structures. (Source - https://www.packworld.com)

- In May 2025, Soteria Flexibles Corp. acquired Hamilton Plastics Inc., a Tennessee-based manufacturer of high-performance barrier films. The acquisition highlights Soteria's potential and market recognition in the medical, food, and industrial packaging sectors. (Source - https://www.plasticstoday.com)

- In March 2024, At the CFIA exhibition in Rennes, France, specialty film producer Jindal Films introduced new mono-material barrier film solutions, BICOR 25 and 30 MBH568 films. The solutions for polypropylene (PP) and polyethylene (PE) nanomaterials are intended to assist packaging companies in complying with the impending European mechanical recycling regulations.

- In October 2023, Madura Tea, an Australian company, used Koehler NexPlus Seal Pure MOB 72 gsm flexible paper packaging. German suppliers Gundlach Packaging Group and Koehler Paper provided test materials after promising results.

Segment Covered in the Report

By Material

- Polyethylene

- Polypropylene

- Polyester

- Polyamide

- Organic Coating

- Inorganic Oxide Coating

By Packaging Type

- Pouches

- Bags

- Blister Packs

By End-use

- Food & Beverage

- Pharmaceutical & Medical

- Electronics

- Agriculture

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting