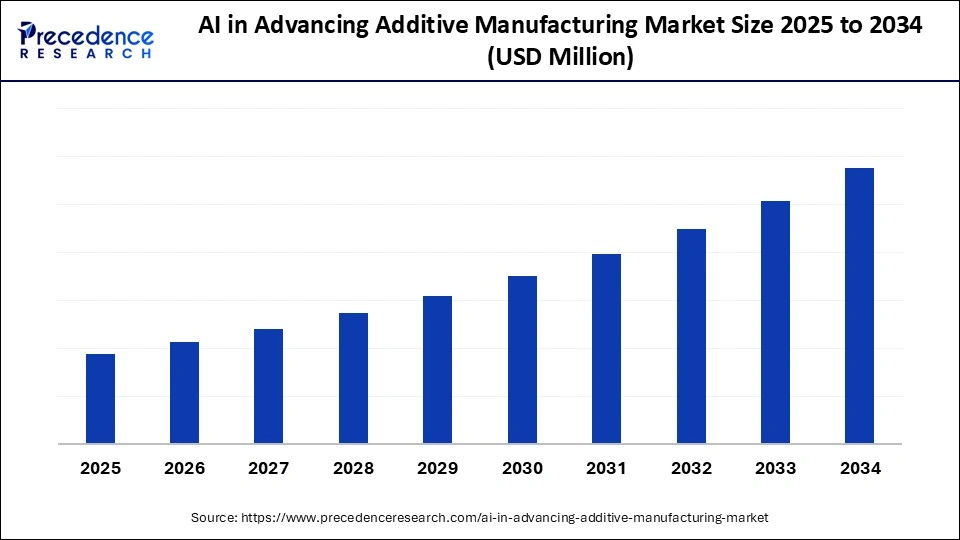

What is the AI in Advancing Additive Manufacturing Market Size?

The global AI in advancing additive manufacturing market is witnessing rapid growth as AI-driven algorithms optimize 3D printing processes, improve material usage, and enhance part quality across industries.The market is growing due to its ability to optimize design, enhance production efficiency, reduce material waste, and enable real-time process monitoring.

AI in Advancing Additive Manufacturing Market Key Takeaways

- North America dominated the AI in advancing additive manufacturing market in 2024.

- Asia Pacific is expected to grow at a notable CAGR during the forecast period.

- By component/offering, the hardware/systems segment held the biggest market share in 2024.

- By component/offering, the software segment is expected to grow at the fastest CAGR during the forecast period.

- By material type, the polymers/plastics segment is expected to grow at the fastest rate during the forecast period.

- By material type, the metals and alloys segment captured the biggest market share in 2024.

- By industry/sector, the automotive industry segment is expected to grow at the fastest CAGR during the forecast period.

- By industry/sector, the healthcare and medical devices segment generated the major market share in 2024.

Market Overview

Why is AI in advancing additive manufacturing market growing?

The AI in advancing additive manufacturing market is rapidly expanding as industries increasingly adopt AI-driven solutions to enhance design precision, optimize production processes, and reduce material waste. AI technologies make it possible for manufacturers to produce complex, customized parts more efficiently and affordably by enabling real-time monitoring, predictive maintenance, and quality control. Further propelling market expansion are developments in machine learning and digital twin technologies, as well as the growing need for lightweight components in the automotive, aerospace, and healthcare industries. World-class businesses are making significant investments in AI integration, which is fostering innovation and quickening the uptake of intelligent additive manufacturing technologies worldwide.

- In September 2025, Airtable launched Airtable Assistant, an AI-powered native copilot designed to transform data into insights, automations, and agents.(Source: https://userpilot.com)

How Is AI Adoption Transforming Production Efficiency in the AI in Advancing Additive Manufacturing Market?

Artificial intelligence adoption is significantly transforming production efficiency in the AI in advancing additive manufacturing market by automating design processes, optimizing material usage, and enhancing quality control. By enabling predictive maintenance and real-time monitoring, machine learning algorithms decrease downtime and increase the lifespan of equipment. AI-powered generative design makes it possible to create lightweight, structurally optimized components, which saves materials and speeds up production cycles. Furthermore, powered defect detection tools increase the accuracy of additive manufacturing processes, guaranteeing better results with less waste.

- In February 2025, AMFG highlighted the role of AI and machine learning solutions in scaling up additive manufacturing operations, emphasizing their importance in the transition to Industry 4.0(Source: https://amfg.ai)

AI in Advancing Additive Manufacturing Market Growth Factors

- Design Optimization: AI algorithms enable complex, lightweight, and high-performance designs that are difficult to achieve with traditional methods.

- Process Efficiency: AI enhances production speed, precision, and consistency by monitoring and controlling printing parameters in real time.

- Material Waste Reduction: AI helps minimize material usage and defects, reducing costs and promoting sustainable manufacturing.

- Predictive Maintenance: AI predicts equipment failures and schedules maintenance, reducing downtime and improving overall productivity.

- Quality Control: AI-powered inspection and anomaly detection ensure higher-quality output with fewer defects.

- Customization and Flexibility: AI allows for rapid prototyping and personalized production, meeting increasing demand for customized products.

- Integration with IoT and Digital Twins: AI combined with IoT devices and digital twins enables smarter, data-driven additive manufacturing operations.

Market Scope

| Report Coverage | Details |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material Type, Industry / Sectorm Component / Offering, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market Dynamics

Drivers

Design Optimization

Topology optimization and generative design are made possible by AI, producing intricate geometries that are both structurally sound and lightweight. When compared to conventional methods, engineers can simulate multiple design variations in a fraction of the time. This accelerates the development of new products, conserves resources, and reduces trial-and-error iterations. Additionally, in sectors like automotive and aerospace, driven design aids in customizing components for performance needs.

- In April 2025, Materialize introduced the 2025 Magics software release, featuring implicit modeling capabilities and intelligent support generation tools. The new magic release aims to reduce build preparation time from days to seconds while maintaining design precision.(Source: https://www.materialise.com)

Material Waste Reduction

By precisely forecasting the quantity needed for every build, AI optimizes material usage and significantly reduces scrap. Algorithms can also detect problems early on, saving production runs from being wasted. This lowers overall manufacturing costs and supports sustainability initiatives. AI helps manufacturers maximize resource efficiency and produce almost zero waste when combined with process simulation.

- In May 2025, Intellegens released a white paper on AI-powered additive manufacturing, focusing on material optimization and waste reduction. The white paper reports the results of a collaborative project in which Alchemite machine learning was applied to optimize and automate advanced 3D printing processes.

(Source: https://intellegens.com)

Restraints

High Implementation Costs

AI integration with additive manufacturing requires a substantial initial investment in hardware, software, and skilled personnel. Adoption is limited because many small and medium-sized businesses (SMEs) cannot afford these expenses. AI systems also require constant upkeep and updates, which increase operating costs and reduce the return on investment. Smaller businesses often struggle to compete due to the additional financial burden of training staff and updating outdated equipment.

Data Security and Privacy Concerns

Sensitive production and design data are essential to AI-driven additive manufacturing. One of the biggest challenges is safeguarding this data from illegal access and cyberattacks. Vulnerabilities can lead to financial loss, reputational harm, and intellectual property theft, which deters some businesses from implementing AI. Advanced cybersecurity measures are also necessary due to the additional vulnerabilities brought about by cloud storage and cross-border data sharing.

Opportunities

Expansion in Aerospace and Automotive Sectors

AI-driven additive manufacturing makes it possible to produce intricate, lightweight parts that are essential for automotive and aerospace applications. Weight reduction enhances performance and fuel economy while artificial intelligence guarantees accuracy and dependability. AI technologies have an expanding chance to improve design optimization, predictive maintenance, and process automation as these industries embrace additive manufacturing more.

- In August 2025, Siemens and Rolls-Royce announced a driven design to manufacturing process for aerospace components at EMO 2025, demonstrating the use of AI and cloud-connected manufacturing to optimize aerospace components for performance and sustainability.(Source: https://blogs.sw.siemens.com)

Sustainable and Eco-Friendly Manufacturing

In additive manufacturing, AI optimizes material use, minimizes waste, and lowers energy consumption. Manufacturers can use AI to monitor emissions and adopt environmentally friendly production methods. AI-driven additive manufacturing can give businesses a competitive edge and draw in eco-aware customers as global sustainability standards tighten.

- In May 2025, Starbucks opened a 3D-printed store in Japan, showcasing sustainable construction methods. Demonstrates the use of additive manufacturing in sustainable architecture.(Source: https://amfg.ai)

Segmental Insights

Component/Offering Insights

Why Did the Hardware/Systems Segment Dominate the AI in Advancing Additive Manufacturing Market in 2024?

Hardware and systems hold the dominant share in the AI in advancing additive manufacturing market, as sophisticated 3D printers, sensors, robotics, and AI-powered hardware continue to be the foundation of manufacturing. To ensure real-time error detection, predictive maintenance, and automation of complex manufacturing tasks, businesses invest heavily in AI-enabled printing systems. Hardware is essential to market leadership because physical infrastructure is necessary for scaling production capacity across industries.

Software is emerging as the fastest-growing component, fueled by the rising demand for simulation, predictive analytics, and design optimization driven by AI. AI-driven software improves part quality, cuts down on material waste, and makes generative design possible, enabling engineers to create previously unattainable, extremely complex geometries. Adoption is being further accelerated by cloud-based platforms and digital twin technology, which is driving software to surpass other offerings in growth rate.

Material Type Insights

Why Did the Polymers/Plastics Segment Dominate the AI in Advancing Additive Manufacturing Market in 2024?

Polymers and plastics dominate the AI in advancing additive manufacturing market due to their versatility, cost-effectiveness, and widespread use across prototyping, consumer goods, and automotive applications. AI helps optimize printing parameters for polymers, improving strength, surface finish, and production speed. With the growing adoption of rapid prototyping and lightweight component manufacturing, polymers remain the most widely used material category in the AI in advancing additive manufacturing market.

Metals and alloys are the fastest-growing material category, driven by their growing application in the production of medical devices, automobiles, and aircraft. In the past, metal printing had a high risk of defects; now, AI integration guarantees accuracy in temperature control layer thickness and structural integrity. Metals are the market segment with the fastest growth due to the growing need for strong yet lightweight components in high-performance industries.

Industry/Sector Insights

Why Did the Automotive Segment Dominate AI in Advancing Additive Manufacturing Market in 2024?

The automotive industry dominates the AI in advancing additive manufacturing market because of OEMs and suppliers leveraging AI-driven 3D printing for rapid prototyping, tooling, and lightweight structural components. AI enhances design flexibility, reduces lead times, and optimizes supply chains, enabling cost-effective production of customized vehicle parts. This broad adoption across design, testing, and production workflows cements automotive as the leading industry in this space.

Healthcare and medical devices represent the fastest-growing segment, with AI-powered additive manufacturing transforming bioprinting of dental devices, prosthetics, and customized implants. AI algorithms customize design to meet the needs of individual patients, guaranteeing better fit, increased functionality, and improved results. The industry's explosive growth is driven by the increasing demand for patient-centered solutions and the regulatory support for medical 3D printing innovation.

Regional Insights

What Made North America Dominate the AI in Advancing Additive Manufacturing Market in 2024?

North America dominates the AI in advancing additive manufacturing market due to its advanced industrial base, significant R&D investments, and presence of leading AI and additive manufacturing companies. The region benefits from government support for smart manufacturing initiatives and strong adoption of Industry 4.0 technologies. Aerospace, automotive, and healthcare players in the areas are at the forefront of integrating AI with additive manufacturing, securing North America's leading position.

Asia Pacific is the fastest-growing region in the AI in advancing additive manufacturing market, driven by the growing manufacturing hubs, fast industrialization, and government-sponsored programs promoting artificial intelligence and cutting-edge 3D printing technologies. To increase productivity, cut expenses, and quicken product development, the areas are progressively embracing AI-powered additive manufacturing. Asia Pacific market expansion is further supported by robust growth in the healthcare and electronics manufacturing sectors.

AI in Advancing Additive Manufacturing Market Companies

- Siemens

- GE Additive

- Autodesk

- 3D Systems

- Stratasys

- Materialise

- Dassault Systèmes

- EOS

- Ai Build

- Authentise

- Oqton

- Inkbit

- AMFG

- Hexagon

- NVIDIA

Recent Developments

- In September 2025, AIM Sweden AB announced the installation of the Colibrium Spectra L electron beam powder bed fusion (E-PBF) system, marking a significant advancement in their manufacturing capabilities. This move makes AIM Sweden the first contract manufacturer in Europe to offer point melting and plate-free start capabilities, enhancing their service offerings. The addition of the Spectra L expands their E-PBF fleet to six machines, solidifying their position as a leader in the European market for advanced additive manufacturing solutions.(Source: https://www.voxelmatters.com)

- In September 2025, Caracol, an Italian manufacturer specializing in large-format additive manufacturing (LFAM), inaugurated its new 10,000-square-foot headquarters and production center in Pflugerville, Texas. This expansion aims to enhance Caracol's manufacturing capacity and innovation capabilities in North America. The new facility is expected to streamline operations, reduce lead times, and strengthen the company's presence in the U.S. market.

(Source: https://www.voxelmatters.com)

Segments Covered in the Report

By Component / Offering

- Hardware / Systems (3D printers, material handling, sensors, etc.)

- Software

- Services (consulting, maintenance, integration, etc.)

By Material Type

- Polymers / Plastics

- Metals / Alloys

- Ceramics, composites, multi material systems

By Industry / Sector

- Automotive

- Aerospace & Defense

- Healthcare / Medical Devices

- Consumer Goods & Electronics

- Tooling & Industrial Machinery

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting