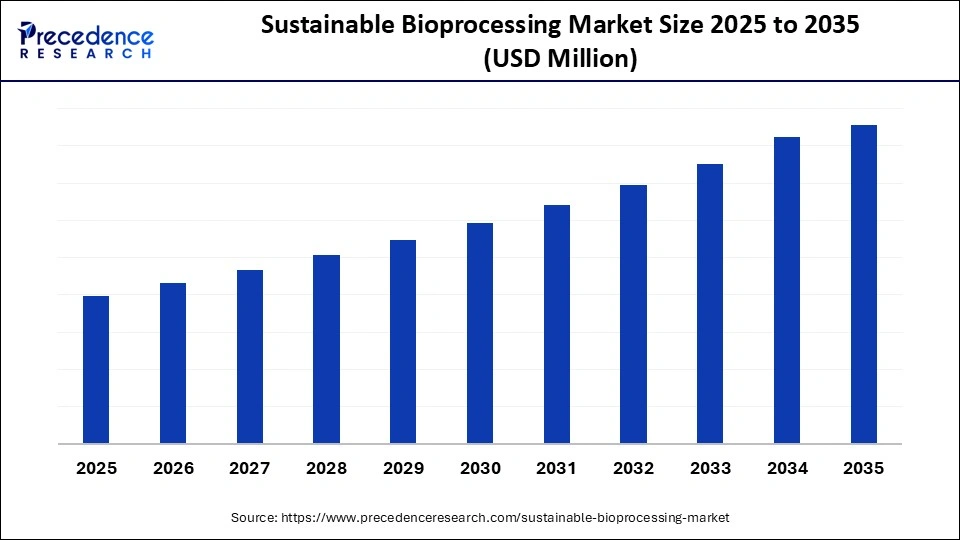

What is the Sustainable Bioprocessing Market Size?

The global sustainable bioprocessing market focuses on eco-friendly biomanufacturing that reduces waste, energy use, and carbon emissions. It supports efficient and sustainable production in pharmaceutical and biotech industries.The market is driven by the global shift toward eco-efficient production, reduced carbon footprint goals, and increasing adoption of green biotechnology solutions.

Market Highlights

- North America dominated the market, holding the largest market share of 40.5% in 2025.

- Asia-Pacific is expected to expand at the fastest CAGR of 16.5% in the market between 2026 and 2035.

- By offering/product, the single-use systems segment held the largest market share of 38.7% in 2025.

- By offering/product, the downstream chromatography & filtration segment is expected to grow at a remarkable CAGR of 14.1% between 2026 and 2035.

- By processing mode/technology, the batch segment held the largest market share of 51.4% in 2025.

- By processing mode/technology, the continuous/perfusion segment is expected to grow at a remarkable CAGR of 14.4% during the forecast period.

- By process stage, the upstream segment contributed the biggest revenue share of 53.4% in the market in 2025.

- By process stage, the downstream segment is expected to show the fastest growth with a CAGR of 14.6% over the forecast period.

- By application/end-user, the biopharmaceuticals segment accounted for the highest revenue share of 46.8% in 2024.

- By application/end-user, the industrial biotechnology segment is expected to experience remarkable growth in the coming years.

- By material/sustainability approach, the reduced-plastic single-use designs segment held the largest market share of 43.2% in 2025.

- By material/sustainability approach, the recyclable/biobased polymers & coatings segment is expected to expand rapidly in the market with a CAGR of 14.8% in the coming years.

- By deployment/business model, the consumables recurring model segment held the largest share of 46.5% in the market in 2025.

- By deployment/business model, the contract manufacturing/CDMO segment is expected to account for the highest CAGR of 15.1 over the studied period.

Accelerating Eco-Innovation: How Sustainable Bioprocessing Is Powering the Next Wave of Clean Production?

Sustainable bioprocessing incorporates innovative equipment like continuous processing, intensified bioreactor systems, single-use equipment, or recyclable equipment, and energy-efficient upstream and downstream technologies. With these solutions, there is a possibility of reducing water usage, carbon emissions, waste generation, and process sustainability. Moreover, the integration of process control, AI-based analytics, intelligent monitoring systems, process stability, predictive maintenance, and real-time optimization drive sustainable bioprocessing.

The market is also driven by growing interest in environmentally friendly production, stringent environmental regulations, and the pressure of manufacturers to make their operations less carbon-intensive. The increasing use of greener manufacturing options is facilitated by technological innovations, such as automation, IoT-based bioprocessing, and next-generation bioreactors, optimizing output and reducing energy usage.

Impacts of AI on the Sustainable Bioprocessing Market

The market is rapidly adopting AI-assisted process optimization, making it possible to monitor processes, control them in real-time, and make decisions automatically in complex biomanufacturing processes. AI enhances transparency in processes through the analysis of extensive volumes of data generated by sensors, bioreactors, and digital twins, allowing for the quick detection of deviations, making better yield predictions, and quality control.

Machine learning algorithms are being optimized for upstream fermentation, downstream purification, and resource-consuming steps, potentiating the use of raw materials and imposing a smaller carbon footprint. AI-enabled digital twins provide a chance to conduct virtual experiments, scale up swiftly, and continually fulfill sustainability goals. The shift to automation is placing sustainable bioprocessing in a perspective where scaling, more efficient operations, and its implementation in an ecologically friendly manner are possible.

Sustainable Bioprocessing Market Outlook

- Industry Growth Overview: The increase in demand for biologics, biofuels, and biobased materials, as well as sustainability regulations, drives market growth. Continuous processing, smart monitoring, and single-use systems are also gaining mainstream popularity, fueling overall industry growth.

- Global Expansion: Sustainable bioprocessing has gained momentum in key regions as companies continue to comply with decarbonization objectives, encouraging them to produce more environmentally friendly products. Asia-Pacific, Europe, and North America are also becoming major growth areas that have high investment and infrastructural development.

- Major Investors: Leading investors are pharmaceutical companies, biotech companies, and venture capital firms that focus on sustainability. Financial support of innovative solutions is also increased by government initiatives, grants, and research collaborations.

- Startup Ecosystem: There are several innovators in the development of the startup ecosystem, and these include bioreactors that are environmentally friendly, monitoring devices, and biomaterials. Startups are now cooperating with other market players to commercialize and deploy sustainable bioprocessing technologies at an accelerated pace.

Market Scope

| Report Coverage | Details |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Segments Covered | Offering/Product, Processing Mode/Technology, Process Stage, Application/End-user, Material/Sustainability Approach, Deployment/Business Model, and region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Segmental Insights

Offering/Product Insights

Which Offering/Product Segment Dominated the Sustainable Bioprocessing Market?

The single-use systems segment held a dominant position in the market with a share of 38.7% in 2025 due to their flexibility, speedy installation, and risk of contamination. Single-use systems help in quick changeovers and high-rate productions. Bioreactors, bags, and tubing can be used to provide efficient and scalable workflows. They save capital and lower maintenance demands. The increasing production of biologics, cell therapies, and vaccines boosts the segment's growth.

The downstream chromatography & filtration segment is expected to grow at the fastest CAGR of 14.1% in the market between 2026 and 2035, as it plays an important role in purification, clarification, and product quality. The segmental growth is attributed to the increased production of biologics, the use of filtration membranes, cartridges, and chromatography consumables. This equipment minimizes process variability and adds more product purity. They are more reliable and consistent with manufacturers.

Processing Mode/Technology Insights

Why Did the Batch Segment Dominate the Sustainable Bioprocessing Market?

The batch segment accounted for a considerable revenue share of 51.4% in the market in 2025 due to its reliability, familiarity with the process, and acceptance by regulatory authorities. Batch systems enable controlled, step-by-step, consistent, and high-quality production of products. It also enables accurate feeding of nutrients, enhancing yields of biologics and recombinant proteins. As it is very scalable and flexible, it applies to a wide range of applications, including vaccines and industrial enzymes.

The continuous/perfusion segment is expected to grow with the highest CAGR of 14.4% in the market during the studied years, due to the need for intensive and highly efficient bioprocessing. Continuous systems promote continuous production, reduce downtimes, and improve volumetric productivity. Perfusion enhances cell viability by ensuring the presence of fresh media and the removal of waste. Continuous bioprocessing aligns with sustainability goals of using fewer resources per unit production. The more traditional batch operations will be less likely to grow because digital control technologies will allow for the increase in continuous systems.

Process Stage Insights

What Made Upstream the Dominant Segment in the Sustainable Bioprocessing Market?

The upstream segment registered its dominance over the global market with a share of 53.4% in 2025 due to the increasing use of advanced bioreactors, cell culture media optimization, and processing technologies. Biomanufacturing relies on upstream operations, which influence the deliverability, productivity, and sustainability of the entire process. Digital monitoring, AI-based automation, and intelligent bioprocessing platforms are very suitable in upstream processes that demand a stringent control of the surrounding environment. Upstream investments have continued to increase due to the demand for biologics, cell therapies, and bio-based materials.

The downstream segment is expected to expand rapidly in the market with a CAGR of 14.6% in the coming years, due to the need for refined purification, filtration efficiency, and quality of products. Downstream processes include clarification, chromatography, and filtration. The demand for downstream systems increases with higher titers and product profiles. Sustainable purification solutions, such as continuous chromatography, membrane filtration, and eco-efficient purification solutions, minimize wastes and energy consumption, which are part of the sustainable objectives.

Application/End-user Insights

Which Application/End-User Segment Led the Sustainable Bioprocessing Market?

The biopharmaceuticals segment led the global market with a share of 46.8% in 2025 due to high demand for monoclonal antibodies, vaccines, and cell and gene therapies. The trend in biopharma production is the focus on sustainable, efficient, and flexible bioprocess technologies to satisfy the global healthcare requirements. They can be produced at low cost and with reduced environmental impact by using single-use bioreactors, optimization of media, and continuous processing solutions.

The industrial biotechnology segment is expected to witness the fastest growth in the market with a CAGR of 14.7% over the forecast period due to the massive expansion of industries implementing sustainable bioprocess technologies to generate enzymes, biomaterials, biofuels, and specialty chemicals. The drive to a new generation of products based on vegetable oils is driving transformation in fermentation, biomass conversion, and waste-to-value platforms. Sustainable bioprocessing can be applied to enhance energy consumption, reduce carbon usage, and promote the use of a circular manufacturing cycle.

Material/Sustainability Approach Insights

Which Material/Sustainability Approach Segment Dominated the Sustainable Bioprocessing Market?

The reduced-plastic single-use designs segment dominated the global market with a share of 43.2% in 2025, owing to the high demand for environmentally responsible disposable solutions. Energy, water, and cleaning chemicals can be saved and assist in supporting green operations. They are versatile, minimize the possibilities of contamination, and reduce turnaround time. As regulatory pressure against plastic waste and sustainability requirements increases, reduced-plastic design in bioreactors, bags, filters, and tubing becomes more significant to companies.

The recyclable/biobased polymers & coatings segment is expected to gain the highest share of the market with a CAGR of 14.8% between 2026 and 2035 due to the increasing use of environmentally friendly materials. Biobased polymers reduce the dependence on fossil materials and decrease the carbon footprint of the bioprocess equipment. Recyclable materials can also help meet the objectives of a circular economy because they allow reuse, recovery, and better lifecycle management. Such materials are biodegradable polymers, plant-based plastics, and high-performance coatings that are developed to withstand durability and bioprocess operations.

Deployment/Business Model Insights

How the Consumables Recurring Model Segment Dominated the Sustainable Bioprocessing Market?

The consumables recurring model segment held the largest revenue share of 46.5% in the market in 2025 due to the demand for single-use parts, filtration systems, culture media, and process consumables. This system provides suppliers with a predictable and stable income since bioprocessing processes demand a steady supply to be replenished. A continued and intensified process by biomanufacturers also leads to a greater demand for high-quality and consistent consumables.

The contract manufacturing/CDMO segment is expected to show the fastest growth with a CAGR of 15.1% over the forecast period, as it offers niche features, scalability, and flexibility to companies that lack in-house infrastructure. CDMOs specialize in sustainable manufacturing, high automation, and compliance with regulations, improving process efficiency. The increasing pipelines of biologics, such as cell and gene therapies, are making CDMOs more dependent. CDMOs are attractive partners of the company, aiming towards ESG objectives due to sustainable facility designs and eco-efficient operations.

Regional Insights

Why Did North America Dominate the Sustainable Bioprocessing Market?

North America held a major revenue share of 40.5% in the market in 2025, due to a robust biotechnology infrastructure, advanced R&D, and early adopters of the digitalised and intensified bioprocessing systems. The region can boast high biopharmaceutical activity, strong regulatory systems, and massive investment in automation, AI-driven optimization, and sustainable facility upgrades.

Uptake is also influenced by sustainable initiatives like carbon footprint objectives and business manufacturing operations that are environmentally friendly. The long-term government/industry investment augments the development of green technologies and advanced plastics-only platforms, which make sure that North America remains on the leading edge of sustainable bioprocessing.

U.S Sustainable Bioprocessing Market Analysis

The North American market is dominated by the U.S. because it has a vast biopharmaceutical manufacturing base, powerful research institutions, and a powerful innovation ecosystem. Biologics, vaccines, and cell and gene therapies involve high volumes of production that result in high demand for sustainable bioprocessing technologies. American firms focus on energy-saving systems, less-plastic designs, and digital monitoring systems to fulfill the ESG and regulatory standards. Positive funding, developed infrastructures, and established biotech manpower boost operational capacity.

How is Asia-Pacific Growing in the Sustainable Bioprocessing Market?

Asia-Pacific is expected to witness the fastest growth during the predicted timeframe. There is rapid growth in biomanufacturing capacity, favorable government policies, and growing investments in biotechnology infrastructure that create a powerful momentum. Developing countries such as China, India, South Korea, and Singapore will develop superior plants and sustainable technology to satisfy the increasing demand.

Regional competitiveness is improved with cost-efficiency in manufacturing, availability of skilled talents, and strategic alliances with other biotech firms across the world. Increasing biologics manufacturing, vaccine manufacturing, and industrial biotechnology projects also further add to adoption. Sustainability, digitalization, and scalable production solutions make the Asia Pacific a key source of growth for the global market.

China Sustainable Bioprocessing Market Trends

The sustainable bioprocessing market in China is developing well due to the growing strength of China as a biomanufacturing hub across the world. Government investments, generous policies, and national programs to enhance the innovation of biopharmaceuticals are hastening the use of environmentally friendly and energy-efficient technologies. The Chinese manufacturers are adapting more to lower-plastic single-use systems, more sophisticated bioreactors, and intensified processing models as a way of maximizing productivity and minimizing waste. The demands of scalable and clean, and flexible production platforms are being pushed by the rapid development of biologics, vaccines, and precision medicine.

Who are the Major Players in the Global Sustainable Bioprocessing Market?

The major players in the sustainable bioprocessing market include Sartorius AG, Danaher Corporation (Cytiva & Pall), Thermo Fisher Scientific, Merck KGaA (MilliporeSigma), Repligen Corporation, Avantor, Inc., Corning Inc., Eppendorf AG, Saint-Gobain Life Sciences, Greiner Bio-One, Lonza Group, Celanese Corporation, Roquette Frères, BASF SE, and DSM.

Recent Developments

- In October 2024, Berry Global introduced clear polypropylene (PP) bottles to be used in medical practices as an alternative to traditional colored PET pill bottles in a more sustainable way. These novel bottles contribute to improved environmental performance and product protection.(Source: https://packagingsolutions.amcor.com)

- In April 2024, SaniSure launched Fill4Sure, a tailored single-use assembly for filling, which is aimed at enhancing the safety, precision, and efficiency of filling medicinal products. The innovation is meant to accelerate the time-to-market of pharmaceutical products and ensure uniformity in operational performance.(Source: https://sanisure.com)

Segments Covered in the Report

By Offering/Product

- Single-use systems (bioreactors, bags, tubing)

- Reusable/stainless equipment

- Consumables (filters, membranes)

- Media & reagents

- Downstream chromatography & filtration

- Process analytics & software

- Services (engineering, lifecycle)

By Processing Mode/Technology

- Batch (fed-batch)

- Continuous/perfusion

- Hybrid (integrated continuous + single-use)

- Cell-free/enzymatic biocatalysis

By Process Stage

- Upstream (bioreactors, cell culture media)

- Downstream (clarification, chromatography, filtration)

- Formulation & fill-finish

- Analytics & quality control

By Application/End-user

- Biopharmaceuticals (mAbs, vaccines, cell & gene therapy)

- Industrial biotechnology (enzymes, specialty chemicals)

- Food & beverage

- Biofuels

- Environmental/bioremediation

By Material/Sustainability Approach

- Recyclable/biobased polymers & coatings

- Reduced-plastic single-use designs

- Reusable stainless components

- Chemical/solvent replacement (green solvents)

- Water & energy recovery systems

By Deployment/Business Model

- OEM sales

- Consumables recurring model

- Contract manufacturing / CDMO

- Equipment-as-a-Service (EaaS)

- Software & digital services (LIMS, PAT)

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

Frequently Asked Questions

Ask For Sample

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

Get a Sample

Get a Sample

Table Of Content

Table Of Content

sales@precedenceresearch.com

sales@precedenceresearch.com

+1 804-441-9344

+1 804-441-9344

Schedule a Meeting

Schedule a Meeting